Plasma cutter advice please!

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

06 Nov 2023 15:09 #284708

by oddwick

Replied by oddwick on topic Plasma cutter advice please!

tommy, you are a fountain of genius. period. i have always seen your threads on retrofits and rebuilds, but i never really paid much attention to the plasma sided of it because i didnt have a plasma. the closest i ever came was with @pinder 's monokrom gui and trying to figure out how to use it for a router. those machines are freakin amazing. like seriously. i dont know how you havent given corps like avid and laguna a serious run for the money!

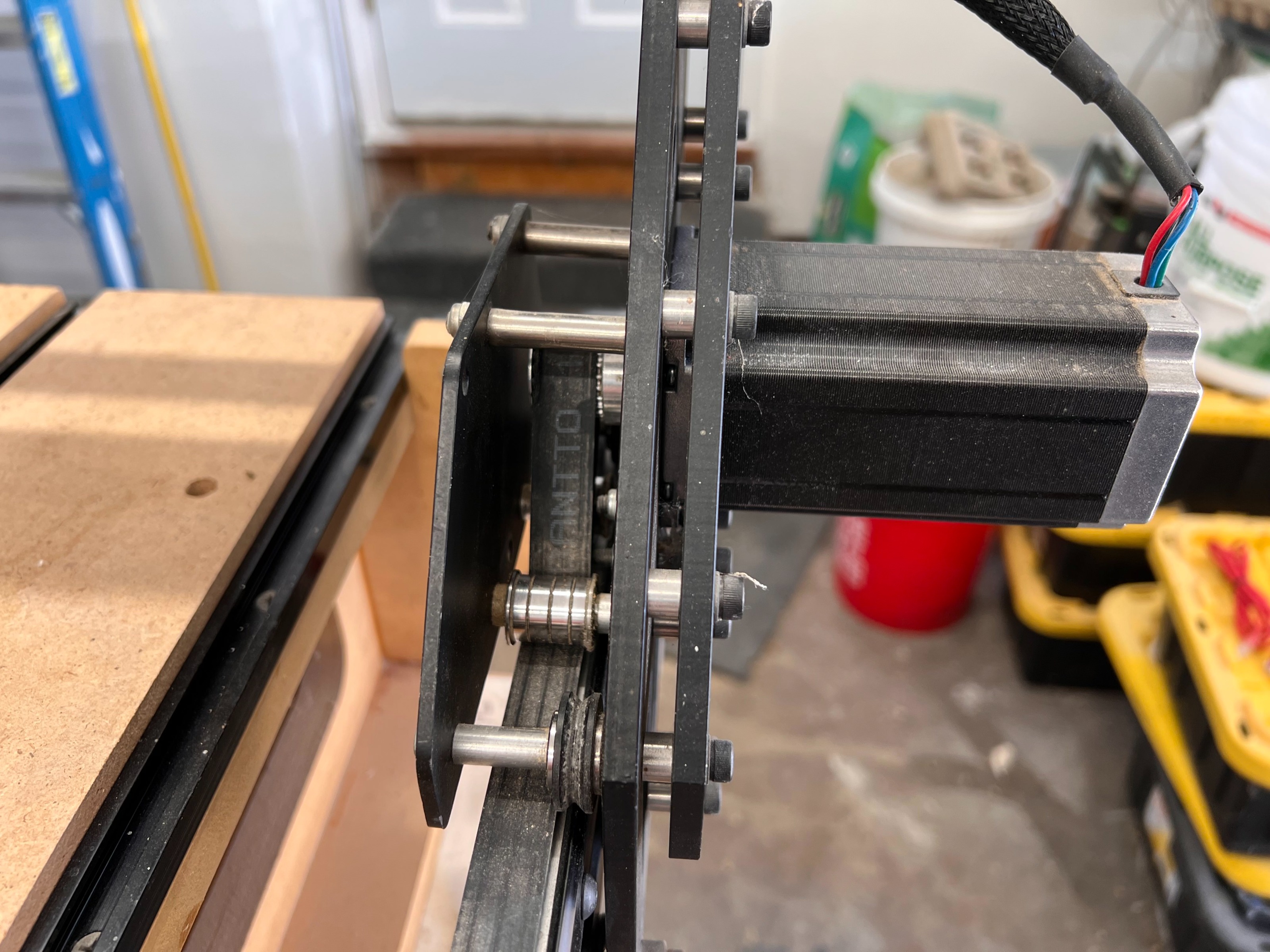

you've sold me on keeping the belts. that is going to save me so much coin. so i see that you use supported round rail instead of square rail. is it a cost or performance issue? what size of belts are you using on those machines? mine is going to be exactly half of one of yours - 1015. also curious if you are reducing because of the weight of the gantry rather than driving it directly. i had also toyed around with the idea of using everman belts, but it would really depend on where my belts actually lie. ill be using hgr20 rail mounted vertically on the sides of al extrusions (everything from the bed up will be aluminum) this gives me around 30-35mm of space between the rails and gantry plate that i would have to figure out a way to keep the belts from floating. i also could mount the motors vertically and run the belts just under the rails.... hmmm. ill have to think on that, i prefer simpler solutions, but i tend towards overthinking

done. just thought a premade solution would be simpler. my electronics ability is limited to just enough to get me in trouble, so i defer to the experts for that. altho, i do find it ironic that a dude that gantry surfs and uses a plasma table as mobile lift lectures people on safetyDon't get me wrong, it will probably work without issues, but the safety margin is non existent, and i insist on safety always.

you've sold me on keeping the belts. that is going to save me so much coin. so i see that you use supported round rail instead of square rail. is it a cost or performance issue? what size of belts are you using on those machines? mine is going to be exactly half of one of yours - 1015. also curious if you are reducing because of the weight of the gantry rather than driving it directly. i had also toyed around with the idea of using everman belts, but it would really depend on where my belts