Plasma cutter advice please!

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

20 Dec 2023 17:52 #288679

by machinedude

Replied by machinedude on topic Plasma cutter advice please!

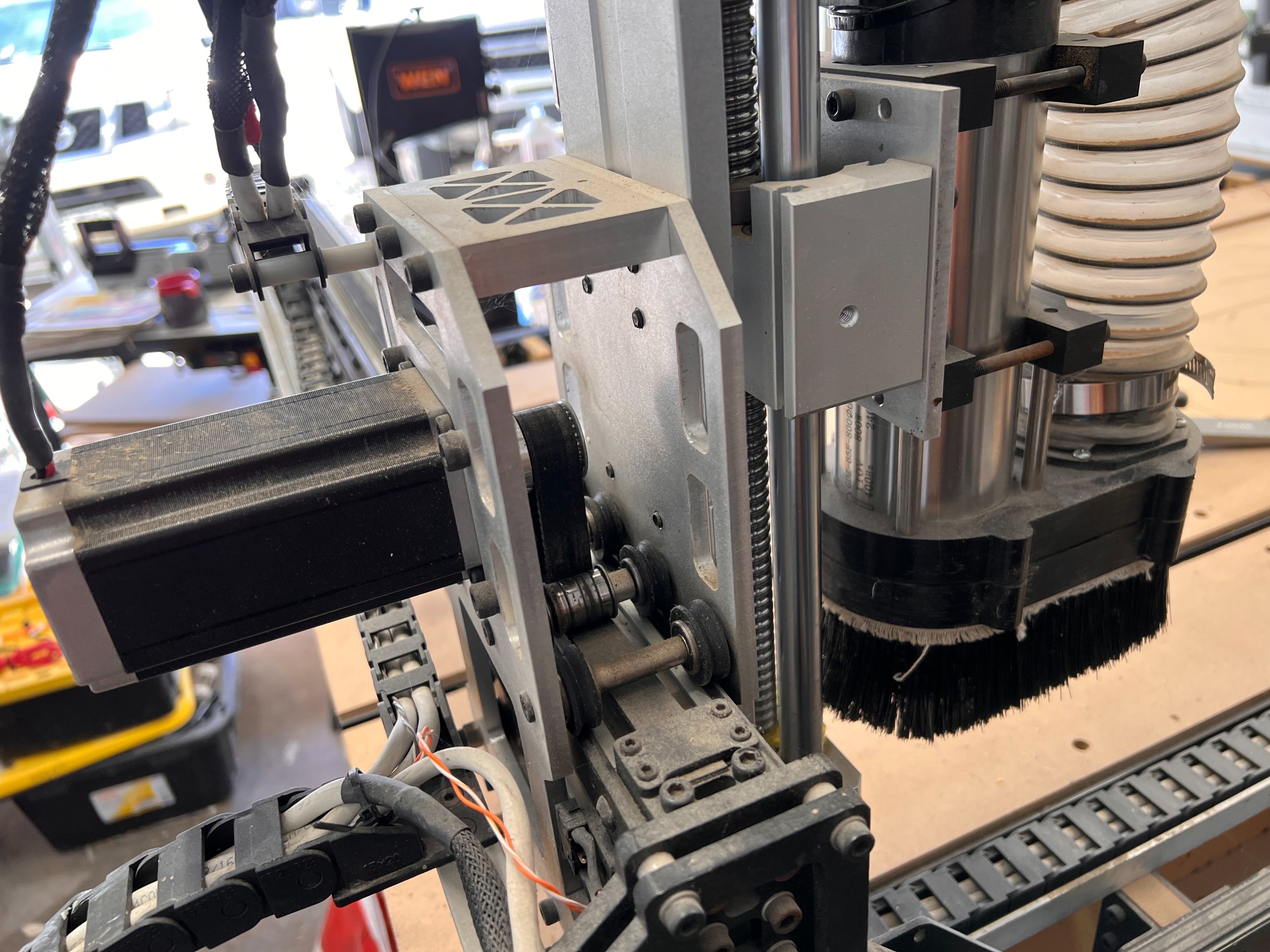

8mm screw with 4 starts with a 8mm lead per rev? looks like a 3D printer screw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

20 Dec 2023 21:22 #288706

by tommylight

Replied by tommylight on topic Plasma cutter advice please!

For Z axis that is fine.8mm screw with 4 starts with a 8mm lead per rev? looks like a 3D printer screw.

