Gui for standalone thc

- bentiggin

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 7

19 Aug 2024 18:01 #308152

by bentiggin

Gui for standalone thc was created by bentiggin

I am working on retrofitting an old cnc plasma.

It has a standalone thc, a hypertherm phc.

Since the thc controls the z axis, the only outputs I think I need for it are cycle start and corner hold/thc off.

Im using a mesa 7i97t so I haven’t be able use mesact to configure it for qtplasmac.

Ive been trying to get it to work in roundabout ways, but the more I learn about qtplasmac, the more I feel like qtplasmac is a poor choice. I love the plasmac look, but it seems way too complicated to make it work with no z, no probe/ohmic, and not being integrated with gcode that wouldn’t be used with my setup.

So I’m trying to figure out which gui would give me the best start for a simple plasma with minimal inputs and outputs. Should I continue trying to use qtplasmac or would axis, gmoccapy, or? be a better choice.

I used to use sheet cam for a mach3 plasma that I had set for super simple gcode. I’d like to use sheetcam again, and keep the gcode simple.

It has a standalone thc, a hypertherm phc.

Since the thc controls the z axis, the only outputs I think I need for it are cycle start and corner hold/thc off.

Im using a mesa 7i97t so I haven’t be able use mesact to configure it for qtplasmac.

Ive been trying to get it to work in roundabout ways, but the more I learn about qtplasmac, the more I feel like qtplasmac is a poor choice. I love the plasmac look, but it seems way too complicated to make it work with no z, no probe/ohmic, and not being integrated with gcode that wouldn’t be used with my setup.

So I’m trying to figure out which gui would give me the best start for a simple plasma with minimal inputs and outputs. Should I continue trying to use qtplasmac or would axis, gmoccapy, or? be a better choice.

I used to use sheet cam for a mach3 plasma that I had set for super simple gcode. I’d like to use sheetcam again, and keep the gcode simple.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

19 Aug 2024 18:08 #308153

by tommylight

Replied by tommylight on topic Gui for standalone thc

Does it also do Initial Height Sensing on its own?

Please Log in or Create an account to join the conversation.

- bentiggin

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 7

19 Aug 2024 18:17 #308154

by bentiggin

Replied by bentiggin on topic Gui for standalone thc

Yes. But it doesn’t have a specific input for it. It has a cycle start input that will cause it to initial height sense and start the arc. It also has a switch for doing the initial height sense.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

19 Aug 2024 19:14 #308158

by tommylight

Replied by tommylight on topic Gui for standalone thc

forum.linuxcnc.org/forum/show-your-stuff...ter-with-ihs-and-ahc

Same thing, been in daily use for over 8 years now. It also had its own THC so no wiring or programming was required for it.

Torch cycle is wired in hal and physically to M3, and the arc ok from plasma is wired to motion inhibit in hal so the machine does not move until the torch is actually on and cutting.

It uses Axis GUI as is, not PlasmaC nor QtPlasmaC.

Same thing, been in daily use for over 8 years now. It also had its own THC so no wiring or programming was required for it.

Torch cycle is wired in hal and physically to M3, and the arc ok from plasma is wired to motion inhibit in hal so the machine does not move until the torch is actually on and cutting.

It uses Axis GUI as is, not PlasmaC nor QtPlasmaC.

Please Log in or Create an account to join the conversation.

- bentiggin

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 7

19 Aug 2024 20:49 #308167

by bentiggin

Replied by bentiggin on topic Gui for standalone thc

That looks similar to what I’m trying to do.

Id like the gui to not have a whole bunch of unnecessary clutter and just add a few buttons and indicators.

Looking in the linuxcnc manual, under axis customization hints, I see “difficult to customize.”

That statement makes me hesitant, since I’m just a beginner with linuxcnc.

So would you still recommend axis even if I’m a complete beginner?

Is gmoccapy easier for a beginner to customize?

Or should someone like me just focus getting a working machine and minimize customizing?