actually lie. ill be using hgr20 rail mounted vertically on the sides of al extrusions (everything from the bed up will be aluminum) this gives me around 30-35mm of space between the rails and gantry plate that i would have to figure out a way to keep the belts from floating. i also could mount the motors vertically and run the belts just under the rails.... hmmm. ill have to think on that, i prefer simpler solutions, but i tend towards overthinking

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

06 Nov 2023 18:27 #284726

by tommylight

I use 15mm wide HTD3 belts for both Y axis, X axis can do just fine with 10mm GT2 belts, reduction is 1:3 or 1:4 depending on what i can find regarding pulleys.

Reduction helps with lowering vibration, more torque so more acceleration, and more "surfing"

Do you have a 3D printer?

Use PETG for parts.

Replied by tommylight on topic Plasma cutter advice please!

I am a dumb f@k!tommy, you are a fountain of genius.

I use 15mm wide HTD3 belts for both Y axis, X axis can do just fine with 10mm GT2 belts, reduction is 1:3 or 1:4 depending on what i can find regarding pulleys.

Reduction helps with lowering vibration, more torque so more acceleration, and more "surfing"

Do you have a 3D printer?

Use PETG for parts.

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

07 Nov 2023 03:52 #284746

by oddwick

im using 15mm 3m belts, and i think ill stick with them. i already have a pile of belts and pulleys. ill keep it the same for all axes. im not a fan of mixing and matching parts, i find its easier to buy in bulk and use the same parts on all axes. plus it makes calibration easier.

ill give the reduction a thought. on the 5x9 i am building, i am reducing 1:4, but it is holy hell to find the right pulleys and belts. its either the id bore, width, or tooth count, but can never find what i need. have a set of pinion gears that took forever to find, but i need a keyway in them and the local shop wants 300 to put 3 3mm keyways in 3 gears. thats ridiculous

and yes i have a printer, a very nice one that i built. what parts to do you print? and they are stout enough?

Replied by oddwick on topic Plasma cutter advice please!

funny, thats what i tell people about myself. my garage looks like a nasa at home kit, yet im still broke and go to a crappy job every day! but i seen your machines, and dude they are slick. ive seen some peoples home built machines and they look cobbled together. but yours could be mistaken easily for something like a shopsabre or laguna!

