- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Pierce height would exceed Z axis maximum limit while ohmic probing

Pierce height would exceed Z axis maximum limit while ohmic probing

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

17 Apr 2021 16:47 #206195

by bevins

It is using continuity ground energizing a relay not using thcad for the ohmic probe.

I don't have a problem with the dirty metal at all. I still dont understand the issue with the "Pierce height would exceed Z axis maximum limit while ohmic probing". I read the error message. This only makes sense to me iof after the first probe, it knows where the Z is, then for some reason plasmac comp raises the Z all the way up. Can I limit this because that would probably fix the error message becasue it would go no where near the Z max limit.

Replied by bevins on topic Pierce height would exceed Z axis maximum limit while ohmic probing

I am not using ohmic3, I am using Ohmic2. Not the thcad but input into mesa.

I don't understand what you're trying to tell me..?

It is using continuity ground energizing a relay not using thcad for the ohmic probe.

I don't have a problem with the dirty metal at all. I still dont understand the issue with the "Pierce height would exceed Z axis maximum limit while ohmic probing". I read the error message. This only makes sense to me iof after the first probe, it knows where the Z is, then for some reason plasmac comp raises the Z all the way up. Can I limit this because that would probably fix the error message becasue it would go no where near the Z max limit.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

17 Apr 2021 17:36 - 17 Apr 2021 17:36 #206199

by snowgoer540

Since you arent using a THCAD (I thought you were), then I don't understand why you are using ohmic2. Ohmic, ohmic2, and ohmic3 are all components for doing "hypersensing" with a Mesa THCAD.

I've explained the error message. You are getting a false trip during the probe. It then thinks your material is MUCH higher than it is. And because of that, it knows that it has no room to get to pierce height. The message is valid.

I know nothing about your ohmic circuit, so I guess I can't tell you why you are getting false trips, but that's what is happening. You proved that because it works when you disable ohmic probing.

Finally, the torch goes to the top when this happens because you've encountered an error that caused the program to pause. When the program pauses, the torch goes up to the top. That's normal PlasmaC behavior, and has nothing to do with probing.

Replied by snowgoer540 on topic Pierce height would exceed Z axis maximum limit while ohmic probing

I am not using ohmic3, I am using Ohmic2. Not the thcad but input into mesa.

I don't understand what you're trying to tell me..?

It is using continuity ground energizing a relay not using thcad for the ohmic probe.

I don't have a problem with the dirty metal at all. I still dont understand the issue with the "Pierce height would exceed Z axis maximum limit while ohmic probing". I read the error message. This only makes sense to me iof after the first probe, it knows where the Z is, then for some reason plasmac comp raises the Z all the way up. Can I limit this because that would probably fix the error message becasue it would go no where near the Z max limit.

Since you arent using a THCAD (I thought you were), then I don't understand why you are using ohmic2. Ohmic, ohmic2, and ohmic3 are all components for doing "hypersensing" with a Mesa THCAD.

I've explained the error message. You are getting a false trip during the probe. It then thinks your material is MUCH higher than it is. And because of that, it knows that it has no room to get to pierce height. The message is valid.

I know nothing about your ohmic circuit, so I guess I can't tell you why you are getting false trips, but that's what is happening. You proved that because it works when you disable ohmic probing.

Finally, the torch goes to the top when this happens because you've encountered an error that caused the program to pause. When the program pauses, the torch goes up to the top. That's normal PlasmaC behavior, and has nothing to do with probing.

Last edit: 17 Apr 2021 17:36 by snowgoer540.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

17 Apr 2021 20:03 #206219

by bevins

OK so if I get what your saying it gets a false probe say half way down and thinks the material is actually higher than it is and tries to go up.

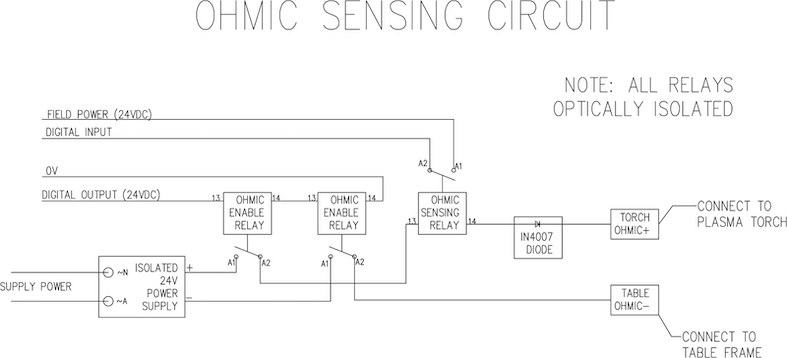

I am using the one of the first Ohmic sensing circuit's rodw put out.

