Best rails position on frame in a dusty workspace

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21034

- Thank you received: 7168

08 Aug 2022 12:38 #249337

by tommylight

Replied by tommylight on topic Best rails position on frame in a dusty workspace

10-15KG

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11546

- Thank you received: 3871

10 Aug 2022 10:48 #249443

by rodw

Replied by rodw on topic Best rails position on frame in a dusty workspace

I would have said stay < 30kg with gantry ends, Z axis and torch, wires etc.

The torch lifter is hard to get under 5kg, the torch is about 1kg so Tommy's target implies use of belts which you may or may not want to use.

The torch lifter is hard to get under 5kg, the torch is about 1kg so Tommy's target implies use of belts which you may or may not want to use.

The following user(s) said Thank You: tommylight, pit34

Please Log in or Create an account to join the conversation.

- pit34

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 4

10 Aug 2022 11:01 #249445

by pit34

Replied by pit34 on topic Best rails position on frame in a dusty workspace

Thanks for those details Rod.

What is your opinion about belts?

I have seen that Tommy use it on his tables, but I mainly see rack and pinions on commercial tables, and on DIY ones too.

What is your opinion about belts?

I have seen that Tommy use it on his tables, but I mainly see rack and pinions on commercial tables, and on DIY ones too.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

10 Aug 2022 16:50 #249457

by robertspark

Replied by robertspark on topic Best rails position on frame in a dusty workspace

I used to use belts on mine (HTD5M), I now use rack and pinion MOD1, bought here if you are in europe (as they were very cheap imo)

www.motedis.co.uk/shop/index.php

they ship from germany

they also have a lot of other motedis websites in US, mexico etc etc.

they are not into chit chat, just order and send whatever you order there is no phone support and the email support is "interesting" if they get something wrong (I asked for 8mm pinions and got 1/4" pinions....)

www.motedis.co.uk/shop/DIY.php

but I would buy from them again anytime

I know a guy that uses chain..... yes chain and sprockets and he has made I believe 9 tables and sold a lot of designs for others

www.motedis.co.uk/shop/index.php

they ship from germany

they also have a lot of other motedis websites in US, mexico etc etc.

they are not into chit chat, just order and send whatever you order there is no phone support and the email support is "interesting" if they get something wrong (I asked for 8mm pinions and got 1/4" pinions....)

www.motedis.co.uk/shop/DIY.php

but I would buy from them again anytime

I know a guy that uses chain..... yes chain and sprockets and he has made I believe 9 tables and sold a lot of designs for others

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11546

- Thank you received: 3871

11 Aug 2022 12:13 #249506

by rodw

Replied by rodw on topic Best rails position on frame in a dusty workspace

When we were looking at commercialising tables, I looked at belts with an Aussie company. They involved the German engineers and the word was not to use them. The Steel used to reinforce belts was not stainless so not rated for any water splash due to rust damaging the belts. I might add we were not looking at dainty belts, more like 20-30mm wide to handle the torque and acceleration we were shooting for.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4689

- Thank you received: 1433

11 Aug 2022 14:01 #249517

by Todd Zuercher

Replied by Todd Zuercher on topic Best rails position on frame in a dusty workspace

Use Kevlar reinforced belts instead of steel ones.

The following user(s) said Thank You: tommylight, pit34

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21034

- Thank you received: 7168

11 Aug 2022 14:49 #249522

by tommylight

Steel reinforced ones tend to break down when used on tight bends.

Replied by tommylight on topic Best rails position on frame in a dusty workspace

Exactly.Use Kevlar reinforced belts instead of steel ones.

Steel reinforced ones tend to break down when used on tight bends.

The following user(s) said Thank You: pit34

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11546

- Thank you received: 3871

11 Aug 2022 19:59 #249548

by rodw

Replied by rodw on topic Best rails position on frame in a dusty workspace

Too long ago but I think it might have been steel for the torque required or the supplier did not offer kevlar. Not a lot of choice in the colonies..Use Kevlar reinforced belts instead of steel ones.

