Access probing parameters while running a job.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11727

- Thank you received: 3972

19 Oct 2021 06:25 #223522

by rodw

Access probing parameters while running a job. was created by rodw

Well, I am finally using QTplasmac on Debian 11 Bullseye with a Python 3 only version of Linuxcnc in production. Matter of fact, QTPlasmac is operating flawlessly near the end of a big nest on 2mm as I write this!

I've always been keen to enhance the probing speed on a job as this can have a massive difference on cycle time. To do this I like to have my probe height about 8-10mm above the material so it rapids down most of the way. But the problem is the material has warped up to 40mm during the job so the torch hits the material at rapid speed. Plasmac recovers perfectly from this but the material is very springy under these conditions so it can take a long time to back off the sheet to complete the probing sequence.

What I would like to be able to do is alter the probe height and safe height during a job on the fly to account for this warpage. Eg start with a 10mm probe height but alter it to 50mm when the sheet has warped up. This would ensure the contact with the material is super gentle and with minimal movement of the material. This would significantly increase cycle times where lots of pierces are involved. But I can't access these settings becasue the parameters tab is disabled when running a job.

An even better solution would be for QTplasmac to remember the material height from the last probe and set the probe height to say 10mm above that material and the safe height to be set say 20mm above that height. This would keep everything going along nicely

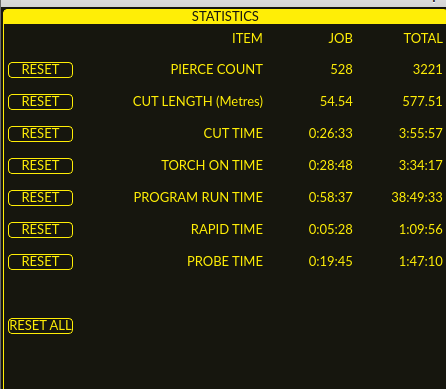

as you can see this job too 58 minutes to cut of which 20 minutes was probing. It would be nice if we could halve the probing time cos I have 2 more nests like this to cut before I go home

I've always been keen to enhance the probing speed on a job as this can have a massive difference on cycle time. To do this I like to have my probe height about 8-10mm above the material so it rapids down most of the way. But the problem is the material has warped up to 40mm during the job so the torch hits the material at rapid speed. Plasmac recovers perfectly from this but the material is very springy under these conditions so it can take a long time to back off the sheet to complete the probing sequence.

What I would like to be able to do is alter the probe height and safe height during a job on the fly to account for this warpage. Eg start with a 10mm probe height but alter it to 50mm when the sheet has warped up. This would ensure the contact with the material is super gentle and with minimal movement of the material. This would significantly increase cycle times where lots of pierces are involved. But I can't access these settings becasue the parameters tab is disabled when running a job.

An even better solution would be for QTplasmac to remember the material height from the last probe and set the probe height to say 10mm above that material and the safe height to be set say 20mm above that height. This would keep everything going along nicely

as you can see this job too 58 minutes to cut of which 20 minutes was probing. It would be nice if we could halve the probing time cos I have 2 more nests like this to cut before I go home

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.195 seconds