how to makeTHCAD10 work with pilot arc plasma

- jay1st

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

12 May 2020 11:25 - 25 May 2020 09:04 #167499

by jay1st

how to makeTHCAD10 work with pilot arc plasma was created by jay1st

Hi everyone, i hope you all went safely through this shitty virus.

I'm currently struggling with my THCAD.

I dont have any variation in voltage according to cut height.

So i think i'm on to something, i'm using a shitty Chinese plasma (waiting for €€€ for a Hypertherm) with HF start.

And the way it works, as i understand it, the arc is generated between the cup shield and the tip, but the shield is ALWAYS connected to ground. So there is no variation according to distance between the plate i'm cutting and the tip.

I would like to cut the connection between the shield and the machine when the ARC OK signal is green (ON)

But i'm at lost here, i need to declare my IO pin to drive a relay in HAL, that i can do i think, but how do i make it interact with the ARC OK bit ?

I'm currently struggling with my THCAD.

I dont have any variation in voltage according to cut height.

So i think i'm on to something, i'm using a shitty Chinese plasma (waiting for €€€ for a Hypertherm) with HF start.

And the way it works, as i understand it, the arc is generated between the cup shield and the tip, but the shield is ALWAYS connected to ground. So there is no variation according to distance between the plate i'm cutting and the tip.

I would like to cut the connection between the shield and the machine when the ARC OK signal is green (ON)

But i'm at lost here, i need to declare my IO pin to drive a relay in HAL, that i can do i think, but how do i make it interact with the ARC OK bit ?

Last edit: 25 May 2020 09:04 by jay1st.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

12 May 2020 12:03 #167504

by tommylight

Replied by tommylight on topic ARC OK signal to activate IO pin

Need some clarification:

For THC the electrode inside the torch together with the clamp (not ground, it is positive, although it can be grounded ) is used.

The Nozzle is used for striking the arc between it and the electrode, during cutting it has no connection to anything in use.

Are you sure you have a shield on the torch?

Even if you do, it is never connected to anything, that is why all the ones that use ohmic probing have a wire and a contact directly attached to that shield. Shield is normally used to protect and cool and direct airflow for the nozzle.

For THC the electrode inside the torch together with the clamp (not ground, it is positive, although it can be grounded ) is used.

The Nozzle is used for striking the arc between it and the electrode, during cutting it has no connection to anything in use.

Are you sure you have a shield on the torch?

Even if you do, it is never connected to anything, that is why all the ones that use ohmic probing have a wire and a contact directly attached to that shield. Shield is normally used to protect and cool and direct airflow for the nozzle.

The following user(s) said Thank You: jay1st

Please Log in or Create an account to join the conversation.

- jay1st

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

12 May 2020 12:19 #167508

by jay1st

Replied by jay1st on topic ARC OK signal to activate IO pin

yes it's connected to ground clamp inside the machine, it's a pilot arc hf system, i should say the nozzle not the shield in ceramic.

The only way to have a variation in voltage depending on distance from plate to nozzle is to cut this wire when arc ok signal is calculated from THCAD input voltage

it's a Panasonic 80 head, very basic and cheap chinese

The only way to have a variation in voltage depending on distance from plate to nozzle is to cut this wire when arc ok signal is calculated from THCAD input voltage

it's a Panasonic 80 head, very basic and cheap chinese

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

12 May 2020 13:04 #167513

by tommylight

Replied by tommylight on topic ARC OK signal to activate IO pin

This one ?

Please Log in or Create an account to join the conversation.

- jay1st

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

12 May 2020 13:20 - 12 May 2020 13:21 #167517

by jay1st

Replied by jay1st on topic ARC OK signal to activate IO pin

Last edit: 12 May 2020 13:21 by jay1st.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

12 May 2020 13:36 #167520

by tommylight

Replied by tommylight on topic ARC OK signal to activate IO pin

Sorry but i can not help any further, the nozzle being connected to ground has thrown me off since i never seen that and i have serviced/wired/installed over 30 of them.

The thing is, nozzle connected to ground means the cutting arc is going from electrode to nozzle, not electrode to material as it should. I am sure it does work, but most of the cut power will remain in the torch, not on the material.

The thing is, nozzle connected to ground means the cutting arc is going from electrode to nozzle, not electrode to material as it should. I am sure it does work, but most of the cut power will remain in the torch, not on the material.

Please Log in or Create an account to join the conversation.

- jay1st

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

12 May 2020 19:36 #167542

by jay1st

Replied by jay1st on topic ARC OK signal to activate IO pin

yeah i know it's weird, but i only need a way to have the ARC OK bit activating an output to open a relay so it can be disconnected from ground.

As in your video you can see the plasma working even though the ground is connected on the nozzle to make it a pilot arc.

Or i can add a relay activated by the TORCH ON signal with a delay of 1 second.

As in your video you can see the plasma working even though the ground is connected on the nozzle to make it a pilot arc.

Or i can add a relay activated by the TORCH ON signal with a delay of 1 second.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

12 May 2020 20:58 #167553

by tommylight

Replied by tommylight on topic ARC OK signal to activate IO pin

Setting that in hal is easy, it should be something like this:

net arc-ok-in mesa-7i76-output-02

That is just as an example, you can use the "show hal configuration" from the machine menu in axis to look for pins and find their exact names.

The issue i have is using a relay to disconnect that while it may have over 100V at over 30A going through it, it might get interesting.

net arc-ok-in mesa-7i76-output-02

That is just as an example, you can use the "show hal configuration" from the machine menu in axis to look for pins and find their exact names.

The issue i have is using a relay to disconnect that while it may have over 100V at over 30A going through it, it might get interesting.

Please Log in or Create an account to join the conversation.

- jay1st

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

13 May 2020 08:02 #167620

by jay1st

Replied by jay1st on topic ARC OK signal to activate IO pin

LOL yes, i did think about it, the wire they use for the pilot arc ground is 1.5mm² i guess it does not have that much amps going through, and with this solution i might be able to keep the nozzle longer as the arc will be on the plate and not on the nozzle.

I'll give it a try today and report back

I'll give it a try today and report back

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

13 May 2020 09:21 #167633

by tommylight

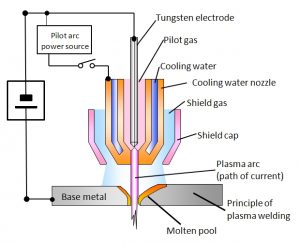

Shielded torch, notice the power and pilot arc connections:

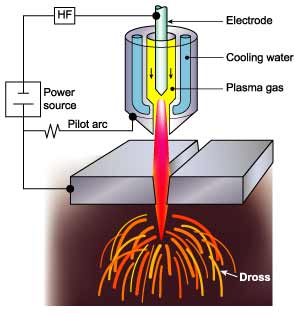

Un shielded torch, again notice the connections:

Replied by tommylight on topic ARC OK signal to activate IO pin

Quite the opposite, it will be on the nozzle.and with this solution i might be able to keep the nozzle longer as the arc will be on the plate and not on the nozzle.

Shielded torch, notice the power and pilot arc connections:

Un shielded torch, again notice the connections:

Attachments:

The following user(s) said Thank You: rodw, jay1st

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.265 seconds