Spurious engagement of Plasmac's Anti-dive

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

Attachments:

Please Log in or Create an account to join the conversation.

- mkardasi

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 18

Look inside the inverter for a dip switch.. I hope you have luck today !

No such luck. The machine is fixed at 20:1

No problem. In your attached files, i cannot find this hal file : esab-plasmac.hal

It could be the error lives in that file. So that's why i mentioned the missing file...

It's loaded in your hal config. When it's not loaded, you get a message btw.

Ah, now I understand. The esab-plasmac.hal is attached to the first post. The forum seems to have appended 2019-06-30 to the filename. esab-plasmac_2019-06-30.hal is the file that you are interested in.

It looks like the kerf detection disables the THC for some period of time (kerf width?) so once you got the first kerf detection event, the THC is never enabled again or the control duty cycle is is low enough that the control loop gain is insufficient to stay within the threshold and therefore does not track the slow change in voltage.

Have you tried simply increasing the kerf crossing threshold to say 3V?

I wonder if a threshold that's more independent of feedback loop bandwidth

would work better (like DVDT of filtered voltage > some threshold) plus some

smarter recovery scheme like detecting the other edge of the kerf

(with DVDT < some other threshold)

It would be nice to see a plot of plasma voltage at an actual kerf crossing...

Hi Peter,

According to the code, Arc Volt has to drop inorder to disable the lockout. I can try that but I'm running out of adjustment. Kerf_override is maxed out at 500 in the GUI so I can only reduce height/volt with the lower limit being 0.001 I'm at 0.002.

if(arc_voltage < target_volts + (kerf_threshold * 0.5)){

kerfcross_is_locked = FALSE;

last_arc_voltage = arc_voltage;