I am a dumb f@k!

im using 15mm 3m belts, and i think ill stick with them. i already have a pile of belts and pulleys. ill keep it the same for all axes. im not a fan of mixing and matching parts, i find its easier to buy in bulk and use the same parts on all axes. plus it makes calibration easier.

ill give the reduction a thought. on the 5x9 i am building, i am reducing 1:4, but it is holy hell to find the right pulleys and belts. its either the id bore, width, or tooth count, but can never find what i need. have a set of pinion gears that took forever to find, but i need a keyway in them and the local shop wants 300 to put 3 3mm keyways in 3 gears. thats ridiculous

and yes i have a printer, a very nice one that i built. what parts to do you print? and they are stout enough?

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

07 Nov 2023 14:08 #284773

by tommylight

Replied by tommylight on topic Plasma cutter advice please!

www.forum.linuxcnc.org/show-your-stuff/3...uild?start=10#165577

www.forum.linuxcnc.org/show-your-stuff/3...uild?start=80#170002

After browsing those, listen to this to give you a bit of motivation

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=100#170656

Have a look at the puppy to calm down

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=110#171915

Just to remind you not to play with dogs

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=110#172157

Then this for inspiration

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=160#182150

Some results of all the labor

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=190#187026

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=230#190379

Here is the entire bill of materials

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=260#191979

And the 3d printed stuff starts here

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=400#220271

www.forum.linuxcnc.org/show-your-stuff/3...uild?start=80#170002

After browsing those, listen to this to give you a bit of motivation

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=100#170656

Have a look at the puppy to calm down

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=110#171915

Just to remind you not to play with dogs

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=110#172157

Then this for inspiration

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=160#182150

Some results of all the labor

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=190#187026

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=230#190379

Here is the entire bill of materials

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=260#191979

And the 3d printed stuff starts here

www.forum.linuxcnc.org/show-your-stuff/3...ild?start=400#220271

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

09 Nov 2023 05:07 - 09 Nov 2023 05:08 #284917

by oddwick

Replied by oddwick on topic Plasma cutter advice please!

