Building 8 x 20 ft CNC machine

- aabtech

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 16

16 Dec 2023 12:25 - 16 Dec 2023 12:34 #288322

by aabtech

Building 8 x 20 ft CNC machine was created by aabtech

Attachments:

Last edit: 16 Dec 2023 12:34 by aabtech.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

16 Dec 2023 15:35 #288340

by tommylight

Replied by tommylight on topic Building 8 x 20 ft CNC machine

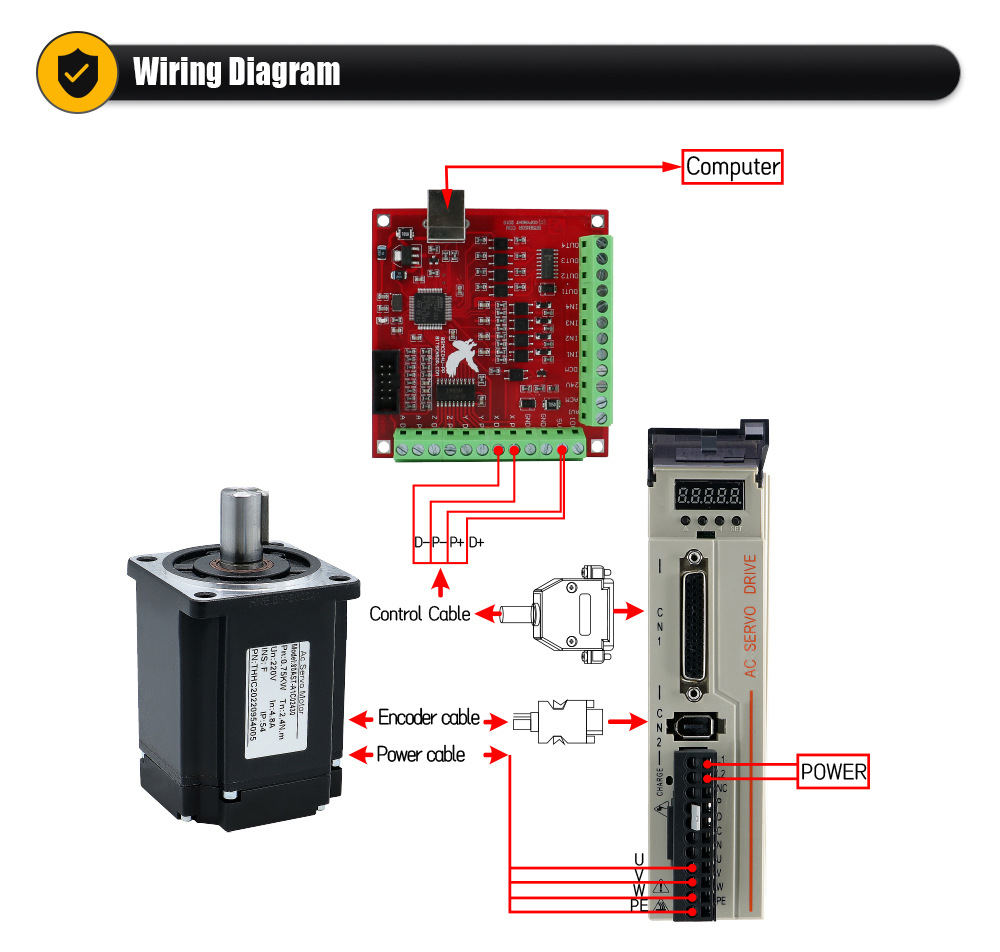

Control cable pinout?

Please Log in or Create an account to join the conversation.

- aabtech

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 16

16 Dec 2023 16:57 #288346

by aabtech

Replied by aabtech on topic Building 8 x 20 ft CNC machine

Yes, and the type of Mesa board to use again can the AC servo motor 1kw rated speed of 3000/5000 handle that 8 X 20 feet CNC table.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

16 Dec 2023 17:54 #288350

by tommylight

Replied by tommylight on topic Building 8 x 20 ft CNC machine

1KW is to much for any plasma, 400W will do just fine as you do need reduction.

An old Messer industrial plasma with 400KG gantry uses 2 of 500W motors with reduction.

-

Pinout of the control cable?

We can not advise you on the board without knowing if the drives have encoder outputs.

If the drive has encoder outputs, Mesa 7i95T has step/dir outputs and encoders inputs, so everything you might need.

An old Messer industrial plasma with 400KG gantry uses 2 of 500W motors with reduction.

-

Pinout of the control cable?

We can not advise you on the board without knowing if the drives have encoder outputs.

If the drive has encoder outputs, Mesa 7i95T has step/dir outputs and encoders inputs, so everything you might need.

Please Log in or Create an account to join the conversation.

- aabtech

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 16

16 Dec 2023 19:18 #288356

by aabtech

Replied by aabtech on topic Building 8 x 20 ft CNC machine

The driver has an encoder output. And what will the ratio of the motor reduction be is planetary gear reducer ok?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

16 Dec 2023 19:35 #288358

by tommylight

Replied by tommylight on topic Building 8 x 20 ft CNC machine

Yes it is, but beware of the cheap ones, those have a lot of backlash.

-

If you can not find Mesa 7i95T, you can also get a Mesa 7i96S and 7i85 or 7i85S.

-

If you can not find Mesa 7i95T, you can also get a Mesa 7i96S and 7i85 or 7i85S.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

16 Dec 2023 20:10 #288363

by RDA

- Mass to be moved

- Max speed to be achieved

- Max acc to be used

Then you roughly find your motor/gearbox/pinion combination. You would want to make sure the torque is enough to get your acc, rpm is enough to get to the speed you want and that the inertia ratio doesnt get too big.

Then just check your gearboxes can handle the speed and torque, then see what the total backlash is and is it inside your specs.

This is a pretty crude/simple approach but should get the sizing to ball park and keep cost/performance in a good level.

Replied by RDA on topic Building 8 x 20 ft CNC machine

Its not about size, its about weight. You typically have some base ”variables” that somewhat define your setup:Yes, and the type of Mesa board to use again can the AC servo motor 1kw rated speed of 3000/5000 handle that 8 X 20 feet CNC table.

- Mass to be moved

- Max speed to be achieved

- Max acc to be used

Then you roughly find your motor/gearbox/pinion combination. You would want to make sure the torque is enough to get your acc, rpm is enough to get to the speed you want and that the inertia ratio doesnt get too big.

Then just check your gearboxes can handle the speed and torque, then see what the total backlash is and is it inside your specs.

This is a pretty crude/simple approach but should get the sizing to ball park and keep cost/performance in a good level.

The following user(s) said Thank You: aabtech

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.092 seconds