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

21 Dec 2023 23:24 #288792

by oddwick

if as machinedude said, thats 8mm/rev, is that fast enough to lift your torch? how do the printed parts hold up to the wear? i really love the double switch for home/probe. that is really brilliant. i definitely see some ideas that i think im going to appropriate there!!

Replied by oddwick on topic Plasma cutter advice please!

done, done, done. sorry, out sick this week and just was able to watch that vid. had client that decided to show up sick rather than miss appointment and now ive been saddled with the cold from hell. i think that getting sick every 4-5 years sounds pretty nice, but when the hammer drops, it really sucks and its usually a debilitating one. but on road to recovery now if i could only find my left lung that i coughed up..Video ... like, subscribe, comment...

I am becoming a youtuber! oh cr@p !!!

forum.linuxcnc.org/show-your-stuff/38547...ild?start=490#288275

if as machinedude said, thats 8mm/rev, is that fast enough to lift your torch? how do the printed parts hold up to the wear? i really love the double switch for home/probe. that is really brilliant. i definitely see some ideas that i think im going to appropriate there!!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20822

- Thank you received: 7097

21 Dec 2023 23:48 #288793

by tommylight

Replied by tommylight on topic Plasma cutter advice please!

Thank you and wishing you fast recovery.

8mm/rev with low inductance Nema 17 and 24V power does reliably 3600mm/m, it does 4200 always, but i lower it just to be safe.

The plastic bits are in use for nearly a year on a machine that gets a lot of use and abuse (ramming the torch on the slats several times a month), nothing gave up or broke yet.

When it does, i will report for sure.

P.S.

while you're at it, see also

@toma.3d

@tomapc

on youtube, those are also mine.

8mm/rev with low inductance Nema 17 and 24V power does reliably 3600mm/m, it does 4200 always, but i lower it just to be safe.

The plastic bits are in use for nearly a year on a machine that gets a lot of use and abuse (ramming the torch on the slats several times a month), nothing gave up or broke yet.

When it does, i will report for sure.

P.S.

while you're at it, see also

@toma.3d

@tomapc

on youtube, those are also mine.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

22 Dec 2023 09:08 #288813

by machinedude

Replied by machinedude on topic Plasma cutter advice please!

on a short axis like Z your not moving very far so rapid rates are not as important here. first you don't have much space to ramp up to speed and second the X and the Y are your bread and butter especially with plasma.

if you can find the torque speed chart for the particular motors you are using with the correct voltage you are running them at you can find out the speed at which you are going to start seeing lost steps from stalling the motors. the higher the voltage the better they will do but things start running warmer so good cooling for the drives is needed if you start push things to the upper limit of what they are rated for.

if you can find the torque speed chart for the particular motors you are using with the correct voltage you are running them at you can find out the speed at which you are going to start seeing lost steps from stalling the motors. the higher the voltage the better they will do but things start running warmer so good cooling for the drives is needed if you start push things to the upper limit of what they are rated for.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

22 Dec 2023 09:13 #288814

by machinedude

Replied by machinedude on topic Plasma cutter advice please!

when you start tuning the Z axis push things to limit then back it off 10 to 20 % for a safety margin.

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

28 Dec 2023 19:50 #289277

by oddwick

Replied by oddwick on topic Plasma cutter advice please!

