Linuxcnc plasma rotary

- Grotius

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

05 Jun 2019 10:36 - 05 Jun 2019 10:43 #135925

by Grotius

Linuxcnc plasma rotary was created by Grotius

This is information to set up Plasma Rotary cutting.

Attached a modified post processor for sheetcam rotary. Rename the file extension from txt to scpost.

1. This postprocessor does not use a touch off or probe function. Probing for tube cutting is not a better option in practical way.

(In my case probing can be activated by selecting a gui screen button, this will trigger the THC2 component probe function, but i don't use probing when cutting tubes.)

2. It uses G64P0.05 for optimal accuracy during cutting.

(G64P0.01 up to G64P0.04 will result in bad rotation movement's (shocking) during corner rotation when cutting square tubes)

3. It set's the plasma power "S" in the g-code when a laser tool is used.

4. important : the Z axis zero point is located at center point of the main chuck. When zeroing your z axis on top of the profile, for example a square tube 100x100mm your z axis is at 50mm when on top of the profile, the z-axis value (50mm) can be included the cutting distance about 3-4mm, no problem.

5. Included is a 100x100mm draftsight dxf template file (flatten tube layout) that correspondent's with the sheetcam square tube layout 100x100mm, corner radius 5mm.

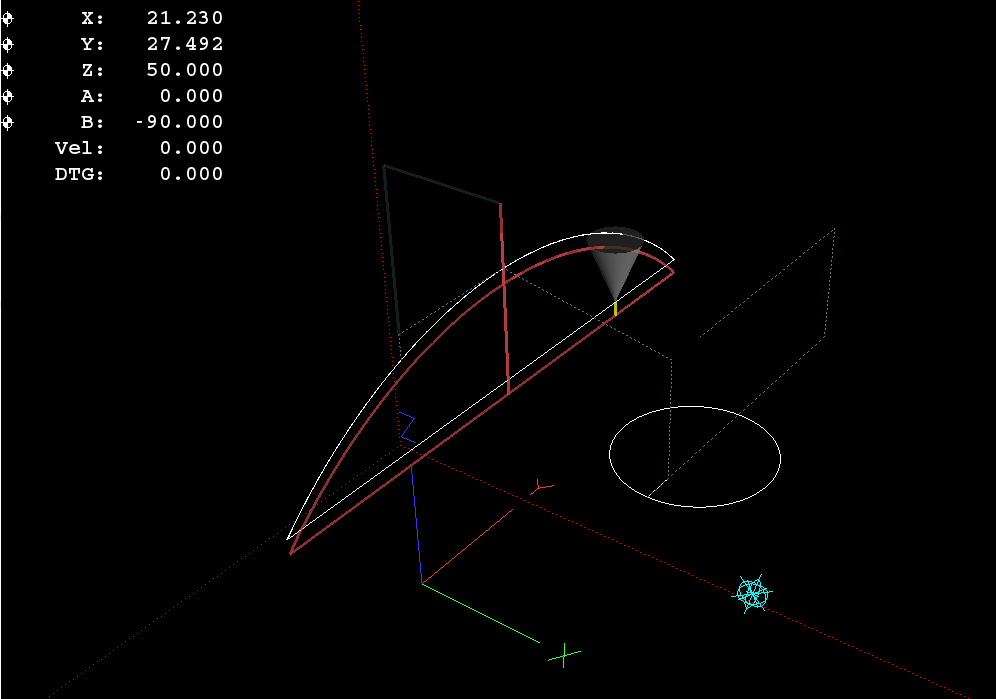

6. Attached picture is the output in linuxcnc. In this example you see probe was used. The probe has offset the actual cutting pat'h a little.

7. Example g-code output

8. The ini file example for a rotary axis setup, in my case axis B. I changed Lineair to Angular. But without changing this,

it work's also. Wrapping the axis does not improve anything in my case.

9. For long tube cutters you need the main chuck driven and the back end chuck driven synchroon to prevent torsing the profile.

For this option you have to modify the ini file and the post processor to adapt a extra axis.

10. Test machine for this config. It's a watertable based on-side rotary cutter.

I hope this info is usefull for our community.