I will check the validity of this. It happens alot so I should be able to see the ohmic lite go on before it hits the material.

Ohmic sensing circuit.....

Replied by bevins on topic Pierce height would exceed Z axis maximum limit while ohmic probing

I am not using ohmic3, I am using Ohmic2. Not the thcad but input into mesa.

I don't understand what you're trying to tell me..?

It is using continuity ground energizing a relay not using thcad for the ohmic probe.

I don't have a problem with the dirty metal at all. I still dont understand the issue with the "Pierce height would exceed Z axis maximum limit while ohmic probing". I read the error message. This only makes sense to me iof after the first probe, it knows where the Z is, then for some reason plasmac comp raises the Z all the way up. Can I limit this because that would probably fix the error message becasue it would go no where near the Z max limit.

Since you arent using a THCAD (I thought you were), then I don't understand why you are using ohmic2. Ohmic, ohmic2, and ohmic3 are all components for doing "hypersensing" with a Mesa THCAD.

I've explained the error message. You are getting a false trip during the probe. It then thinks your material is MUCH higher than it is. And because of that, it knows that it has no room to get to pierce height. The message is valid.

I know nothing about your ohmic circuit, so I guess I can't tell you why you are getting false trips, but that's what is happening. You proved that because it works when you disable ohmic probing.

Finally, the torch goes to the top when this happens because you've encountered an error that caused the program to pause. When the program pauses, the torch goes up to the top. That's normal PlasmaC behavior, and has nothing to do with probing.

OK so if I get what your saying it gets a false probe say half way down and thinks the material is actually higher than it is and tries to go up.

I am using the one of the first Ohmic sensing circuit's rodw put out.

I will check the validity of this. It happens alot so I should be able to see the ohmic lite go on before it hits the material.

Ohmic sensing circuit.....

Attachments:

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

17 Apr 2021 21:45 - 17 Apr 2021 21:46 #206231

by bevins

Replied by bevins on topic Pierce height would exceed Z axis maximum limit while ohmic probing

There is some things that are working how I would expect them to work. Maybe I just dont get it.

example: vel only show 60 while cutting and it doesnt go over even if I override it and raise it up, The material shows 185 cut feed rate, and FR on main screen shows 185

but when cutting it doesnt go over 60. I can jog over 500. It is set now that I can jog about 400ipm.

I dont know where it is stopping it at 60 where it says vel on main screen. I assume that is the velocity it is cutting at in IPM because I am set for that.

Another issue is for example when cutting out letters, when it is done inside cut arcing lead out it stops after arc goes up and cycle pause is flashing, so I either need to hit cycle start and sometimes it goes on with gcode and sometimes it goes down probes and torch comes on and just sits there. I don't know what this behavior is caused by.

Those are the two main issue, other than testing thc which is next. I cut alot lately testing and these issues are always there. While using the float switch I do not have the issue but I need to look into why I am getting false probe hits if in fact I am.

example: vel only show 60 while cutting and it doesnt go over even if I override it and raise it up, The material shows 185 cut feed rate, and FR on main screen shows 185

but when cutting it doesnt go over 60. I can jog over 500. It is set now that I can jog about 400ipm.

I dont know where it is stopping it at 60 where it says vel on main screen. I assume that is the velocity it is cutting at in IPM because I am set for that.

Another issue is for example when cutting out letters, when it is done inside cut arcing lead out it stops after arc goes up and cycle pause is flashing, so I either need to hit cycle start and sometimes it goes on with gcode and sometimes it goes down probes and torch comes on and just sits there. I don't know what this behavior is caused by.

Those are the two main issue, other than testing thc which is next. I cut alot lately testing and these issues are always there. While using the float switch I do not have the issue but I need to look into why I am getting false probe hits if in fact I am.

Last edit: 17 Apr 2021 21:46 by bevins.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

18 Apr 2021 00:14 - 18 Apr 2021 03:40 #206244

by phillc54

Replied by phillc54 on topic Pierce height would exceed Z axis maximum limit while ohmic probing

Can you post a compressed file of your config and also the gcode file you are having issues with in regards to cut velocity.