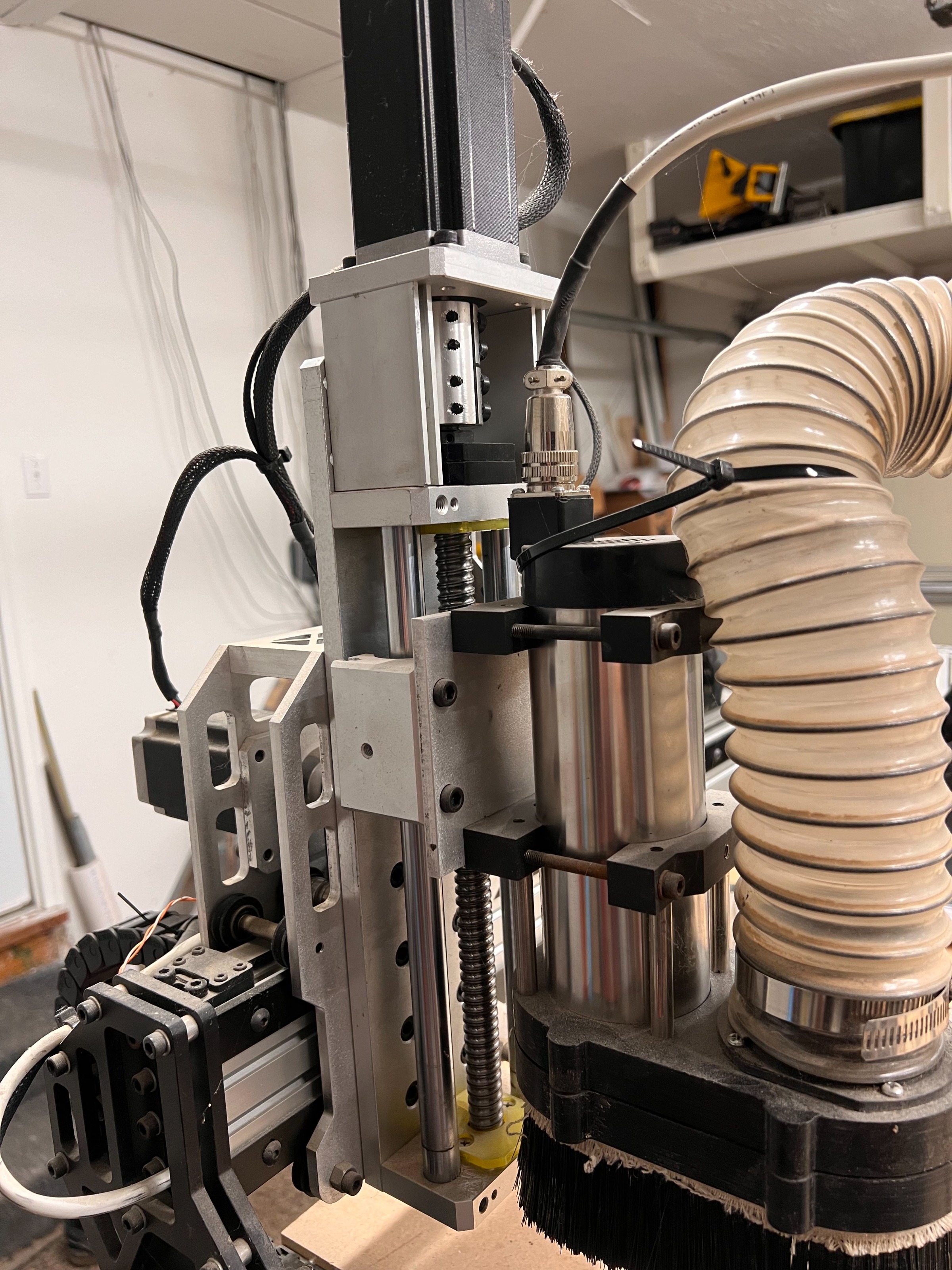

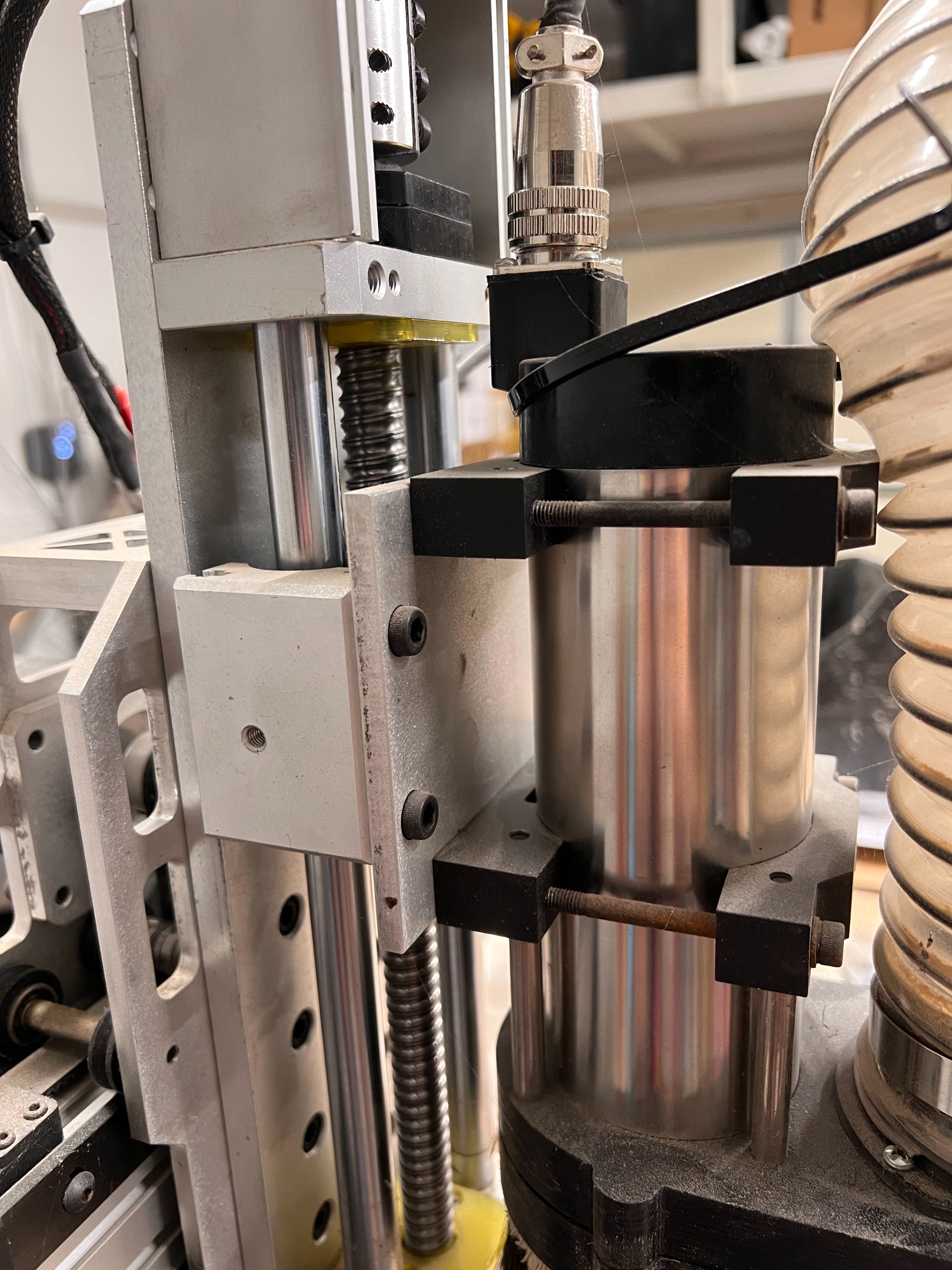

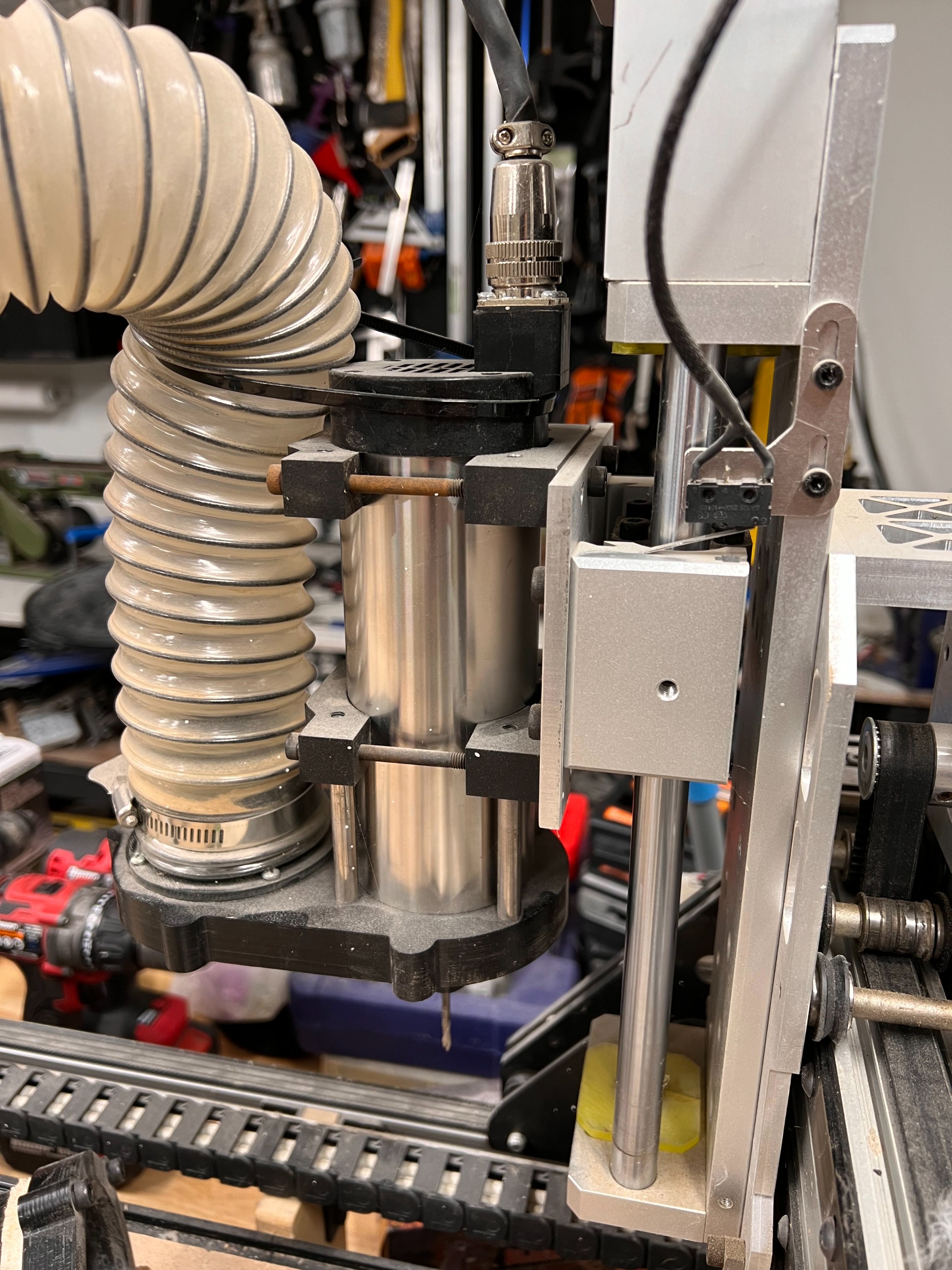

the z axis that i have is a complete unit and i am just going to recycle it for my plasma. it is using a nema 23 directly driving a 1205 ballscrew and has around 6-7" of travel. it is pretty fast and responsive in regards to movement. it is just about worthless for a router tho. the mounting plate on it is only about maybe 50mm high and has some pretty serious flexing issues when under load. like there were times that i would have to run without a dustshoe when doing vcarving becaue the bristles from the shoe would flex it up and the bit would lose contact with the work piece.

i have a pic of the unit, but its not a good angle really. thought i had a better pic. maybe later. but you can see how flimsy the mount is on it. but since a plasma is non contact, it should work fantastically for it. i am definitely going to pilfer a version of tommy's gravity switch. that is brilliant and i have a good idea on how i can incorporate into a torch mount for me. i am also thinking that since its a