Attached a modified post processor for sheetcam rotary. Rename the file extension from txt to scpost.

1. This postprocessor does not use a touch off or probe function. Probing for tube cutting is not a better option in practical way.

(In my case probing can be activated by selecting a gui screen button, this will trigger the THC2 component probe function, but i don't use probing when cutting tubes.)

2. It uses G64P0.05 for optimal accuracy during cutting.

(G64P0.01 up to G64P0.04 will result in bad rotation movement's (shocking) during corner rotation when cutting square tubes)

3. It set's the plasma power "S" in the g-code when a laser tool is used.

4. important : the Z axis zero point is located at center point of the main chuck. When zeroing your z axis on top of the profile, for example a square tube 100x100mm your z axis is at 50mm when on top of the profile, the z-axis value (50mm) can be included the cutting distance about 3-4mm, no problem.

5. Included is a 100x100mm draftsight dxf template file (flatten tube layout) that correspondent's with the sheetcam square tube layout 100x100mm, corner radius 5mm.

6. Attached picture is the output in linuxcnc. In this example you see probe was used. The probe has offset the actual cutting pat'h a little.

7. Example g-code output

Warning: Spoiler!

N0010 (Filename: template_koker_100x100.ngc)

N0020 (Post processor: LinuxCNC Rotary EX AZ.scpost)

N0030 (Date: 05/06/19)

N0040 G21 (Units: Metric)

N0050 G40 G90 G64P0.05

N0060 F1 S1

N0070 G00 Z68.6396

N0080 (Part: template_koker_100x100)

N0090 (Operation: Outside Offset, 10 amp, T1: Mark 10Amp)

