- Hardware & Machines

- CNC Machines

- Plasma & Laser

- New build, small plasma that got to be very complicated build.

New build, small plasma that got to be very complicated build.

- tommylight

-

Topic Author

Topic Author

- Online

- Moderator

-

Less

More

- Posts: 21264

- Thank you received: 7259

16 Oct 2019 00:07 - 19 Oct 2019 13:38 #147957

by tommylight

New build, small plasma that got to be very complicated build. was created by tommylight

Well, it started as a small plasma for the sake of this thread:

forum.linuxcnc.org/plasma-laser/35349-cn...building-them#118668

That was renamed, was open source something or another.

This time i was thinking more of how it will look, not just making it functional and that led to some design ideas that proved quite terrible and time consuming. It should look much better, for sure, but any servicing of dismantling is a pain in the a$$, and it has to be disassembled to be painted, so OH JOY !

Will take some pictures tomorrow and post them here, not finished yet, but all the motors are in place, belts also, floating head is nearly finished, the wiring needs to be done, electronics are done, etc.

Will be also posting this to the above thread at the beginning where the small machine is discussed.

Regards,

Tom.

Here are some pictures:

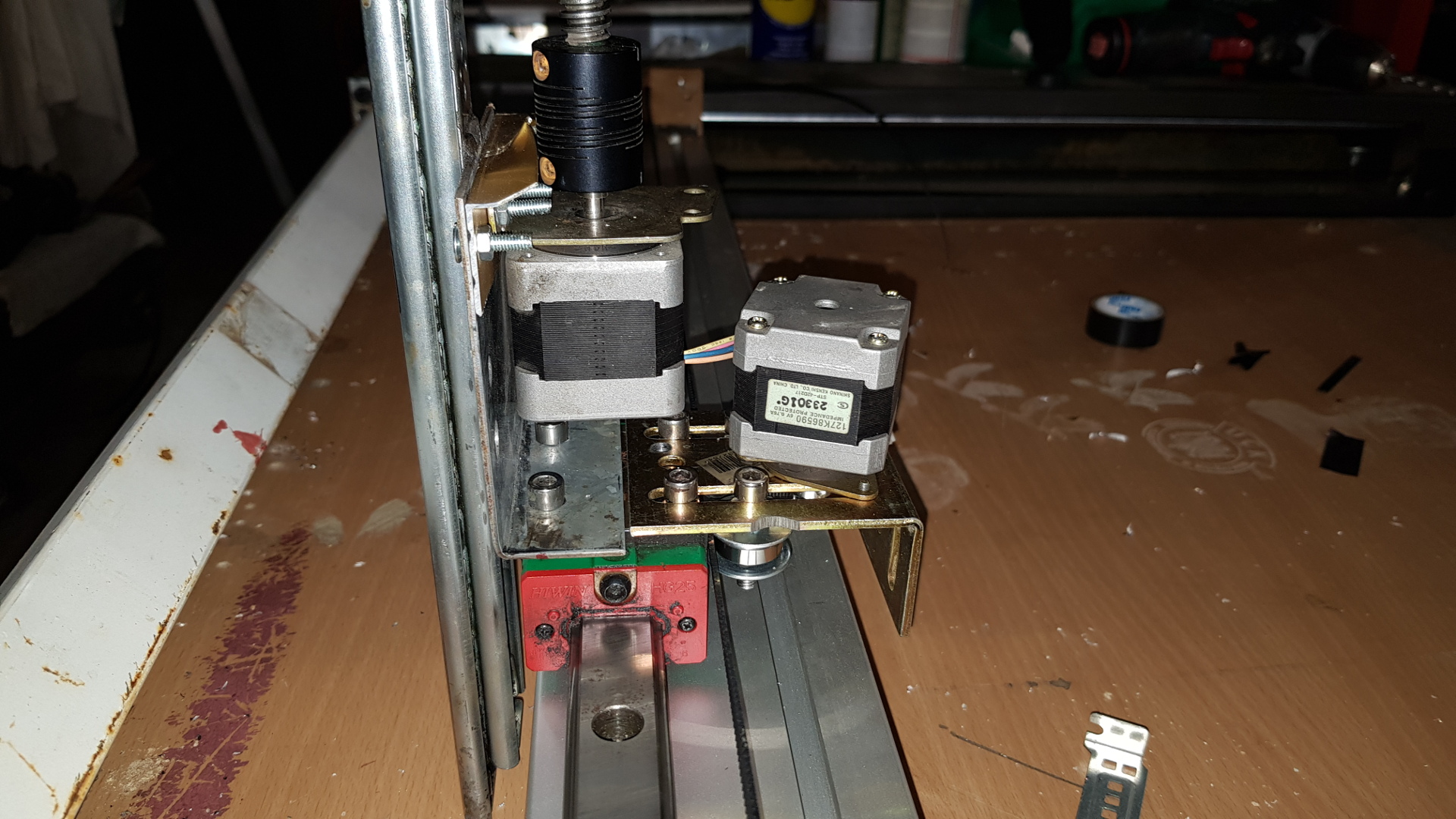

Machine from one side, floating head with X and Z axis motors mounted.