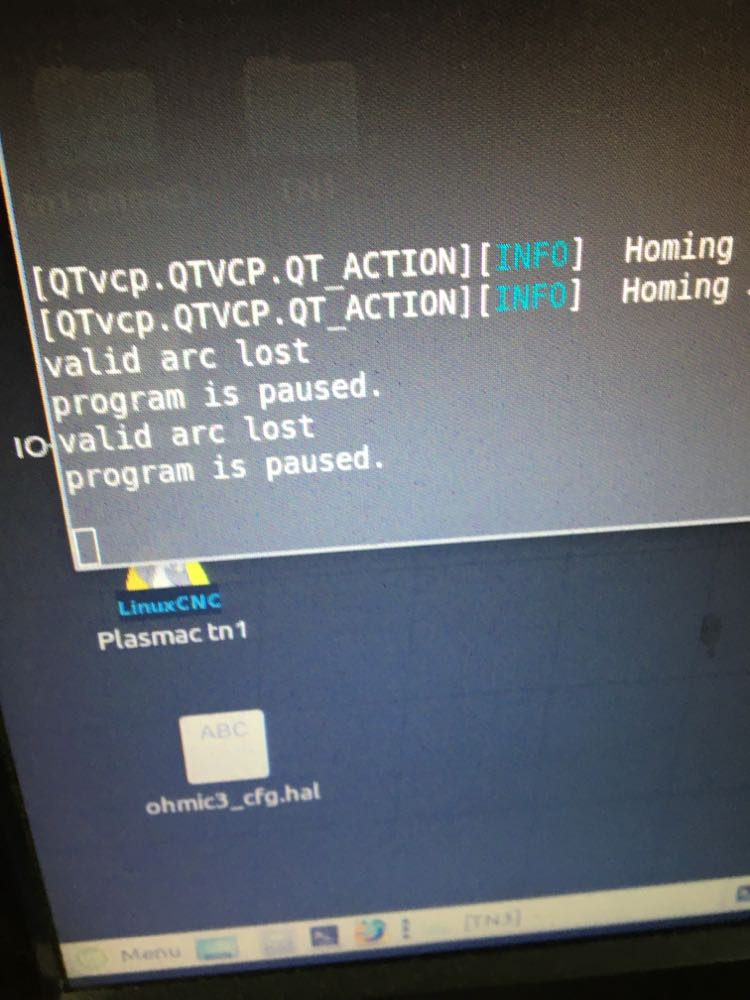

When it stops with CYCLE PAUSE flashing is there a popup error message or a error message in the terminal.

Here is another way of wiring relays for ohmic similar to what islander261 was using, it may be worth a try.

When it stops with CYCLE PAUSE flashing is there a popup error message or a error message in the terminal.

Here is another way of wiring relays for ohmic similar to what islander261 was using, it may be worth a try.

Warning: Spoiler!

Attachments:

Last edit: 18 Apr 2021 03:40 by phillc54.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

18 Apr 2021 11:48 - 18 Apr 2021 11:57 #206296

by bevins

I'll try that but I dont see the difference really.I didnt see the relay fire when I got this message last night. I was checking after snow sent me in this direction.

OK I attached the config and gcode where it goes no faster than 60 as it shows in the gui.

Valid arc lost.... I dont get that one. IT was at the end of an operation when it is leading out. Why would I get arc loss. The gcode was M5 cut stop, so why would the program pause? line 102 of gcode

Replied by bevins on topic Pierce height would exceed Z axis maximum limit while ohmic probing

Can you post a compressed file of your config and also the gcode file you are having issues with in regards to cut velocity.

When it stops with CYCLE PAUSE flashing is there a popup error message or a error message in the terminal.

Here is another way of wiring relays for ohmic similar to what islander261 was using, it may be worth a try.

Warning: Spoiler!

I'll try that but I dont see the difference really.I didnt see the relay fire when I got this message last night. I was checking after snow sent me in this direction.

OK I attached the config and gcode where it goes no faster than 60 as it shows in the gui.

Warning: Spoiler!

