Best rails position on frame in a dusty workspace

- daiman444

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 8

06 Oct 2022 09:57 #253598

by daiman444

Replied by daiman444 on topic Best rails position on frame in a dusty workspace

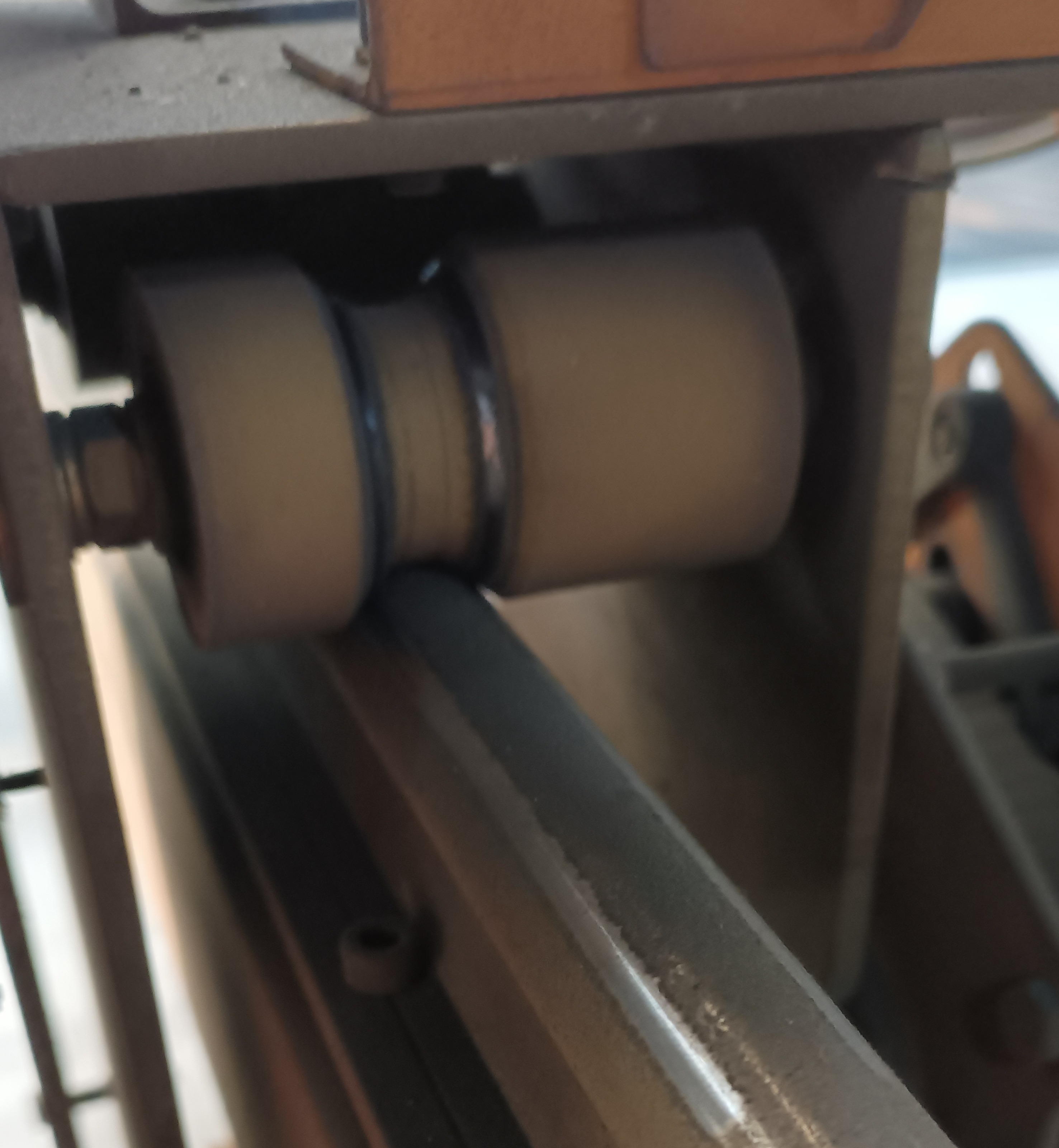

Greetings. read the discussion thread. I can add my input to the discussion. such things as linear and cylindrical bearings, as well as ball screws, are very afraid of the dust that plasma produces in colossal volumes. And I don’t find the point of putting hiwin based on my practice. Plasma does not produce precision sized parts and tolerances of up to 0.5 mm are absolutely normal. therefore, over the years of operation, I came to the solution of ordinary plastic wheels on aligned guides. such supports of the plasma cutting machine are not afraid of dust or scale adhering to the guides. they also absorb small vibrations quite well and do not create noise. also, such wheels create absolutely no resistance in comparison with linear bearings, which will inevitably get dust. in terms of accuracy of parts, the maximum discrepancy is no more than 1 mm per 6000 mm of cut length, but I think this is more due to deformations of the metal itself during cutting and the "instability" of the arc itself. on a plasma cutting machine, the portal does not perceive any strong resistances like a milling or turning machine, so this solution is enough with a large margin. I wish you successful construction of the machine.

Attachments:

The following user(s) said Thank You: arvidb, tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.096 seconds