THCAD-10

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

27 Mar 2019 18:04 #129783

by Dee436

THCAD-10 was created by Dee436

Wasn’t sure if I should start a new thread or reply in this one, chose to reply to this as it closely resembles my situation.

I have read through the thread a number of times as well as the various man pages and Mesa documents. I am using the same components I.e Mesa 5i25-7i76-Thcad 10 on a gantry plasma. I orinally configured using pncconf, then RodW helped me to get my torch to start and the Arc Ok signal to work. As a result I have been able to cut items but as the steel warps my torch gets closer to the steel until it touches. As I have the thcad I would like to utilise it. I have installed the thc-pid component that JT uploaded in the thread and modified my hal, postgui hal and Ini files to reflect the thc details in the files uploaded by kb8wmc. I got the pyvcp screen ok and thc showed active as soon as the machine was enabled. When I tried to home all, which has always worked perfectly I could see z axis value changing on the dro but no action on the actual machine. I then tried to home my x axis which again has always worked and although that appeared to be working it ignored the home and limit switch and by the time i got it stopped had broken the switch and hit the hard stop. I have just finished re-aligning the z axis and fitting a new limit/home switch. I reverted back to the pncconf files and homing is working again. I realise that something I copied across obviously caused an issue but my level of knowledge at the moment is not telling my what. I have been constantly reading manuals for day now but am just tearing my hair out trying to get anywhere.

I am not interested in fancy screens and gauges or built in routines, is there a simple set of commands I can use to get the thcad to function and follow a requested voltage? I liked the look of the hal code uploaded by islander261 on page 2 of the thread but guess there is a lot more I would need to do before I could utilise it. Also I have tried connecting a battery to test the output of the thcad but it always reads zero. I am supposed to have the machine running a cut when testing this?

Or Is there a simpler thc that would be easier for me to use

I have read through the thread a number of times as well as the various man pages and Mesa documents. I am using the same components I.e Mesa 5i25-7i76-Thcad 10 on a gantry plasma. I orinally configured using pncconf, then RodW helped me to get my torch to start and the Arc Ok signal to work. As a result I have been able to cut items but as the steel warps my torch gets closer to the steel until it touches. As I have the thcad I would like to utilise it. I have installed the thc-pid component that JT uploaded in the thread and modified my hal, postgui hal and Ini files to reflect the thc details in the files uploaded by kb8wmc. I got the pyvcp screen ok and thc showed active as soon as the machine was enabled. When I tried to home all, which has always worked perfectly I could see z axis value changing on the dro but no action on the actual machine. I then tried to home my x axis which again has always worked and although that appeared to be working it ignored the home and limit switch and by the time i got it stopped had broken the switch and hit the hard stop. I have just finished re-aligning the z axis and fitting a new limit/home switch. I reverted back to the pncconf files and homing is working again. I realise that something I copied across obviously caused an issue but my level of knowledge at the moment is not telling my what. I have been constantly reading manuals for day now but am just tearing my hair out trying to get anywhere.

I am not interested in fancy screens and gauges or built in routines, is there a simple set of commands I can use to get the thcad to function and follow a requested voltage? I liked the look of the hal code uploaded by islander261 on page 2 of the thread but guess there is a lot more I would need to do before I could utilise it. Also I have tried connecting a battery to test the output of the thcad but it always reads zero. I am supposed to have the machine running a cut when testing this?

Or Is there a simpler thc that would be easier for me to use

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17584

- Thank you received: 5142

27 Mar 2019 19:06 #129787

by PCW

Replied by PCW on topic THCAD-10

Can you post your current hal and ini files?

As a basic hardware test, If you connect a 9V battery to a (powered) THCAD inputs, the yellow LED on the THCAD-10 should blink faster

As a basic hardware test, If you connect a 9V battery to a (powered) THCAD inputs, the yellow LED on the THCAD-10 should blink faster

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

27 Mar 2019 19:18 #129788

by Dee436

Replied by Dee436 on topic THCAD-10

Hi PCW

Thanks for the reply. That is the one thing I did see with a battery connected, the led did flash faster. I am sure the board is fine, the mesa boards seem very robust. It is unfortunately the just me the user who does not know how to use it in this instance.

Thanks for the reply. That is the one thing I did see with a battery connected, the led did flash faster. I am sure the board is fine, the mesa boards seem very robust. It is unfortunately the just me the user who does not know how to use it in this instance.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

27 Mar 2019 19:24 #129790

by Grotius

Replied by Grotius on topic THCAD-10

@Darran,

Can you come closer to your exact problem. Is it the way you connect item's in hal other item's?

I don't use Mesa, so i can't help you with pre configuration's. Only for parport and ethercat i can help you in plasma world.

Can you come closer to your exact problem. Is it the way you connect item's in hal other item's?

I don't use Mesa, so i can't help you with pre configuration's. Only for parport and ethercat i can help you in plasma world.

Please Log in or Create an account to join the conversation.

