Powermax 45xp lost arc delay (Solved)

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

The hard thing is that I could get it to work by moving the ground clamp closer to the cutting location for a while then the problem would pop back up. So I'd turn off the cutter and back on and that would sometimes allow it to cut again and sometimes not. Then I'd hit the pulse button and that seemed to get it to cut sometimes and sometimes not.

So I suspect none of those things actually effected anything and it was just intermittent and tricking me. Also the fact it is intermittent makes it hard to duplicate for serious testing and fixing.

Seems a lot similar to:

"It may be of importance to note: When this was all going on, with the SSR, I noticed that if i had the ground clamp near the torch I had a MUCH higher chance (but not always and the length of time the pilot arc was stable varied) of getting a reliable pilot arc. If I took the ground clamp off the table, it would never fire."

From this post

Yes, agreed. I sense a mechanical relay in my future but still want to try some hal scoping to ensure I have proper delay set for the THC.

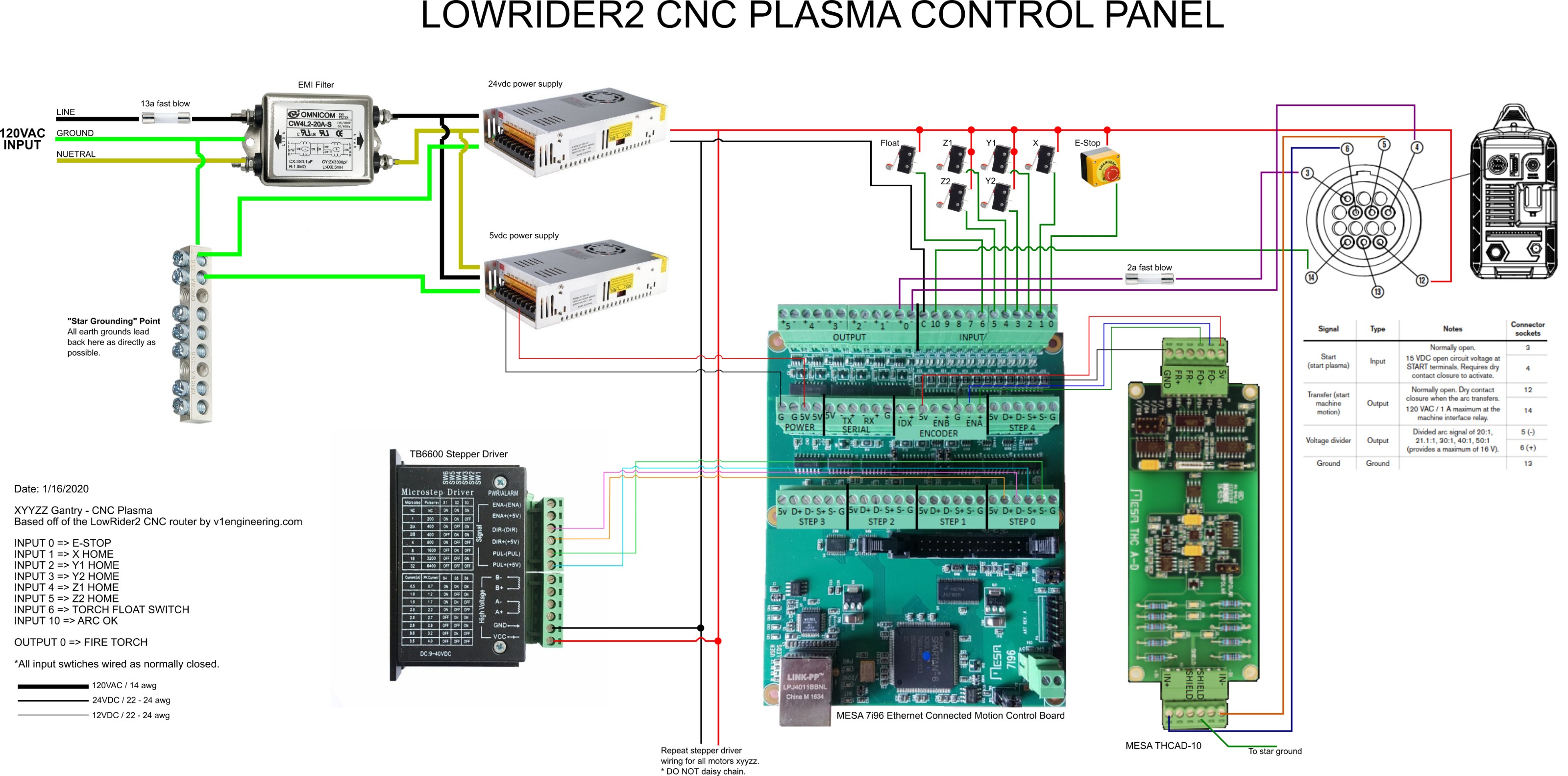

Also the polarity theory is interesting that Rod just mentioned. I have mine wired like in the attached picture.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 10747

- Thank you received: 3543

Also the polarity theory is interesting that Rod just mentioned. I have mine wired like in the attached picture.

