Issues THC.

- paulsao1

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

29 Sep 2025 18:08 #335560

by paulsao1

Issues THC. was created by paulsao1

Greetings everyone!!!

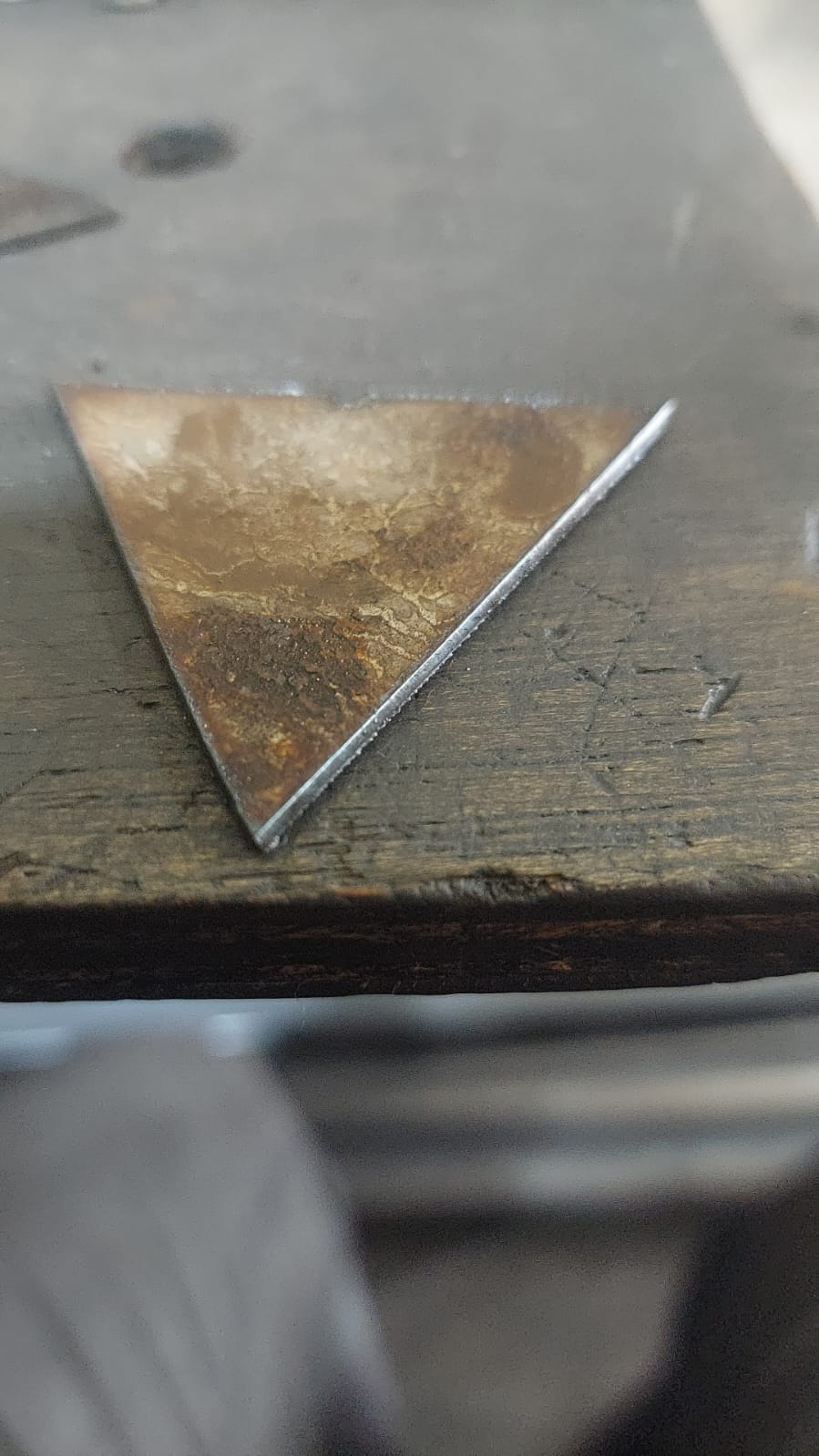

I've been using Qtplasmac for over 3 years without any problems, but 2 days ago I had a problem with the THC. I'm attaching a photo. It seems to be out of control when exiting or entering a corner at high speed. This is the first time this has happened to me. It could be something to do with the PID tuning; the normal values are P=10, which is always used.

I've been using Qtplasmac for over 3 years without any problems, but 2 days ago I had a problem with the THC. I'm attaching a photo. It seems to be out of control when exiting or entering a corner at high speed. This is the first time this has happened to me. It could be something to do with the PID tuning; the normal values are P=10, which is always used.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21368

- Thank you received: 7288

29 Sep 2025 18:27 #335561

by tommylight

Replied by tommylight on topic Issues THC.

Try P=5 and post picture.

Also, watch the voltage on screen, does it fluctuate a lot? +-10V is OK, even a bit more is still OK, but 50V difference is not OK and might be interference or loose contacts on the plasma side.

Also, watch the voltage on screen, does it fluctuate a lot? +-10V is OK, even a bit more is still OK, but 50V difference is not OK and might be interference or loose contacts on the plasma side.

The following user(s) said Thank You: paulsao1

Please Log in or Create an account to join the conversation.

- paulsao1

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

29 Sep 2025 18:46 #335562

by paulsao1

Replied by paulsao1 on topic Issues THC.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21368

- Thank you received: 7288

29 Sep 2025 19:03 #335564

by tommylight

Replied by tommylight on topic Issues THC.

Yes it is, but that also depends on a lot of other external conditions, like current set, air supply and pressure and moisture in it, nozzle size and type, feed rate, material composition, etc etc, so any of change and the cutting result will change, most of the time not noticeably but sometimes very noticeably.

If you have an older plasma source with a big transformer, that will also vary with the input voltage and spikes and drops in the line ripple.

As a general rule:

-thinner material or faster feed rate = more P

-thicker material or slower feed rate = less P

-

On most of my machines i have it set at 7 and never change as they do mostly cut the same 2-3mm material all day long but sometimes they do cut 6-10mm thick so it works fine for both materials as the wavy cut is not very noticeable on thin material.

If you have an older plasma source with a big transformer, that will also vary with the input voltage and spikes and drops in the line ripple.

As a general rule:

-thinner material or faster feed rate = more P

-thicker material or slower feed rate = less P

-

On most of my machines i have it set at 7 and never change as they do mostly cut the same 2-3mm material all day long but sometimes they do cut 6-10mm thick so it works fine for both materials as the wavy cut is not very noticeable on thin material.

The following user(s) said Thank You: paulsao1

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.106 seconds