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

27 Mar 2019 20:24 #129793

by Dee436

Replied by Dee436 on topic THCAD-10

Hi Grotius

My problem is connecting in hal. The mechanics of the machine i am good with as I built it, wiring again is no problem. The main issue is I do not yet know anything about Linuxcnc, I was a computer admin so am computer literate I just dont know the software yet. I bought the cards and decided on Linuxcnc when I did not have such a rush to get the machine working, I now have work for it so need it running.

The thcad is all connected and I can work out the offsets required I just do not understand what needs to go in hal to make it work

My problem is connecting in hal. The mechanics of the machine i am good with as I built it, wiring again is no problem. The main issue is I do not yet know anything about Linuxcnc, I was a computer admin so am computer literate I just dont know the software yet. I bought the cards and decided on Linuxcnc when I did not have such a rush to get the machine working, I now have work for it so need it running.

The thcad is all connected and I can work out the offsets required I just do not understand what needs to go in hal to make it work

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

27 Mar 2019 20:39 #129794

by islander261

Replied by islander261 on topic THCAD-10

Here is a simple example from my system, used daily.

John

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11620

- Thank you received: 3911

27 Mar 2019 20:44 #129795

by rodw

Replied by rodw on topic THCAD-10

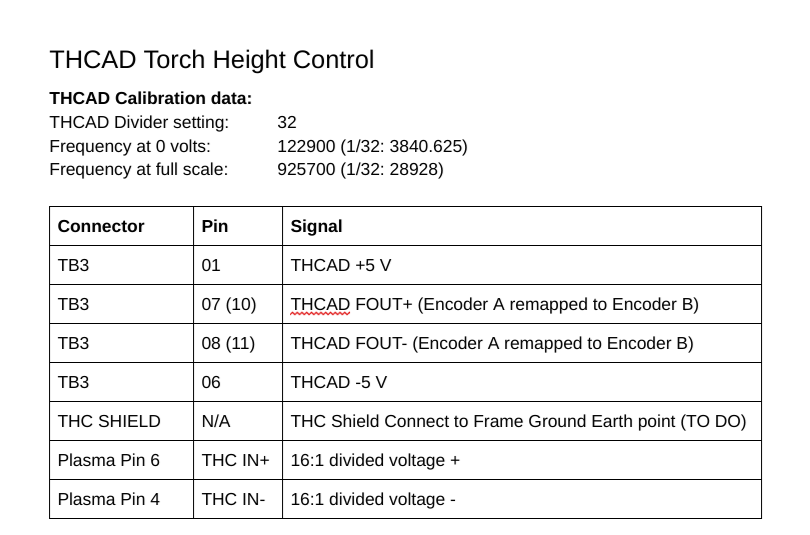

Here is a screen shot of my pinouts for the 7i76e for the wiring of the THCAD. Yours should be similar Note that my system is non standard as I blew something up and PCW wrote me new firmware that mapped the Encoder B to Encoder A so ignore the numbers in brackets

Set the THCAD link to be 1/32

So once again halshow will be your friend. With the 9 volt battery connected, you should first check the encoder pins and one of them should be close to 90% of the 1/32 frequency based on your calibration data. Then it is a matter of scaling the reading back to a voltage reading. You can do this using standard hall components, but I wrote a component to do it, If you look through this section, you will find it.

Set the THCAD link to be 1/32

So once again halshow will be your friend. With the 9 volt battery connected, you should first check the encoder pins and one of them should be close to 90% of the 1/32 frequency based on your calibration data. Then it is a matter of scaling the reading back to a voltage reading. You can do this using standard hall components, but I wrote a component to do it, If you look through this section, you will find it.

Please Log in or Create an account to join the conversation.

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

27 Mar 2019 21:23 #129796

by Dee436

Replied by Dee436 on topic THCAD-10

Hi John.

I saw this config earlier in the thread and wanted to try it. Is there any other setup required to use it? Hiw do you input the required voltage?

I saw this config earlier in the thread and wanted to try it. Is there any other setup required to use it? Hiw do you input the required voltage?

Please Log in or Create an account to join the conversation.

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

27 Mar 2019 21:25 #129797

by Dee436

Replied by Dee436 on topic THCAD-10

Hi Rod

I have all the physical connections complete. Its the code in hal that is causing me issues

I have all the physical connections complete. Its the code in hal that is causing me issues

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

27 Mar 2019 21:31 #129798

by islander261

Replied by islander261 on topic THCAD-10

Just hook a known voltage (9v battery) to the input of the THCAD card for a quick test. You will need a voltage divider between your THCAD and plasma machine. It can be a built in one or home brew. The THCAD is pretty input over voltage immune. Assuming you have a US single phase plasma you should be good with anything greater than about 15:1. Read the THCAD manual as it has instructions for selecting a single series resistor for simplicity. If you have a HV/HF start machine then your divider will need to be a little more complex to keep the rf out of the THCAD.

John

John

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.092 seconds