Dc servo motor control

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

05 Apr 2022 23:02 #239400

by tommylight

Replied by tommylight on topic Dc servo motor control

Noisy servo drive/m0otor almost always is due to bad brushes, be it the motor brushes or the tacho brushes.

It will also be caused by one or more burnt rotor windings or shorts in the commutator.

Check the corresponding drive, if it get noticeably hotter than the other drives, one of the above is the cause.

Failing to fix that will cause issues with tuning during normal use, namely even if the system is tuned properly, after a while the motor and the drive will heat so the tuning will shift, usually enough to cause following errors during fast moves.

Been there, done that.

It will also be caused by one or more burnt rotor windings or shorts in the commutator.

Check the corresponding drive, if it get noticeably hotter than the other drives, one of the above is the cause.

Failing to fix that will cause issues with tuning during normal use, namely even if the system is tuned properly, after a while the motor and the drive will heat so the tuning will shift, usually enough to cause following errors during fast moves.

Been there, done that.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

07 Apr 2022 15:00 #239551

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Tommy i turned a small pot onside the drive 1/8 turn, now it is silent, still seems to work ok, but im not sure why this could be.

On other notes, would you have any idea what polarity arc voltage is on the i/o cable for the thcad? I am confused because the work lead is positive on this machine.

Maybe i will have to test first

On other notes, would you have any idea what polarity arc voltage is on the i/o cable for the thcad? I am confused because the work lead is positive on this machine.

Maybe i will have to test first

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

07 Apr 2022 15:31 #239555

by tommylight

Replied by tommylight on topic Dc servo motor control

Work lead or clamp is always positive on plasma cutters.

Seems like red is positive, but you can always use a DVM to check.

Seems like red is positive, but you can always use a DVM to check.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

09 Apr 2022 18:50 #239767

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Ive it wired to the plug but Il leave it unplugged and check with a dvm when i first get cutting.

When i go through the the pncconf i can select and encoder input as the arc voltage but i dont get a configuration page to setup the thcad.

When i go through the the pncconf i can select and encoder input as the arc voltage but i dont get a configuration page to setup the thcad.

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

12 Apr 2022 22:50 #240092

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Tommy, I have now done a few cuts and got the arc voltage working correctly in qtplasmac. I was a little confused as there was nowhere to configure the thcad in the pncconf but then i realised it is simply set within the qtplasmac interface.

I have a bigger problem now though, I have damaged 2 of the -10+10v AN outputs! They have got pinned at 13.4vdc, a reset does not change this so something on the board is damaged. Im not sure how this has happened, I have each driver signal ground to the tb5 ground pins and the shield to the cabinet ground. A few digital output have also failed. I have enough output to do but wont if I destroy another AN output.

Im using a 5v 10 amp meanwell psu to supply to the 7i92 and supplying 5v to the 7i77 through the cable.

For field power I am using the ESAB 28vdc supply, perhaps this could be part of the problem, not sure. Temped to change to 24vdc meanwell.

I had a cnc4pc ohmic sensor i had spare wired in, the enable relay inside it started to flicker very fast (even when it should have been disabled) this could also be a cause of my problems.

I have retained the esab grounding strip and shielding.

The plasma is a ht2000 running oxygen at 200 amps.

Problems seem to happen around times of starting arc.

I have a bigger problem now though, I have damaged 2 of the -10+10v AN outputs! They have got pinned at 13.4vdc, a reset does not change this so something on the board is damaged. Im not sure how this has happened, I have each driver signal ground to the tb5 ground pins and the shield to the cabinet ground. A few digital output have also failed. I have enough output to do but wont if I destroy another AN output.

Im using a 5v 10 amp meanwell psu to supply to the 7i92 and supplying 5v to the 7i77 through the cable.

For field power I am using the ESAB 28vdc supply, perhaps this could be part of the problem, not sure. Temped to change to 24vdc meanwell.

I had a cnc4pc ohmic sensor i had spare wired in, the enable relay inside it started to flicker very fast (even when it should have been disabled) this could also be a cause of my problems.

I have retained the esab grounding strip and shielding.