N0100 G00 X21.2304 Y-0.0009 Z68.6396 B-225.0008

N0110 Z68.6396

N0120 S10

N0130 M03

N0140 G01 Y5.5398 Z68.3980 B-220.0061 F23972.7134

N0150 Y11.0385 Z67.6750 B-215.0113

N0160 Y16.4534 Z66.4759 B-210.0166

N0170 Y21.7433 Z64.8099 B-205.0218

N0180 Y26.8681 Z62.6898 B-200.0270

N0190 Y31.7888 Z60.1314 B-195.0323

N0200 Y36.4681 Z57.1544 B-190.0375

N0210 Y40.8704 Z53.7813 B-185.0427

N0220 Y44.9623 Z50.0377 B-180.0480

N0230 Y44.5683 Z50.0000 B-180.0000 F1280.5484

N0240 Y-44.7861 F1400.0

N0250 Y-42.9583 Z51.9530 B-177.4561 F11856.3912

N0260 Y-38.7073 Z55.5148 B-172.4614 F23972.7134

N0270 Y-34.1622 Z58.6930 B-167.4666

N0280 Y-29.3577 Z61.4635 B-162.4718

N0290 Y-24.3303 Z63.8051 B-157.4771

N0300 Y-19.1181 Z65.7001 B-152.4823

N0310 Y-13.7606 Z67.1341 B-147.4875

N0320 Y-8.2987 Z68.0962 B-142.4928

N0330 Y-2.7737 Z68.5791 B-137.4980

N0340 Y2.7723 Z68.5792 B-132.5032

N0350 Y8.2973 Z68.0964 B-127.5085

N0360 Y13.7592 Z67.1344 B-122.5137

N0370 Y19.1167 Z65.7005 B-117.5190

N0380 Y24.3290 Z63.8056 B-112.5242

N0390 Y29.3565 Z61.4641 B-107.5294

N0400 Y34.1611 Z58.6938 B-102.5347

N0410 Y38.7062 Z55.5157 B-97.5399

N0420 Y42.9573 Z51.9539 B-92.5451

N0430 Y44.7862 Z50.0000 B-90.0000 F11862.6162

N0440 Y-44.5682 F1400.0

N0450 Y-44.9633 Z50.0367 B-89.9533 F1283.2724

N0460 Y-40.8715 Z53.7804 B-84.9585 F23972.7134

N0470 Y-36.4692 Z57.1536 B-79.9638

N0480 Y-31.7900 Z60.1307 B-74.9690

N0490 Y-26.8693 Z62.6892 B-69.9742

N0500 Y-21.7446 Z64.8095 B-64.9795

N0510 Y-16.4547 Z66.4755 B-59.9847

N0520 Y-11.0399 Z67.6747 B-54.9899

N0530 Y-5.5412 Z68.3979 B-49.9952

N0540 Y-0.0005 Z68.6396 B-45.0004

N0550 Y5.5403 Z68.3980 B-40.0057

N0560 Y11.0390 Z67.6749 B-35.0109

N0570 Y16.4538 Z66.4758 B-30.0161

N0580 Y21.7437 Z64.8098 B-25.0214

N0590 Y26.8685 Z62.6896 B-20.0266

N0600 Y31.7892 Z60.1312 B-15.0318

N0610 Y36.4684 Z57.1541 B-10.0371

N0620 Y40.8707 Z53.7810 B-5.0423

N0630 Y44.9626 Z50.0373 B-0.0476

N0640 Y44.5683 Z50.0000 B0.0000 F1281.4536

N0650 Y-44.7862 F1400.0

N0660 Y-42.9580 Z51.9533 B2.5443 F11858.4662

N0670 Y-38.7069 Z55.5151 B7.5391 F23972.7134

N0680 Y-34.1618 Z58.6933 B12.5338

N0690 Y-29.3573 Z61.4637 B17.5286

N0700 Y-24.3299 Z63.8053 B22.5234

N0710 Y-19.1176 Z65.7002 B27.5181

N0720 Y-13.7602 Z67.1342 B32.5129

N0730 Y-8.2982 Z68.0963 B37.5076

N0740 Y-2.7732 Z68.5792 B42.5024

N0750 Y2.7728 B47.4972

N0760 Y8.2978 Z68.0963 B52.4919

N0770 Y13.7597 Z67.1343 B57.4867

N0780 Y19.1172 Z65.7004 B62.4815

N0790 Y24.3294 Z63.8054 B67.4762

N0800 Y29.3569 Z61.4639 B72.4710

N0810 Y34.1614 Z58.6935 B77.4657

N0820 Y38.7065 Z55.5154 B82.4605

N0830 Y42.9577 Z51.9536 B87.4553

N0840 Y44.7862 Z50.0000 B90.0000 F11860.5412

N0850 Y-44.5682 F1400.0

N0860 Y-44.9630 Z50.0370 B90.0471 F1282.3616

N0870 Y-40.8711 Z53.7807 B95.0419 F23972.7134

N0880 Y-36.4688 Z57.1539 B100.0367

N0890 Y-31.7896 Z60.1310 B105.0314

N0900 Y-26.8689 Z62.6894 B110.0262

N0910 Y-21.7442 Z64.8096 B115.0209

N0920 (Operation: Inside Offset, 25 amp, T2: Plasma 25Amp)

N0930 M05

N0940 G00 X21.2304 Y-21.7442 Z68.6396 B115.0209

N0950 Y0.0000 B135.0000

N0960 X53.5212 Y-6.5999 B-180.0000

N0970 Z50.0000

N0980 S25

N0990 M03

N1000 G01 Y-11.5999 Z50.0000 F1400.0

N1010 G03 I0.0000 J11.6000

N1020 G00 Y37.3271 B180.0000

N1030 Z68.6396

N1040 Y0.0000 B135.0000

N1050 M05 M308. The ini file example for a rotary axis setup, in my case axis B. I changed Lineair to Angular. But without changing this,

it work's also. Wrapping the axis does not improve anything in my case.

Warning: Spoiler!

