New Plasma build in OZ

- 34by151

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 16

12 Jul 2021 04:24 #214356

by 34by151

Replied by 34by151 on topic New Plasma build in OZ

My thinking as well on the slides.

For some reason I though your was for 6m sheet, so I will be simular size.

Toyed with downdraft but after modeling in solidworks could not get the results I was after. Well could do it but did not want the investment in the fans needed so went back to water table.

I planning to have a gutter between the table and slats (50mm) all around.

So the cutting area will be 1900x3200 with and extra 500mm for the parking area. I will locate a sump under the parking area for the fill and drain connections.

For some reason I though your was for 6m sheet, so I will be simular size.

Toyed with downdraft but after modeling in solidworks could not get the results I was after. Well could do it but did not want the investment in the fans needed so went back to water table.

I planning to have a gutter between the table and slats (50mm) all around.

So the cutting area will be 1900x3200 with and extra 500mm for the parking area. I will locate a sump under the parking area for the fill and drain connections.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

12 Jul 2021 04:42 #214357

by thefabricator03

Replied by thefabricator03 on topic New Plasma build in OZ

Like you we dont really have the tools to move the large 6m sheets around easily. 3000x1500 is plenty big for our workshop.

For a large table the fans needed do become rather expensive. I am pretty happy with my water table.

I have made removable slat holders so the slats can be lifted out in sections which for a large machine that get used a fair bit saved a lot of time.

Make sure you size your tank according to your water pan volume and add a bit more volume, I did not size my first tank correctly and had to make a new one.

For a large table the fans needed do become rather expensive. I am pretty happy with my water table.

I have made removable slat holders so the slats can be lifted out in sections which for a large machine that get used a fair bit saved a lot of time.

Make sure you size your tank according to your water pan volume and add a bit more volume, I did not size my first tank correctly and had to make a new one.

Please Log in or Create an account to join the conversation.

- 34by151

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 16

12 Jul 2021 05:06 #214358

by 34by151

Replied by 34by151 on topic New Plasma build in OZ

Thats very much like what im planning.

The only real difference will be making the area between your tray and the rails a drain. For me fixes 2 issues, overfilling the table and splashing over the sides.

I will be repourposing the same setup tanks and pumps from the old table.

A pair of IBC's for the tanks (located outside). The pump is actually a 2hp pool sand filter setup with glass beads in the filter. Pump inlet and outlet connected to a manafold with 50mm irrigation solenoids. This allows fill and drain, tank pump out and tank recurculate. I find the filter works great in getting rid of the soot in the water. Works best with the 2 tanks.Circuate water for 20mins and it turns from black to allmost clear. A quick backwash of the filter into the scrap bin and its done.

The only real difference will be making the area between your tray and the rails a drain. For me fixes 2 issues, overfilling the table and splashing over the sides.

I will be repourposing the same setup tanks and pumps from the old table.

A pair of IBC's for the tanks (located outside). The pump is actually a 2hp pool sand filter setup with glass beads in the filter. Pump inlet and outlet connected to a manafold with 50mm irrigation solenoids. This allows fill and drain, tank pump out and tank recurculate. I find the filter works great in getting rid of the soot in the water. Works best with the 2 tanks.Circuate water for 20mins and it turns from black to allmost clear. A quick backwash of the filter into the scrap bin and its done.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

12 Jul 2021 05:19 #214360

by thefabricator03

Replied by thefabricator03 on topic New Plasma build in OZ

Thats interesting about your two tanks,

I have done the same and used a large pump to move the water. I originally wanted to use air pressure to move the water but that turns the tank into a pressure vessel which then comes with its own set of safety standards you must conform to. Its not worth the hassle in a workplace to have any unnecessary pressure vessels as they need to be registered and inspected regularly.

I have done the same and used a large pump to move the water. I originally wanted to use air pressure to move the water but that turns the tank into a pressure vessel which then comes with its own set of safety standards you must conform to. Its not worth the hassle in a workplace to have any unnecessary pressure vessels as they need to be registered and inspected regularly.

Please Log in or Create an account to join the conversation.

- 34by151

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 16

12 Jul 2021 06:51 #214364

by 34by151

Replied by 34by151 on topic New Plasma build in OZ

Exactly on the pressure vessel.

One tank will be just under the table volume

I went IBC's as they are cheep, under $100 near new and can be easily moved if needed.

My shop has a 1m retaining wall along one side. So the tanks are below ground level for quick gravity feed if needed.

