THC Servo Start

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

11 Jun 2018 06:21 #112174

by rodw

Replied by rodw on topic THC Servo Start

The current workaround is to also send the feedrate/60 by an M67 E1 Qnnnn command in your Sheetcam POST where it sets the cutting speed with the gcode F command. Then update your HAL files and replace references to motion.requested-vel with motion.analog-out-01. Please check your config to make sure this digital pin is not in use and use another pin if it is (the E1 parameter).

Then install the component John (islander261) posted for corner lock. .

PCW has added a feature request in the linuxcnc issues register and there has been a couple of comments about modifying the code.

Also, I've rewritten my torch voltage sampler to wait until the current_vel is near the feed rate (default 95%) and sent it over to John but neither of us has tested it yet. So we've finally nearly got a full feature set for plasma

Then install the component John (islander261) posted for corner lock. .

PCW has added a feature request in the linuxcnc issues register and there has been a couple of comments about modifying the code.

Also, I've rewritten my torch voltage sampler to wait until the current_vel is near the feed rate (default 95%) and sent it over to John but neither of us has tested it yet. So we've finally nearly got a full feature set for plasma

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

11 Jun 2018 13:10 #112186

by rodw

Replied by rodw on topic THC Servo Start

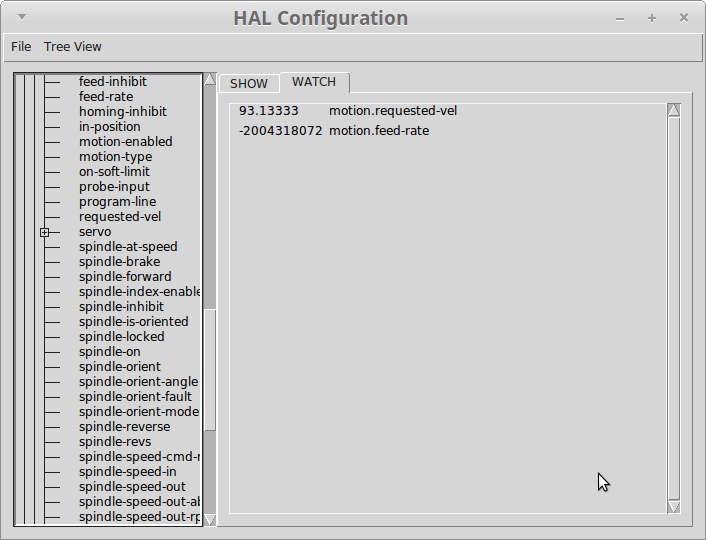

I added a new field called feed_rate to the

emcmotStatus and emcmot_hal_data structures

I then tried what Sebastion suggested on the issues tracker github.com/LinuxCNC/linuxcnc/issues/440

and this is what I got.

in /src/emc/tp/tp.c, I addedin src/emc/motion/control.c (to load the Hal structure)And in /src/emc/motion/motion.c

I didn't understand what Sebastian mean when he said "And when the tcq drains, set that pin to 0." but the value drops to zero between cutting segments.

Any ideas would be much appreciated.

emcmotStatus and emcmot_hal_data structures

I then tried what Sebastion suggested on the issues tracker github.com/LinuxCNC/linuxcnc/issues/440

and this is what I got.

in /src/emc/tp/tp.c, I added

emcmotStatus->feed_rate = tc->reqvel;*(emcmot_hal_data->feed_rate) = emcmotStatus->feed_rate;if ((retval = hal_pin_s32_newf(HAL_OUT, &(emcmot_hal_data->feed_rate), mot_comp_id, "motion.feed-rate")) != 0) goto error;I didn't understand what Sebastian mean when he said "And when the tcq drains, set that pin to 0." but the value drops to zero between cutting segments.

Any ideas would be much appreciated.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

11 Jun 2018 13:22 #112187

by rodw

Replied by rodw on topic THC Servo Start

The following user(s) said Thank You: Clive S, KCJ

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

11 Jun 2018 14:17 #112193

by rodw

Pedro, I've sent you an email. If you can reply to it, I'll send you a solution. (Providing it tests OK for John)

Replied by rodw on topic THC Servo Start

hi, I have been playing for two days with this corner lock concept, just to discover by myself the requested vel signal behavior, now I'm stuck, I have set up a rule in SheetCAM to disable THC in corners, it works but is not the most elegant solution, I think have an output pin with the real requested velocity is the way to go, please let me know if it is possible.

