QTPlasmac interpreting Sheetcam material selection, M190

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

23 Jun 2022 02:02 #245640

by LinfieldGarage

QTPlasmac interpreting Sheetcam material selection, M190 was created by LinfieldGarage

Hello All,

I was working on aligning both Sheetcam and the QTPlasmac materials lists when I noticed QTP doing something odd. I grabbed the Hypertherm materials and Plasmac materials lists from the forum and imported them into both Sheetcam and QTP successfully.

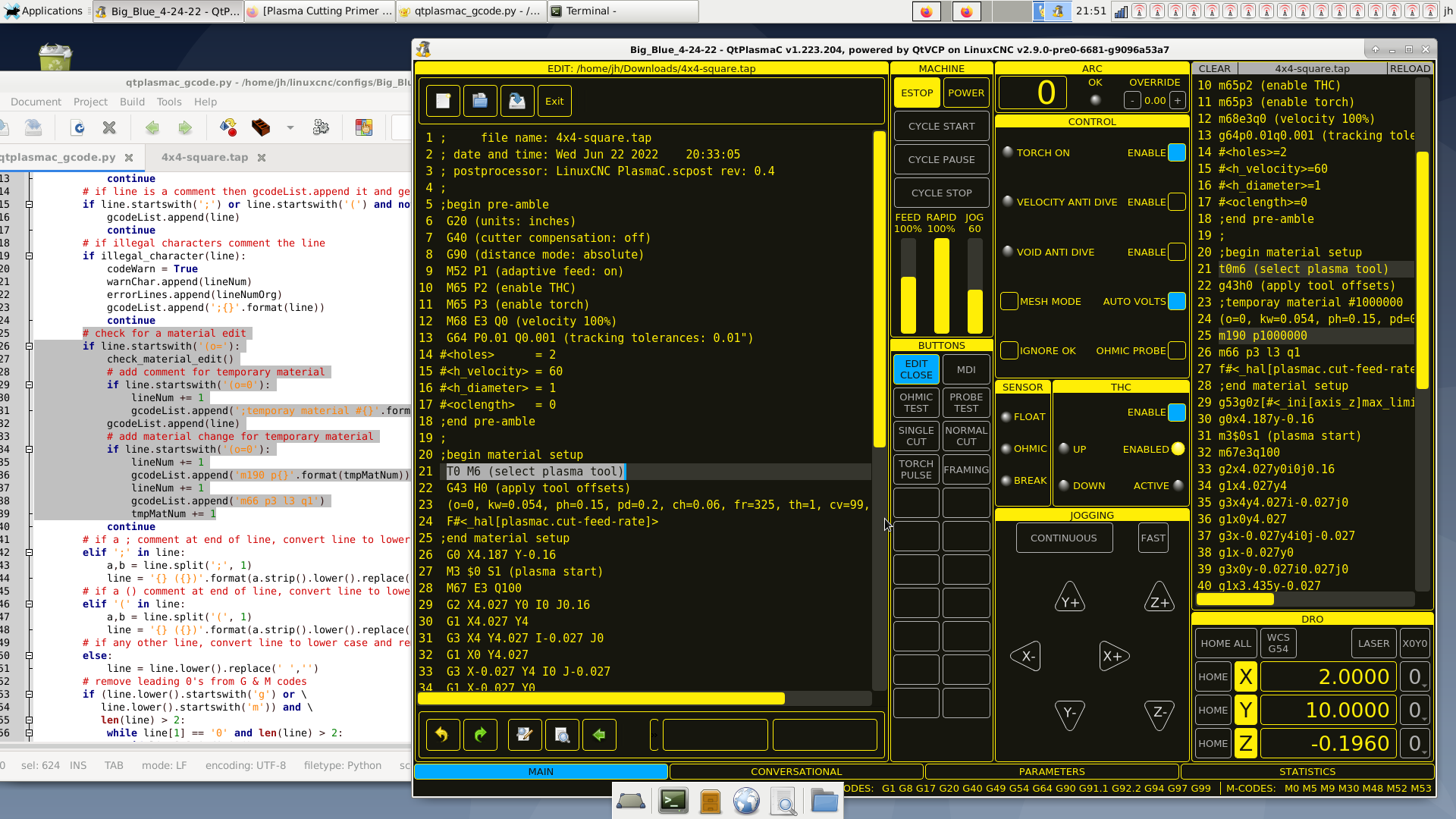

In the screenshot below you can see that the Gcode output by Sheetcam is trying to call material 6 on line 21. On line 23 you see o=0, and the other material settings.

