OpenPnP with LinuxCNC via linuxcncrsh?

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

14 Apr 2023 16:21 - 14 Apr 2023 16:23 #269010

by blazini36

OpenPnP with LinuxCNC via linuxcncrsh? was created by blazini36

I've been working on building a PnP machine and I'm at the point where I'm starting to get software and firmware setup. Not terribly familiar with OpenPnP yet but since it's a gcode sender it's typically used with modified 3d printer firmwares/boards. I'm not really upto snuff on the 3d printer world but I grabbed a board and started setting up Marlin on it and from a configuration standpoint it's pure crap. Obviously it's intended for 3D printers but the it's been adapted for extra axis for stuff like this but 3d printing is so ingrained in the configuration it's just a mess.

Playing with OpenPnP a bit I realize that pretty much everything is some kind of driver, like the gcode sender is a driver and from what I understand it's not terribly hard to make or modify one though I haven't really went down that rabbithole yet. Someone has tried using Linuxcncrsh which seems like the obvious way to go, they had some success and that's the last anyone heard about it. github.com/openpnp/openpnp/issues/1341#issuecomment-986319188

That person was using OpenPnP and LinuxCNC on 2 separate PCs. I would like to run LinuxCNC and OpenPnP on the same machine through a local port. Aparrently the issue the guy there had is that linuxcncrsh has some extra message setup besides just plain Gcode. This should be something easily handled with a custom OpenPnP gcode driver. At the moment I don't know much about setting up a gcode driver in openpnp and linuxcncrsh isn't talked about much around here.

Since I haven't jumped into it yet I don't have a specific question, I'm just wondering if anyone has some insight on running linuxcnc via linuxcncrsh and setting all of that up. It's also kind of convenient that Remora supports these 3D printer boards so it's like all the rest of the pieces are pretty much there.

Playing with OpenPnP a bit I realize that pretty much everything is some kind of driver, like the gcode sender is a driver and from what I understand it's not terribly hard to make or modify one though I haven't really went down that rabbithole yet. Someone has tried using Linuxcncrsh which seems like the obvious way to go, they had some success and that's the last anyone heard about it. github.com/openpnp/openpnp/issues/1341#issuecomment-986319188

That person was using OpenPnP and LinuxCNC on 2 separate PCs. I would like to run LinuxCNC and OpenPnP on the same machine through a local port. Aparrently the issue the guy there had is that linuxcncrsh has some extra message setup besides just plain Gcode. This should be something easily handled with a custom OpenPnP gcode driver. At the moment I don't know much about setting up a gcode driver in openpnp and linuxcncrsh isn't talked about much around here.

Since I haven't jumped into it yet I don't have a specific question, I'm just wondering if anyone has some insight on running linuxcnc via linuxcncrsh and setting all of that up. It's also kind of convenient that Remora supports these 3D printer boards so it's like all the rest of the pieces are pretty much there.

Last edit: 14 Apr 2023 16:23 by blazini36.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21263

- Thank you received: 7257

14 Apr 2023 17:59 #269016

by tommylight

Replied by tommylight on topic OpenPnP with LinuxCNC via linuxcncrsh?

Mrtoyota is working on a PnP, he has a topic here on the forum with plenty of details.

Just in case you missed it.

Just in case you missed it.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

14 Apr 2023 18:19 #269019

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

I saw it but IIRC he's using LinuxCNC straight up with some Python scripts, but I think he stalled on it? Unless he's doing some major work I'd think it would be hard to replicate OpenPnP's functionality, maybe he'll chime in here.

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

14 Apr 2023 18:38 #269020

by my1987toyota

Replied by my1987toyota on topic OpenPnP with LinuxCNC via linuxcncrsh?

Admittedly my stuff in the pick and place section is kind of all over the map. That said more information about

your particular build would help immensely. Also I am not sure why you don't want to solely use Linuxcnc and

start with a standard interface first . Axis is a perfect starting point. If you are not having to actuate feeders then

I highly recommend the MESA 7i96s board to keep costs down. If you need to actuate feeders by sending

a simple on/off command then I recommend the addition of the 7i71 or 7i72 output card. You will need to

add stepper or servo drives but that would be up to you to decide. Also I recommend starting with Linuxcnc 2.9

since it is set up for python 3. You can also use QTVCP and cam_align for position alignment after homing.