; file name: Nolhan_Inside.ngc

; date and time: Sat Apr 17 2021 16:53:15

; postprocessor: plasmac.scpost rev: F

;

;begin pre-amble

G20 (units: inches)

G40 (cutter compensation: off)

G90 (distance mode: absolute)

M52 P1 (adaptive feed: on)

M65 P2 (enable THC)

M65 P3 (enable torch)

M68 E3 Q0 (velocity 100%)

G64 P0.01 Q0.001 (tracking tolerances: 0.01")

F#<_hal[plasmac.cut-feed-rate]>

;end pre-amble

;

;begin material setup

M190 P4 (ht-105 {105 amp} 12ga steel .105 material)

M66 P3 L3 Q2 (wait for valid change)

F#<_hal[plasmac.cut-feed-rate]>

;end material setup

;

;begin operation #1, cutting, 19.24"

G0 X13.19365 Y1.40228

M3 $0 S1 (cut start)

G2 X13.30878 Y1.33033 I0.02159 J-0.09354

G3 X13.41184 Y1.19915 I0.19119 J0.04413

G3 X13.60069 Y1.14789 I0.19304 J0.33772

G1 X13.66769 Y1.14734

G1 X13.66756 Y1.13165

G1 X12.59794 Y1.14044

G1 X12.59806 Y1.15532

G3 X12.74203 Y1.16105 I0.02701 J1.13233

G1 X12.74271 Y1.16113

G3 X12.92180 Y1.25849 I-0.03594 J0.27951

G1 X12.92359 Y1.26084

G3 X12.95256 Y1.32530 I-0.16787 J0.11420

G1 X12.95275 Y1.32611

G3 X12.97696 Y1.54547 I-1.00138 J0.22155

G1 X12.97738 Y1.57433

G1 X12.99131 Y3.26922

G3 X12.98095 Y3.48524 I-1.36408 J0.04286

G3 X12.92043 Y3.61080 I-0.20932 J-0.02353

G1 X12.91940 Y3.61178

G3 X12.86376 Y3.64997 I-0.17176 J-0.19062

G3 X12.68403 Y3.69533 I-0.18430 J-0.35155

G1 X12.61894 Y3.69586

G1 X12.61907 Y3.71155

G1 X13.68869 Y3.70276

G1 X13.68857 Y3.68800

G3 X13.56151 Y3.68361 I-0.02779 J-1.03720

G1 X13.56063 Y3.68351

G3 X13.39403 Y3.61686 I0.04559 J-0.35549

G1 X13.39206 Y3.61527

G3 X13.32248 Y3.48794 I0.14146 J-0.15996

G3 X13.30729 Y3.26663 I1.31757 J-0.20162

G1 X13.30112 Y2.51524

G3 X13.32889 Y2.48701 I0.02800 J-0.00023

G1 X14.54944 Y2.47698

G3 X14.57767 Y2.50477 I0.00023 J0.02800

G1 X14.58385 Y3.30446

G3 X14.56871 Y3.49846 I-0.94986 J0.02348

G1 X14.56846 Y3.49971

G3 X14.46539 Y3.63099 I-0.19105 J-0.04390

G3 X14.27654 Y3.68224 I-0.19303 J-0.33770

G1 X14.21147 Y3.68278

G1 X14.21160 Y3.69846

G1 X15.27929 Y3.68969

G1 X15.27917 Y3.67491

G3 X15.15403 Y3.67052 I-0.02673 J-1.02381

G1 X15.15259 Y3.67035

G3 X15.02452 Y3.62836 I0.05931 J-0.39720

G3 X14.91694 Y3.48738 I0.08893 J-0.17941

G1 X14.91680 Y3.48663

G3 X14.89983 Y3.25345 I1.23778 J-0.20730

G1 X14.88590 Y1.51110

G3 X14.90106 Y1.31848 I0.93859 J-0.02306

G1 X14.90113 Y1.31807

G3 X14.95783 Y1.21835 I0.17863 J0.03558

G3 X15.01347 Y1.18016 I0.17183 J0.19072

G3 X15.19320 Y1.13480 I0.18432 J0.35161

G1 X15.25829 Y1.13427

G1 X15.25816 Y1.11858

G1 X14.19047 Y1.12736

G1 X14.19060 Y1.14222

G3 X14.33375 Y1.14798 I0.02687 J1.11470

G1 X14.33449 Y1.14806

G3 X14.51244 Y1.24547 I-0.03668 J0.27828

G1 X14.51387 Y1.24731

G3 X14.54410 Y1.31193 I-0.16289 J0.11561

G1 X14.54432 Y1.31279

G3 X14.56949 Y1.53238 I-0.96176 J0.22150

G1 X14.56992 Y1.56124

G1 X14.57649 Y2.36138

G3 X14.54872 Y2.38961 I-0.02800 J0.00023

G1 X13.32817 Y2.39964

G3 X13.29994 Y2.37186 I-0.00023 J-0.02800

G1 X13.29337 Y1.52419

G3 X13.30852 Y1.33157 I0.93854 J-0.02306

G1 X13.30878 Y1.33033

G2 X13.23144 Y1.21981 I-0.09468 J-0.01610

M5 $0(cut stop)