Uning 2 tanks allows the filter to circulate between the tanks removing the soot. Does not take long to do and works really well. Pool pumps a re cheep as well and move a lot of volume. They also handle 10mm solids but the inlet on the table should be screened anyway so your only really dealing with soot in the pump.

A sand filter and pump willmove 1000L in about 4 minutes and cost about $600 new

One tank will be just under the table volume

I went IBC's as they are cheep, under $100 near new and can be easily moved if needed.

My shop has a 1m retaining wall along one side. So the tanks are below ground level for quick gravity feed if needed.

Uning 2 tanks allows the filter to circulate between the tanks removing the soot. Does not take long to do and works really well. Pool pumps a re cheep as well and move a lot of volume. They also handle 10mm solids but the inlet on the table should be screened anyway so your only really dealing with soot in the pump.

A sand filter and pump willmove 1000L in about 4 minutes and cost about $600 new

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

12 Jul 2021 08:01 #214368

by rodw

Replied by rodw on topic New Plasma build in OZ

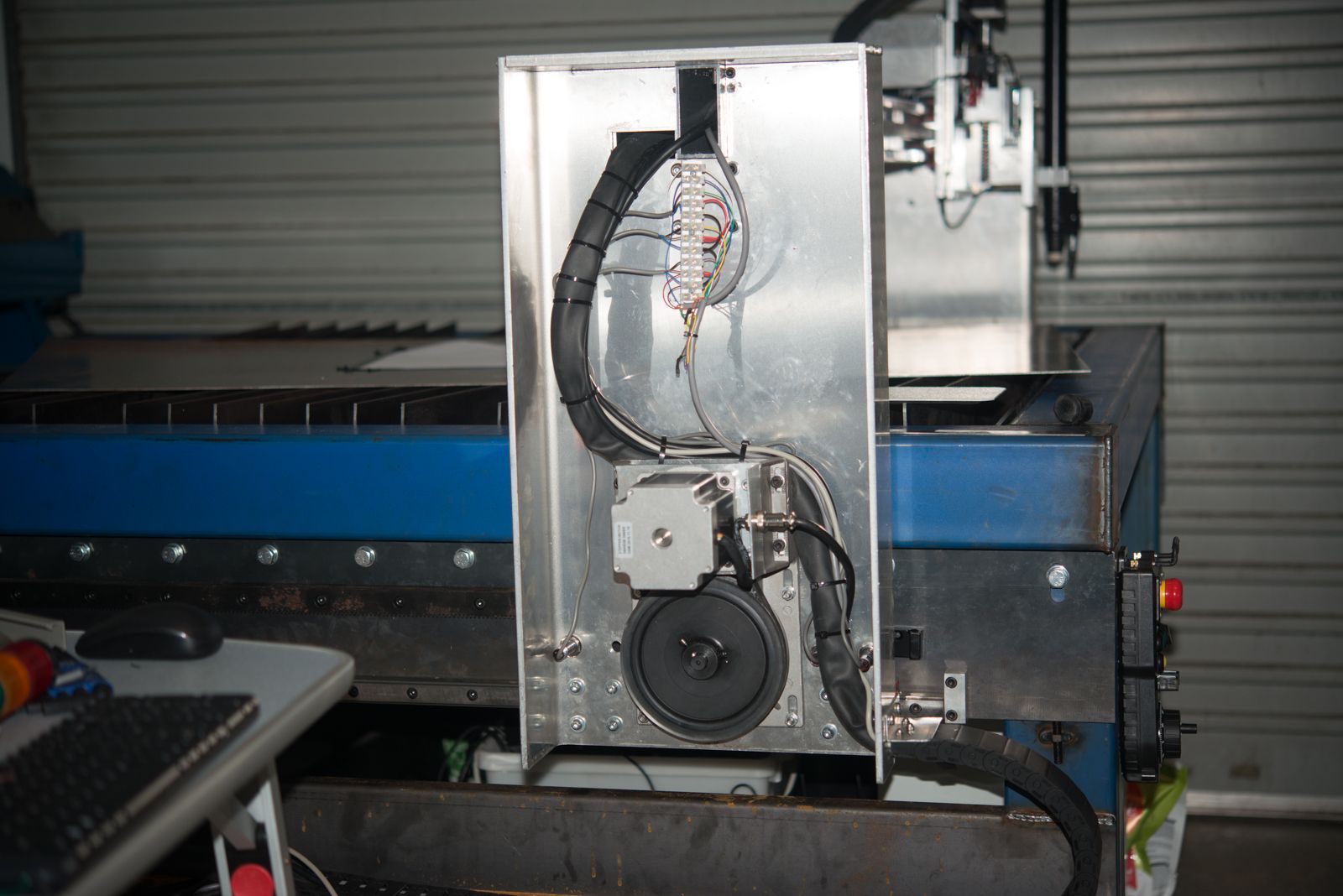

on the subject of side mounted rails, I mounted mine lower on a steel plate that rested on grubscrews at each end to allow it to be aligned before clamping off. This also would have let me shim the mounting plate but it was not required as we were able to make a temporary "gantry mounted upside down when welding to check for alignment

