My Newb Plasma Table Attempted Build

- dvn4life1972

- Offline

- Platinum Member

-

- Posts: 401

- Thank you received: 168

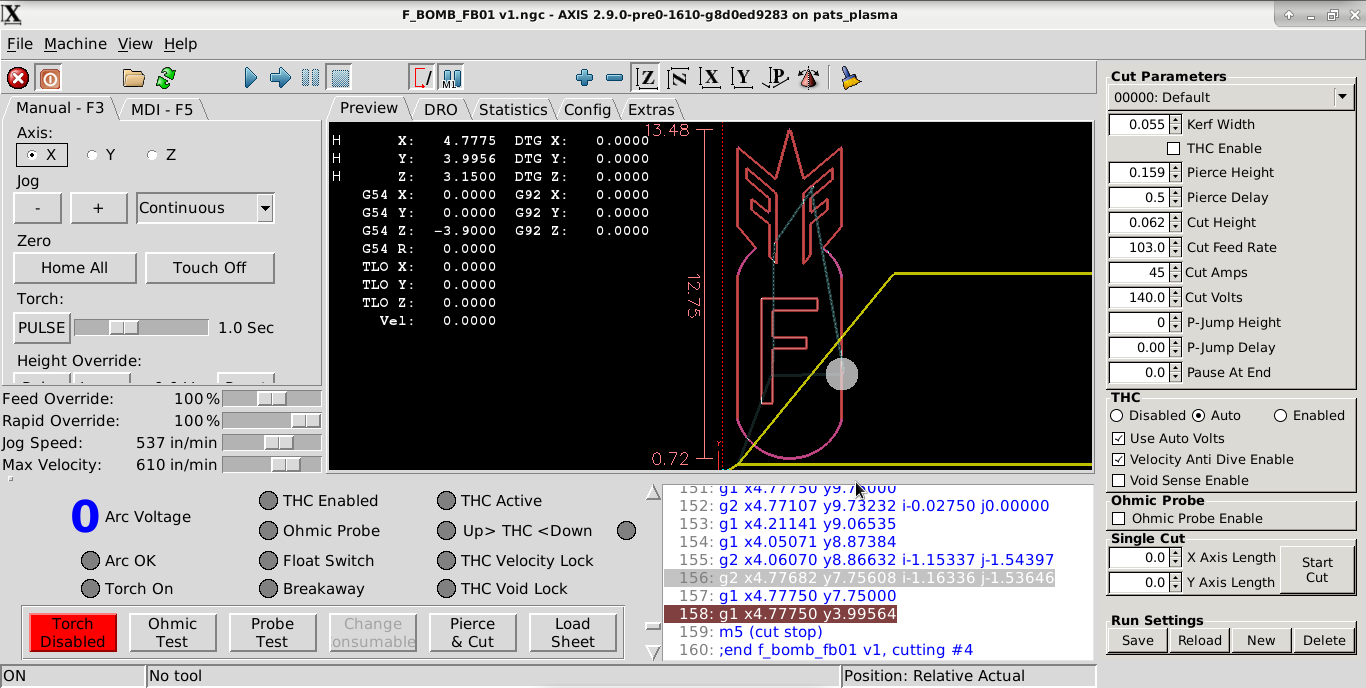

Its taken me a good while to get my head around Sheetcam. Thre are lots of hidden gems. One thing that annoyed me that it seemed to have a mind of its own about cut order. So last full nest on 2mm I overrode it and it took for ages for me to set the order of each piece. So when I cut it I had a lot of warpage so I got to learn what the Sheetcam setting "Minimise for thermal distortion" really meant. Anyway, Les from sheetcam is a good guy and has contributed a bit of code to Linuxcnc and has always provided me with awesome support.

I tried out Sheetcam yesterday on a simple part, same one I referenced with Phil that I tried to run a post on in fusion 360. Sheetcam did the post and I attempted to cut it, but my torch was diving after some long lines into the float switch and shutting off. I disabled THC and it took care of it, so there's something to work out on the table itself. The holes came out really strange. I used the pp for Sheetcam that Phil posted, although until I redraw the dxf in fusion I'm not going to say it was 'this' or 'that' that caused the cut issues (aside from the torch diving, which isn't a Sheetcam issue at all).

Pat

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

- Posts: 401

- Thank you received: 168

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17753

- Thank you received: 5190

(look at the height of notches where the fins join the body of the bomb)

I think you can see where it slipped: right top V cut of right hand fin

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

- Posts: 401

- Thank you received: 168

Pat

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

- Posts: 401

- Thank you received: 168

I only have 60A consumables, so the charts call for 211ipm on the 10ga. Trouble is my compressor is way too small to keep up with that lol. So...gonna get a bigger one and probably some 40A consumables, as I won't be cutting very frequently any material over 7ga thickness.

The bracket was cut at 150ipm, but 195ipm was leaving nearly undetectable amounts of dross on the back. I guess it's time to get the water pan finished up...thing is leaving tons of the typical fine plasma cutting residue in my shop.

Thanks for the help.

Pat

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21378

- Thank you received: 7290

Nice.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

- Posts: 401

- Thank you received: 168

Whenever I attempt to use Auto or Enabled THC, i get two errors within maybe 12 or so inches of cutting...valid arc lost, and float switch, which pauses and stops the cut. Also, holes aren't slowing down per the cut rules I've set in Sheetcam...presumably due to the same underlying cause. Whenever I disabled THC, it cuts fine but still does not slow for corners and holes...however with the THC disabled there is never any valid arc lost or float switch tripped errors either. Any insight is appreciated, as always.

I think I do have the cut settings dialed in pretty well. This is 1/4" thick HR steel with zero cleanup, front and back. Just the corners and holes aren't slowing speed.

Pat

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Does the torch actually hit the matarial and cuase this?Whenever I attempt to use Auto or Enabled THC, i get two errors within maybe 12 or so inches of cutting...valid arc lost, and float switch

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

- Posts: 401

- Thank you received: 168

Does the torch actually hit the matarial and cuase this?

Yes, It starts going - (down) very slowly and then valid arc is lost and it triggers the float switch. Attached the gcode file.

Pat

Please Log in or Create an account to join the conversation.