New Plasmacutter

- Giuseppe

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 81

- Thank you received: 9

05 Jul 2021 12:18 #213760

by Giuseppe

New Plasmacutter was created by Giuseppe

Hi,

after i finished my cnc cutter i do some tests and the problem i have is that the arc sometimes whant not start correct.

Sometimes it stucks.

So i think is the better choise to buy a cutter with a pilot ignition.

Now i see some videos how peaples connect a wire from the clamp to the toarch to realise a pilot ignition.

Is this the same way how the expensive cutters work? Or are there some differences?

kind regards

Giuseppe

after i finished my cnc cutter i do some tests and the problem i have is that the arc sometimes whant not start correct.

Sometimes it stucks.

So i think is the better choise to buy a cutter with a pilot ignition.

Now i see some videos how peaples connect a wire from the clamp to the toarch to realise a pilot ignition.

Is this the same way how the expensive cutters work? Or are there some differences?

kind regards

Giuseppe

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

07 Jul 2021 00:04 #213918

by tommylight

-High Voltage start uses a transformer at 50 or 60 Hz to raise the voltage to over 2000V, a huge resistor to dump some of the power and is wired directly to the electrode on one side and to the nozzle on the other side, also there is a RC filter to protect the rectifier from destruction at every arc start. Highly reliable, causes plenty of interference, especially as the nozzle/electrode get black inside and the arc is harder to start.

-High Voltage / High Frequency start uses a smaller high frequency (usually over 20 kHz) transformer and switching electronics on the primary side that creates 15000V through a sparc gap and another winding on a ferite core to witch the main electrode wire is also wound with the other side going to the nozzle, also has RC filters to protect rectifiers and a dumping resistor. Very reliable, causes huge amounts of interference, less sensitive to electrode/nozzle getting all black inside.

-Blow back start uses a spring loaded electrode that gets pushed back when the air is turned on while at the same time lets 3 to 5A of current through the electrode to the nozzle, so when the electrode retracts the sparc is created at what point the full cutting power is released. Pretty reliable, costs a lot in electrodes as they fail much faster due to current passing through a spring, less interference than both of the above.

-Scratch start uses ... well scratching the nozzle to the material to create a sparc, so it has nothing that the above machines have. Not sure about wiring as i never used one. Most probably creates more interference than BlowBack, but less than other two above.

Replied by tommylight on topic New Plasmacutter

There are differences, quite a lot actually:

Is this the same way how the expensive cutters work? Or are there some differences?

-High Voltage start uses a transformer at 50 or 60 Hz to raise the voltage to over 2000V, a huge resistor to dump some of the power and is wired directly to the electrode on one side and to the nozzle on the other side, also there is a RC filter to protect the rectifier from destruction at every arc start. Highly reliable, causes plenty of interference, especially as the nozzle/electrode get black inside and the arc is harder to start.

-High Voltage / High Frequency start uses a smaller high frequency (usually over 20 kHz) transformer and switching electronics on the primary side that creates 15000V through a sparc gap and another winding on a ferite core to witch the main electrode wire is also wound with the other side going to the nozzle, also has RC filters to protect rectifiers and a dumping resistor. Very reliable, causes huge amounts of interference, less sensitive to electrode/nozzle getting all black inside.

-Blow back start uses a spring loaded electrode that gets pushed back when the air is turned on while at the same time lets 3 to 5A of current through the electrode to the nozzle, so when the electrode retracts the sparc is created at what point the full cutting power is released. Pretty reliable, costs a lot in electrodes as they fail much faster due to current passing through a spring, less interference than both of the above.