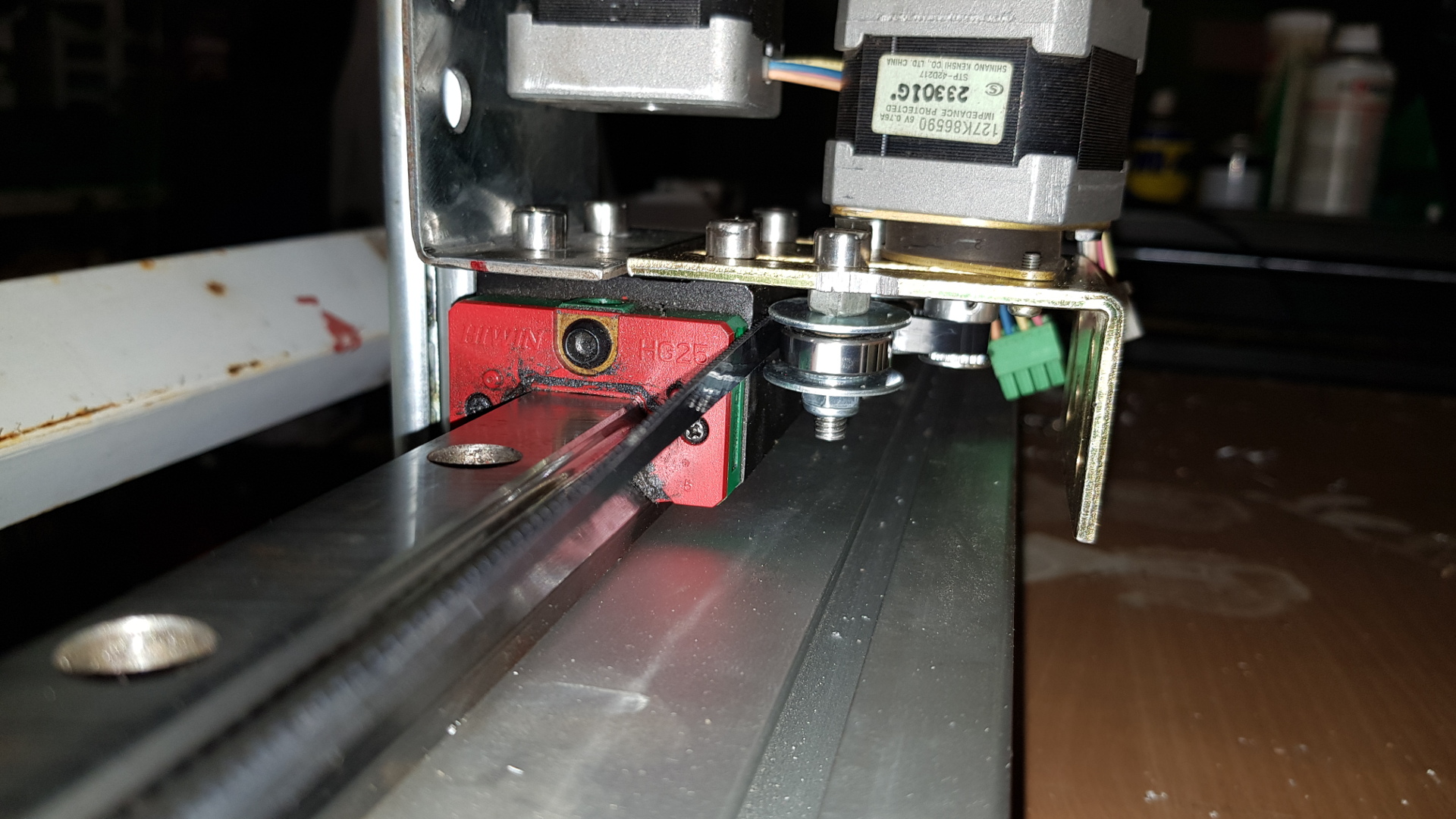

A close up of motors

A close up of the X axis motor, bearings, GT2 16teeth pulley and belt

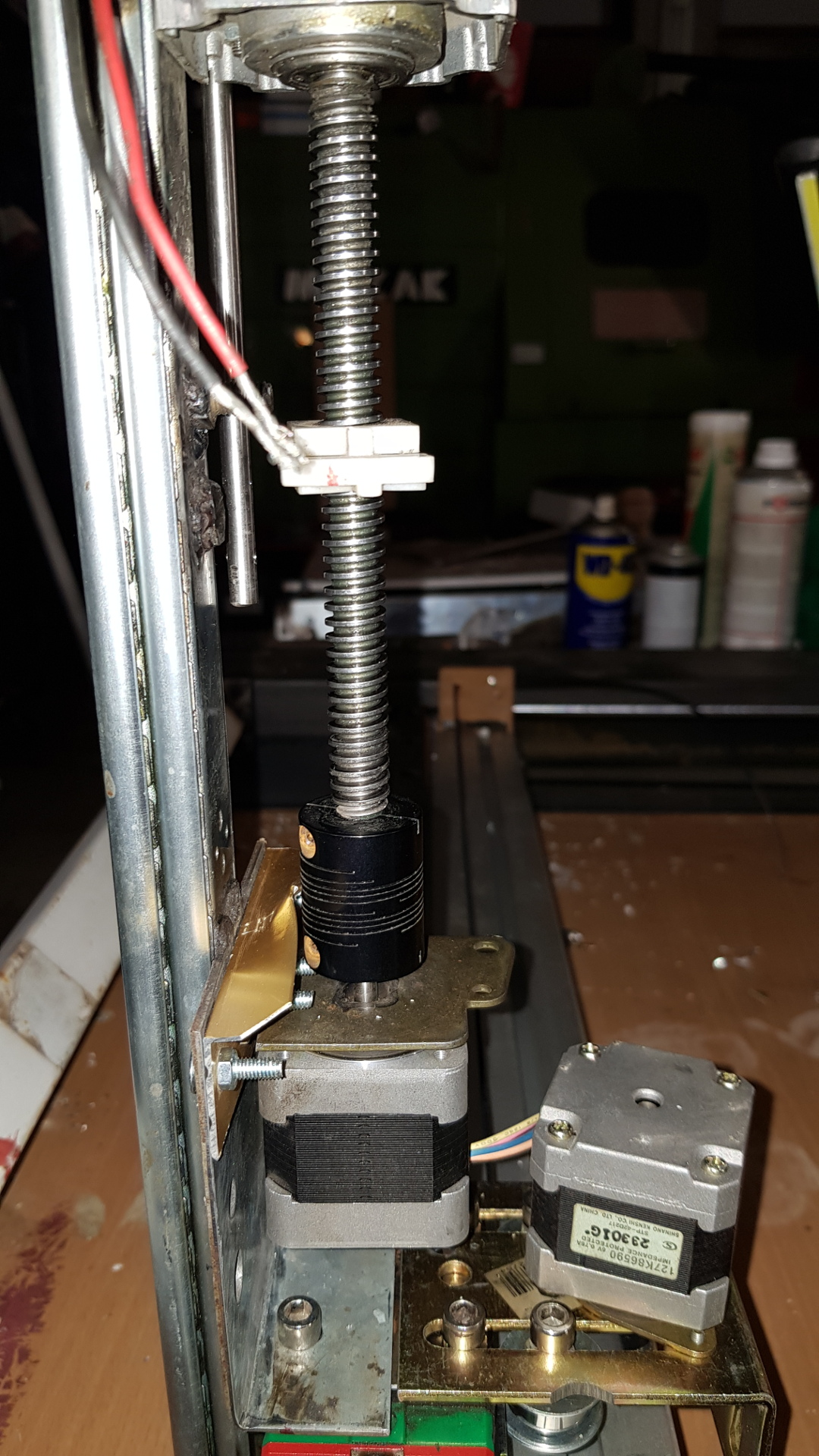

Z axis motor and screw, notice the nut is not attached yet, was attached last night but was flexing to much so a new mount is in order.