I’d hate to go through this retrofit and have a screen that looks like it should be on a mill, but I can get over that if it’s unrealistic for a newbie set up a custom plasma display.

Id like the gui to not have a whole bunch of unnecessary clutter and just add a few buttons and indicators.

Looking in the linuxcnc manual, under axis customization hints, I see “difficult to customize.”

That statement makes me hesitant, since I’m just a beginner with linuxcnc.

So would you still recommend axis even if I’m a complete beginner?

Is gmoccapy easier for a beginner to customize?

Or should someone like me just focus getting a working machine and minimize customizing?

I’d hate to go through this retrofit and have a screen that looks like it should be on a mill, but I can get over that if it’s unrealistic for a newbie set up a custom plasma display.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

20 Aug 2024 08:59 #308200

by rodw

Replied by rodw on topic Gui for standalone thc

Start with Axis always... move to another GUI once you have a good moving machine.

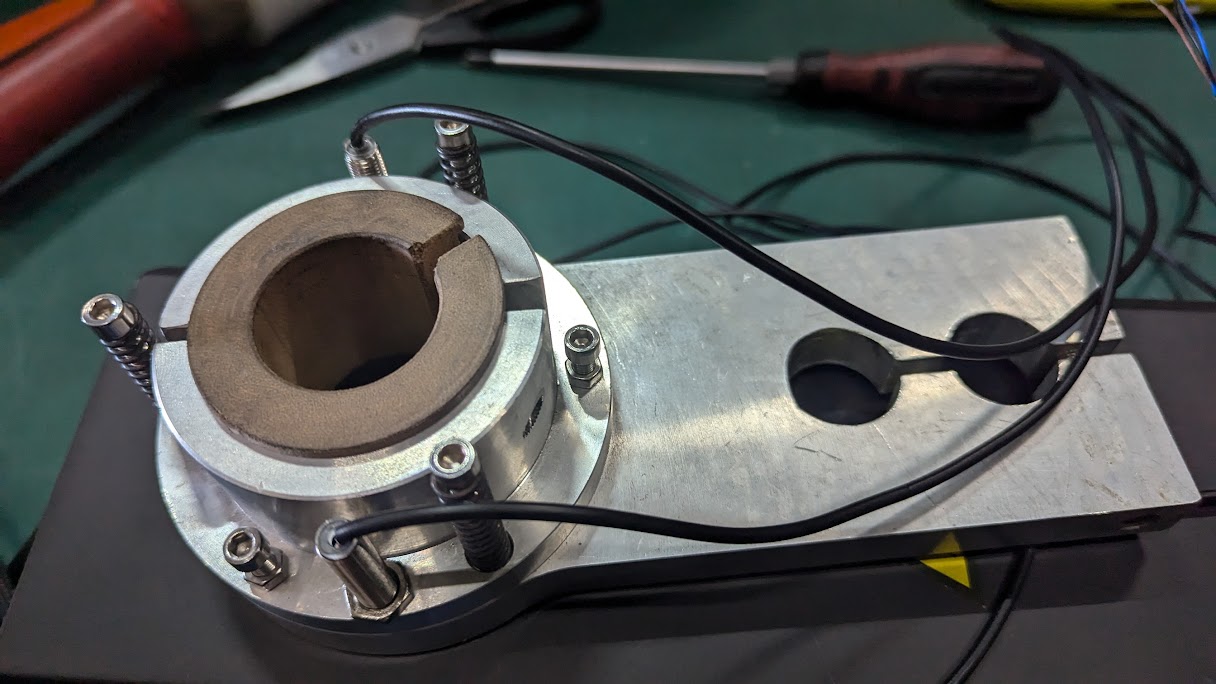

As an alternative view point, a stepper driven torch lifter with float switch and breakaway costs about $500. I just shipped a 72 kg QTplasmac controller package today, and we are replacing a motor driven torch lifter. He is also getting a 433 mhz wireless pendant. The client is really excited about the addidtional safety features he will get like breakaway, probe pausing motion if triggered by cutting and moving from DM542 drivers on 24 volts to Lam Technologies DS1076 drivers with 60 volt AC power, high quality Moon's motors with custom made 5:1 planetary gearboxes will lift this old slug into orbit!