I will be posting my machine's profile files in the next month and that can help get you an idea of what to do.

Their is also dm17ry he built a PnP with LCNC 2.7 or 2.8 and has listed his github files for it, it maybe worth a look.

github.com/yur7aev/linuxpnp

your particular build would help immensely. Also I am not sure why you don't want to solely use Linuxcnc and

start with a standard interface first . Axis is a perfect starting point. If you are not having to actuate feeders then

I highly recommend the MESA 7i96s board to keep costs down. If you need to actuate feeders by sending

a simple on/off command then I recommend the addition of the 7i71 or 7i72 output card. You will need to

add stepper or servo drives but that would be up to you to decide. Also I recommend starting with Linuxcnc 2.9

since it is set up for python 3. You can also use QTVCP and cam_align for position alignment after homing.

I will be posting my machine's profile files in the next month and that can help get you an idea of what to do.

Their is also dm17ry he built a PnP with LCNC 2.7 or 2.8 and has listed his github files for it, it maybe worth a look.

github.com/yur7aev/linuxpnp

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

14 Apr 2023 18:53 #269021

by my1987toyota

I am not a programmer by trade so having to learn as I go has it's draw backs. with The PnP stuff it really comes down to what

you have to have.

Do you absolutely need a polished purpose specific interface to do what you need?

Do you need to work with automatic feeders?

Do you need the machine to be really precise (0201) size parts and extremely fine pitch chip placement?

Does the machine have to look like it belongs on today's factory floors?

If not you can compromise on alot and get away with it . If it servs your purpose.

If it's for yourself you don't have to worry about looks as long as the product your machine is building looks good.

Replied by my1987toyota on topic OpenPnP with LinuxCNC via linuxcncrsh?

stalled no. My problem is dealing with 5 or so projects at once and that's before where I work needing stuff done for them. LOLI saw it but IIRC he's using LinuxCNC straight up with some Python scripts, but I think he stalled on it? Unless he's doing some major work I'd think it would be hard to replicate OpenPnP's functionality, maybe he'll chime in here.

I am not a programmer by trade so having to learn as I go has it's draw backs. with The PnP stuff it really comes down to what

you have to have.

Do you absolutely need a polished purpose specific interface to do what you need?

Do you need to work with automatic feeders?

Do you need the machine to be really precise (0201) size parts and extremely fine pitch chip placement?

Does the machine have to look like it belongs on today's factory floors?

If not you can compromise on alot and get away with it . If it servs your purpose.

If it's for yourself you don't have to worry about looks as long as the product your machine is building looks good.

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

14 Apr 2023 19:06 #269022

by my1987toyota

Replied by my1987toyota on topic OpenPnP with LinuxCNC via linuxcncrsh?

WOW I just realized it has been 2 months since my last PnP update and alot has changed since that video.

I guess I will have to do another update video soon.

the machine now is on its own roll around stand and has the computer monitor and keyboard on a support columb

it also has for the most part been migrated to version 2.9.

for now though the below video shows were it WAS 2 months ago.

I guess I will have to do another update video soon.

the machine now is on its own roll around stand and has the computer monitor and keyboard on a support columb

it also has for the most part been migrated to version 2.9.

for now though the below video shows were it WAS 2 months ago.

