Water cutter retorfit

- Nick1001

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 3

11 Nov 2022 03:48 - 11 Nov 2022 03:49 #256399

by Nick1001

Water cutter retorfit was created by Nick1001

Hi everyone,

New to linuxcnc but have a bit of experience with cnc machines in general, i have a water cutter that just had its screen and control board die so its not useless, i have ordered a Mesa 7196s and am looking for advice as to finding the wiring schematic or how the current setup is wired some other way so i can then wire it up to the new Mesa board. Any help or advice in general would be appreciated. I am planning on using a setup similar to a plasma cutter setup for the config and ui ideally with a few custom buttons and indicators to control and indicate the status of a few water cutter related things namely water on/off, machine oil on/off, pump oil on/off, aggregate on/off, i know most of these are physical switches and thus the wireing for that is easy its mostly the stepper motor drivers im having issues decoding becuase being a chinese machine all naming is in chenglish or Chinese or is just numbers that are matched at either end.

Also sorry if this isnt the place i couldnt find anyone mentioning water cutters anywhere.

Thanks

New to linuxcnc but have a bit of experience with cnc machines in general, i have a water cutter that just had its screen and control board die so its not useless, i have ordered a Mesa 7196s and am looking for advice as to finding the wiring schematic or how the current setup is wired some other way so i can then wire it up to the new Mesa board. Any help or advice in general would be appreciated. I am planning on using a setup similar to a plasma cutter setup for the config and ui ideally with a few custom buttons and indicators to control and indicate the status of a few water cutter related things namely water on/off, machine oil on/off, pump oil on/off, aggregate on/off, i know most of these are physical switches and thus the wireing for that is easy its mostly the stepper motor drivers im having issues decoding becuase being a chinese machine all naming is in chenglish or Chinese or is just numbers that are matched at either end.

Also sorry if this isnt the place i couldnt find anyone mentioning water cutters anywhere.

Thanks

Last edit: 11 Nov 2022 03:49 by Nick1001.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

11 Nov 2022 10:56 #256412

by tommylight

Replied by tommylight on topic Water cutter retorfit

Pictures, lots of pictures, we are very good at figuring things from pictures. Not so much from words.

As with any machine, no matter how big and complicated it is, it is made of smal and simple things, so try looking at it in small sections or groups, like inputs, outputs, valves, step/dir, analog (if any), etc.

As with any machine, no matter how big and complicated it is, it is made of smal and simple things, so try looking at it in small sections or groups, like inputs, outputs, valves, step/dir, analog (if any), etc.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

11 Nov 2022 12:14 #256420

by my1987toyota

Replied by my1987toyota on topic Water cutter retorfit

If it were me starting fresh learning Linuxcnc and putting a conversion together at the same time

I would first get the E-stop button wired don't worry about anything else until the E-stop is operational

Personally I wire them so that if the circuit is broken it means the E-stop has been triggered ( Fail Safe ) .

next start simple just get the X, Y, and Z moving. You said you were having trouble with them. Are

they actually stepper drivers or servo drivers. Tommylight is right about uploading pictures they help

immensely

Next get the home switches wired. After that the End Limit Switches if equipped. If no Limit Switches present you're stuck with soft limits unless you want to add your own. Make sure your travels are calibrated before you test near the ends of travel.

Now for the frustrating part learning how to program the custom buttons to do what you want them to do.

I usually make multiple profiles " Simple Machine " in Linuxcnc to only test specific Buttons, MPG controls, ect.

It's a great way to learn how Linuxcnc works. The Linuxcnc Manual is very much your friend as well

as the forum. Once you have a bare bones profile save it as a backup. that way if in the event of a

computer failure or a change that doesn't work right you have a profile to fall back on. I have been

glad I did on multiple occasions .

Also make wiring schematics . They speed up diagnostics if or when something goes wrong years later.

Like when a rodent decides to chew on some wires.

lastly and most importantly only make the machine as complicated as you need it to be .

I would first get the E-stop button wired don't worry about anything else until the E-stop is operational

Personally I wire them so that if the circuit is broken it means the E-stop has been triggered ( Fail Safe ) .

next start simple just get the X, Y, and Z moving. You said you were having trouble with them. Are

they actually stepper drivers or servo drivers. Tommylight is right about uploading pictures they help

immensely

Next get the home switches wired. After that the End Limit Switches if equipped. If no Limit Switches present you're stuck with soft limits unless you want to add your own. Make sure your travels are calibrated before you test near the ends of travel.

Now for the frustrating part learning how to program the custom buttons to do what you want them to do.

I usually make multiple profiles " Simple Machine " in Linuxcnc to only test specific Buttons, MPG controls, ect.

It's a great way to learn how Linuxcnc works. The Linuxcnc Manual is very much your friend as well

as the forum. Once you have a bare bones profile save it as a backup. that way if in the event of a

computer failure or a change that doesn't work right you have a profile to fall back on. I have been

glad I did on multiple occasions .

Also make wiring schematics . They speed up diagnostics if or when something goes wrong years later.

Like when a rodent decides to chew on some wires.

lastly and most importantly only make the machine as complicated as you need it to be .