[AXIS_B]

MIN_LIMIT = -10000

MAX_LIMIT = 10000

MAX_VELOCITY = 275

MAX_ACCELERATION = 325

[JOINT_5]

TYPE = ANGULAR

HOME = 0.0

MAX_VELOCITY = 275

MAX_ACCELERATION = 325

STEPGEN_MAXACCEL = 750

SCALE = -63.1363

FERROR = 1

MIN_FERROR = .25

MIN_LIMIT = -100000

MAX_LIMIT = 100000

HOME_LATCH_VEL = 0

HOME_SEARCH_VEL = 0

HOME_FINAL_VEL = 0

HOME_IGNORE_LIMITS = YES

HOME_OFFSET = 0

HOME_SEQUENCE = 09. For long tube cutters you need the main chuck driven and the back end chuck driven synchroon to prevent torsing the profile.

For this option you have to modify the ini file and the post processor to adapt a extra axis.

10. Test machine for this config. It's a watertable based on-side rotary cutter.

I hope this info is usefull for our community.

Last edit: 05 Jun 2019 10:43 by Grotius.

The following user(s) said Thank You: BigJohnT, chimeno, tommylight, rodw, AgentWD40, jay1st

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

05 Jun 2019 13:24 #135940

by pl7i92

Replied by pl7i92 on topic Linuxcnc plasma rotary

nice mashine setup

thank you

the sheetcam got a module that got tube sqare and Round in Full version witch handeles the Linuxcnc Thcud component

it the post you addet different then the standard sheetcam linuxcnc_rotary

thank you

the sheetcam got a module that got tube sqare and Round in Full version witch handeles the Linuxcnc Thcud component

it the post you addet different then the standard sheetcam linuxcnc_rotary

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

05 Jun 2019 14:58 - 05 Jun 2019 17:32 #135947

by Grotius

Replied by Grotius on topic Linuxcnc plasma rotary

Hi Maximilian,

nice machine setup

The customer requested a rotary axis. Normally it's a dry rotary axis. But his wish was a rotary water table. So i made some

extra work for the same price !!! Customer is happy.

the sheetcam got a module that got tube sqare and Round in Full version witch handeles the Linuxcnc Thcud component

Yes and no for the THCud component, see item 2 below for the rotary plugin :

sheetcam.com/Register/purchase

1. SheetCam TNG (£110.00)

2. Rotary pipe cutting (Receive a £5 discount if you purchase this with SheetCam)

Total : $217.43 US dollars

Thcud component

For tube cutting you don't really need torch height control. So if we look into the THCud source code :

( in my case the torch height control is fully functional, see comment's below of i/o stream )

I look at the THCud source code, i mention that this code is not very usefull for a rotary plasma machine.

What is useful is to connect in hal your plasma arc oke signal of the plasma inverter to motion.feed-hold-inhibited.

This would be the most simple succesfull solution rotary cutter machine.

This day's there are several component's designed, like in progress the plasmac or my THC2-ehtercat component wich is done and has many in and output's, to have a look in the i/o stream :

is the post you added different then the standard sheetcam linuxcnc_rotary

Yes, it's different. The one i provided can also be used for :

1. oxy-fuel on rotary axis, it has preheat function's during processing.

2. In my first post i commented about it also set's the plasma power of the inverter.

3. It also can use a second torch head, and offset's for the second torch head are provided as x,y and z scriber value's.

4. And more options like better accuracy, and trough experience no height problem's after cutting many profile parts.

The provided post processor is a very good alternative for the standard LinuxCNC plasma rotatif post processor, which is standard included by the default sheetcam install. The provided post processor is used for over year's and has cut more then 50km of pipe and profiles over the last years. I cutted about 10km of pipe with this processor, to give you an idea.

Without the GPL2 licence Linuxcnc would be less and less powerfull as today's Linuxcnc power is very, very high, top level, high end solution's can be made without problem's. No window's pc can compare with linux at this day's. It's the same vision as Elon Musk and Linus Torvalds and many other's, like the custom linux user's all over the world.

We collect and share info, data and provide example's, give code back, just as the GPL2 licence is intended for.

The extra added line's in the post processor are good to be provided as GPL2 based lines.