-Scratch start uses ... well scratching the nozzle to the material to create a sparc, so it has nothing that the above machines have. Not sure about wiring as i never used one. Most probably creates more interference than BlowBack, but less than other two above.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- Giuseppe

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 81

- Thank you received: 9

08 Jul 2021 18:50 - 08 Jul 2021 18:50 #214044

by Giuseppe

Replied by Giuseppe on topic New Plasmacutter

Yes thats right but there are lot of cutters with pilotignition out there but i dont know if the cheaper one works also for cnc?

for example this one

link amazon

i have this one

link amazon

for example this one

link amazon

i have this one

link amazon

Last edit: 08 Jul 2021 18:50 by Giuseppe.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

08 Jul 2021 21:54 #214051

by tommylight

Replied by tommylight on topic New Plasmacutter

Unclear if you want or have the StahlWerk, but either way they are nice, a friend has one for nearly a year and it is working just fine.

www.stahlwerk-schweissgeraete.de//plasma-cutter/

www.stahlwerk-schweissgeraete.de//plasma-cutter/

Please Log in or Create an account to join the conversation.

- Giuseppe

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 81

- Thank you received: 9

10 Jul 2021 19:53 - 10 Jul 2021 19:53 #214212

by Giuseppe

Replied by Giuseppe on topic New Plasmacutter

I have the Stahlwerk. But sometimes i have ignition problems.

I am not shure but this one has a hf ignition and it is not necessary to scrat the metal to start. It is enought to told it 1-2 mm away from the metal. Or not?

Why is sometimes the ignition stucks?

Thats the reason why i whant to buy a cutte with pilot ignition.

I am not shure but this one has a hf ignition and it is not necessary to scrat the metal to start. It is enought to told it 1-2 mm away from the metal. Or not?

Why is sometimes the ignition stucks?

Thats the reason why i whant to buy a cutte with pilot ignition.

Last edit: 10 Jul 2021 19:53 by Giuseppe.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

10 Jul 2021 21:40 #214220

by tommylight

Replied by tommylight on topic New Plasmacutter

StahlWerk has pilot start so it should work even from 3 or 4 or 5mm from the material.

Reasons for arc start failing:

-to low air pressure

-to high air pressure

-charred electrode and nozzle (black inside)

-nozzle and electrode not tightened/inserted properly

-nozzle touching the material

--

Yes, nozzle on the pilot plasma must NOT touch the material as that will fail to start

Air pressure should be 5 to 5.5 Bar while air is running, not when air is stopped, use the built in regulator to check and adjust air.

Reasons for arc start failing:

-to low air pressure

-to high air pressure

-charred electrode and nozzle (black inside)

-nozzle and electrode not tightened/inserted properly

-nozzle touching the material

--

Yes, nozzle on the pilot plasma must NOT touch the material as that will fail to start

Air pressure should be 5 to 5.5 Bar while air is running, not when air is stopped, use the built in regulator to check and adjust air.

Please Log in or Create an account to join the conversation.