Its not a theory. Its fact!

Interesting that you have the polarity marked on your 7i96 but the Plasma cutters are silent on polarity. (probably becasue it does not matter on a mechanical relay which was probably what was widely in use when the docs were written years ago...)

For my Thermal Dynamics A120 plasma cutter

pin 3 = spindle ENA -

pin4 = spindle ENA+

On your diagram you have the polarity reversed. I wonder if all these issues can be traced back to the one circuit diagram as this is not the first time I've seen your schematic?

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

Also the polarity theory is interesting that Rod just mentioned. I have mine wired like in the attached picture.

Its not a theory. Its fact!

Interesting that you have the polarity marked on your 7i96 but the Plasma cutters are silent on polarity. (probably becasue it does not matter on a mechanical relay which was probably what was widely in use when the docs were written years ago...)

For my Thermal Dynamics A120 plasma cutter

pin 3 = spindle ENA -

pin4 = spindle ENA+

On your diagram you have the polarity reversed. I wonder if all these issues can be traced back to the one circuit diagram as this is not the first time I've seen your schematic?

Sorry Rod. "Theory" was the wrong word to use.

Maybe that is it then for me too. Polarity backwards. Too bad Hypertherm doesn't list it in their manual like TD does. I'll try swapping the wires before I do anything else. That way we are only testing one variable at a time to ensure we know what exactly fixed it. Hope to get a chance to go freeze tomorrow.

Unless you think that is a bad idea. I read over in another post that switching the polarity will start the torch in the on position.

forum.linuxcnc.org/27-driver-boards/3659...96-and-thcad?start=0

Second post.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2394

- Thank you received: 782

Second post.

(just as a who's who in case you're curious) PCW is the guy who designed and sells all of the MESA hardware. Having the polarity reversed will just cause the torch to stick on (I did see that with the MOSFET type SSR I used) so be careful there. Since your torch is not stuck on on powerup, you have it correct currently.

I do find it interesting that you described the exact same thing I described regarding the ground clamp proximity to the torch. 99.95% chance it will go away with a mechanical relay.

You don't even have to get a mechanical relay to test whether or not it will fix your problem. Move the ground clamp off the table so it's not contacting any nearby metal (or just disconnect it from the front of the Hypertherm) so that it's not firing correctly by pulsing the torch in the GUI. Disconnect the two torch on wires from the output of the 7i96. Touch them together, if it fires perfectly, you have your answer.

Just my $0.02 but HALScoping your THC delay is definitely a prudent step in calibrating your table, that said I think it comes after getting a torch/cut start issue fixed. If you can't start a cut reliably, you aren't likely to get reliable data regarding when to allow the THC to be in charge.

Hopefully you get cutting reliably soon! I feel you on the cold thing, been really chilly lately over here in PA as well.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 10747

- Thank you received: 3543

Hopefully you get cutting reliably soon! I feel you on the cold thing, been really chilly lately over here in PA as well.

Where's the snowgoer! You of all people complaining about the cold...

Actually, now that Plasmac has a setting to ignore ArcOK, It would be worth doing some tests with ArcOK disabled becasue that would isolate testing to just the torch start.

The torch start and ArcOK are separated by milliseconds and are closely related (eg if you don't get an arcOK, the torch will turn off). The only way you can measure them is to use halscope.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2394

- Thank you received: 782

Hopefully you get cutting reliably soon! I feel you on the cold thing, been really chilly lately over here in PA as well.

Where's the snowgoer! You of all people complaining about the cold...

Supposed to get 6-9" of snow tonight into Friday. More if the storm tracks further North. Pretty excited about that. Luckily my name isn't "coldgoer" ... testing on the actual plasma table is less fun when you cant feel your fingers after a few minutes lol. Heat takes too long to justify turning it on for even an hour session of testing. brr...

Actually, now that Plasmac has a setting to ignore ArcOK, It would be worth doing some tests with ArcOK disabled becasue that would isolate testing to just the torch start.

The torch start and ArcOK are separated by milliseconds and are closely related (eg if you don't get an arcOK, the torch will turn off). The only way you can measure them is to use halscope.

I'd agree with you if he didn't describe the exact same ground-clamp-proximity-to-torch-affecting-the-reliability-of-a-stable-pilot-arc issue I had while using an SSR.