A quote from Elvis : " time can do so much "

nice machine setup

The customer requested a rotary axis. Normally it's a dry rotary axis. But his wish was a rotary water table. So i made some

extra work for the same price !!! Customer is happy.

the sheetcam got a module that got tube sqare and Round in Full version witch handeles the Linuxcnc Thcud component

Yes and no for the THCud component, see item 2 below for the rotary plugin :

sheetcam.com/Register/purchase

1. SheetCam TNG (£110.00)

2. Rotary pipe cutting (Receive a £5 discount if you purchase this with SheetCam)

Total : $217.43 US dollars

Thcud component

For tube cutting you don't really need torch height control. So if we look into the THCud source code :

( in my case the torch height control is fully functional, see comment's below of i/o stream )

Warning: Spoiler!

component thcud "Torch Height Control Up/Down Input";

description

"""

Torch Height Control

This THC takes either an up or a down input from a THC

If enabled and torch is on and X + Y velocity is within tolerance of set speed

allow the THC to offset the Z axis as needed to maintain voltage.

If enabled and torch is off and the Z axis is moving up remove any correction

at a rate not to exceed the rate of movement of the Z axis.

If enabled and torch is off and there is no correction

pass the Z position and feed back untouched.

If not enabled pass the Z position and feed back untouched.

Typical Physical Connections using a Parallel Port

.br

Parallel Pin 12 <= THC controller Plasma Up

.br

Parallel Pin 13 <= THC controller Plasma Down

.br

Parallel Pin 15 <= Plasma Torch Arc Ok Signal

.br

Parallel Pin 16 => Plasma Torch Start Arc Contacts

HAL Plasma Connections

.br

net torch-up thcud.torch-up <= parport.0.pin-12-in

.br

net torch-down thcud.torch-down <= parport.0.pin-13-in

.br

net torch-on motion.spindle-on => parport.0.pin-16-out (start the arc)

.br

net arc-ok thcud.arc-ok <= motion.digital-in-00 <= parport.0.pin-15-in (arc ok signal)

HAL Motion Connections

.br

net requested-vel thcud.requested-vel <= motion.requested-vel

.br

net current-vel thcud.current-vel <= motion.current-vel

Pyvcp Connections

In the xml file you need something like:

<pyvcp>

<checkbutton>

<text>"THC Enable"</text>

<halpin>"thc-enable"</halpin>

</checkbutton>

</pyvcp>

Connect the Pyvcp pins in the postgui.hal file like this:

net thc-enable thcud.enable <= pyvcp.thc-enable

""";

author "John Thornton";

license "GPLv2 or greater";

option singleton yes;

// Input Pins

pin in bit torch_up "Connect to an input pin";

pin in bit torch_down "Connect to input pin";

pin in float current_vel "Connect to motion.current-vel";

pin in float requested_vel "Connect to motion.requested-vel";

pin in bit torch_on "Connect to motion.spindle-on";

pin in bit arc_ok "Arc Ok from Plasma Torch";

pin in bit enable "Enable the THC, if not enabled Z position is passed through";

pin in float z_pos_in "Z Motor Position Command in from axis.n.motor-pos-cmd";

// Output Pins

pin out float z_pos_out "Z Motor Position Command Out";

pin out float z_fb_out "Z Position Feedback to Axis";

pin out float cur_offset "The Current Offset";

pin out bit vel_status "When the THC thinks we are at requested speed";

pin out bit removing_offset "Pin for testing";

// Parameters

param rw float velocity_tol "The deviation percent from planned velocity";

param rw float correction_vel "The Velocity to move Z to correct";

// Global Variables

variable float offset;

variable float last_z_in;

function _;

;;

#include "rtapi_math.h"

FUNCTION(_) {

if(enable){

float min_velocity = requested_vel -(requested_vel*(velocity_tol*0.01));

if(current_vel > 0 && current_vel >= min_velocity){vel_status = 1;}

else {vel_status =0;}

if(torch_on && arc_ok && vel_status){ // allow correction

if(torch_down){

offset -= correction_vel;

}

if(torch_up){

offset += correction_vel;

}

last_z_in = 0;

}

if(!torch_on){ // remove any offset

float z_diff;

z_diff = z_pos_in - last_z_in;

if(z_diff > 0 && offset != 0){ // torch is moving up

removing_offset = 1;

if(offset > 0){ // positive offset

if(offset > z_diff){ // remove some

offset -= z_diff;