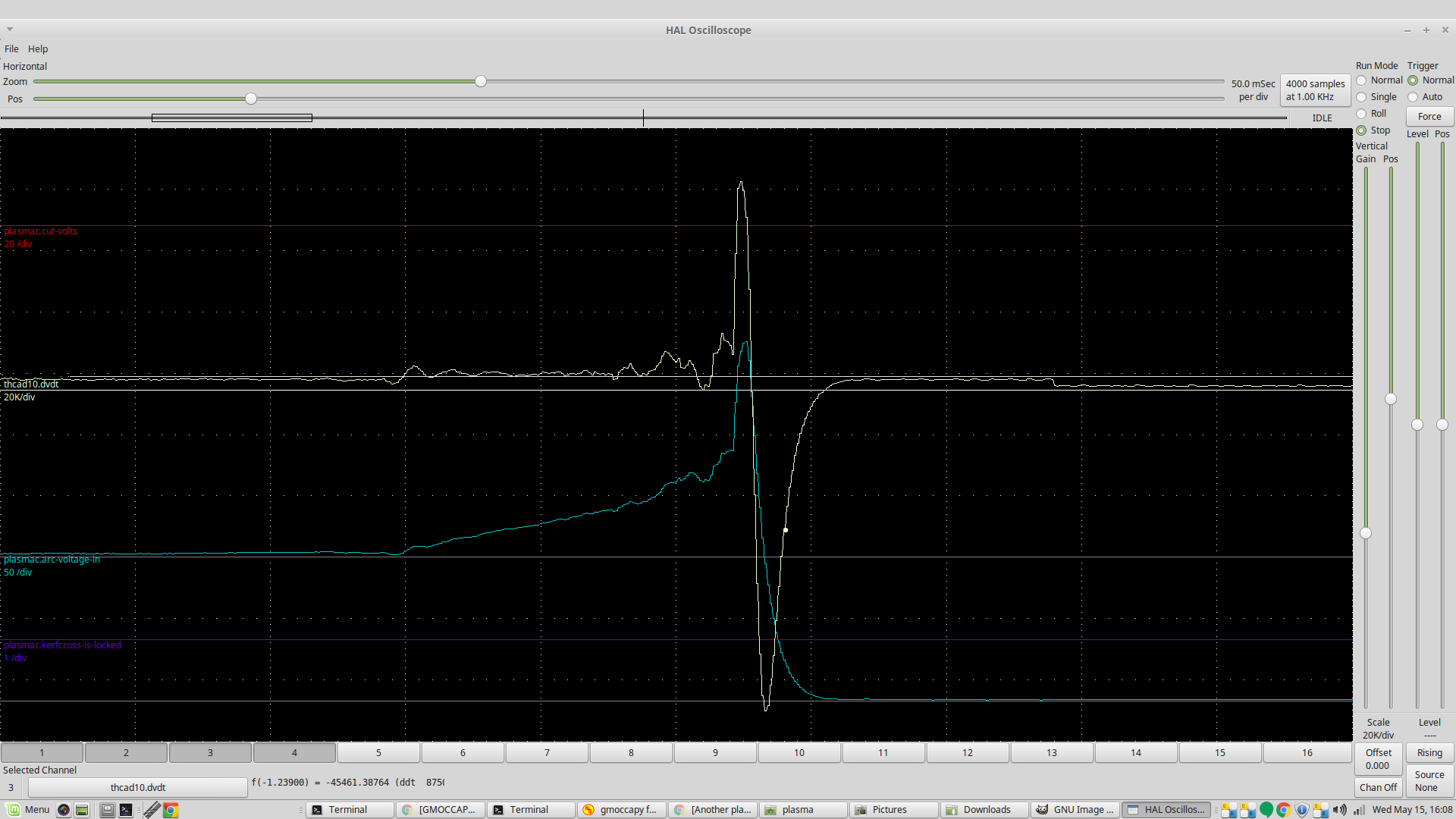

}Rod was kind enough to share his component which calculates dv/dt. I just finished splicing it in to my config and cut 4 straight lines 0.200" apart, then I cut across those 4 lines. This is the resultant plot. F/32 & encoder.filter enabled. The lowpass filtering disabled.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

self.builder.get_object('kerfcross-override-adj').configure(100,10,500,1,0,0)I won't be doing anything to kerf crossing until I get my machine going.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

I only run simple parts mostly but have not really had the need to cross over a kerf I have just cut,

Could I get a example of when it would be used.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

This might be a silly question but what is the purpose of kerf crossing?

I only run simple parts mostly but have not really had the need to cross over a kerf I have just cut,

Could I get a example of when it would be used.

I felt the same but I have found that if you are cutting a hole in thicker material, you can get a dive at the end of the cut when te slug falls away. It would also let you do an overburn so the arc on the bottom side can finish the hole cut. I think it would also be useful when severing a sheet.

I have heard some people actually cut rectangular parts without wasting any material between them. Eg cut them out as if you were cutting out paper pieces with a ruler and knife.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

This might be a silly question but what is the purpose of kerf crossing?

I only run simple parts mostly but have not really had the need to cross over a kerf I have just cut,

Could I get a example of when it would be used.

I am not really experienced enough to comment but from what I have read it is another one of those "yep, you definitely need it" or "nah, never had a need for it" things...

