THC Servo Start

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

01 Jun 2018 18:19 #111403

by islander261

THC Servo Start was created by islander261

Hello

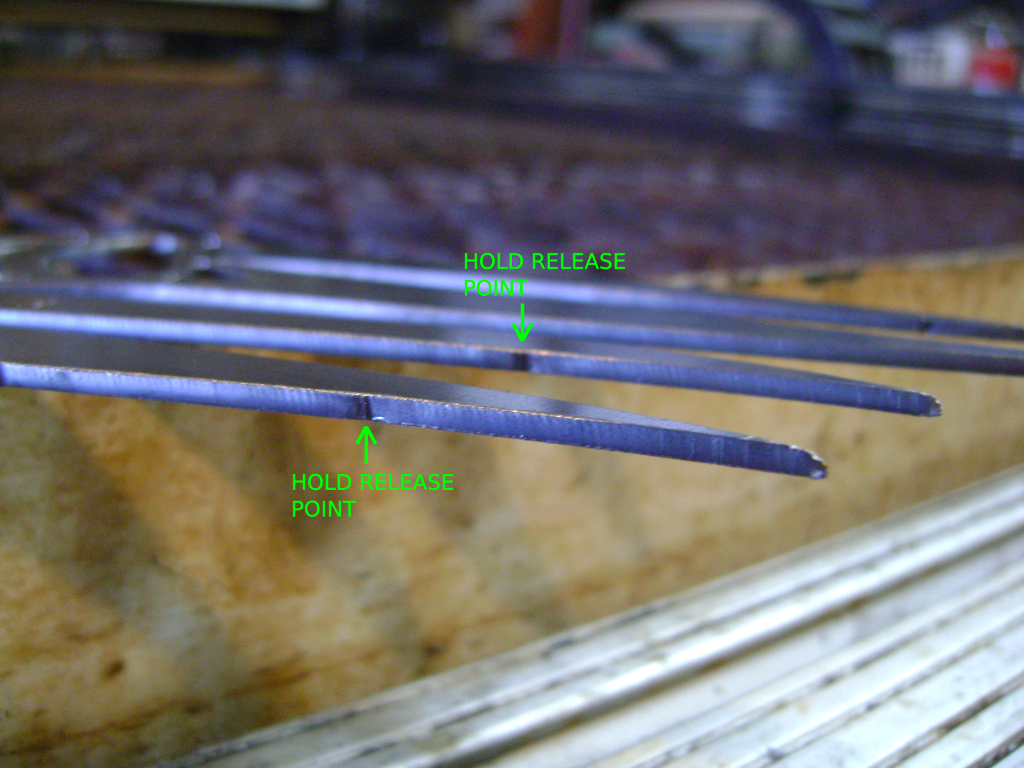

I have found some strange behavior when cutting that didn't show when I was testing with straight lines. The torch is making a small "divot" in the cut when the THC starts servoing after starting the cut and when it starts servoing again after a corner, velocity or kerf crossing hold. The "divot" is small and only visible from the bottom or side of the part. This is cutting 14ga ( about 2mm) hot rolled steel sheet at 220ipm at 45A. All the hold controls are done in HAL components so I don't think there is much delay happening. Sorry,I don't have any halscope plots of this happening because it is so hard to get the triggering right when cutting out a whole sheet of parts. I will start on a dedicated test at some point down the road that I can monitor with halscope.

John

I have found some strange behavior when cutting that didn't show when I was testing with straight lines. The torch is making a small "divot" in the cut when the THC starts servoing after starting the cut and when it starts servoing again after a corner, velocity or kerf crossing hold. The "divot" is small and only visible from the bottom or side of the part. This is cutting 14ga ( about 2mm) hot rolled steel sheet at 220ipm at 45A. All the hold controls are done in HAL components so I don't think there is much delay happening. Sorry,I don't have any halscope plots of this happening because it is so hard to get the triggering right when cutting out a whole sheet of parts. I will start on a dedicated test at some point down the road that I can monitor with halscope.