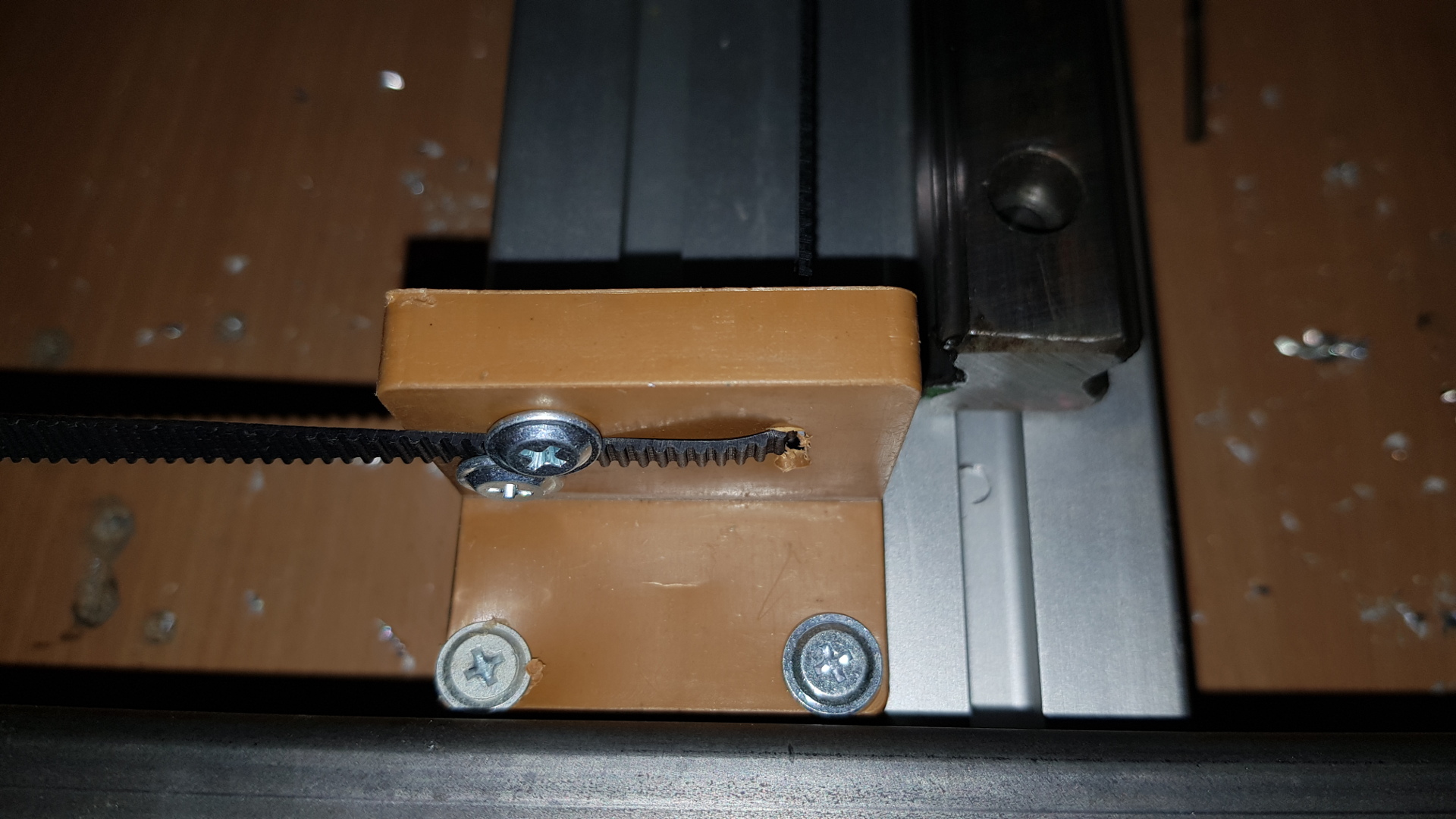

X axis belt mount and hard stop since this will have no limit switches.

One of the Y axis motors and mount, also round rail mount can be seen, same on both sides of the Y axis. The opposite side of that tube has a bearing mounted for the belt, belt is spring loaded on both sides.

Video of it moving.

forum.linuxcnc.org/plasma-laser/35349-cn...building-them#118668

That was renamed, was open source something or another.

This time i was thinking more of how it will look, not just making it functional and that led to some design ideas that proved quite terrible and time consuming. It should look much better, for sure, but any servicing of dismantling is a pain in the a$$, and it has to be disassembled to be painted, so OH JOY !

Will take some pictures tomorrow and post them here, not finished yet, but all the motors are in place, belts also, floating head is nearly finished, the wiring needs to be done, electronics are done, etc.

Will be also posting this to the above thread at the beginning where the small machine is discussed.

Regards,

Tom.

Here are some pictures:

Machine from one side, floating head with X and Z axis motors mounted.