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

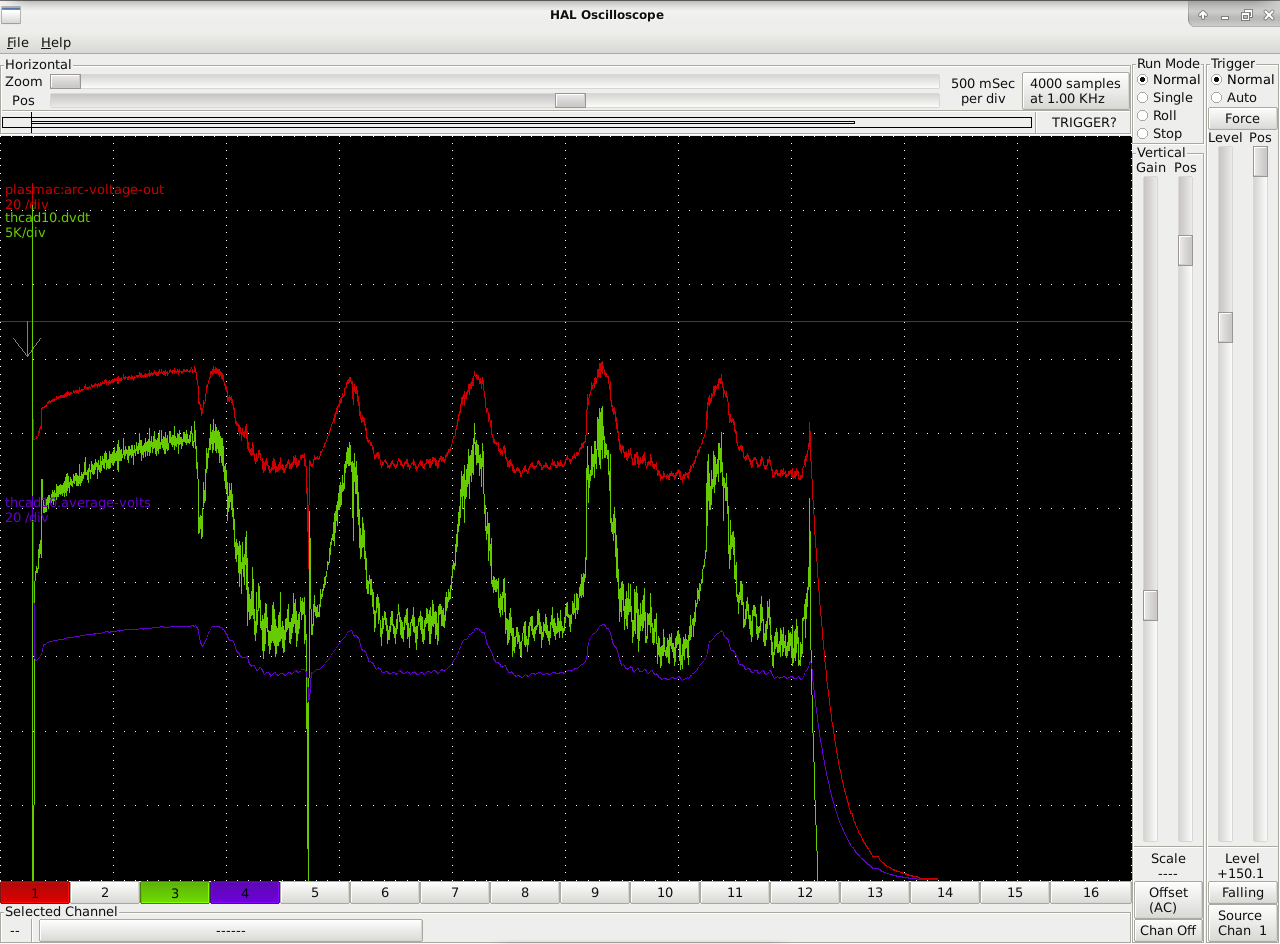

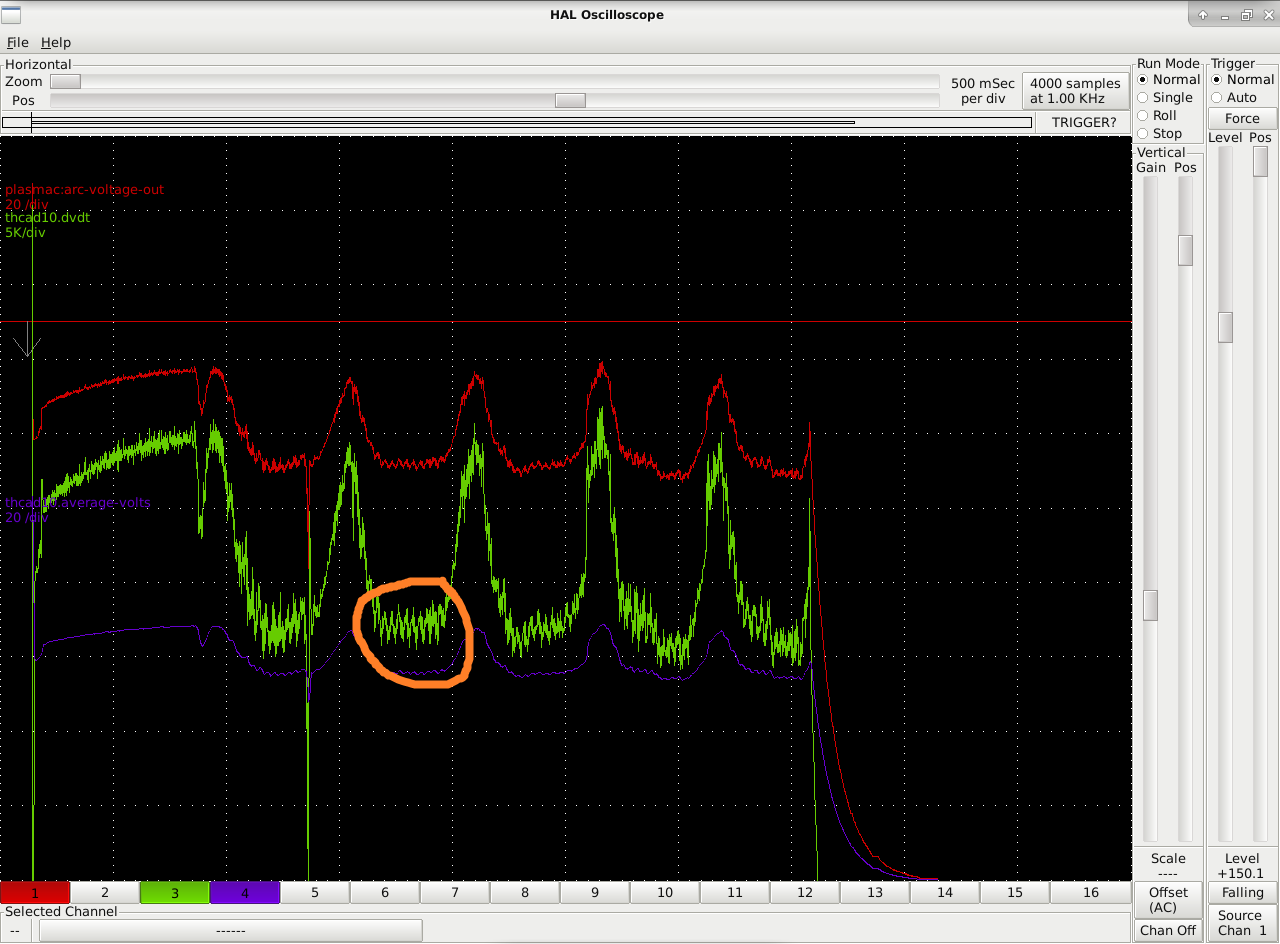

Set a threshold just above that and plot the disable pin so we know its turning on and off.

If that is working, and the threshold looks good, it will be time to try it with THC turned on and the disable pin connected to Plasmac.

Also, make sure you have at least 1.5 seconds of cutting before the kerf crossing to allow the arc to stabilise.

What plasma cutter? Your signal seems very noisy so you might benefit from trying some of the things in the EMI thread in the plasma section here. (been there, done that)

OOPS: I forgot to say we don't have any code to turn the THC back on again yet.!

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

I felt the same but I have found that if you are cutting a hole in thicker material, you can get a dive at the end of the cut when te slug falls away. It would also let you do an overburn so the arc on the bottom side can finish the hole cut. I think it would also be useful when severing a sheet.

I have heard some people actually cut rectangular parts without wasting any material between them. Eg cut them out as if you were cutting out paper pieces with a ruler and knife.

The way I overcame the first problem is turn the THC control off before the end of the cut, That way it maintains the same height it was at just before the end and will continue on without diving as it reaches the keft.