Pedro, I've sent you an email. If you can reply to it, I'll send you a solution. (Providing it tests OK for John)

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

11 Jun 2018 23:41 #112219

by rodw

Replied by rodw on topic THC Servo Start

Sorry guys, a false start, the feed-rate pin is a copy of requested-vel

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

11 Jun 2018 23:58 #112220

by islander261

Replied by islander261 on topic THC Servo Start

Oh well, it at least got me to organize all my custom components so it is easy to update my rtlib after the recompile.

John

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

12 Jun 2018 08:01 #112227

by rodw

Sorry about that. Not the first dry gully you've been up on this project I'm sure! I have to get the code into a git repository so it accessible by all (and can get pushed to master branch).

I did do a bit more digging and am sure it can be resolved.

Replied by rodw on topic THC Servo Start

Oh well, it at least got me to organize all my custom components so it is easy to update my rtlib after the recompile.

John

Sorry about that. Not the first dry gully you've been up on this project I'm sure! I have to get the code into a git repository so it accessible by all (and can get pushed to master branch).

I did do a bit more digging and am sure it can be resolved.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

16 Jun 2018 06:59 #112458

by rodw

Replied by rodw on topic THC Servo Start

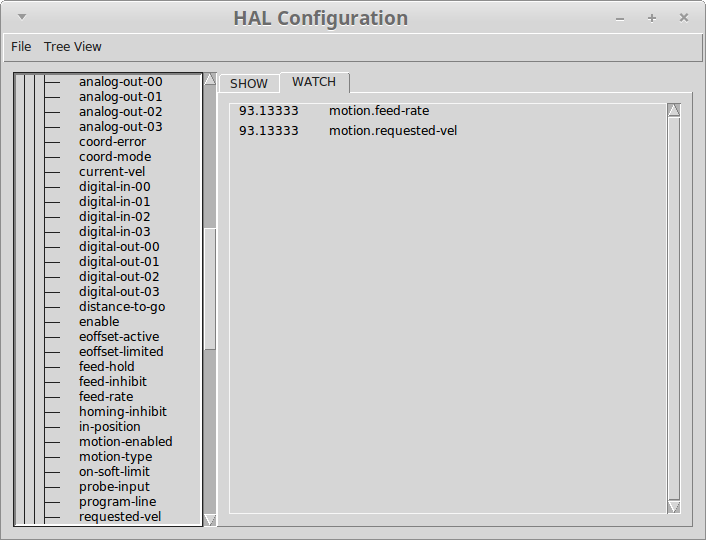

Just a bit of an update. And a Solution!

After a bit of research I found something and asked the devs if we could remap the F code..

Some of the developers had forgotten that the F code can be remapped. There is a complete sim example already included.

It uses a subroutine called setfeed.ngc and you just have to change it to

And use motion.analog.out.01 instead of motion.current-vel in your HAL file.

After I confirmed this worked in a sim and grijalvap has tested this on a live config.

So the only thing missing is some decent documentation on remapping as its a bit convoluted to migrate it from a sim to a live config.

After a bit of research I found something and asked the devs if we could remap the F code..

Some of the developers had forgotten that the F code can be remapped. There is a complete sim example already included.

It uses a subroutine called setfeed.ngc and you just have to change it to

o<setfeed> sub

(debug, in setfeed feed=#<feed>)

; using the code being remapped here means 'use builtin behaviour'

M67 E1 Q[#<feed>/60]

F#<feed>

; signal success be returning a value > 0:

o<setfeed> endsub [1]

m2And use motion.analog.out.01 instead of motion.current-vel in your HAL file.

After I confirmed this worked in a sim and grijalvap has tested this on a live config.

So the only thing missing is some decent documentation on remapping as its a bit convoluted to migrate it from a sim to a live config.

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

Less

More

- Posts: 198

- Thank you received: 63

16 Jun 2018 16:12 #112482

by grijalvap

Replied by grijalvap on topic THC Servo Start

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

16 Jun 2018 22:03 #112497

by rodw

What do you mean? Its already 8:00am Sunday morning here! Time to get out of bed!