The plasma is a ht2000 running oxygen at 200 amps.

Problems seem to happen around times of starting arc.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

12 Apr 2022 23:01 #240093

by tommylight

Replied by tommylight on topic Dc servo motor control

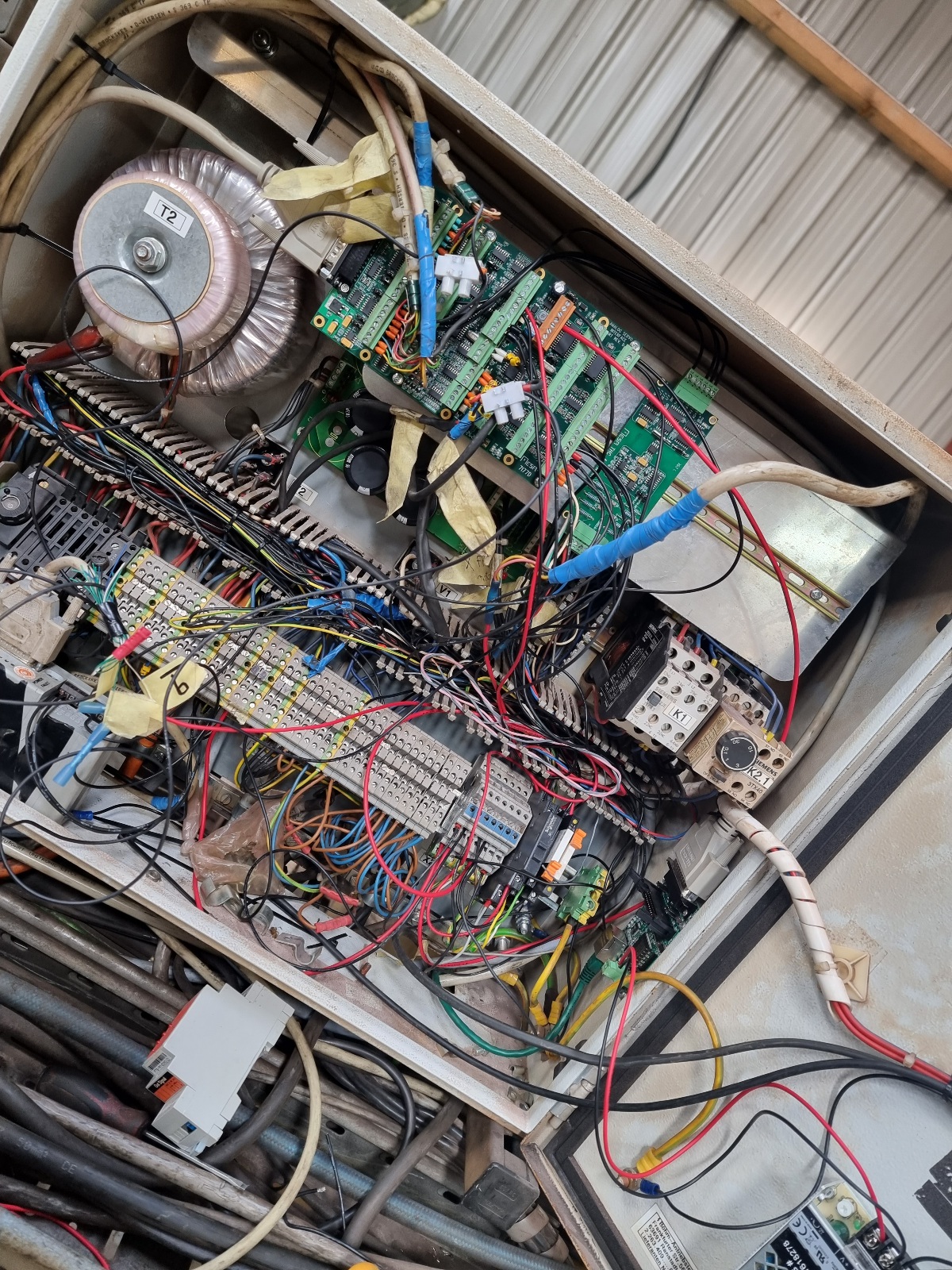

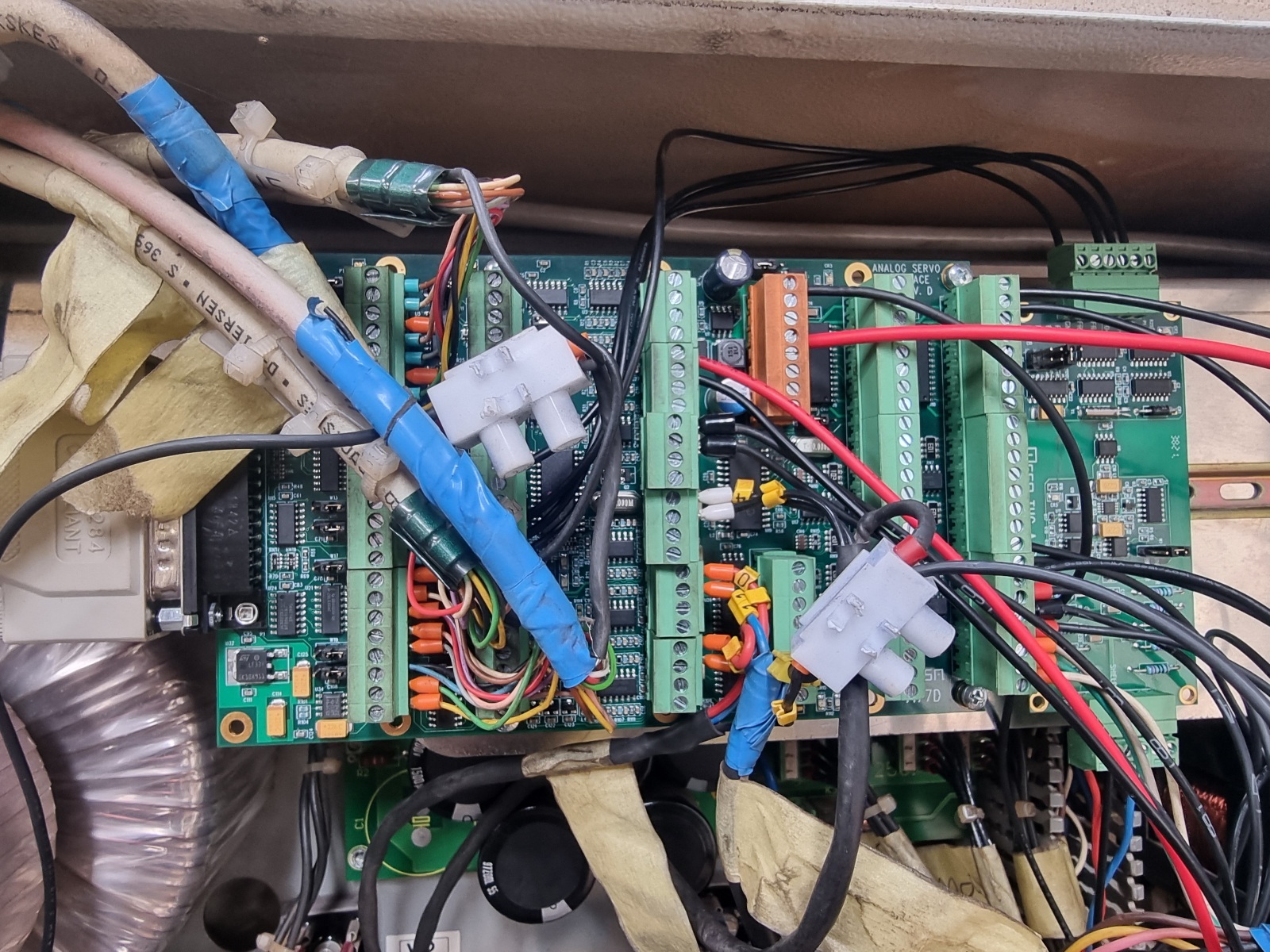

Pictures of everything, wiring in the control box, mesa, thcad, etc.