;end operation #1, cutting

;

;begin operation #2, cutting, 11.63"

G0 X10.42176 Y1.40828

M3 $0 S1 (cut start)

G2 X10.54707 Y1.35602 I0.03653 J-0.08878

G1 X10.55063 Y1.34736

G1 X10.55123 Y1.34601

G3 X10.66196 Y1.25867 I0.14347 J0.06803

G1 X10.66417 Y1.25830

G3 X10.95512 Y1.24501 I0.22640 J1.76588

G3 X11.37822 Y1.25622 I0.05636 J5.86394

G3 X11.61073 Y1.30768 I-0.05459 J0.79773

G1 X11.61280 Y1.30857

G3 X11.86581 Y1.53054 I-0.27074 J0.56378

G3 X12.00901 Y1.80724 I-1.42725 J0.91405

G1 X12.01984 Y1.80501

G1 X11.81466 Y1.13973

G1 X9.82891 Y1.12740

G1 X9.82881 Y1.14215

G3 X9.98041 Y1.15103 I0.01393 J1.06067

G1 X9.98117 Y1.15114

G3 X10.16591 Y1.27543 I-0.04144 J0.26102

G1 X10.16799 Y1.27963

G3 X10.19910 Y1.42091 I-0.42372 J0.16737

G3 X10.20398 Y1.56874 I-1.65637 J0.12865

G1 X10.19305 Y3.29385

G3 X10.16543 Y3.52162 I-0.94600 J0.00085

G1 X10.16486 Y3.52361

G3 X10.06815 Y3.64057 I-0.19704 J-0.06447

G1 X10.06770 Y3.64081

G3 X9.88345 Y3.68330 I-0.17186 J-0.32453

G1 X9.81304 Y3.68286

G1 X9.81294 Y3.69854

G1 X10.94652 Y3.70558

G1 X10.94661 Y3.69033

G3 X10.72559 Y3.66689 I0.00446 J-1.09603

G1 X10.72474 Y3.66670

G3 X10.55795 Y3.55765 I0.07026 J-0.28955

G1 X10.55668 Y3.55584

G3 X10.52317 Y3.46648 I0.18982 J-0.12217

G3 X10.50971 Y3.22093 I1.39088 J-0.19933

G1 X10.52069 Y1.53215

G3 X10.54618 Y1.35852 I0.58811 J-0.00234

G2 X10.48230 Y1.23872 I-0.09184 J-0.02796

M5 $0(cut stop)

;end operation #2, cutting

;

;begin operation #3, cutting, 7.33"

G0 X8.51183 Y1.24935

M3 $0 S1 (cut start)

G2 X8.50318 Y1.38484 I0.06342 J0.07207

G3 X8.69568 Y1.73095 I-0.69992 J0.61588

G3 X8.76702 Y2.17426 I-1.70927 J0.50243

G3 X8.72184 Y2.82353 I-2.71765 J0.13710

G3 X8.55798 Y3.26525 I-1.37161 J-0.25754

G3 X8.20489 Y3.58099 I-0.65230 J-0.37417

G1 X8.20444 Y3.58118

G3 X8.07642 Y3.62114 I-0.28778 J-0.69696

G1 X8.07641 Y3.71750

G2 X8.64648 Y3.47406 I-0.15246 J-1.14623

G2 X9.09562 Y2.82279 I-0.81152 J-1.04015

G2 X9.11964 Y2.04094 I-1.50514 J-0.43753

G2 X8.50362 Y1.19407 I-1.28089 J0.28424

G2 X8.07640 Y1.04784 I-0.58621 J1.01541

G1 X8.07640 Y1.13526

G3 X8.50310 Y1.38475 I-0.16838 J0.77761

G1 X8.50318 Y1.38484

G2 X8.63867 Y1.39349 I0.07207 J-0.06342

M5 $0(cut stop)

;end operation #3, cutting

;