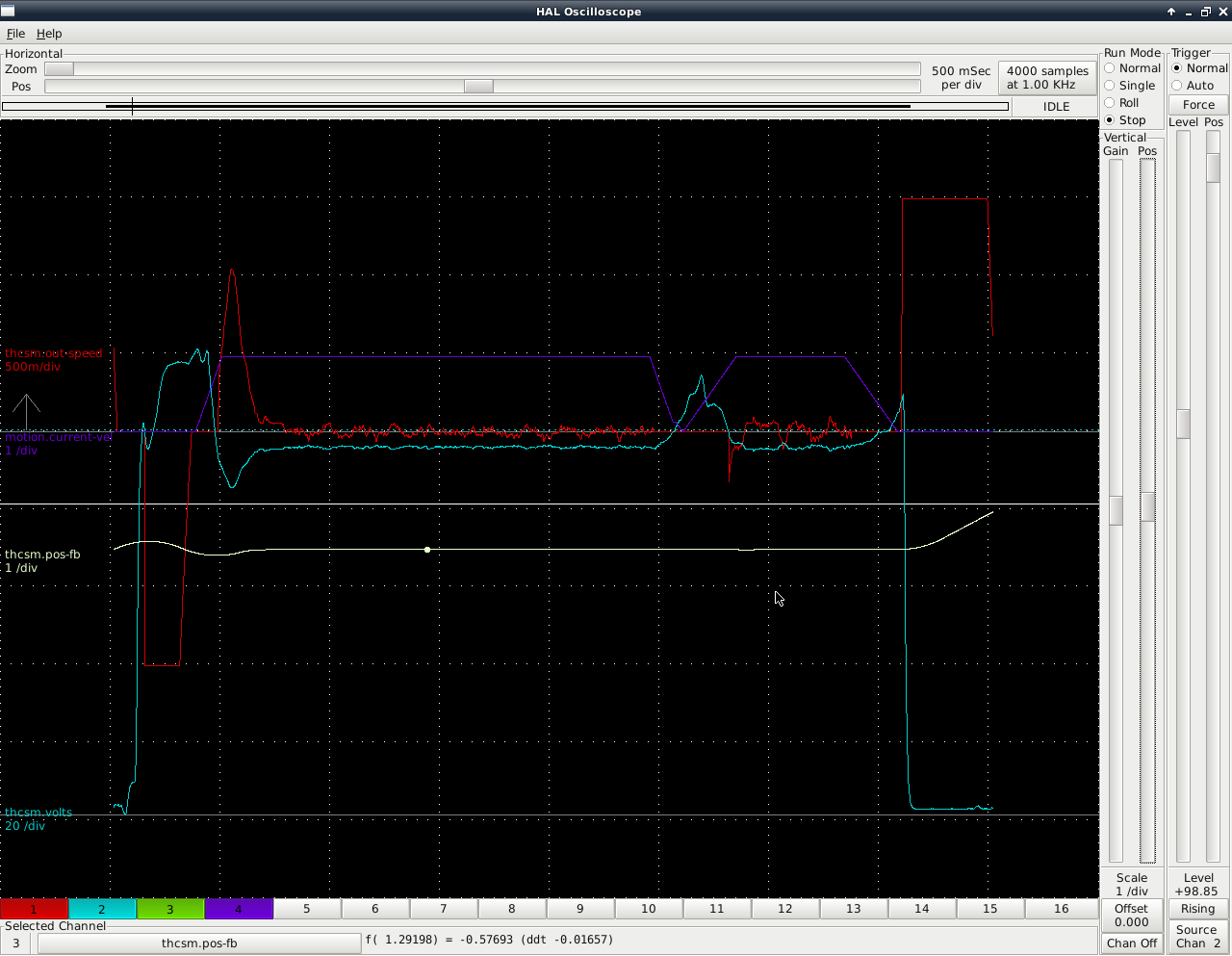

So good to see this finally coming together for a few people. Those results look great.

Replied by rodw on topic THC Servo Start

Can't await until Sunday.

I have implemented the Remap solution on a Live Cutting system attached you can see the signals

What do you mean? Its already 8:00am Sunday morning here! Time to get out of bed!

So good to see this finally coming together for a few people. Those results look great.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 2.545 seconds