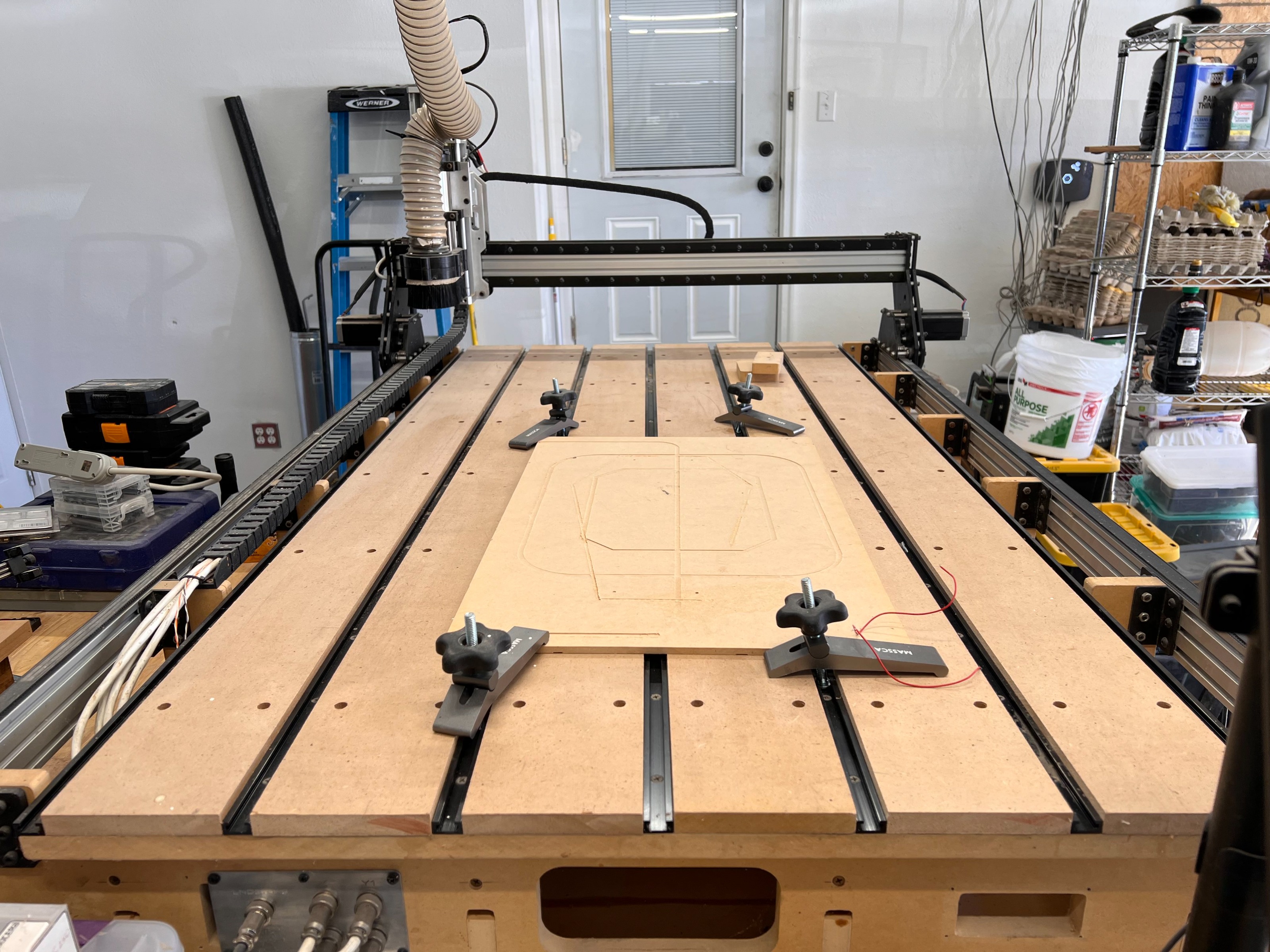

thats pretty ingenius using 3d printers for the caps and covers. i have created a bunch of t emplates for cutting caps out of 3mm aluminum for all my covers. so this is the machine that i am replacing:

its one of my first big designs and was before i really thought on a bigger scale. it is good for what it is, but im going to basically hawk all of the parts from it to make this plasma cutter.

