- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Plasma Current Control on the Fly (synchronous with motion)

Plasma Current Control on the Fly (synchronous with motion)

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

17 Apr 2021 07:22 #206158

by robertspark

Replied by robertspark on topic Plasma Current Control on the Fly (synchronous with motion)

thanks Rod, but we are going off topic, as I just want to know WHO is controlling their current on the fly and HOW they are doing it or have done it.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

17 Apr 2021 07:28 #206159

by rodw

Replied by rodw on topic Plasma Current Control on the Fly (synchronous with motion)

I don't think anyone has controlled current except with the Hypertherm RS485

And Grotius as I mentioned but it was a different brand of machine.

And Grotius as I mentioned but it was a different brand of machine.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

17 Apr 2021 07:49 #206160

by robertspark

Replied by robertspark on topic Plasma Current Control on the Fly (synchronous with motion)

thanks, no problem I'll see if anyone else puts their head above the sandbags.

I've got a little while before the 2x SPINx1 arrive. I'm also dabbling with a PCB to integrate a max325, I think I may just plonk one on a tiny PCB interface board.

I've got a little while before the 2x SPINx1 arrive. I'm also dabbling with a PCB to integrate a max325, I think I may just plonk one on a tiny PCB interface board.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Apr 2021 08:15 #206161

by phillc54

Replied by phillc54 on topic Plasma Current Control on the Fly (synchronous with motion)

A little bit OT as well but I used a

ACPL-M484-000E

as a replacement for a pot to control the spindle speed of my mill using PWM via a parallel port.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

17 Apr 2021 08:47 #206163

by rodw

Replied by rodw on topic Plasma Current Control on the Fly (synchronous with motion)

Here is what Grotius did. You may like to read back a few posts..

forum.linuxcnc.org/27-driver-boards/3559...tall?start=20#124610

He never did share further info on this.

forum.linuxcnc.org/27-driver-boards/3559...tall?start=20#124610

He never did share further info on this.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

17 Apr 2021 09:00 #206165

by robertspark

Replied by robertspark on topic Plasma Current Control on the Fly (synchronous with motion)

thanks very much Rod, I'm going to get a bit more info off my pmx45 today as I know what the pot is, have high Res photos of my pmx45 internals.... but forgot (how!) to measure the differential voltage across the pot. (to be fair it was not important with my earlier solution... but with the Mesa SPINx1 it has a range listed in the manual of 5-15v)

I also wanted to have a closer look at the torch fire circuit (from the 2x CPC pins) too

I also wanted to have a closer look at the torch fire circuit (from the 2x CPC pins) too

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

17 Apr 2021 10:19 - 17 Apr 2021 10:21 #206169

by rodw

Replied by rodw on topic Plasma Current Control on the Fly (synchronous with motion)

You can see Grotius wrote a custom component to manage the current.

I think if I was doing this, this component would have 3 inputs:

requested-current (from your M67, 0-45 amps for you)

motion.current-vel

motion.feed-upm (2.9 only)

Ref: linuxcnc.org/docs/devel/html/man/man9/motion.9.html

Two parameters.

Max-current (setp to 45 amps for you)

Max-PWM (setp to your PWM max voltage)

And one output

PWM-output

So the component would scale the M67 requested-current value in amps to output an appropriately scaled PWM

Then over time, you could start looking at some calculations to automatically set the PWM output.

eg.

I think if I was doing this, this component would have 3 inputs:

requested-current (from your M67, 0-45 amps for you)

motion.current-vel

motion.feed-upm (2.9 only)

Ref: linuxcnc.org/docs/devel/html/man/man9/motion.9.html

Two parameters.

Max-current (setp to 45 amps for you)

Max-PWM (setp to your PWM max voltage)

And one output

PWM-output

So the component would scale the M67 requested-current value in amps to output an appropriately scaled PWM

Then over time, you could start looking at some calculations to automatically set the PWM output.

eg.

if( feed-upm/60.0 < current-vel)

{

// do some algorithm to set pwm output.

}

Last edit: 17 Apr 2021 10:21 by rodw.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

17 Apr 2021 10:35 #206170

by robertspark

Replied by robertspark on topic Plasma Current Control on the Fly (synchronous with motion)