}

else {offset = 0;}

}

if(offset < 0){ // negative offset

if(offset < z_diff){ // remove some

offset += z_diff;

}

else {offset = 0;}

}

}

else {removing_offset = 0;}

last_z_in = z_pos_in;

}

z_pos_out = z_pos_in + offset;

z_fb_out = z_pos_in; // keep axis motor position fb from being confused

}

if(!enable){

z_pos_out = z_pos_in;

z_fb_out = z_pos_in; // keep axis motor position fb from being confused

}

}

I look at the THCud source code, i mention that this code is not very usefull for a rotary plasma machine.

What is useful is to connect in hal your plasma arc oke signal of the plasma inverter to motion.feed-hold-inhibited.

This would be the most simple succesfull solution rotary cutter machine.

This day's there are several component's designed, like in progress the plasmac or my THC2-ehtercat component wich is done and has many in and output's, to have a look in the i/o stream :

Warning: Spoiler!

author "Grotius CNC Machines";

license "GPLv2 or greater";

option singleton yes;

// Input Pins

pin in bit Enable "Enable THC2 component";

pin out bit Reset_offsets "Reset offsets to orginal condition when component is not enable";

pin in bit Probe_enable "Connected to user interface button";

pin in float Zpos_in "";

pin out float Zpos_out "";

pin in float Travelheight "Z axis travelheigt in";

pin in float Cutheight "Z axis cut height in";

pin out float Speed "Z axis output speed to ini.z.max_velocity";

pin in float Maxspeed "Z axis input speed";

pin in float Probespeed "Z axis input probing speed";

pin in float Piercespeed "Z axis input pierce speed";

pin in float Adaptive_feed_in "Adaptive feed in -1 to 1 from grotius_gui speedwidget";

pin out float Adaptive_feed_out "Adaptive feed out -1 to 1 to posgui.hal for making negative speed at restart procedure";

pin in float Piercedelay "Z axis pierce delay time in seconds";

pin out bit Piercetime_reached "Piercetime reached";

pin in float Up_down_resolution "When Torch up, then correction 0.1mm or 1mm resolution";

pin in float Axis_z_eoffset "Connected to external offsets z real time current z axis position input";

pin in float Pierceheight "the pierce height value in mm";

pin out float Offset "Z axis Offset command to external offsets, the z axis is moving to this offset when set, even in pause";

pin in bit Torch_on_in "Connected to spindle-cw";

pin out bit Probe_trigger "If probe is triggered this pin becomes high";

pin out bit Cutting_trigger "At cutheight and cutting";

pin in float Probe_search_limit "Connected to user interface input, z axis probe end limit. For example Z -10 = probing to max Z-10.";

pin in float Probe_switch_offset "Probe sensor switch correction value, positive z-value";

pin out float Zpos_probe "Z value when probe was triggered";

pin out bit arc_ok_led "";

pin out bit arc_lost_led "";

pin out bit torch_up_led "";

pin out bit torch_down_led "";

pin in bit Probe_in "connected to probe sensor";

pin out bit Torch_on_out "";

pin in float thc_divided_voltage "Ethercat 0-10volt analog input EL3162";

pin in float Cut_chart_voltage "Screen input value related to plasma defined cutting charts";

pin out bit Pause_machine "Connect to motion.feed-hold-inhibited";

pin out bit Probe_this_start "We must probe next start, our calculation has reached over the xy limits";

pin in float Axis_x_pos_cmd "Connect to axis.x.pos-cmd";

pin in float Axis_y_pos_cmd "Connect to axis.x.pos-cmd";

pin in float Dist_x "Connect to user gui, maximum input value over x axis";

pin in float Dist_y "Connect to user gui, maximum input value over y axis";

pin out float Snapshot_x_pos "Monitoring if snapshot is done";

pin out float Snapshot_y_pos "Monitoring if snapshot is done";

pin out bit Probe_over_distance_yes "Led indicator";

variable double Time; //time for pierce delay

variable double Restart_time;

pin out bit Cutheight_trigger "";

pin in bit inverter_ready "";

pin in bit run "";

pin out bit is_running "";

pin out bit init "";

pin in bit arc_ok_togglebutton "";

pin out bit state_no_probe;

pin out bit state_probe;

pin out bit state_toggelbutton;

pin in bit restart;

pin out bit restart_trigger;is the post you added different then the standard sheetcam linuxcnc_rotary

Yes, it's different. The one i provided can also be used for :

1. oxy-fuel on rotary axis, it has preheat function's during processing.