;begin operation #4, cutting, 7.53"

G0 X7.20493 Y1.37556

M3 $0 S1 (cut start)

G2 X7.34032 Y1.36551 I0.06267 J-0.07272

G3 X7.77039 Y1.12622 I0.54106 J0.46630

G1 X7.77040 Y1.04025

G2 X7.33070 Y1.16480 I0.09770 J1.18330

G2 X6.70849 Y1.91376 I0.58374 J1.11788

G2 X6.65401 Y2.62346 I1.57658 J0.47798

G2 X7.03583 Y3.37374 I1.27678 J-0.17747

G2 X7.77040 Y3.71911 I0.87076 J-0.89816

G1 X7.77039 Y3.63463

G3 X7.60791 Y3.59760 I0.09179 J-0.77787

G1 X7.60740 Y3.59742

G3 X7.24586 Y3.31267 I0.25344 J-0.69368

G3 X7.06792 Y2.87895 I1.00845 J-0.66709

G3 X7.02948 Y2.30063 I2.27528 J-0.44167

G3 X7.11796 Y1.77495 I2.05848 J0.07622

G3 X7.34006 Y1.36581 I1.12082 J0.34358

G1 X7.34032 Y1.36551

G2 X7.33027 Y1.23012 I-0.07272 J-0.06267

M5 $0(cut stop)

;end operation #4, cutting

;

;begin operation #5, cutting, 18.62"

G0 X3.66113 Y3.37318

M3 $0 S1 (cut start)

G2 X3.52554 Y3.36629 I-0.07124 J0.06435

G3 X3.48155 Y3.40461 I-1.07946 J-1.19507

G1 X3.47929 Y3.40632

G3 X3.30725 Y3.48657 I-0.33372 J-0.49091

G3 X3.15368 Y3.50823 I-0.14874 J-0.49923

G1 X3.12743 Y3.50784

G1 X3.12686 Y3.52408

G1 X3.79813 Y3.54763

G1 X5.46361 Y1.64475

G3 X5.51266 Y1.66418 I0.02107 J0.01844

G1 X5.45831 Y3.20777

G3 X5.42423 Y3.43084 I-0.91318 J-0.02535

G1 X5.42354 Y3.43297

G3 X5.31033 Y3.55063 I-0.19171 J-0.07117

G3 X5.13602 Y3.57886 I-0.15011 J-0.37456

G1 X5.07336 Y3.57666

G1 X5.07281 Y3.59234

G1 X5.93076 Y3.62243

G1 X5.93128 Y3.60758

G3 X5.78612 Y3.59517 I0.02091 J-1.09955

G1 X5.78542 Y3.59505

G3 X5.61163 Y3.48347 I0.04732 J-0.26484

G1 X5.61008 Y3.48096

G3 X5.58341 Y3.40201 I0.20988 J-0.11487

G1 X5.58336 Y3.40161

G3 X5.57398 Y3.18213 I1.16515 J-0.15969

G1 X5.65062 Y0.99718

G1 X5.62215 Y0.99618

G1 X3.82573 Y3.03991

G3 X3.77671 Y3.02044 I-0.02103 J-0.01849

G1 X3.83466 Y1.37422

G3 X3.86776 Y1.15135 I0.94498 J0.02647

G1 X3.86813 Y1.15010

G3 X3.89461 Y1.09650 I0.19645 J0.06372

G1 X3.89609 Y1.09455

G1 X3.90271 Y1.08656

G1 X3.90500 Y1.08411

G3 X4.07961 Y1.00571 I0.19902 J0.20962

G1 X4.08015 Y1.00567

G3 X4.21964 Y1.00458 I0.07922 J1.21126

G1 X4.22016 Y0.98966

G1 X3.36221 Y0.95957

G1 X3.36169 Y0.97444

G3 X3.50575 Y0.98679 I-0.02200 J1.10352

G1 X3.50638 Y0.98689

G3 X3.68129 Y1.09846 I-0.04671 J0.26614

G1 X3.68289 Y1.10103

G3 X3.70956 Y1.17998 I-0.20980 J0.11484

G1 X3.70961 Y1.18038

G3 X3.71899 Y1.39987 I-1.16546 J0.15971

G1 X3.65495 Y3.22554

G3 X3.64786 Y3.24320 I-0.02798 J-0.00098

G3 X3.52554 Y3.36629 I-1.20179 J-1.07198

G2 X3.51865 Y3.50188 I0.06435 J0.07124

M5 $0(cut stop)