I understand why you're suggesting ignoring arc-ok, but speaking for my experience with my table, ignoring arc-ok didn't help either. The whole thing really gets you chasing your tail. While I was narrowing down root cause, I would sometimes have established cuts that died for no apparent reason in the middle of the cut (in 1/2" thick flat no-rust material), and this was while I was ignoring arc-ok to try to eliminate variables, and since ignoring arc-ok disables the THC, that was ruled out as well.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 10747

- Thank you received: 3543

Both have to use a relay on outputs

I started with a mechanical relay and replaced it with a Mosfet relay a couple of years ago.

Snowgoer started with a Mosfet relay and replaced it with a mechanical relay.

I'm going to assume there is little difference in the triggering of a Hyperthem and Thermal Dynamics machines. After all, they seem to behave the same way if the circuit is active low..

So the question is why does a Mosfet relay work for me and not for Snowgoer on the same circuit.?

The answer has to be the relays are different.

Now robertspark gave us an additional datapoint

I've just stuck my ammeter on the PMX45 and this time I got the current rising to about 15.1mA in a little over a minute.

It would be nice to know what the current draw was at the start of that one minute becasue thats the timeframe I'm hearing.

In the same post, Robert also flagged a possible issue in a cryptic way.

Load current 0.0025...6 A (i.e. 2.5mA minimum current? .... possible issue??))

So Snowgoers relay has a current range of 2.6 mA to 6 amps

My Relay has a range from 1 mA to 0.5 amps.

I think it can be concluded that my relay is more suited to the task and Snowgoer's is close to that pesky minimum current again which is the "possible issue" Robert was alluding to.

So the 7i76/7i76 spindle relay works for me, why wouldn't it work for snowgoer? That point we don't know yet. I think we need to call upon the test pilot to confirm this

Then we have PhillC switching his 30 amp plasma directly with a 7i96 output

Sorry to be continuing this but there is something here we don't yet understand but we are converging on discovering whats going on.

one thing we have proven is that becasue of my experience, is that some MOSFET relays will work! Its just that you need to choose wisely!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19419

- Thank you received: 6513

Those are the issues in all of the above, i would hate to see this topic concluding SSR are not good for plasma as that is the way it is going so far, besides Phill and Rod who are using them, but reading the whole topic Rod seems to be against them and for them !?!?!?

SSR are used in all kinds of switching environments, from welders (have one) to high power metal melting furnaces, but plasma is altogether another beast due to so much interference it creates. So i do agree with PCW that using an SSR should work properly.

Normal relays are immune to any interference, so using them is the easy way out, and if everything else works then by all means do use them. Chasing the above mentioned issues can take long and sometimes can not be found with a magnifying glass, but most of the time it is something simple in the wiring causing such hiccups.

Moving the ground clamp to vary the failure rate should have been a very good clue something in the wiring is not OK.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2394

- Thank you received: 782

And I know you are omitting OP, but it's reasonable at this point (humor me here even though I know you're likely not to agree) to say that he's also not successful with the 7i96 SSR.

Also, it's worth considering that if everyone who is using an SSR (on a MESA card or otherwise) has the ground clamp already on the table, or near by the torch, or permanently affixed to the table, they might not see the full brunt of the issue and are blaming dropped arcs and what not on something else. Ground clamp proximity does play a part in all of this.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2394

- Thank you received: 782

Interference, missing ground, ground loops, wiring ( boards not at the same potential ), etc.

Those are the issues in all of the above, i would hate to see this topic concluding SSR are not good for plasma as that is the way it is going so far, besides Phill and Rod who are using them, but reading the whole topic Rod seems to be against them and for them !?!?!?

SSR are used in all kinds of switching environments, from welders (have one) to high power metal melting furnaces, but plasma is altogether another beast due to so much interference it creates. So i do agree with PCW that using an SSR should work properly.

Normal relays are immune to any interference, so using them is the easy way out, and if everything else works then by all means do use them. Chasing the above mentioned issues can take long and sometimes can not be found with a magnifying glass, but most of the time it is something simple in the wiring causing such hiccups.

Moving the ground clamp to vary the failure rate should have been a very good clue something in the wiring is not OK.

Yea, I tend to agree there is probably more going on here. For me the thing in the wiring that wasn't ok was the SSR. Was that ultimately a symptom of a larger problem? Probably. That said, I go back to the fact that when the Hypertherm manual calls for dry contact closure; they are looking for a mechanical relay. They describe their internal arc ok relay as "provides dry contact closure" and I know for a 100% fact hypertherm uses a mechanical relay for arc-ok. Did Hypertherm use the wrong technical term? Probably.

That said, I have shielded cables, good grounds, etc.

Should be able to use an appropriate SSR in place of a mechanical relay and can successfully use one are two totally different things. I agree in theory they're better, that's why I tried one. In practice, for me, and a few others, they do not work in this application.

Please Log in or Create an account to join the conversation.