2. In my first post i commented about it also set's the plasma power of the inverter.

3. It also can use a second torch head, and offset's for the second torch head are provided as x,y and z scriber value's.

4. And more options like better accuracy, and trough experience no height problem's after cutting many profile parts.

The provided post processor is a very good alternative for the standard LinuxCNC plasma rotatif post processor, which is standard included by the default sheetcam install. The provided post processor is used for over year's and has cut more then 50km of pipe and profiles over the last years. I cutted about 10km of pipe with this processor, to give you an idea.

Without the GPL2 licence Linuxcnc would be less and less powerfull as today's Linuxcnc power is very, very high, top level, high end solution's can be made without problem's. No window's pc can compare with linux at this day's. It's the same vision as Elon Musk and Linus Torvalds and many other's, like the custom linux user's all over the world.

We collect and share info, data and provide example's, give code back, just as the GPL2 licence is intended for.

The extra added line's in the post processor are good to be provided as GPL2 based lines.

A quote from Elvis : " time can do so much "

Last edit: 05 Jun 2019 17:32 by Grotius.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

05 Jun 2019 23:37 #135986

by tommylight

Replied by tommylight on topic Linuxcnc plasma rotary

@Grotius

Your machines look much better than mine!

Good job and thank you.

Your machines look much better than mine!

Good job and thank you.

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

06 Jun 2019 13:09 #136039

by BigJohnT

Replied by BigJohnT on topic Linuxcnc plasma rotary

Indeed that is a very nice machine!

JT

JT

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

08 Jun 2019 21:14 - 08 Jun 2019 21:23 #136307

by Grotius

Replied by Grotius on topic Linuxcnc plasma rotary

Thanks for the compliment's.

I was testing the postprocesor for a while and i see 2-3 tiny thing's that has to be solved.

1. M30 has to be changed to M2.

2. Sheetcam has a little bug at the second last line of the g-code, not very important. Will compare some output code monday.

It only appear's when you don't cut off the profile, but the last cut is a circle cut. Then it prompt to forget a M5 when moving away.

3. G64P0.01 is accurate enough for sheet cutting, for tube cutting G64P0.05 is not accurate enough at some perpendiculair moves. I have too look how to solve this, I only need the G64P0.05 to ensure a acceptable rotary speed with the torch moving handshake, problem appear's only when cutting big profiles on the rotary. I hope to solve this monday.

I was testing the postprocesor for a while and i see 2-3 tiny thing's that has to be solved.

1. M30 has to be changed to M2.

2. Sheetcam has a little bug at the second last line of the g-code, not very important. Will compare some output code monday.

It only appear's when you don't cut off the profile, but the last cut is a circle cut. Then it prompt to forget a M5 when moving away.

3. G64P0.01 is accurate enough for sheet cutting, for tube cutting G64P0.05 is not accurate enough at some perpendiculair moves. I have too look how to solve this, I only need the G64P0.05 to ensure a acceptable rotary speed with the torch moving handshake, problem appear's only when cutting big profiles on the rotary. I hope to solve this monday.

Last edit: 08 Jun 2019 21:23 by Grotius.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

08 Jun 2019 23:46 #136316

by tommylight

Replied by tommylight on topic Linuxcnc plasma rotary

Are you using the THC to follow the contour of square tubing or from gcode output of sheetcam driving Z axis without THC?

Did some experimenting a while back with a fast Z axis and a Prima THC, it did work quite good, but noticed that on the way down the torch would lag a bit meaning to high from the tube, but the cut was OK. This was with max. 50X50mm square tubing, did not need more so did not try but I doubt it would work as the slope becomes to much for the THC to follow. Also this was with only one moving axis, so the torch was moving only in one axis and Z height.