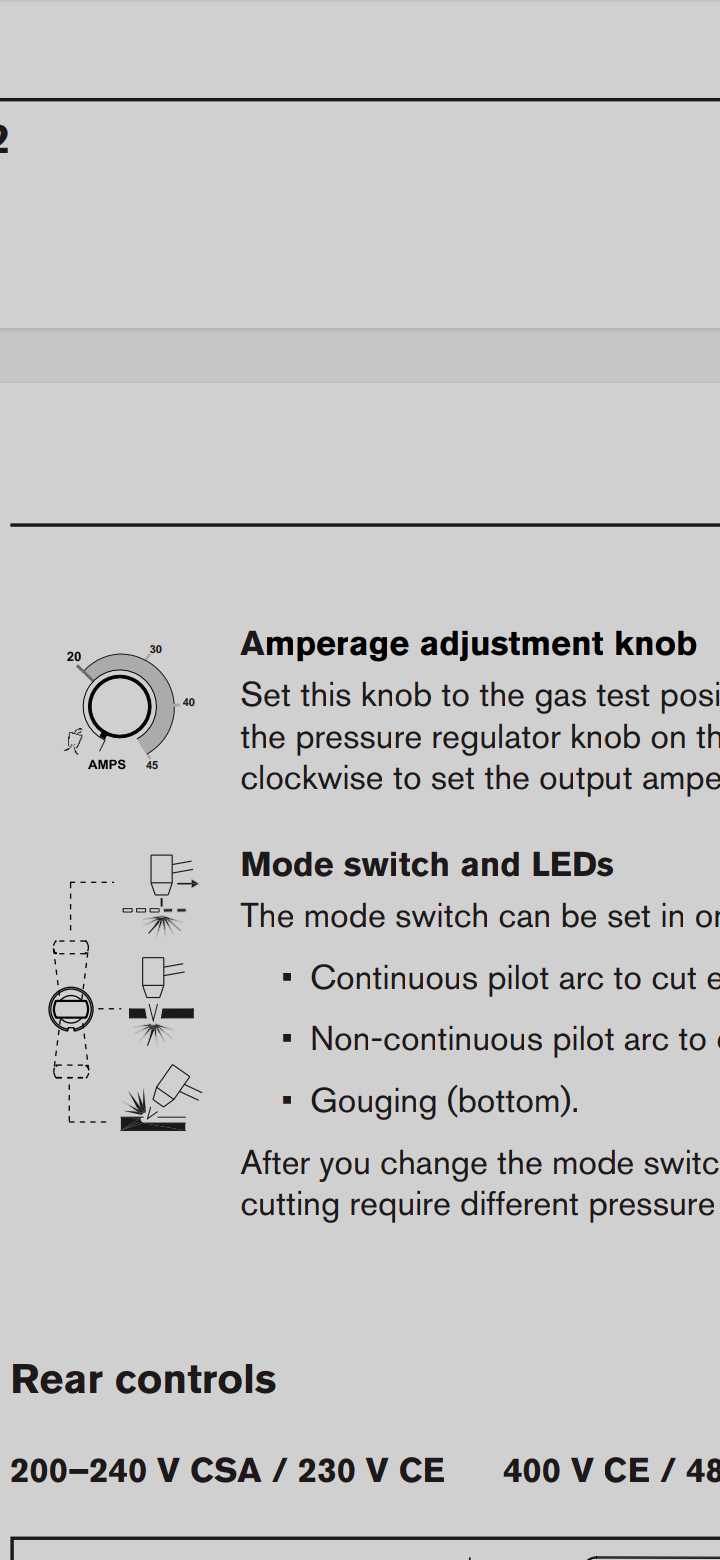

remember the manual pot does not go from zero to 45 A,

at the extreme LHS it goes into an air test mode, and the lowest amperage is 20A

the 45xp goes from 10A to 45A (annoyed the hell out of me about 2months after I bought the 45 the 45xp came out as I would have gone with the 45xp with CPC and rs485... c'est la vie!)

at the extreme LHS it goes into an air test mode, and the lowest amperage is 20A

the 45xp goes from 10A to 45A (annoyed the hell out of me about 2months after I bought the 45 the 45xp came out as I would have gone with the 45xp with CPC and rs485... c'est la vie!)

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

17 Apr 2021 11:01 - 17 Apr 2021 11:01 #206174

by rodw

Replied by rodw on topic Plasma Current Control on the Fly (synchronous with motion)

Thats exactly the reason why a custom component was suggested. Those peculiarities can be incorporated into it.

You could have another pin for air test mode that if true would send the correct PWM and it could also make sure the minimum value is set to 20 amps or higher. The minimum value (20amp/10amp) might be another parameter.

You could have another pin for air test mode that if true would send the correct PWM and it could also make sure the minimum value is set to 20 amps or higher. The minimum value (20amp/10amp) might be another parameter.

Last edit: 17 Apr 2021 11:01 by rodw.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

17 Apr 2021 11:11 #206175

by robertspark

Replied by robertspark on topic Plasma Current Control on the Fly (synchronous with motion)

I'll see where it goes, just happy to have it gcode controlled at the moment on some static M67 parameters

the default (initial startup) pwm setting will also be 100% duty cycle (45A), as I don't want it blowing compressed air for no reason other than the board was just enabled. it will also make the transition from manual pot to digital pot appear seamless.

I have a 200A current sensor to hand that I'd like to check the effect on adding this arrangement does not detrimentally affect the 45a cutting current

uk.farnell.com/allegro-microsystems/acs7...726&gross_price=true

that is the plan...

the default (initial startup) pwm setting will also be 100% duty cycle (45A), as I don't want it blowing compressed air for no reason other than the board was just enabled. it will also make the transition from manual pot to digital pot appear seamless.

I have a 200A current sensor to hand that I'd like to check the effect on adding this arrangement does not detrimentally affect the 45a cutting current

uk.farnell.com/allegro-microsystems/acs7...726&gross_price=true

that is the plan...

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Plasma Current Control on the Fly (synchronous with motion)

Time to create page: 0.111 seconds