Display motion.current-vel ?

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

23 Jul 2025 18:06 #332231

by skunkworks

Display motion.current-vel ? was created by skunkworks

Am I missing it? Is there a way to display the current velocity of the machine while cutting?

Thanks!

BTW - Just setup Plasmac using pncconf - It was painless and QTPlasmac is a really nice gui. No problems.. (mesa style board with thc10)

Great work!

sam

Thanks!

BTW - Just setup Plasmac using pncconf - It was painless and QTPlasmac is a really nice gui. No problems.. (mesa style board with thc10)

Great work!

sam

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

23 Jul 2025 18:25 #332234

by skunkworks

Replied by skunkworks on topic Display motion.current-vel ?

Short video

photos.app.goo.gl/sL9v2GkA7igL8KGU9

also - (I have just started using it and only have the 1 material in which is 1/4 inch. ) Made a sample program using conversational to get the jest of the gcode.

See below for the gcode I used as reference.

It uses tool 0 as far as I can tell - and as far as feed rate this seems correct - when I change tool 0's feed rate - it changes the programs feed rate. OK..

But - I have the arc voltage set to 120. When the program runs - the arc voltage is a constant 115. I actually added 5v on the override so it actually shows 120 when cutting.

am I doing something wrong?

G20 G64P0.004 G40 G49 G80 G90 G92.1 G94 G97 (preamble)

(conversational circle)

;using material #0: Basic default Material

M190 P0

M66 P3 L3 Q1

f#<_hal[plasmac.cut-feed-rate]>

g0 x0.152304 y0.152304

m3 $0 s1

g2 x0.152304 y0.152304 i0.367696 j0.367696

m5 $0

G20 G64P0.004 G40 G49 G80 G90 G92.1 G94 G97 (postamble)

m2

photos.app.goo.gl/sL9v2GkA7igL8KGU9

also - (I have just started using it and only have the 1 material in which is 1/4 inch. ) Made a sample program using conversational to get the jest of the gcode.

See below for the gcode I used as reference.

It uses tool 0 as far as I can tell - and as far as feed rate this seems correct - when I change tool 0's feed rate - it changes the programs feed rate. OK..

But - I have the arc voltage set to 120. When the program runs - the arc voltage is a constant 115. I actually added 5v on the override so it actually shows 120 when cutting.

am I doing something wrong?

G20 G64P0.004 G40 G49 G80 G90 G92.1 G94 G97 (preamble)

(conversational circle)

;using material #0: Basic default Material

M190 P0

M66 P3 L3 Q1

f#<_hal[plasmac.cut-feed-rate]>

g0 x0.152304 y0.152304

m3 $0 s1

g2 x0.152304 y0.152304 i0.367696 j0.367696

m5 $0

G20 G64P0.004 G40 G49 G80 G90 G92.1 G94 G97 (postamble)

m2

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

23 Jul 2025 18:29 #332236

by skunkworks

Replied by skunkworks on topic Display motion.current-vel ?

lol - never mind.. I think I found it.. I will test tonight..

If Use Auto Volts is checked then the actual cut voltage is sampled at the end of the THC Delay time and this is used as the target voltage to adjust the height of the torch.

If Use Auto Volts is not checked then the voltage displayed as Cut Volts in the MATERIAL section of the PARAMETERS Tab is used as the target voltage to adjust the height of the torch.

If Use Auto Volts is checked then the actual cut voltage is sampled at the end of the THC Delay time and this is used as the target voltage to adjust the height of the torch.

If Use Auto Volts is not checked then the voltage displayed as Cut Volts in the MATERIAL section of the PARAMETERS Tab is used as the target voltage to adjust the height of the torch.

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

24 Jul 2025 14:16 #332262

by skunkworks

Replied by skunkworks on topic Display motion.current-vel ?

Yes - unchecking autovolts then uses the material voltage. Duh

thanks again

sam

thanks again

sam

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

27 Jul 2025 02:42 #332395

by rodw

Replied by rodw on topic Display motion.current-vel ?

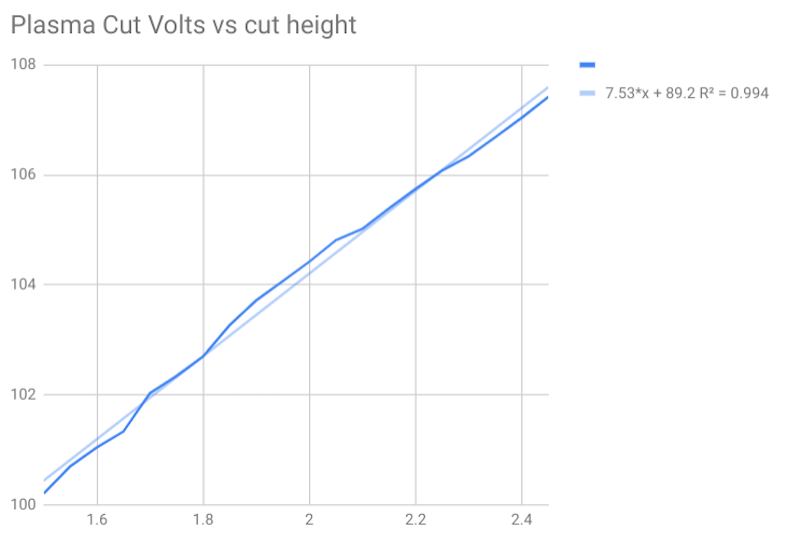

Yes, this is preferred in my book. You want to know the torch height and the voltage quoted in cut charts may not be correct due to worn/eroded electrodes etc so its far better to sample the torch voltage once the voltage has stabilised and keep that constant. There is a very high correlation between torch voltage and torch height so its an excellent process control variable. This is covered in the Plasma Primer in the docs.Yes - unchecking autovolts then uses the material voltage. Duh

thanks again

sam

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

02 Aug 2025 15:38 #332678

by skunkworks

Replied by skunkworks on topic Display motion.current-vel ?

I was surprised at how close it was to the set voltage (based on the cut height setting.) Well thought out.

I have not played with this plasma in ages - it was initially setup by me before eoffsets.. It worked good - but this was much easier..

sam

I have not played with this plasma in ages - it was initially setup by me before eoffsets.. It worked good - but this was much easier..

sam

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

05 Aug 2025 05:15 #332867

by rodw

Replied by rodw on topic Display motion.current-vel ?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.084 seconds