Here is the lifter (200mm travel)

As an alternative view point, a stepper driven torch lifter with float switch and breakaway costs about $500. I just shipped a 72 kg QTplasmac controller package today, and we are replacing a motor driven torch lifter. He is also getting a 433 mhz wireless pendant. The client is really excited about the addidtional safety features he will get like breakaway, probe pausing motion if triggered by cutting and moving from DM542 drivers on 24 volts to Lam Technologies DS1076 drivers with 60 volt AC power, high quality Moon's motors with custom made 5:1 planetary gearboxes will lift this old slug into orbit!

Here is the lifter (200mm travel)

Attachments:

Please Log in or Create an account to join the conversation.

- bentiggin

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 7

20 Aug 2024 21:58 #308247

by bentiggin

Replied by bentiggin on topic Gui for standalone thc

Well, I guess I’m stuck and didn’t explain my issue.

I set up a config in axis. X and y axis move appropriately when jogged, and the dro displays accordingly.

My 4 limit/home switches trigger in halshow. The limits will trigger machine power button.

My 2 inputs trigger digital inputs in halshow.

My 2 outputs get triggered when commanded in halshow.

And I don’t know where to go from here. I’m stuck. If I bought a new lifter, I’d be stuck in the same spot.

I obviously need to link the I/o’s to functions/buttons/gcode, but I don’t know how.

Im reading the manual and trying sample axis configurations, but I just can’t get anywhere.

Like input 1 is the breakaway. But I can’t figure out how to tell that to linuxcnc.

I thought maybe I can just copy the limit switches, but I don’t even see how they trigger the machine off button in any of the hal or ini files.

And if I can’t figure out the breakaway, I don’t have much hope for cycle start or thc hold.

Is it rude to ask for a plasma specific axis configuration?

I appreciate the input, I just wish knew enough to ask the right questions.

Rodc, I assumed you suggested the lifter for functionality, but maybe you’re actually telling me to use a lifter that integrates with qtplasmac. I did consider using Linuxcnc to control the z motor and read arc volts with a mesa thcad instead of the standalone hypertherm phc control, but I thought that just sounded like more work, more money, and more potential pit falls. But in retrospect maybe I should’ve done that just to make it easy to use qtplasmac. And a mesa card that works with pncconf instead of mesact

I set up a config in axis. X and y axis move appropriately when jogged, and the dro displays accordingly.

My 4 limit/home switches trigger in halshow. The limits will trigger machine power button.

My 2 inputs trigger digital inputs in halshow.

My 2 outputs get triggered when commanded in halshow.

And I don’t know where to go from here. I’m stuck. If I bought a new lifter, I’d be stuck in the same spot.

I obviously need to link the I/o’s to functions/buttons/gcode, but I don’t know how.

Im reading the manual and trying sample axis configurations, but I just can’t get anywhere.

Like input 1 is the breakaway. But I can’t figure out how to tell that to linuxcnc.

I thought maybe I can just copy the limit switches, but I don’t even see how they trigger the machine off button in any of the hal or ini files.

And if I can’t figure out the breakaway, I don’t have much hope for cycle start or thc hold.

Is it rude to ask for a plasma specific axis configuration?

I appreciate the input, I just wish knew enough to ask the right questions.