John

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21152

- Thank you received: 7222

01 Jun 2018 21:47 #111415

by tommylight

Replied by tommylight on topic THC Servo Start

That is strange, if the THC servo is on the servo thread maximum delay should be about 0.1 to 0.2mm at that speed, i can not figure out why is that taking so long ( roughly guessing from the picture, over 1 second ). Can you test that on a straight line? Might that be because of the radius ( arc ) at the beginning and active corner lock ? Can you test it with corner lock disabled ?

Thank you.

Tom

Thank you.

Tom

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

01 Jun 2018 22:02 #111417

by islander261

Replied by islander261 on topic THC Servo Start

Tommylight

Thank you for the reply. The point at which the THC starts servoing is correct. I have a about .75s delay between the arc ok or ok to move signal from the plasma power supply before the THC starts servoing. The marks from the corner hold being released are in about the correct place. I have not tested with no corner hold (I actually use a velocity hold instead of a hard distance) yet but expect to see no hold release mark when I do. I didn't have this happen when I did all my straight line testing while getting the THC working correctly.

John

Thank you for the reply. The point at which the THC starts servoing is correct. I have a about .75s delay between the arc ok or ok to move signal from the plasma power supply before the THC starts servoing. The marks from the corner hold being released are in about the correct place. I have not tested with no corner hold (I actually use a velocity hold instead of a hard distance) yet but expect to see no hold release mark when I do. I didn't have this happen when I did all my straight line testing while getting the THC working correctly.

John

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

01 Jun 2018 22:02 #111418

by PCW

Replied by PCW on topic THC Servo Start

How is the hold done?

If you have a PID loop with I term, you must disable the PID (say by tying its command and feedback inputs to the same value) when its not in control or you will get integral windup, causing a major glitch when you re-enable the control loop

If you have a PID loop with I term, you must disable the PID (say by tying its command and feedback inputs to the same value) when its not in control or you will get integral windup, causing a major glitch when you re-enable the control loop

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

02 Jun 2018 01:07 #111426

by islander261

Replied by islander261 on topic THC Servo Start

PCW

Thank you for the reply. I cause a height hold to happen by disabling (setting pid.enable to false) the THC pid component. I was under the impression that this reset the integrator. From the docs:

pid.N.enable bit in

When true, enables the PID calculations. When false, output is zero, and all internal integrators, etc, are reset.

I was counting on the docs being correct when I came up with this scheme for THC.

I am running the classic method for using Mesa stepper cards. I use the pid output as a velocity input to the 7I76E card step generator when under control of the THC logic just like when it is under command from the motion component for positioning.

John

Thank you for the reply. I cause a height hold to happen by disabling (setting pid.enable to false) the THC pid component. I was under the impression that this reset the integrator. From the docs:

pid.N.enable bit in

When true, enables the PID calculations. When false, output is zero, and all internal integrators, etc, are reset.

I was counting on the docs being correct when I came up with this scheme for THC.

I am running the classic method for using Mesa stepper cards. I use the pid output as a velocity input to the 7I76E card step generator when under control of the THC logic just like when it is under command from the motion component for positioning.

John

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

02 Jun 2018 01:39 #111428

by islander261

Replied by islander261 on topic THC Servo Start

PCW

Sorry I have two systems that do not have seamless integration. Please find attached a block diagram of my Z axis setup with THC.

John

Sorry I have two systems that do not have seamless integration. Please find attached a block diagram of my Z axis setup with THC.