In the interpreted Gcode on the right, you see that QTP ignored the "T0 M6" line, and added "m190 1000000" on line 25. I opened the QTP python code and found the section that deals with m190 (including the typo which helped me find this). It seems to create a temporary material 1000000 when it doesn't know what else to do. This caused the machine to run the Default material settings, not the actual material 6 settings.

Do we know if the Sheetcam PP is outputting materials incorrectly, if that "o=0" should be something else, or if I have something setup wrong?

Thanks in advance,

Jamie

I was working on aligning both Sheetcam and the QTPlasmac materials lists when I noticed QTP doing something odd. I grabbed the Hypertherm materials and Plasmac materials lists from the forum and imported them into both Sheetcam and QTP successfully.

In the screenshot below you can see that the Gcode output by Sheetcam is trying to call material 6 on line 21. On line 23 you see o=0, and the other material settings.

In the interpreted Gcode on the right, you see that QTP ignored the "T0 M6" line, and added "m190 1000000" on line 25. I opened the QTP python code and found the section that deals with m190 (including the typo which helped me find this). It seems to create a temporary material 1000000 when it doesn't know what else to do. This caused the machine to run the Default material settings, not the actual material 6 settings.

Do we know if the Sheetcam PP is outputting materials incorrectly, if that "o=0" should be something else, or if I have something setup wrong?

Thanks in advance,

Jamie

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

23 Jun 2022 02:16 #245642

by phillc54

Replied by phillc54 on topic QTPlasmac interpreting Sheetcam material selection, M190

t0m6 is selecting the torch, if you had a scribe it would be selected with t1m6

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_scribe

material #6 would be m190p6

linuxcnc.org/docs/devel/html/plasma/qtpl...ic_material_handling

o=0 creates a temporary material

linuxcnc.org/docs/devel/html/plasma/qtpl...ml#qt_magic-comments

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_scribe

material #6 would be m190p6

linuxcnc.org/docs/devel/html/plasma/qtpl...ic_material_handling

o=0 creates a temporary material

linuxcnc.org/docs/devel/html/plasma/qtpl...ml#qt_magic-comments

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

23 Jun 2022 02:23 #245644

by LinfieldGarage

Replied by LinfieldGarage on topic QTPlasmac interpreting Sheetcam material selection, M190

Hey guys,

I answered my own question. Here is what I did for documentation's sake.