Rodc, I assumed you suggested the lifter for functionality, but maybe you’re actually telling me to use a lifter that integrates with qtplasmac. I did consider using Linuxcnc to control the z motor and read arc volts with a mesa thcad instead of the standalone hypertherm phc control, but I thought that just sounded like more work, more money, and more potential pit falls. But in retrospect maybe I should’ve done that just to make it easy to use qtplasmac. And a mesa card that works with pncconf instead of mesact

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5162

21 Aug 2024 00:08 - 21 Aug 2024 00:15 #308251

by PCW

Replied by PCW on topic Gui for standalone thc

Unfortunately to do this by hand does require learning some hal

commands and components because on most there would be some

logic or gating involved, but as a very simple example with no added

logic:

net breakaway joint.0.amp-fault-in hm2_7i97.0.inmux.00.input-05

Note that joint.0.amp-fault-in and hm2_7i97.0.inmux.00.input-05 are both pins that

exist in your running LinuxCNC configuration, the net command simple connects them.

The "breakaway" is the name of the signal that connects the pins. Its an arbitrary name

unless it's already defined somewhere else.

For example:

net brown_wire joint.0.amp-fault-in hm2_7i97.0.inmux.00.input-05

will function identically (though perhaps be a bit harder to understand)

This statement will cause a fault and stop motion if hm2_7i97.0.inmux.00.input-05 goes high

You might need to use hm2_7i97.0.inmux.00.input-05-not depending on your

switch wiring.

(the input number is up to you, just used 05 in this example)

commands and components because on most there would be some

logic or gating involved, but as a very simple example with no added

logic:

net breakaway joint.0.amp-fault-in hm2_7i97.0.inmux.00.input-05

Note that joint.0.amp-fault-in and hm2_7i97.0.inmux.00.input-05 are both pins that

exist in your running LinuxCNC configuration, the net command simple connects them.

The "breakaway" is the name of the signal that connects the pins. Its an arbitrary name

unless it's already defined somewhere else.

For example:

net brown_wire joint.0.amp-fault-in hm2_7i97.0.inmux.00.input-05

will function identically (though perhaps be a bit harder to understand)

This statement will cause a fault and stop motion if hm2_7i97.0.inmux.00.input-05 goes high

You might need to use hm2_7i97.0.inmux.00.input-05-not depending on your

switch wiring.

(the input number is up to you, just used 05 in this example)

Last edit: 21 Aug 2024 00:15 by PCW.

Please Log in or Create an account to join the conversation.

- bentiggin

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 7

21 Aug 2024 01:21 #308255

by bentiggin

Replied by bentiggin on topic Gui for standalone thc

I know it’s hard to tell by my dumb questions, but learning some Hal commands and components is exactly what I’m trying to do.

so I added your joint.0.amp-fault-in and it works exactly as you stated. Awesome.

How do I learn this? I’m currently flipping through the Hal part of the manual and I don’t see anything about amp-fault.

Is there a reference list for Hal commands?

I now see it in Hal show, under pin/joint/0/amp-fault-in. Can I find description of these somewhere?

so I added your joint.0.amp-fault-in and it works exactly as you stated. Awesome.

How do I learn this? I’m currently flipping through the Hal part of the manual and I don’t see anything about amp-fault.

Is there a reference list for Hal commands?

I now see it in Hal show, under pin/joint/0/amp-fault-in. Can I find description of these somewhere?

Please Log in or Create an account to join the conversation.

- bentiggin

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 7

21 Aug 2024 01:40 #308256

by bentiggin

Replied by bentiggin on topic Gui for standalone thc

I now I want something like this.

Hit execute gcode file.

g0 x10 y10

m3-> activates hm2_7i97.0.ssr.00.out-00

this should make the thc do its height sense, then fire the arc. Then send arc-ok to hm_7i97.0.inmux.00.input-04.

and linuxcnc should should follow file from there.

Id also like to send a corner hold signal, but that seems a bit more complicated

Hit execute gcode file.

g0 x10 y10

m3-> activates hm2_7i97.0.ssr.00.out-00

this should make the thc do its height sense, then fire the arc. Then send arc-ok to hm_7i97.0.inmux.00.input-04.

and linuxcnc should should follow file from there.

Id also like to send a corner hold signal, but that seems a bit more complicated

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.182 seconds