The following user(s) said Thank You: tommylight, blazini36, svb

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

14 Apr 2023 19:30 #269024

by my1987toyota

Replied by my1987toyota on topic OpenPnP with LinuxCNC via linuxcncrsh?

and this is dm17ry's rig. It's far more capable then what I run but it's still straight up Linuxcnc and extra python and O-code

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

14 Apr 2023 20:30 #269030

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

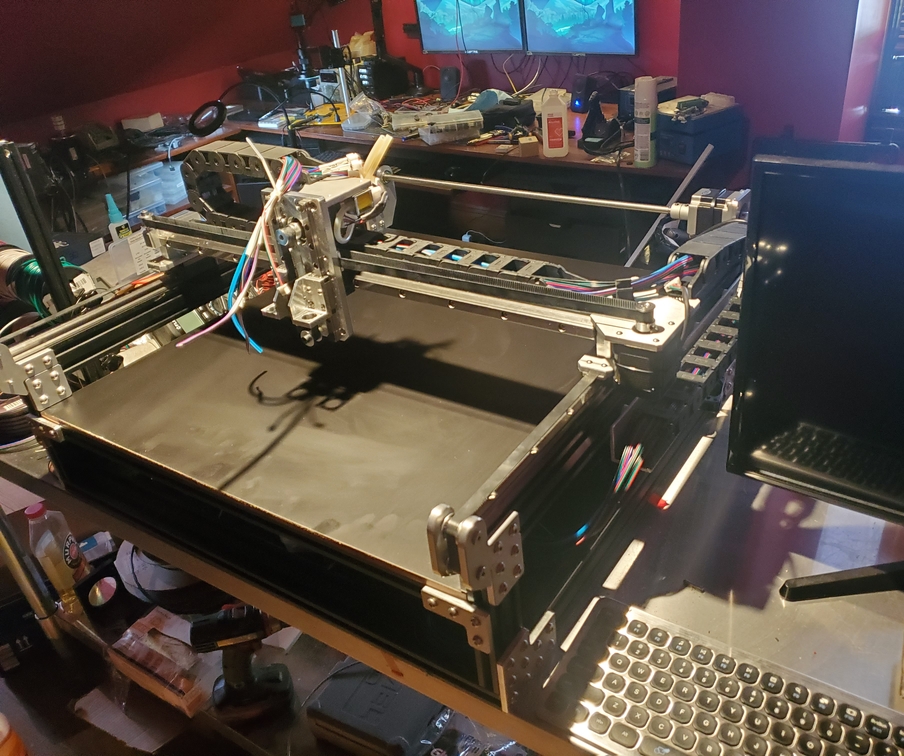

This is my PnP at the moment, still waiting on heads and vacuum pumps but I should be able to get the software stuff started. Maybe at some point I can kit it up and sell it, probably do well against something like a LumenPnP for what that costs.