;end operation #5, cutting

;

;begin operation #6, cutting, 13.90"

G0 X18.12594 Y1.24406

M3 $0 S1 (cut start)

G2 X18.25881 Y1.21618 I0.05250 J-0.08037

G1 X18.25968 Y1.21493

G3 X18.45824 Y1.07799 I0.29674 J0.21785

G3 X18.54736 Y1.06006 I0.16215 J0.57564

G1 X18.54693 Y1.04233

G1 X17.56668 Y1.06630

G1 X17.56709 Y1.08322

G3 X17.72727 Y1.11198 I-0.02624 J0.60678

G1 X17.72900 Y1.11260

G3 X17.83821 Y1.29031 I-0.06419 J0.16186

G1 X17.83806 Y1.29158

G3 X17.76595 Y1.54675 I-0.95148 J-0.13114

G1 X17.61656 Y1.92780

G3 X17.59118 Y1.94557 I-0.02607 J-0.01022

G1 X17.12681 Y1.95692

G1 X17.16554 Y2.04338

G1 X17.53908 Y2.03424

G3 X17.56584 Y2.07243 I0.00068 J0.02799

G1 X17.14632 Y3.14474

G3 X17.09480 Y3.14623 I-0.02608 J-0.01020

G1 X16.61163 Y2.09575

G1 X16.54813 Y1.95400

G1 X16.34360 Y1.50750

G3 X16.28776 Y1.33002 I0.59999 J-0.28630

G1 X16.28759 Y1.32881

G3 X16.34317 Y1.18328 I0.16570 J-0.02009

G1 X16.34389 Y1.18268

G3 X16.43584 Y1.13578 I0.15315 J0.18672

G3 X16.58530 Y1.10791 I0.25780 J0.96750

G1 X16.58487 Y1.09031

G1 X15.81381 Y1.10916

G1 X15.81430 Y1.12918

G3 X15.98059 Y1.17664 I-0.11596 J0.72137

G1 X15.98434 Y1.17855

G3 X16.07678 Y1.26488 I-0.16232 J0.26647

G3 X16.23963 Y1.55019 I-1.34400 J0.95627

G1 X16.25536 Y1.58456

G1 X17.22443 Y3.70671

G1 X17.25511 Y3.70596

G1 X18.12203 Y1.48369

G3 X18.25881 Y1.21618 I1.32636 J0.50946

G2 X18.18221 Y1.10409 I-0.09435 J-0.01774

M5 $0(cut stop)

;end operation #6, cutting

;

;begin operation #7, cutting, 18.62"

G0 X19.59740 Y3.40742

M3 $0 S1 (cut start)