ballscrew, i really should come up with some version of a dust cover for it just to play it safe. right now i have things on a little bit of a hold just because i am trying to build 2 machines at once and get my house ready to sell and move and move my business. not like having too much on your plate at one time lol!

i have a pic of the unit, but its not a good angle really. thought i had a better pic. maybe later. but you can see how flimsy the mount is on it. but since a plasma is non contact, it should work fantastically for it. i am definitely going to pilfer a version of tommy's gravity switch. that is brilliant and i have a good idea on how i can incorporate into a torch mount for me. i am also thinking that since its a ballscrew, i really should come up with some version of a dust cover for it just to play it safe. right now i have things on a little bit of a hold just because i am trying to build 2 machines at once and get my house ready to sell and move and move my business. not like having too much on your plate at one time lol!

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

30 Dec 2023 01:41 #289351

by machinedude

Replied by machinedude on topic Plasma cutter advice please!

Any kind of roller linear rail that uses T slot extrusion as the rail is bad for any kind of cutting operation. round rails with no support are not that great either for cutting forces. Add all that to a high gantry and it just gets worse yet. T slot extrusion is horrible for torsional deflection on a gantry beam.

a 1205 ball screw has a 5mm pitch so it is actually slower than a 3D printing screw with a 8mm lead. the greater the lead the faster the travel rate but as you move up in speed you loose the torque. all that would come into play based on how heavy things are but you should be fine there. i don't see a plasma torch being heavier than a spindle for a router.

a 1205 ball screw has a 5mm pitch so it is actually slower than a 3D printing screw with a 8mm lead. the greater the lead the faster the travel rate but as you move up in speed you loose the torque. all that would come into play based on how heavy things are but you should be fine there. i don't see a plasma torch being heavier than a spindle for a router.