The following user(s) said Thank You: Masiwood123, Nick1001

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

11 Nov 2022 12:47 #256426

by tommylight

Replied by tommylight on topic Water cutter retorfit

It is a stepper system, so e-stop is not important, but

It is a water jet at 2000 or 4000 BAR, so e-stop is very important!

It is Chinese made, so pressing e-stop usually does nothing, from experience!

It is a water jet at 2000 or 4000 BAR, so e-stop is very important!

It is Chinese made, so pressing e-stop usually does nothing, from experience!

Please Log in or Create an account to join the conversation.

- Nick1001

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 3

12 Nov 2022 03:41 #256482

by Nick1001

Replied by Nick1001 on topic Water cutter retorfit

Thanks people, i will get photos on Monday when im back at the shop, is there anything other then the drivers and the back of the old control board that would be helpful? As for EStop yes that will the the first thing wired up and then simple axis. I have started looking at making a wiring diagram but dont understand what the wires are because its all labled with nothing but numbers and Chinese. From what i have seen there is "Hybrid stepper motor"s on the x and y axis, an unknow probably DC motor on the z axis with no visable controller. The sand blaster and main water value is controled through some phneumatics with solanoids interfacing with the control board. The other thing that i discovered after posting my origional post is that all the wires have been put into multicore cable at ever possiable chance thus making tracing wires... difficult.

Thanks for the help

Thanks for the help

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

13 Nov 2022 01:21 #256556

by my1987toyota

Replied by my1987toyota on topic Water cutter retorfit

other helpful pictures would include the Z axis motor, the inside of the control cabinet,

the control panel, that sort of thing. As far as the multi wire cables this can actually make

life easier when tracing things out. A very important tool will be a multi meter for voltage and

continuity testing . you will probably want to keep a note pad with you so you can write down

what wire number does what. Also be ready to research alot of the components individually

online that way you will be able to get pinouts of what wire should do what.

the control panel, that sort of thing. As far as the multi wire cables this can actually make

life easier when tracing things out. A very important tool will be a multi meter for voltage and

continuity testing . you will probably want to keep a note pad with you so you can write down

what wire number does what. Also be ready to research alot of the components individually

online that way you will be able to get pinouts of what wire should do what.

Please Log in or Create an account to join the conversation.

- Nick1001

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 3

13 Nov 2022 21:48 #256612

by Nick1001

Replied by Nick1001 on topic Water cutter retorfit

Here are some pictures, the connecter that has y** labeled on all the pins has an identical one next to it starting with x. The motor in this photo is the z axis, the other two are inside the machinery and hard to get access to to get a photo. I have done a quickish google on the stepper drivers and while i can find many to purchase i could not find a manual or anything, i will have a better look today,

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

13 Nov 2022 23:10 - 13 Nov 2022 23:13 #256628

by andypugh

Replied by andypugh on topic Water cutter retorfit

Attachments:

Last edit: 13 Nov 2022 23:13 by andypugh.

Please Log in or Create an account to join the conversation.

- Nick1001

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 3

13 Nov 2022 23:18 - 13 Nov 2022 23:19 #256631

by Nick1001

Replied by Nick1001 on topic Water cutter retorfit

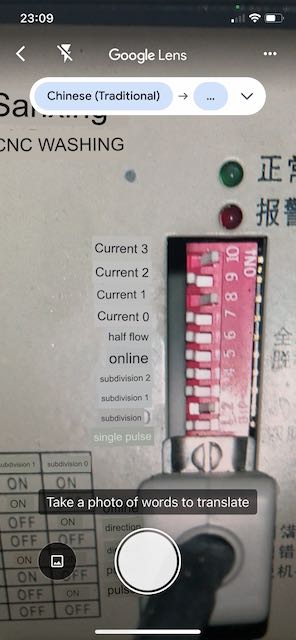

I did some translating, the connection to the control baord that has the dozen ish blue wires has ground on the top 2 from the left and an end stop on the next pin, i didnt bother translating the bottom yet as i now know its endstops, as for the driver here is what i got

Table on the right is current

Table on the left is steps per rotation

Connector

脱机 offline +

方向, direction - 出错 Error -

方向 direction + 出错 Error +

脉冲 Pulse - 脱机Offline -

脉冲 pulse +

Text on the right

三相混合式 步进电机驱动器

Three Phase Hybrid Stepper Motor Driver

Table on the right is current

Table on the left is steps per rotation

Connector

脱机 offline +

方向, direction - 出错 Error -

方向 direction + 出错 Error +

脉冲 Pulse - 脱机Offline -

脉冲 pulse +

Text on the right

三相混合式 步进电机驱动器

Three Phase Hybrid Stepper Motor Driver

Last edit: 13 Nov 2022 23:19 by Nick1001.

Please Log in or Create an account to join the conversation.

- Nick1001

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 3

13 Nov 2022 23:19 #256632

by Nick1001

Replied by Nick1001 on topic Water cutter retorfit

Ok looks like its easier then my way, i did try this and was having issues, how did you get it to work?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.160 seconds