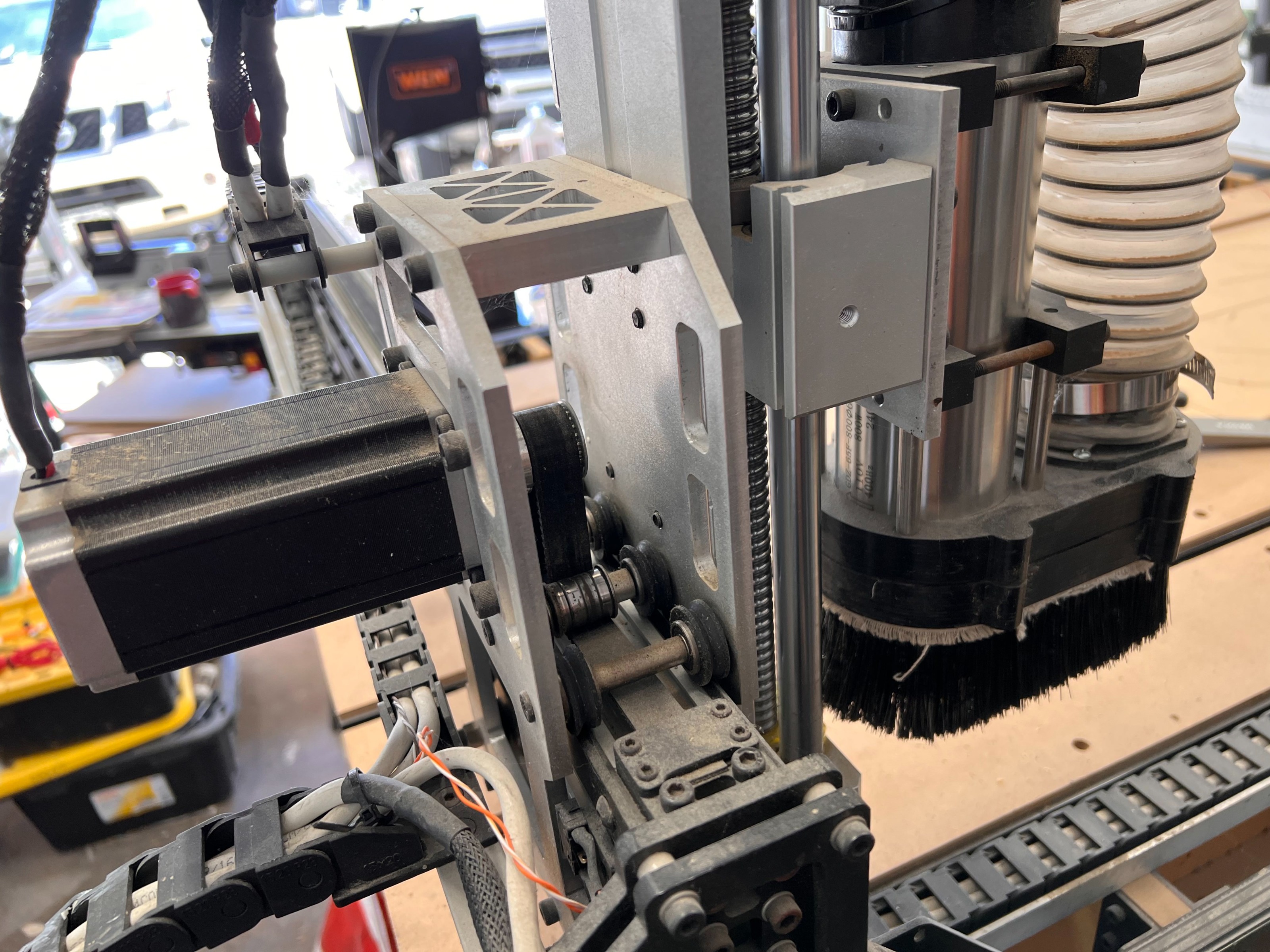

and this is the machine that i will be cutting all of the parts with. it will also be the starting point for my design as well, minus the ballscrews now. and of course a steel base. i am really proud of this machine and it works amazing and has a decent cut area for its size too.

and this is the printer that i will be using to as well. core xy and prints super fast and reliable. cant ask for better!

so today i ordered my rails and some 10mm aluminum plate to get started on the gantry. after reading through your posts, i am envious of your ability to get aluminum so cheap there. its easily 2-3x more expensive here. now i just need to find myself a good pulley reduction set that wont break the bank.

its one of my first big designs and was before i really thought on a bigger scale. it is good for what it is, but im going to basically hawk all of the parts from it to make this plasma cutter.

and this is the machine that i will be cutting all of the parts with. it will also be the starting point for my design as well, minus the ballscrews now. and of course a steel base. i am really proud of this machine and it works amazing and has a decent cut area for its size too.

and this is the printer that i will be using to as well. core xy and prints super fast and reliable. cant ask for better!

so today i ordered my rails and some 10mm aluminum plate to get started on the gantry. after reading through your posts, i am envious of your ability to get aluminum so cheap there. its easily 2-3x more expensive here. now i just need to find myself a good pulley reduction set that wont break the bank.

Attachments:

Last edit: 09 Nov 2023 05:08 by oddwick.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 605

- Thank you received: 17

05 Dec 2023 11:57 - 05 Dec 2023 11:59 #287258

by vre

Replied by vre on topic Plasma cutter advice please!

