Dc servo motor control

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

14 Apr 2022 16:18 #240243

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Tommy, I will do what i should have done from the start,

my touchscreen computer would not fit in the old cabinet, so I mounted it on its own where the old control was and tried mounting the mesa equiptment in the power box.

I will fabricate a new control box that my computer will slot into, and mount mesa boards there. I will use the grounding bar also that was in old control box. Luckily i have not cut the encoder cables or the homing sensor cables and still have the analogue signal cable from the old control, so relocation should bot be too bad.

You said at the start to use the old control box! Yes this would have been much easier! I guess esab done this for good reason. I wish I had just got a different computer. However at this stage fabrication of a new box will be the best solution and give me the computer i want. I have completely underestimated the damage that the interference could do, the HF start seems to be the issue, I got away so easy with little 45xp before that I got lazy.

I have a few solid state relays for i/o, would these be ok on the power box din rail with sheilded cable from the mesa?

I also have a 3 switches on the z axis, z-, z+ and collision, all physical switches, what would the best way be to isolate these from the mesa? Or will shielded cable be sufficient?

Ah well, at least I have some more knowledge for diagnostics in the future, and will hopefully end up with a moee reliable machine...

my touchscreen computer would not fit in the old cabinet, so I mounted it on its own where the old control was and tried mounting the mesa equiptment in the power box.

I will fabricate a new control box that my computer will slot into, and mount mesa boards there. I will use the grounding bar also that was in old control box. Luckily i have not cut the encoder cables or the homing sensor cables and still have the analogue signal cable from the old control, so relocation should bot be too bad.

You said at the start to use the old control box! Yes this would have been much easier! I guess esab done this for good reason. I wish I had just got a different computer. However at this stage fabrication of a new box will be the best solution and give me the computer i want. I have completely underestimated the damage that the interference could do, the HF start seems to be the issue, I got away so easy with little 45xp before that I got lazy.

I have a few solid state relays for i/o, would these be ok on the power box din rail with sheilded cable from the mesa?

I also have a 3 switches on the z axis, z-, z+ and collision, all physical switches, what would the best way be to isolate these from the mesa? Or will shielded cable be sufficient?

Ah well, at least I have some more knowledge for diagnostics in the future, and will hopefully end up with a moee reliable machine...