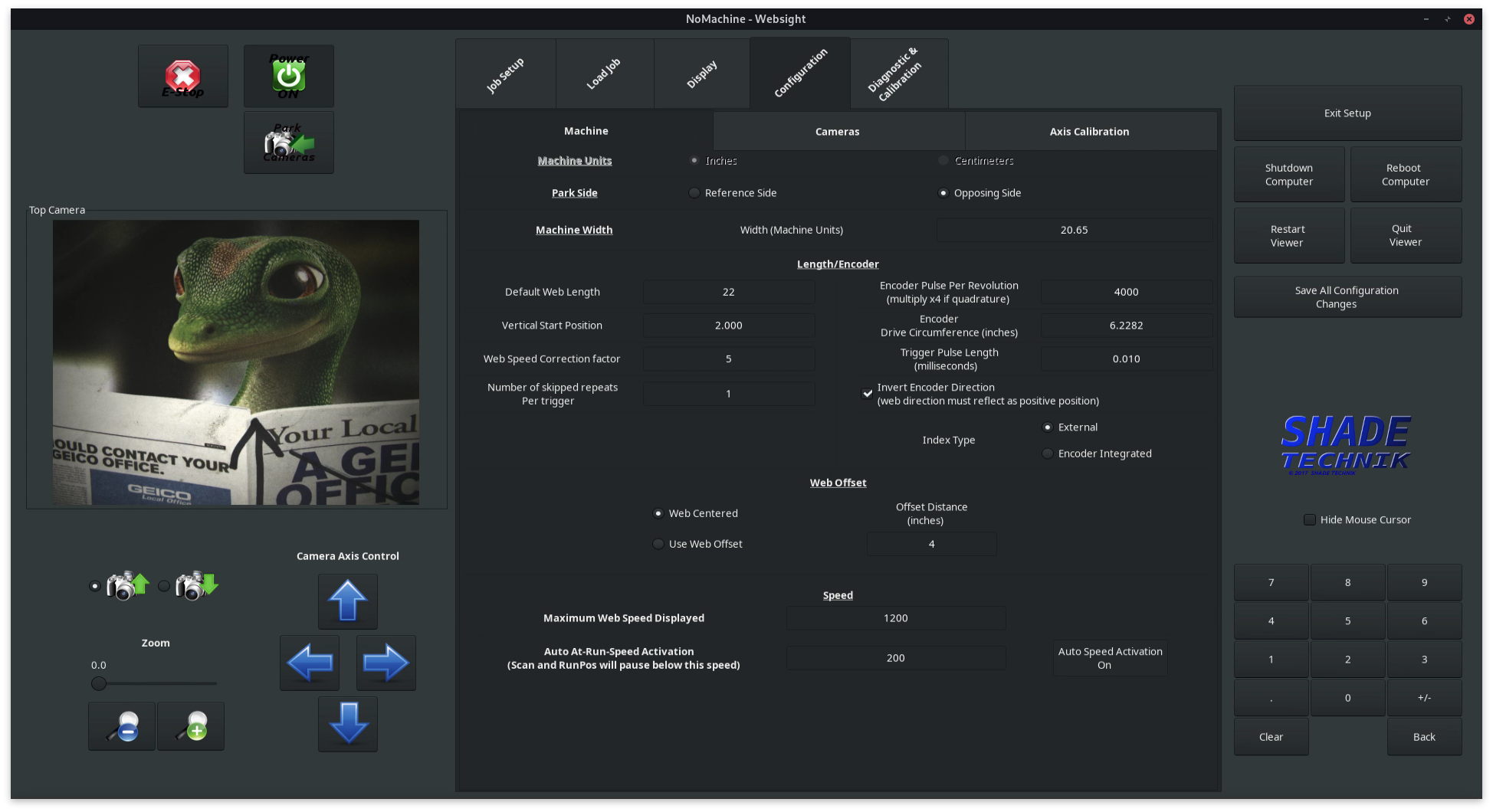

The PC an everything is under the Top platform. It's all belts/steppers so I'm not looking for speed but it's all linear rail so hopefully I can get some good accuracy.I've seen dm17ry's videos, that's damn impressive but that's not going to be easy to replicate even though the configs are online. Honestly I would't touch anything Py2/GTK2 based with a 10ft pole anymore. I have another LCNC machine that's focused on machine vision, nothing to do with PnPs though. Right now I'm going through the painful process of converting the custom GTK2/Py2 UI to Qt/Py3.From This:

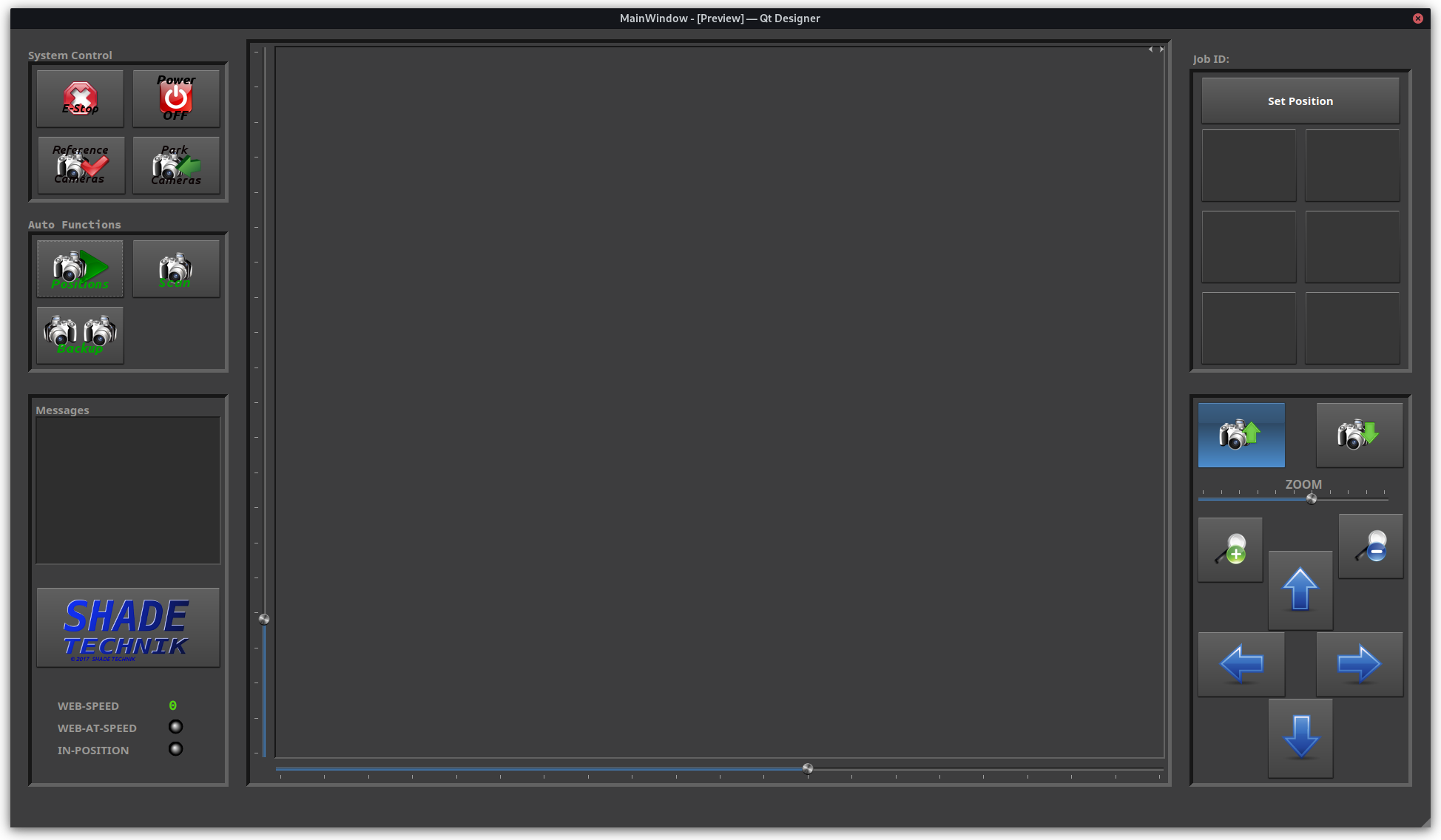

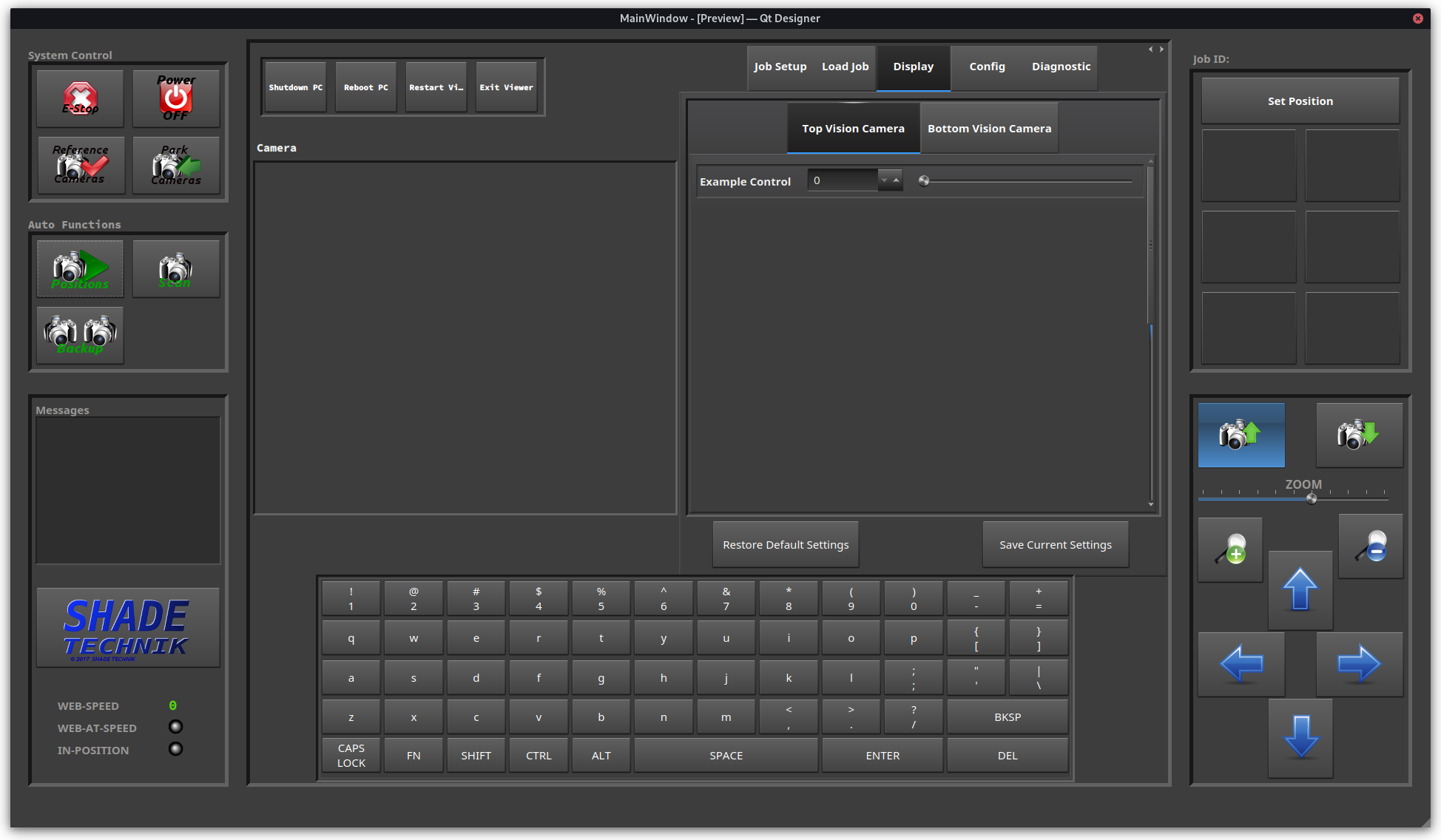

To This:

I made the UI's but programming isn't my thing so I've had Python guys helping me which is really the problem with the whole PnP thing. I just need mine to do the thing for me, I don't want to go down some crazy rabbithole of code that I can't deal with personally. It really would be great if someone made a purpose built UI for LinuxCNC for PnPs that was configurable like Gmoccapy.

As for capabilities I usually design my PCBs with a 0402 minimum because I hand assemble them and 0201 really sucks to do by hand. 0402 I can stick with. Feeders I'll worry about down the road. There's a bunch of 3D printed feeder types out there that look capable, but initially I'd probably just do strip feeders and trays or something.

I have a 7i96 laying around since I switched a prototype machine over to a 7i96s but I don't want to use it here, as I don't want to use external drivers. I'm still looking into Remora because all this thing really needs is a 3D printer style controller. Otherwise I'd either make my own controller if I can find a LCNC compatible firmware project or use smaller Mesa card with pin headers and make a Field IO board for it with onboard drivers.

It'd be nice if we could get some kind of unified effort into a pick and place specific LinuxCNC interface. I'd certainly be down to help, but I obviously won't be writing the code for it. I've seen your posts but I haven't really followed it that well since it was a work in progress and being that everyone else uses OpenPnP that's what I planned on doing. What I don't really want to get too into is a bunch of scripts with no documentation that it's really hard to figure out what to do with. Barring a purpose built UI for LCNC, it seems like OpenPnP commanding LCNC via linuxcncrsh is a really good alternative unless some limitations pop up.