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

13 Apr 2022 12:10 #240140

by Joeymcc

very messy at rhe moment, i have removed the ohmic sens9r by the time i had too the pictures, it was a cnc4pc one as in link

Sensor

My ohmic sense wire runs into a box above the torch and then is took down with a multicore cable to the main panel, perhaps i should have it separate.

Replied by Joeymcc on topic Dc servo motor control

very messy at rhe moment, i have removed the ohmic sens9r by the time i had too the pictures, it was a cnc4pc one as in link

Sensor

My ohmic sense wire runs into a box above the torch and then is took down with a multicore cable to the main panel, perhaps i should have it separate.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

13 Apr 2022 15:39 #240152

by tommylight

Replied by tommylight on topic Dc servo motor control

First picture, daisy chained ground is a no no, grounds for both power supplies must be connected to the screw on the door.

Second and third picture ... oh hell, the Mesa should have been installed where the monitor was in the control box, if at all possible move it there, together with the PC, power box is not a good place to have low voltage signaling.

THCAD should be mounted on the back of the plasma cutter, shielded cable wired to mesa and shield tied to one of the screws in the control box.

The cable for the new drive analog control must be shielded, shield grounded together with other analog drive shields.

There is a 220V cable in the control box, add a 3 socket power strip to it for the PC and monitor.

Second and third picture ... oh hell, the Mesa should have been installed where the monitor was in the control box, if at all possible move it there, together with the PC, power box is not a good place to have low voltage signaling.

THCAD should be mounted on the back of the plasma cutter, shielded cable wired to mesa and shield tied to one of the screws in the control box.

The cable for the new drive analog control must be shielded, shield grounded together with other analog drive shields.

There is a 220V cable in the control box, add a 3 socket power strip to it for the PC and monitor.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

14 Apr 2022 00:41 #240199

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

I will sort out the daisy chain. The z axis drive is now in the power box also (bottom left) I ended up chaning to a parker oem670t drive, it tuned in good, i can still change to sheilded wires for the drive.

I will try moving the thcad board.

If needed I can remount and use old computer box, however my problem is damage to the components, not interference, before problem occured cutting preformance was fine. Problem occured while arc was starting. Previous to this the ohmic sensor was going crazy. One thing I had done which could possibly have caused problems was I wired ohmic sensor to the ground point on the gantry, not to the table, the lead from the gantry to the table and ground rod end up at the far away end of the table (8m, 4 vaccum bins linked with eath cable and bolts) to where i was cutting. I was using quite a high peirce height. Perhaps the arc has found a path through the ohmic wire from the torch cap and back to the electronics that way. I have now run the ohmic ground to the table.

I will try moving the thcad board.

If needed I can remount and use old computer box, however my problem is damage to the components, not interference, before problem occured cutting preformance was fine. Problem occured while arc was starting. Previous to this the ohmic sensor was going crazy. One thing I had done which could possibly have caused problems was I wired ohmic sensor to the ground point on the gantry, not to the table, the lead from the gantry to the table and ground rod end up at the far away end of the table (8m, 4 vaccum bins linked with eath cable and bolts) to where i was cutting. I was using quite a high peirce height. Perhaps the arc has found a path through the ohmic wire from the torch cap and back to the electronics that way. I have now run the ohmic ground to the table.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

14 Apr 2022 09:10 #240220

by tommylight

Remove ohmic sensing completely, make the machine work properly, then try ohmic if you think you might need it.

And i do mean "remove" not just disable in hal, remove all the wires, power supply, everything.

And you are correct, with plasma, the arc start will mess up things, cutting is ok.

Replied by tommylight on topic Dc servo motor control

Damage to components is caused by that interference, most probably, so denial and insisting on "it was OK" will not fix it..... however my problem is damage to the components, not interference,

Remove ohmic sensing completely, make the machine work properly, then try ohmic if you think you might need it.

And i do mean "remove" not just disable in hal, remove all the wires, power supply, everything.

And you are correct, with plasma, the arc start will mess up things, cutting is ok.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.174 seconds