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

16 Apr 2022 18:27 #240414

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

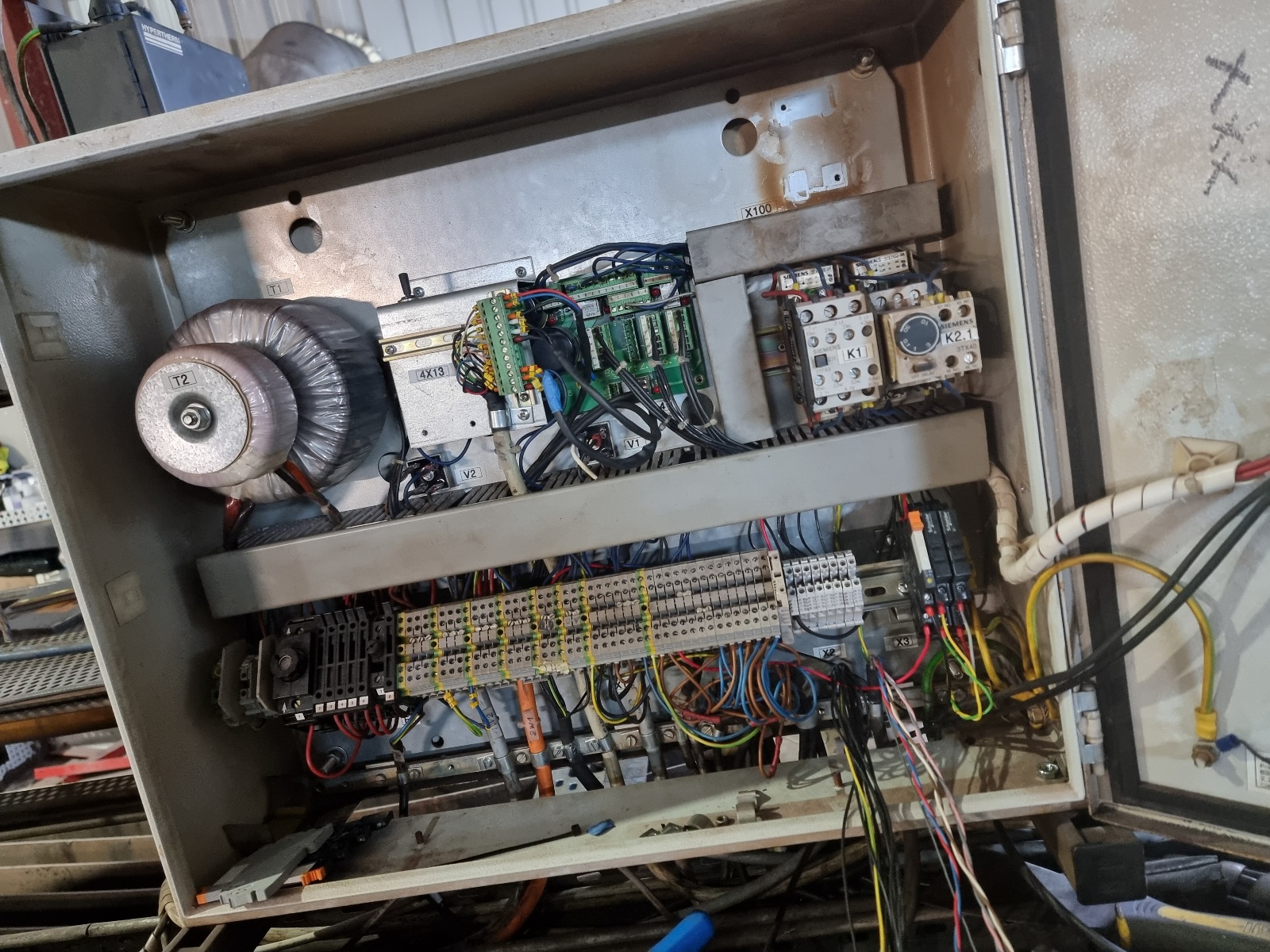

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

17 Apr 2022 10:59 #240454

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

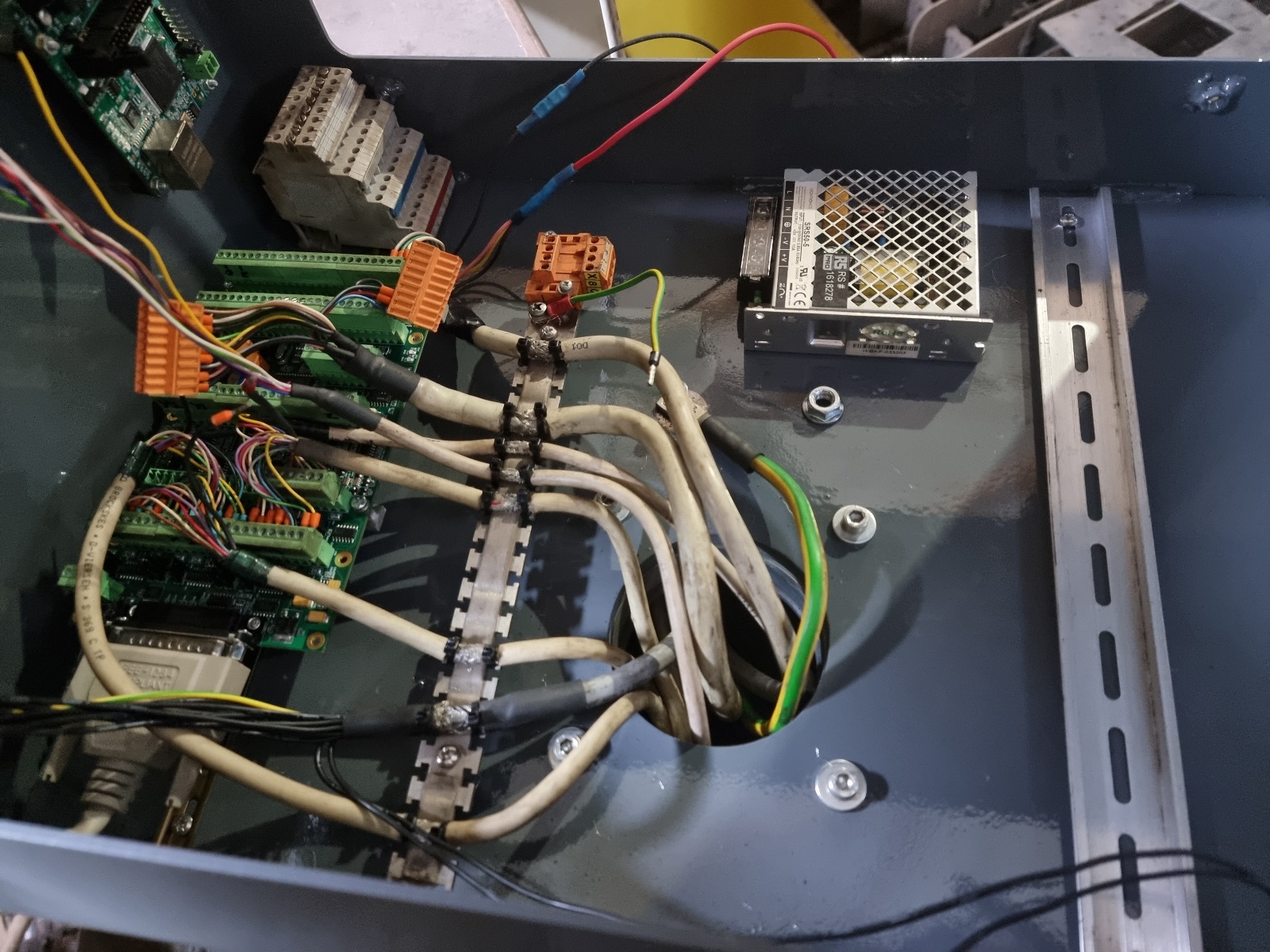

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

17 Apr 2022 12:04 #240462

by tommylight

Replied by tommylight on topic Dc servo motor control

Is that a Mesa 7i92M ?

if yes, that can be plugged directly into the Mesa 7i76 or 7i77.

if yes, that can be plugged directly into the Mesa 7i76 or 7i77.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

17 Apr 2022 13:31 #240467

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Yes it is a 7i92, I could do that with a male-male adaptor, both have female plugs.

When installing the old esab cable for the -10+10V analogue signal I have noticed 2 things:

1. I Had pins the wrong way around. I had signal ground and the -+10v Incorrect!!

2. On the esab wiring the 0v signal pins and the shield are connected, , this is not what I would have expected, I thought that the shield would have went to ground bar and signal ground would be separate. Is it best to connect the signal ground along with the shield?

When installing the old esab cable for the -10+10V analogue signal I have noticed 2 things:

1. I Had pins the wrong way around. I had signal ground and the -+10v Incorrect!!

2. On the esab wiring the 0v signal pins and the shield are connected, , this is not what I would have expected, I thought that the shield would have went to ground bar and signal ground would be separate. Is it best to connect the signal ground along with the shield?

Attachments:

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

17 Apr 2022 23:39 #240521

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

18 Apr 2022 00:09 #240524

by tommylight

Replied by tommylight on topic Dc servo motor control

Much better!

As for the analog signals being tied to ground, i am sure i separated them, but i am also sure i did not mention that to anyone i helped with the retrofit, so it should work both ways, granted you have good grounding in the shop.

As for the analog signals being tied to ground, i am sure i separated them, but i am also sure i did not mention that to anyone i helped with the retrofit, so it should work both ways, granted you have good grounding in the shop.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

- Joeymcc

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 17

18 Apr 2022 12:33 #240556

by Joeymcc

Replied by Joeymcc on topic Dc servo motor control