To This:

I made the UI's but programming isn't my thing so I've had Python guys helping me which is really the problem with the whole PnP thing. I just need mine to do the thing for me, I don't want to go down some crazy rabbithole of code that I can't deal with personally. It really would be great if someone made a purpose built UI for LinuxCNC for PnPs that was configurable like Gmoccapy.

As for capabilities I usually design my PCBs with a 0402 minimum because I hand assemble them and 0201 really sucks to do by hand. 0402 I can stick with. Feeders I'll worry about down the road. There's a bunch of 3D printed feeder types out there that look capable, but initially I'd probably just do strip feeders and trays or something.

I have a 7i96 laying around since I switched a prototype machine over to a 7i96s but I don't want to use it here, as I don't want to use external drivers. I'm still looking into Remora because all this thing really needs is a 3D printer style controller. Otherwise I'd either make my own controller if I can find a LCNC compatible firmware project or use smaller Mesa card with pin headers and make a Field IO board for it with onboard drivers.

It'd be nice if we could get some kind of unified effort into a pick and place specific LinuxCNC interface. I'd certainly be down to help, but I obviously won't be writing the code for it. I've seen your posts but I haven't really followed it that well since it was a work in progress and being that everyone else uses OpenPnP that's what I planned on doing. What I don't really want to get too into is a bunch of scripts with no documentation that it's really hard to figure out what to do with. Barring a purpose built UI for LCNC, it seems like OpenPnP commanding LCNC via linuxcncrsh is a really good alternative unless some limitations pop up.

Attachments:

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 426

14 Apr 2023 21:08 #269033

by my1987toyota

Replied by my1987toyota on topic OpenPnP with LinuxCNC via linuxcncrsh?

blazini36 I totally agree 0201 SUUUCKS. The Machine looks good. The strip feeders are a good option. the only reason I

currently use auto feeders is because they were already installed on the machine. Well that and building hundreds of boards

a day strip feeders would get old quick. Unfortunately I am not a coder / programmer either. I do tend to be persistent when

I NEED to figure a problem out. But divide that across multiple simultaneous projects and you can see why my stuff always

takes awhile.

The big risk with trying to make a product and bring it to market is the problem of saturation. If it's a niche market and their

already exist options ( Charm High, Opulo, NeoDen, ECT ) it will become a hard sell. So please be careful if you go

that route.

That said I wish you the best with your project.

currently use auto feeders is because they were already installed on the machine. Well that and building hundreds of boards

a day strip feeders would get old quick. Unfortunately I am not a coder / programmer either. I do tend to be persistent when

I NEED to figure a problem out. But divide that across multiple simultaneous projects and you can see why my stuff always

takes awhile.

The big risk with trying to make a product and bring it to market is the problem of saturation. If it's a niche market and their

already exist options ( Charm High, Opulo, NeoDen, ECT ) it will become a hard sell. So please be careful if you go

that route.

That said I wish you the best with your project.

The following user(s) said Thank You: tommylight, blazini36

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

14 Apr 2023 21:53 #269040

by blazini36

Replied by blazini36 on topic OpenPnP with LinuxCNC via linuxcncrsh?

Well the PNP is something I already had to design and model alot of machined parts for to make my own, most of which can just be waterjetted. As for a "product" it's nothing I'd take super seriously. There's a pretty hard gap in the hobby PnP market as you go from a LumenPnP for $2k that's all plastic 3d printed stuff to the $4k+ machines you mentioned with proprietary controls. So basically if ya wan't something that's not made mostly out of plastic that has some DIY friendly electronics in it, I could probably throw some pre-assembled stuff in a box for you that'll get ya 80% where ya wanna be. Not looking to build a business on PnP machines, I just made this thing to make the other stuff I do a bit easier.

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

Time to create page: 0.163 seconds