A close up of motors

A close up of the X axis motor, bearings, GT2 16teeth pulley and belt

Z axis motor and screw, notice the nut is not attached yet, was attached last night but was flexing to much so a new mount is in order.

X axis belt mount and hard stop since this will have no limit switches.

One of the Y axis motors and mount, also round rail mount can be seen, same on both sides of the Y axis. The opposite side of that tube has a bearing mounted for the belt, belt is spring loaded on both sides.

Video of it moving.

Attachments:

Last edit: 19 Oct 2019 13:38 by tommylight. Reason: added video

The following user(s) said Thank You: phillc54, chimeno, Clive S

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

16 Oct 2019 05:05 #147966

by machinedude

Replied by machinedude on topic New build, small plasma that got to be very complicated build.

will be watching for the pictures i like pictures

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

16 Oct 2019 06:43 #147971

by pl7i92

Replied by pl7i92 on topic New build, small plasma that got to be very complicated build.

hi my recent plasma build got 4 workdays

and took me 700USD including table Plasma and CNC rail kit as well as a very low cost TB6600 36V 270Oz Kit

it works for small sheets

thats all I(we) need

and took me 700USD including table Plasma and CNC rail kit as well as a very low cost TB6600 36V 270Oz Kit

it works for small sheets

thats all I(we) need

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

16 Oct 2019 06:44 - 16 Oct 2019 06:45 #147973

by thefabricator03

Pictures?

Replied by thefabricator03 on topic New build, small plasma that got to be very complicated build.

hi my recent plasma build

Pictures?

Last edit: 16 Oct 2019 06:45 by thefabricator03.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

16 Oct 2019 06:51 #147976

by pl7i92

Replied by pl7i92 on topic New build, small plasma that got to be very complicated build.

i got a video online

it is always the same Education mashine we do in Schools

it is always the same Education mashine we do in Schools

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

16 Oct 2019 06:54 #147977

by machinedude

Replied by machinedude on topic New build, small plasma that got to be very complicated build.

i got way more than $700 in my build for sure. and sadly i'm not done yet. between linear rails and everything else i'm probably looking at something like $4,000 by the time i am done minus the plasma cutter on a 4' x 8' table. hopefully

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

16 Oct 2019 07:57 #147979

by thefabricator03

Its going to be one hell of a machine though. Money well spent I would say.

Replied by thefabricator03 on topic New build, small plasma that got to be very complicated build.

i got way more than $700 in my build for sure. and sadly i'm not done yet. between linear rails and everything else i'm probably looking at something like $4,000 by the time i am done minus the plasma cutter on a 4' x 8' table. hopefully

Its going to be one hell of a machine though. Money well spent I would say.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

16 Oct 2019 09:51 #147980

by machinedude

Replied by machinedude on topic New build, small plasma that got to be very complicated build.

it will get a work out in testing. i have a mini mill head that is getting slapped on for a second function. still processing 140 feet of flat stock for the table and will still be short and need another 40 feet or so. over all weight is going to be over 750lbs but probably under 1,000 pounds minus a water table. it's built like a tank for sure but that was the plan from the beginning.

i figured the mini mill head would give me a good idea of how accurate the whole machine will be. doubt i would ever try steel but aluminum is fair game. hopefully when the table and gantry come together and i get an indicator on the frame i am within +/- .005 or better across the work space.

@tommy

don't feel bad i have the same trouble with my design being complicated , time consuming and just all around being a pain in the a$$. goes with the hobby i guess. if it was easy everyone would be doing it

i figured the mini mill head would give me a good idea of how accurate the whole machine will be. doubt i would ever try steel but aluminum is fair game. hopefully when the table and gantry come together and i get an indicator on the frame i am within +/- .005 or better across the work space.

@tommy

don't feel bad i have the same trouble with my design being complicated , time consuming and just all around being a pain in the a$$. goes with the hobby i guess. if it was easy everyone would be doing it

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Online

- Moderator

-

Less

More

- Posts: 21264

- Thank you received: 7259

16 Oct 2019 18:31 #148031

by tommylight

Replied by tommylight on topic New build, small plasma that got to be very complicated build.

Added pictures to the original post.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

16 Oct 2019 22:50 #148057

by thefabricator03

Replied by thefabricator03 on topic New build, small plasma that got to be very complicated build.

Tom,

Are those rails 35's? Do you think you could of gotten away with 25's?

Are those rails 35's? Do you think you could of gotten away with 25's?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- New build, small plasma that got to be very complicated build.

Time to create page: 0.228 seconds