- Giuseppe

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 81

- Thank you received: 9

11 Jul 2021 07:09 - 11 Jul 2021 07:17 #214235

by Giuseppe

Replied by Giuseppe on topic New Plasmacutter

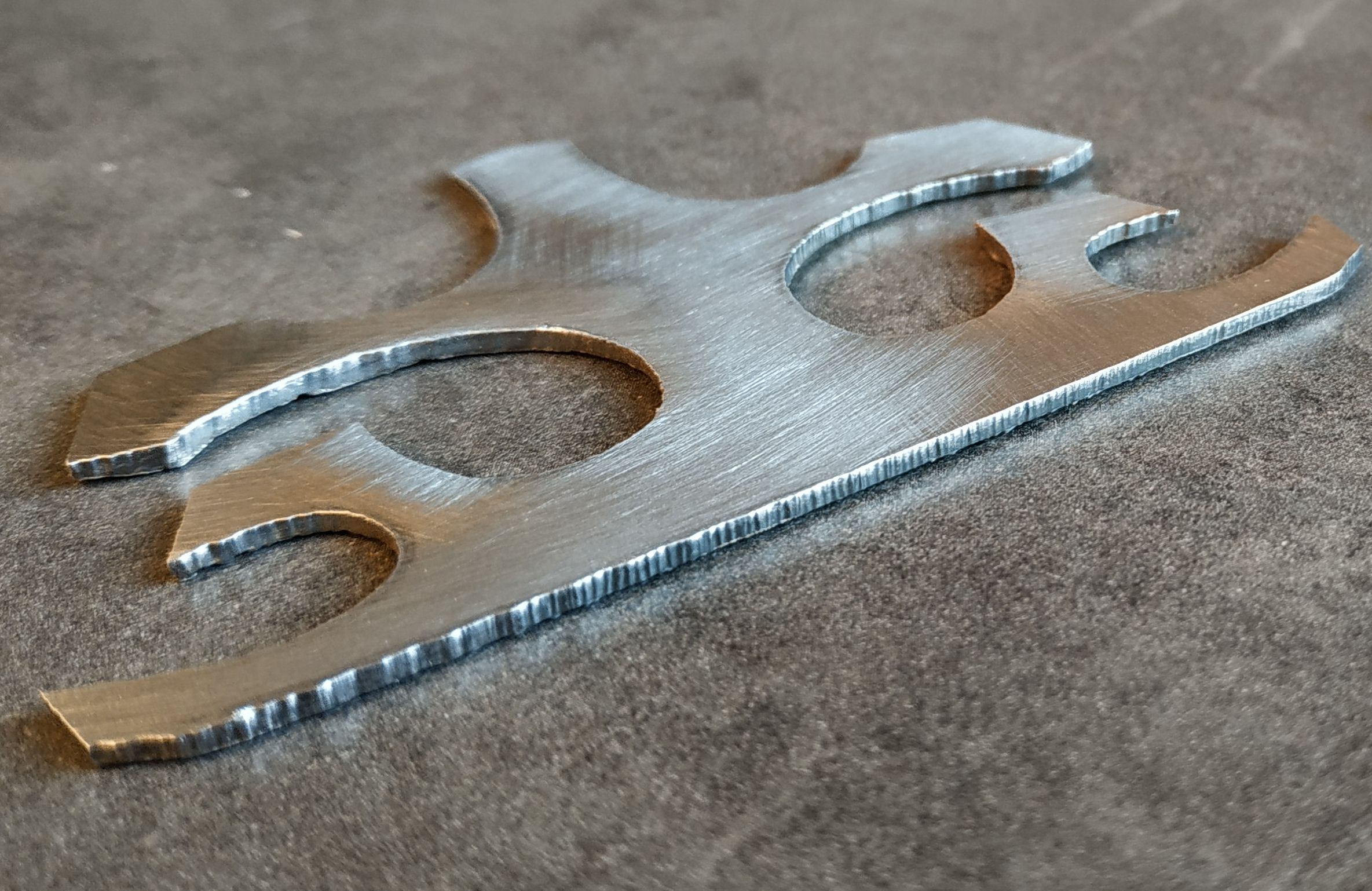

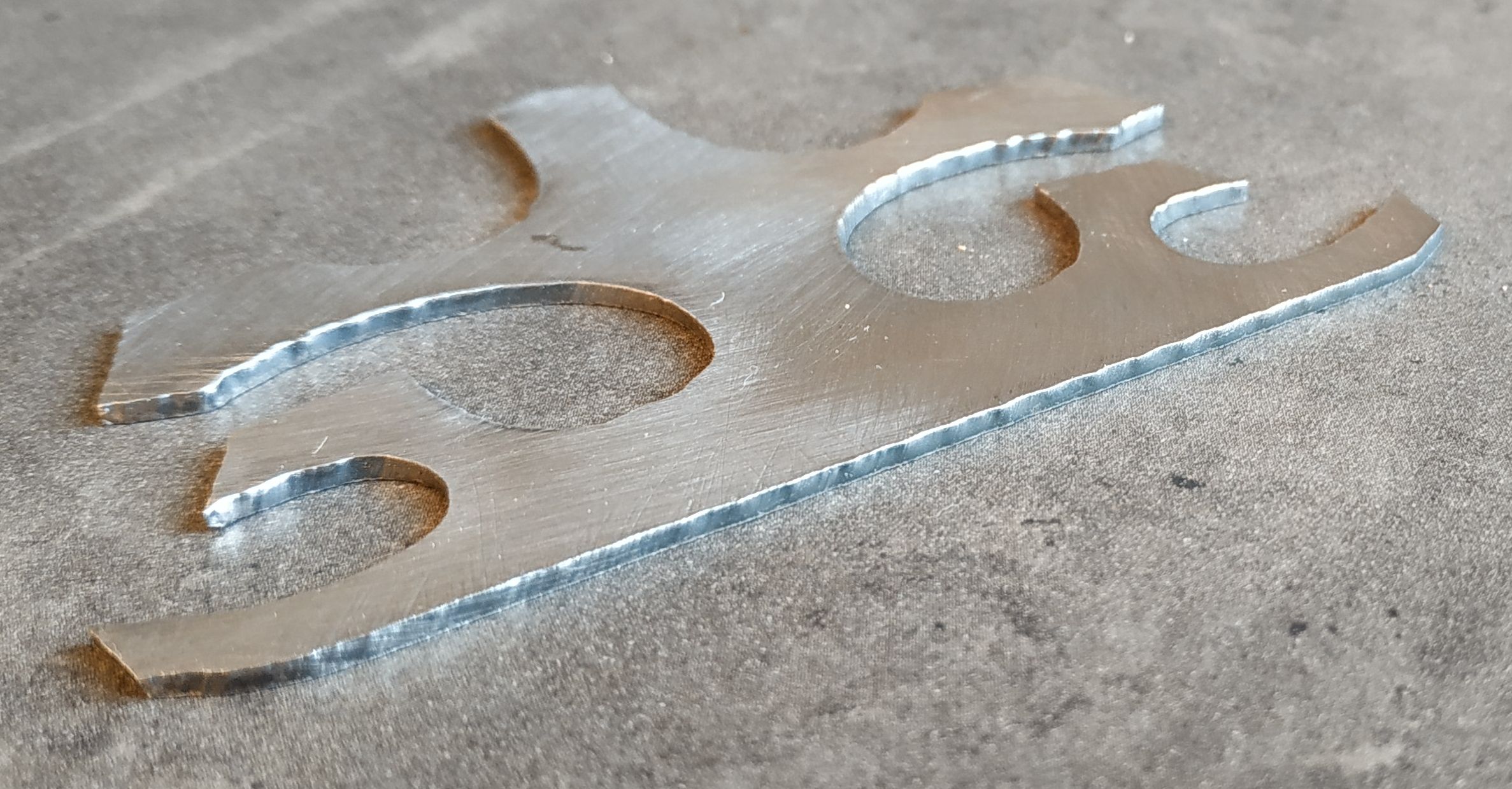

I have upload a video with the issue and some pics of a testcut

file.io/VjqzlbHP0nJc

I am not really happy with the result.

This is cut with 1000 mm / min

and this with 2000 mm / min

What do you thing is the problem, is the machin not stiff onough?

file.io/VjqzlbHP0nJc

I am not really happy with the result.

This is cut with 1000 mm / min

and this with 2000 mm / min

What do you thing is the problem, is the machin not stiff onough?

Last edit: 11 Jul 2021 07:17 by Giuseppe.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

11 Jul 2021 07:36 #214236

by tommylight

Replied by tommylight on topic New Plasmacutter

Pictures of the machine ?

That is from vibrations for sure, but what acceleration are you using ?

Try lowering accelleration a bit, but anything under 200mm/s/s is to low for cutting thin sheets.

That is from vibrations for sure, but what acceleration are you using ?

Try lowering accelleration a bit, but anything under 200mm/s/s is to low for cutting thin sheets.

Please Log in or Create an account to join the conversation.

- Giuseppe

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 81

- Thank you received: 9

11 Jul 2021 11:04 - 11 Jul 2021 11:05 #214243

by Giuseppe

Replied by Giuseppe on topic New Plasmacutter

Attachments:

Last edit: 11 Jul 2021 11:05 by Giuseppe.

Please Log in or Create an account to join the conversation.

- Giuseppe

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 81

- Thank you received: 9

11 Jul 2021 11:27 #214245

by Giuseppe

Replied by Giuseppe on topic New Plasmacutter

This is the entrys under

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1370.0

MAX_VELOCITY = 200.0

MAX_ACCELERATION = 900.0

why is here other entrys

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1370.0

MAX_VELOCITY = 200.0

MAX_ACCELERATION = 900.0

why is here other entrys

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.187 seconds