The following user(s) said Thank You: pit34

Please Log in or Create an account to join the conversation.

- pit34

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 4

15 Aug 2022 12:46 - 15 Aug 2022 13:54 #249777

by pit34

Replied by pit34 on topic Best rails position on frame in a dusty workspace

Ok, thanks. I have easily founds Kevlar ones in France. So I will go for this solution.

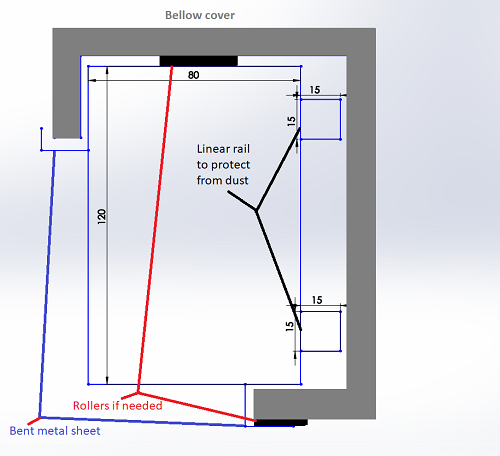

I am thinking since few days about how to protect Y axis rails. I do not want to let rails exposed to dust, so I have found two solutions. The first one is to use "below covers" like this :

Those cover would be placed like on this picture :

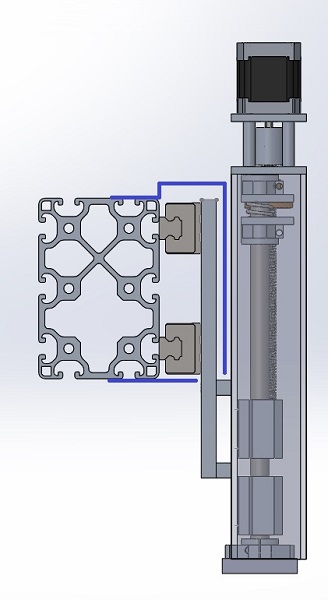

The second one is to use a special Z head design with spacer to be able to put fairings on top of rails. Those fairings would be made of bent aluminum sheet and positioned like the violet lines on this picture :

It is cheaper and simpler to install, but I am worried about geometry issues that this solution could cause. The moment created under the rails in particular.

What do you think about these two solutions ?

Currently, the Y rails are the HGR15 ones, the beam is a 80x120 profile like this one :

The whole gantry without Y motor and torch is about 25kg. So I am pretty close to the target weight.

I am thinking since few days about how to protect Y axis rails. I do not want to let rails exposed to dust, so I have found two solutions. The first one is to use "below covers" like this :

Those cover would be placed like on this picture :

The second one is to use a special Z head design with spacer to be able to put fairings on top of rails. Those fairings would be made of bent aluminum sheet and positioned like the violet lines on this picture :

It is cheaper and simpler to install, but I am worried about geometry issues that this solution could cause. The moment created under the rails in particular.

What do you think about these two solutions ?

Currently, the Y rails are the HGR15 ones, the beam is a 80x120 profile like this one :

The whole gantry without Y motor and torch is about 25kg. So I am pretty close to the target weight.

Attachments:

Last edit: 15 Aug 2022 13:54 by pit34.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19750

- Thank you received: 4583

24 Aug 2022 12:31 #250321

by andypugh

The convoluted load path will affect rigidity, more of a concern for a mill than a plasma.

Your design looks good, and could easily be augmented with brush strips if required.

Replied by andypugh on topic Best rails position on frame in a dusty workspace

The moment on the rails depends only on where the force is applied relative to the rails, it does not depend on what the load path is between the two.

It is cheaper and simpler to install, but I am worried about geometry issues that this solution could cause.

The convoluted load path will affect rigidity, more of a concern for a mill than a plasma.

Your design looks good, and could easily be augmented with brush strips if required.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.191 seconds