John

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

02 Jun 2018 02:36 #111433

by PCW

Replied by PCW on topic THC Servo Start

Yes, the PID integrator is reset by enable so that should be OK

It should be possible to trigger halscope on the edge of enable to check what's happening

It should be possible to trigger halscope on the edge of enable to check what's happening

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

02 Jun 2018 03:50 #111438

by islander261

Replied by islander261 on topic THC Servo Start

PCW

I had a very long winded reply that was killed by my poor typing skills. I know how to use a 'scope but it is really hard to pick the correct cut segments out of a 14,000 line gcode program. I plan on putting together some tests the mimic this problem as soon as I get time from production work. I never saw this problem during my all my straight line testing to get the THC working well. I am trying to transition my LinuxCNC control system to production work right now.

I love my Mesa cards and openly recommend them to anyone that wants to build their own CNC control. I do have the 7I76E and THCAD combination working really well for plasma cutting now except for this little divot thing (well at least better than my old commercial control system).

John

I had a very long winded reply that was killed by my poor typing skills. I know how to use a 'scope but it is really hard to pick the correct cut segments out of a 14,000 line gcode program. I plan on putting together some tests the mimic this problem as soon as I get time from production work. I never saw this problem during my all my straight line testing to get the THC working well. I am trying to transition my LinuxCNC control system to production work right now.

I love my Mesa cards and openly recommend them to anyone that wants to build their own CNC control. I do have the 7I76E and THCAD combination working really well for plasma cutting now except for this little divot thing (well at least better than my old commercial control system).

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3903

02 Jun 2018 04:07 #111439

by rodw

Don't you hate that? What Peter is saying is that you should be able to let Halscope sit there idling and it will trigger and start logging when the pid is enabled so it only starts logging when it has to.

Replied by rodw on topic THC Servo Start

I had a very long winded reply that was killed by my poor typing skills.

Don't you hate that? What Peter is saying is that you should be able to let Halscope sit there idling and it will trigger and start logging when the pid is enabled so it only starts logging when it has to.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

02 Jun 2018 04:17 #111440

by islander261

Replied by islander261 on topic THC Servo Start

PCW

Yes, I understand how to use a 'scope. The problem only started showing up (or I noticed it) while I am transitioning my LinuxCNC control system to production use. So I am cutting on a sheet with 600 to 900 pierces or cut segments and I have to catch one of the problem segments while trying to watch out for any other major problems that may actually damage the machine. A bad torch crash can cost upwards of $300 in parts to repair even with a break away torch mount, don't ask how I know this. Hey I built this system from open source tools and I am not a professional machine tool builder or control system builder. While cutting at 220ipm things are happening very fast and it is hard to see details while looking out for serious damaging stuff. This is continuous cutting over an hour to an hour and a half period so keeping the concentration going while watching a boring (when it works correctly) process is a challenge.

I plan on setting up some controlled testing for this in the near future when I get a break in production. I also

Please don't get me wrong I love my Mesa hardware and recommend it to anyone after having a close source commercial system for years. With that equipment one was left to guess about problems and the support was always quick to blame you for not following their poor instructions instead of finding the real source of poor cutting, usually their software or hardware.

John

Yes, I understand how to use a 'scope. The problem only started showing up (or I noticed it) while I am transitioning my LinuxCNC control system to production use. So I am cutting on a sheet with 600 to 900 pierces or cut segments and I have to catch one of the problem segments while trying to watch out for any other major problems that may actually damage the machine. A bad torch crash can cost upwards of $300 in parts to repair even with a break away torch mount, don't ask how I know this. Hey I built this system from open source tools and I am not a professional machine tool builder or control system builder. While cutting at 220ipm things are happening very fast and it is hard to see details while looking out for serious damaging stuff. This is continuous cutting over an hour to an hour and a half period so keeping the concentration going while watching a boring (when it works correctly) process is a challenge.

I plan on setting up some controlled testing for this in the near future when I get a break in production. I also

Please don't get me wrong I love my Mesa hardware and recommend it to anyone after having a close source commercial system for years. With that equipment one was left to guess about problems and the support was always quick to blame you for not following their poor instructions instead of finding the real source of poor cutting, usually their software or hardware.

John

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.121 seconds