Please Log in or Create an account to join the conversation.

- oddwick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 19

30 Dec 2023 05:17 - 30 Dec 2023 05:18 #289357

by oddwick

Replied by oddwick on topic Plasma cutter advice please!

yeah it was an early design. i built big before i learned to think big. with what i use it for, its actually not the aluminum extrusions that are my weak point. 99% of my deflection comes from the delrin vgroove wheels and the fact that the mounting point on the z axis is only about 50mm wide. combine that with a high z axis which is always a weak point and it was a recipe for disaster. its replacement will be using aluminum t-slot for the gantry, but 80x160mm heavy beam. according to the the specs, i am looking at < 0.1mm deflection with a load of 100kg. considering it is only for wood and acrylic and occasionally aluminum clad, that is well within my tolerance levels.

this z was an aftermarket unit that i came across and used it as an upgrade for the original one that was using a tr8*4 with a delrin nut, but that was way undersized for a spindle that heavy. this one has a lot of travel, but i just went out and got some better pics of it, and i was mistaken. it is acually a 1605 ballscrew with a pair of 20mm rods. granted a 1605 is slower than a tr8, but i gain in resolution and it of course runs so much smoother than the tr8. originally i had intended to recycle the parts of this machine to create a 'lathe' which was basically a 4 axis with a super short y and horizontal z that i could use to do gun stocks and furniture turnings. but then i decided i could do more with a plasma so the lathe got back burnered until i get better situated.

i know that this z is definitely overkill for a plasma, but i have it and that will keep me from having to buy another one. actually, it would have been tolerable for a router had it only had another set of bearings on the rails and could mount a bigger plate on it. in addition, i am going to recycle the aluminum for the gantry which is again overkill, but i have it and its already the size i plan on using as well as the aluminum rails. so far i have picked up 1500/1000 hgr20 rails to use instead of those stupid v wheels. i have broke so many of those its truly pathetic. i would buy them in bulk just to keep them on hand and never again. well, they were actually great when i first got started, but as i have gotten better and more ambitious, its time to stop beating a dead horse. i got my thcad2 from jt the other day, and of course all the electronics will be swapped over. i may need to order some power supplies because its been a while since ive been inside of the control box and i cant remember if the ones in there are 24v or 48v. i know one machine is 24 and the other 48, but i just cant remember which one is which. my aluminum also got here the week before last, so i can start cutting at least some of the plates. the gantry plates are going to be 10mm and 6.35mm for the x carriage. now all i am waiting on are getting my steel parts cut and my pulleys for the reduction coming in from china. then we seriously start to build!

this z was an aftermarket unit that i came across and used it as an upgrade for the original one that was using a tr8*4 with a delrin nut, but that was way undersized for a spindle that heavy. this one has a lot of travel, but i just went out and got some better pics of it, and i was mistaken. it is acually a 1605 ballscrew with a pair of 20mm rods. granted a 1605 is slower than a tr8, but i gain in resolution and it of course runs so much smoother than the tr8. originally i had intended to recycle the parts of this machine to create a 'lathe' which was basically a 4 axis with a super short y and horizontal z that i could use to do gun stocks and furniture turnings. but then i decided i could do more with a plasma so the lathe got back burnered until i get better situated.

i know that this z is definitely overkill for a plasma, but i have it and that will keep me from having to buy another one. actually, it would have been tolerable for a router had it only had another set of bearings on the rails and could mount a bigger plate on it. in addition, i am going to recycle the aluminum for the gantry which is again overkill, but i have it and its already the size i plan on using as well as the aluminum rails. so far i have picked up 1500/1000 hgr20 rails to use instead of those stupid v wheels. i have broke so many of those its truly pathetic. i would buy them in bulk just to keep them on hand and never again. well, they were actually great when i first got started, but as i have gotten better and more ambitious, its time to stop beating a dead horse. i got my thcad2 from jt the other day, and of course all the electronics will be swapped over. i may need to order some power supplies because its been a while since ive been inside of the control box and i cant remember if the ones in there are 24v or 48v. i know one machine is 24 and the other 48, but i just cant remember which one is which. my aluminum also got here the week before last, so i can start cutting at least some of the plates. the gantry plates are going to be 10mm and 6.35mm for the x carriage. now all i am waiting on are getting my steel parts cut and my pulleys for the reduction coming in from china. then we seriously start to build!

Attachments:

Last edit: 30 Dec 2023 05:18 by oddwick.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.148 seconds