The second part of your answer is called common line cutting, I have not tried it but I am tempted to do it with some parts I cut. It will be very interesting to follow you guys breaking new ground, I know others have developed what you guys are trying to achieve (Hypertherm) but the difference is a free to use system compared to a tens of thousand dollar system.

I approach Hypertherm mid last year about buying their software and hardware and they would not sell their control system to me. For that to happen I would have to do some training.that I would have to pay for before they would allow it.

What Linuxcnc has become will disrupt Hypertherm's hold on the plasma market. I am hoping to make a dent in it very shortly using Linuxcnc as the foundation.

I cant thank Phill and the others enough for what they have made easily available and free to use and modify,

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

The way I overcame the first problem is turn the THC control off before the end of the cut, That way it maintains the same height it was at just before the end and will continue on without diving as it reaches the keft.

Thats the point, if we can come up with a reliable void sensing algorithm, you won't have to disable the THC as in combination with the corner lock feature the controller will just look after it all for you. Thats one of the things people get with the Hypertherm system for all that cash!

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

I am gearing up to do a bunch of cutting as my machine has been down for 4 months with my CandCNC dramas and building the new controller and I have been outsourcing all of my cutting,

I could try a few things and get some data if needed, I just need to know what you guys are looking for.

Please Log in or Create an account to join the conversation.