Tommy, my next decision, IHS. I had planned to use ohmic so I removed the esab sensor (2 prox sensors on a air cyclinder). But with the problem earlier Im not sure what to do, you advise to setup first without ohmic, what method should I use? Im used to ohmic on my smaller machine. So far I can think of:

1. Refit the proximity sensor and air piston setup, however sometimes this was troublesome dependant on the geometry of small parts which were already missing from the cut sheet.

2. Fit a float switch, the magnetic holder is not strong enough and the torch is knocked off before the z axis carriage lifts, however perhaps it is best to modify this as would be reliable.

3. Fit relay ohmic, I could disconnect the ohmic probe from the circuit during cutting with perhaps 2 relays during cutting. Would it be best to use spdt relay with the resting postion pin to ground?

4. Same as 3 but use thcad plate sensing.

What method is most sucessfull for this type of machine? This machine will not be used for less than 5mm sheet, mostly 8-25mm plates

1. Refit the proximity sensor and air piston setup, however sometimes this was troublesome dependant on the geometry of small parts which were already missing from the cut sheet.

2. Fit a float switch, the magnetic holder is not strong enough and the torch is knocked off before the z axis carriage lifts, however perhaps it is best to modify this as would be reliable.

3. Fit relay ohmic, I could disconnect the ohmic probe from the circuit during cutting with perhaps 2 relays during cutting. Would it be best to use spdt relay with the resting postion pin to ground?

4. Same as 3 but use thcad plate sensing.

What method is most sucessfull for this type of machine? This machine will not be used for less than 5mm sheet, mostly 8-25mm plates

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

18 Apr 2022 16:00 #240568

by tommylight

Replied by tommylight on topic Dc servo motor control

2

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

19 Apr 2022 02:01 #240623

by phillc54

Replied by phillc54 on topic Dc servo motor control

I agree with Tommy, #2 for the materials that you are cutting.

If you did go with #1, QtPlasmaC can do offset probing so that the proximity sensor would probe at the actual pierce coordinates.

If you did go with #3, use a solid state relay, not a mechnical relay.

If you did go with #1, QtPlasmaC can do offset probing so that the proximity sensor would probe at the actual pierce coordinates.

If you did go with #3, use a solid state relay, not a mechnical relay.

The following user(s) said Thank You: Joeymcc

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.360 seconds