Attachments:

Please Log in or Create an account to join the conversation.

- 34by151

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 16

16 Jul 2021 07:44 #214998

by 34by151

Replied by 34by151 on topic New Plasma build in OZ

Finally got most of it into Solidwoks

I havent drawn everything in and will need to do that before I can do some FEA testing.

Here is the basic design

Working area is 3300mm x 1900mm

Gantry has a parking area

A sump is located at the far end under the parking area

Water pan is flat to make cleanout easy

Rails are on the bottom

Legs are on height adjustable casters

Rails are removable and sit in 3 removable trays

Around the edge is a splash gutter

Need to finish drawing it up and run some tests

I also plan to use timimg belt drive for X and Y

First quotes are comming in for the Hwin Rails, hope to order them soon and get building

Cheers

Jim

I havent drawn everything in and will need to do that before I can do some FEA testing.

Here is the basic design

Working area is 3300mm x 1900mm

Gantry has a parking area

A sump is located at the far end under the parking area

Water pan is flat to make cleanout easy

Rails are on the bottom

Legs are on height adjustable casters

Rails are removable and sit in 3 removable trays

Around the edge is a splash gutter

Need to finish drawing it up and run some tests

I also plan to use timimg belt drive for X and Y

First quotes are comming in for the Hwin Rails, hope to order them soon and get building

Cheers

Jim

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

16 Jul 2021 09:25 #215006

by rodw

Replied by rodw on topic New Plasma build in OZ

Looks good..

I'm a bit concerned about your casters. The threaded extension rod seems quite small. I used 4 x 300 kg casters but also made provision for adjustable feet on an M30 thread. Needless to say, I have removed the casters due to excessive wobble. Even without a water tray, its darn near impossible to move my 4 x 4 table on the casters.... but they were handy until I finally got it to its final location...

Please share your Hiwin pricing when it comes in. I added a new Chinese supplier yesterday who list it. I might be able to help. I ordered a Z axis as a sample so will see what it looks like when it arrives.

I'm a bit concerned about your casters. The threaded extension rod seems quite small. I used 4 x 300 kg casters but also made provision for adjustable feet on an M30 thread. Needless to say, I have removed the casters due to excessive wobble. Even without a water tray, its darn near impossible to move my 4 x 4 table on the casters.... but they were handy until I finally got it to its final location...

Please share your Hiwin pricing when it comes in. I added a new Chinese supplier yesterday who list it. I might be able to help. I ordered a Z axis as a sample so will see what it looks like when it arrives.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

16 Jul 2021 09:29 #215007

by rodw

Replied by rodw on topic New Plasma build in OZ

Also I forgot to say I would also suggest extending the base of your gantry end out some distance so you can run a brace up to the top of your gantry to stiffen it up. Just in case you do something silly like I did and get your steppers to accelerate at 0.5 G!

My gantry ends are quite different now.....

My gantry ends are quite different now.....

Please Log in or Create an account to join the conversation.

- 34by151

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 16

16 Jul 2021 09:49 #215011

by 34by151

Replied by 34by151 on topic New Plasma build in OZ

The casters are a mix of GD150F for the main 150x150 legs and GD80F for the iside legs.

The 150F is rated to 1500kg and the 80F to 550kg.

Hat you cant see in the pic is the mounting plate. Im guessingyour looking at the adjuster bolt that lowers the wheel. Thes normall sit on the pad and the wheel is only down to move it.

If it was to be moved it would be with the forklift or the tractor doing the moving

The 150F is rated to 1500kg and the 80F to 550kg.

Hat you cant see in the pic is the mounting plate. Im guessingyour looking at the adjuster bolt that lowers the wheel. Thes normall sit on the pad and the wheel is only down to move it.

If it was to be moved it would be with the forklift or the tractor doing the moving

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.124 seconds