For 2.5m travel on plasma x axis can use 30mm wide htd5m belt

or must go with rack - pinion?

What about high lead ballscrew (32mm pitch)?

I will use aluminum profile shown in image.

or must go with rack - pinion?

What about high lead ballscrew (32mm pitch)?

I will use aluminum profile shown in image.

Last edit: 05 Dec 2023 11:59 by vre.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

05 Dec 2023 12:08 #287261

by tommylight

The amount of stuff i have gathered in my shops is astonishing, and that makes me p.o., a lot as those are all parts with no actual value till i find the time to put them together into a machine, then they do have value... collecting dust mostly as i have no time to use them! Circular void, or to put it easier to understand = chasing my own tail!

Replied by tommylight on topic Plasma cutter advice please!

LOL, same here except no job for quite a while now since i live in a messed up country and ... to long.my garage looks like a nasa at home kit, yet im still broke and go to a crappy job every day!

The amount of stuff i have gathered in my shops is astonishing, and that makes me p.o., a lot as those are all parts with no actual value till i find the time to put them together into a machine, then they do have value... collecting dust mostly as i have no time to use them! Circular void, or to put it easier to understand = chasing my own tail!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

05 Dec 2023 12:16 #287263

by tommylight

And ballscrews really do not like the fine metal powder from cutting with plasma, so they would have to be fully covered.

Replied by tommylight on topic Plasma cutter advice please!

To much, 15mm wide HTD3 should do just fine, if the head is not to heavy. Stainless steel or carbon fiber reinforced, preferably the last.For 2.5m travel on plasma x axis can use 30mm wide htd5m belt

I did use rack and pinion but the ones i can find here cause to much vibrations, so i use belts.or must go with rack - pinion?

That will do just fine, but the price is way to high, 20 or 25mm pitch is better for plasma. Still extremely expensive.What about high lead ballscrew (32mm pitch)?

And ballscrews really do not like the fine metal powder from cutting with plasma, so they would have to be fully covered.

Damn, that is some nice profile!I will use aluminum profile shown in image.

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 605

- Thank you received: 17

06 Dec 2023 14:04 - 06 Dec 2023 14:13 #287352

by vre

Replied by vre on topic Plasma cutter advice please!

Rapids 30m/min are ok or can i go upto 60m/min ?

I will use servo motors with reduction and because i need good acceleration

that translates to a lot of torque so i think more stiff belt htd5m 30mm wide is better.

The motor with the pulley will be at the side of profile(not moving with torch) and belt will do loop inside the profile

and outside where the ballscrew is now in the photo so belt will be 5m total length.

@tommylight if you you want this profile check it

vallder.com/product/cnc-x-axis-alu-profile-200x96/

also has a china torch yk that cuts very good.

I will use servo motors with reduction and because i need good acceleration

that translates to a lot of torque so i think more stiff belt htd5m 30mm wide is better.

The motor with the pulley will be at the side of profile(not moving with torch) and belt will do loop inside the profile

and outside where the ballscrew is now in the photo so belt will be 5m total length.

@tommylight if you you want this profile check it

vallder.com/product/cnc-x-axis-alu-profile-200x96/

also has a china torch yk that cuts very good.

Last edit: 06 Dec 2023 14:13 by vre.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

06 Dec 2023 16:31 #287366

by tommylight

Replied by tommylight on topic Plasma cutter advice please!

Usually, 12-18m/m, no need for more speed. My personal ones i keep at 24-36m/m for testing, and one was capable of doing 55m/m all day long.

Cutting is done at max 8m/m, so speed saves time only during moving from one point to another. Of course you can try faster, but you get diminishing returns in cut quality.

-

That is in Bulgaria so i would have to go get it myself there, i can not just order it.

I was in Bulgaria over 50 times!

Cutting is done at max 8m/m, so speed saves time only during moving from one point to another. Of course you can try faster, but you get diminishing returns in cut quality.

-

That is in Bulgaria so i would have to go get it myself there, i can not just order it.

I was in Bulgaria over 50 times!

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.875 seconds