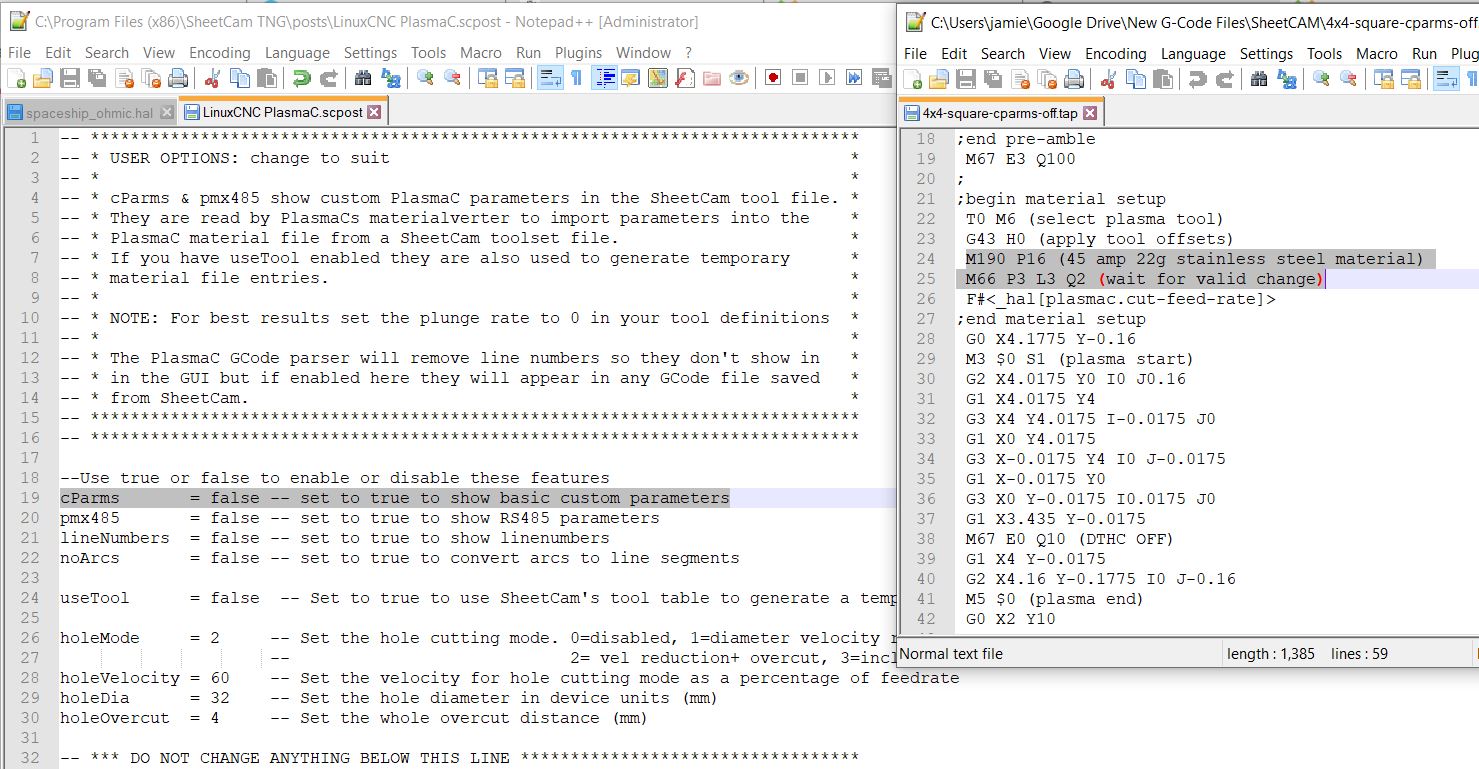

In the Sheetcam PP there is an option called cparms (custom parameters). When "cparms=true" it outputs extra commands that caused the behavior I noticed.

When "cparms=false" the Sheetcam PP outputs the correct material choice in the proper M190 format. See screenshot for an example of the corrected Gcode.

Hope this helps someone someday.

I answered my own question. Here is what I did for documentation's sake.

In the Sheetcam PP there is an option called cparms (custom parameters). When "cparms=true" it outputs extra commands that caused the behavior I noticed.

When "cparms=false" the Sheetcam PP outputs the correct material choice in the proper M190 format. See screenshot for an example of the corrected Gcode.

Hope this helps someone someday.

Attachments:

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

23 Jun 2022 02:25 #245646

by LinfieldGarage

Replied by LinfieldGarage on topic QTPlasmac interpreting Sheetcam material selection, M190

Thank you Phil,

Makes perfect sense. I think I have her figured out now.

Makes perfect sense. I think I have her figured out now.

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

23 Jun 2022 12:29 #245673

by LinfieldGarage

Replied by LinfieldGarage on topic QTPlasmac interpreting Sheetcam material selection, M190

Hey Phil,

I wanted to say thanks again for taking the time to post these links. I was reading the manpages on my Linuxcnc machine but not getting the details so clearly. The links you posted seem more complete and make more sense.

I sort of reverse engineered the whole material handling thing based on the behavior I saw in the files I posted, but the doc links you posted tell the whole story. It is a cool system that you guys have developed.

Thanks again for all the help you provide on this forum.

J

I wanted to say thanks again for taking the time to post these links. I was reading the manpages on my Linuxcnc machine but not getting the details so clearly. The links you posted seem more complete and make more sense.

I sort of reverse engineered the whole material handling thing based on the behavior I saw in the files I posted, but the doc links you posted tell the whole story. It is a cool system that you guys have developed.

Thanks again for all the help you provide on this forum.

J

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.142 seconds