G2 X19.46168 Y3.41056 I-0.06629 J0.06944

G3 X19.42063 Y3.45203 I-1.16479 J-1.11207

G1 X19.41850 Y3.45390

G3 X19.25286 Y3.54664 I-0.36912 J-0.46500

G3 X19.10131 Y3.57958 I-0.18526 J-0.48713

G1 X19.07511 Y3.58114

G1 X19.07574 Y3.59738

G1 X19.74692 Y3.57127

G1 X21.26729 Y1.55058

G3 X21.31764 Y1.56633 I0.02237 J0.01683

G1 X21.37745 Y3.10972

G3 X21.35995 Y3.33469 I-0.91239 J0.04218

G1 X21.35941 Y3.33687

G3 X21.25520 Y3.46257 I-0.19643 J-0.05680

G3 X21.08345 Y3.50360 I-0.17736 J-0.36246

G1 X21.02080 Y3.50603

G1 X21.02141 Y3.52171

G1 X21.87924 Y3.48834

G1 X21.87867 Y3.47350

G3 X21.73298 Y3.47184 I-0.06036 J-1.09781

G1 X21.73228 Y3.47178

G3 X21.55072 Y3.37334 I0.02763 J-0.26760

G1 X21.54899 Y3.37096

G3 X21.51656 Y3.29418 I0.20059 J-0.12996

G1 X21.51648 Y3.29379

G3 X21.49092 Y3.07560 I1.15016 J-0.24532

G1 X21.40596 Y0.89096

G1 X21.37749 Y0.89207

G1 X19.73693 Y3.06290

G3 X19.68661 Y3.04710 I-0.02234 J-0.01688

G1 X19.62280 Y1.40110

G3 X19.63935 Y1.17640 I0.94423 J-0.04342

G1 X19.63963 Y1.17513

G3 X19.66209 Y1.11971 I0.20022 J0.04886

G1 X19.66341 Y1.11766

G1 X19.66942 Y1.10920

G1 X19.67152 Y1.10659

G3 X19.83987 Y1.01551 I0.21394 J0.19430

G1 X19.84040 Y1.01543

G3 X19.97943 Y1.00404 I0.16849 J1.20236

G1 X19.97885 Y0.98912

G1 X19.12102 Y1.02248

G1 X19.12160 Y1.03735

G3 X19.26617 Y1.03902 I0.05957 J1.10327

G1 X19.26681 Y1.03908

G3 X19.44949 Y1.13742 I-0.02690 J0.26882

G1 X19.45128 Y1.13988

G3 X19.48370 Y1.21663 I-0.20114 J0.13018

G1 X19.48379 Y1.21703

G3 X19.50934 Y1.43523 I-1.15050 J0.24536

G1 X19.58034 Y3.26064

G3 X19.57457 Y3.27878 I-0.02798 J0.00109

G3 X19.46168 Y3.41056 I-1.27769 J-0.98028

G2 X19.46482 Y3.54629 I0.06944 J0.06629

M5 $0(cut stop)

;end operation #7, cutting

;

;begin post-amble

G40 (cutter compensation: off)

G90 (distance mode: absolute)

M65 P2 (enable THC)

M65 P3 (enable torch)

M68 E3 Q0 (velocity 100%)

M5 $-1 (backup stop)

;end post-amble

;

;begin statistics

;Pierces = 7

; Cuts = 7, Length = 96.88"

;end statistics

;

M30 (end program)

Valid arc lost.... I dont get that one. IT was at the end of an operation when it is leading out. Why would I get arc loss. The gcode was M5 cut stop, so why would the program pause? line 102 of gcode

Last edit: 18 Apr 2021 11:57 by bevins.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

18 Apr 2021 12:11 #206297

by phillc54

this is in units per second, so 60 in/min

Replied by phillc54 on topic Pierce height would exceed Z axis maximum limit while ohmic probing

This line in the [TRAJ] section of the ini file is the reason for your slow velocity:OK I attached the config and gcode where it goes no faster than 60 as it shows in the gui.

MAX_LINEAR_VELOCITY = 1.00

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

18 Apr 2021 12:23 - 18 Apr 2021 12:23 #206300

by bevins

Thanks, I stared at the ini for a long time and didnt see it. lol

Replied by bevins on topic Pierce height would exceed Z axis maximum limit while ohmic probing

This line in the [TRAJ] section of the ini file is the reason for your slow velocity:OK I attached the config and gcode where it goes no faster than 60 as it shows in the gui.

this is in units per second, so 60 in/minMAX_LINEAR_VELOCITY = 1.00

Thanks, I stared at the ini for a long time and didnt see it. lol

Last edit: 18 Apr 2021 12:23 by bevins.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

18 Apr 2021 12:36 #206301

by bevins

Replied by bevins on topic Pierce height would exceed Z axis maximum limit while ohmic probing

I just found that when ohmic probing it was tripped when it started probing. I blew out the nozzle with air and I saw a bit of water came out. Once I did that the ohmic trigger went away, so can I assume this is probably the issue with the ohmic probing?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21185

- Thank you received: 7239

18 Apr 2021 19:53 #206327

by tommylight

Replied by tommylight on topic Pierce height would exceed Z axis maximum limit while ohmic probing

If at all possible, no lead outs on plasma cutting.

By the time the machine reaches the end of a cut the part has already fallen or there is no material left as it was cut already at the start, so avoiding lead outs is a god habit.

And yes, water can cause ohmic issues, hence the ohmic is never used on water tables, but somehow Rod, Phill, Snowwy and some others here made it work reliably using PCW and Mesa THCAD.

By the time the machine reaches the end of a cut the part has already fallen or there is no material left as it was cut already at the start, so avoiding lead outs is a god habit.

And yes, water can cause ohmic issues, hence the ohmic is never used on water tables, but somehow Rod, Phill, Snowwy and some others here made it work reliably using PCW and Mesa THCAD.

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Pierce height would exceed Z axis maximum limit while ohmic probing

Time to create page: 0.156 seconds