I am aware that having both axis X and Y moving and using a post processor is much better and can cut any size the machine can handle, but I did not have the post processor and lacked time.

Thanks for the info.

BTW, the last rotary I built had only probing with no THC as it was only for round tubing. Ended up pretty cheap and the client is extremely happy with it. Also looked nicer than the rest of my machines. I did post pictures and videos here I think.......or did I???

Did some experimenting a while back with a fast Z axis and a Prima THC, it did work quite good, but noticed that on the way down the torch would lag a bit meaning to high from the tube, but the cut was OK. This was with max. 50X50mm square tubing, did not need more so did not try but I doubt it would work as the slope becomes to much for the THC to follow. Also this was with only one moving axis, so the torch was moving only in one axis and Z height.

I am aware that having both axis X and Y moving and using a post processor is much better and can cut any size the machine can handle, but I did not have the post processor and lacked time.

Thanks for the info.

BTW, the last rotary I built had only probing with no THC as it was only for round tubing. Ended up pretty cheap and the client is extremely happy with it. Also looked nicer than the rest of my machines. I did post pictures and videos here I think.......or did I???

Please Log in or Create an account to join the conversation.

- Grotius

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

09 Jun 2019 20:16 - 09 Jun 2019 20:19 #136400

by Grotius

Replied by Grotius on topic Linuxcnc plasma rotary

@Tommy,

Are you using the THC to follow the contour of square tubing or from gcode output of sheetcam driving Z axis without THC?

In my case we can do both option's. It will execute the movement's based on gcode. When activating the torch height control

it will do correction's based on torch volt control. The torch volt control is based on the integrated Exernal Offset branche.

Did some experimenting a while back with a fast Z axis and a Proma THC, it did work quite good, but noticed that on the way down the torch would lag a bit meaning to high from the tube,

Users can use the Probe function if they want to. Optimizing the switch offset value output's in a perfect start height. But i prefer to not use the probe function for tube cutters.

I did post pictures and videos here I think.......or did I???

Yes, you did post pictures of your tube cutter application.

Additional info for tube cutters in linux.

The negative adaptive feed result's in a very simple restart procedure, done by the component. In my case the THC2 component designed for sheet metal cutters works even so good for a tube cutter i mentioned.

Are you using the THC to follow the contour of square tubing or from gcode output of sheetcam driving Z axis without THC?

In my case we can do both option's. It will execute the movement's based on gcode. When activating the torch height control

it will do correction's based on torch volt control. The torch volt control is based on the integrated Exernal Offset branche.

Did some experimenting a while back with a fast Z axis and a Proma THC, it did work quite good, but noticed that on the way down the torch would lag a bit meaning to high from the tube,

Users can use the Probe function if they want to. Optimizing the switch offset value output's in a perfect start height. But i prefer to not use the probe function for tube cutters.

I did post pictures and videos here I think.......or did I???

Yes, you did post pictures of your tube cutter application.

Additional info for tube cutters in linux.

The negative adaptive feed result's in a very simple restart procedure, done by the component. In my case the THC2 component designed for sheet metal cutters works even so good for a tube cutter i mentioned.

Last edit: 09 Jun 2019 20:19 by Grotius.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

09 Jun 2019 23:32 #136423

by tommylight

Replied by tommylight on topic Linuxcnc plasma rotary

Thank you for letting me know, I was not sure if I did post it. Way to much to do and another issue I have since the end of last year is I will have to move soon as my house and workshop are going to be demolished to make way for new buildings so I can not expand the workshop for now and it got very cramped there so a lot of projects got frozen.

Not a nice feeling at all, but the good thing is I will have a much larger workshop, but the wait is killing me !!!

Not a nice feeling at all, but the good thing is I will have a much larger workshop, but the wait is killing me !!!

Please Log in or Create an account to join the conversation.

- marcolagares

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

01 Dec 2020 12:54 #190750

by marcolagares

Replied by marcolagares on topic Linuxcnc plasma rotary

Hi Grotius,

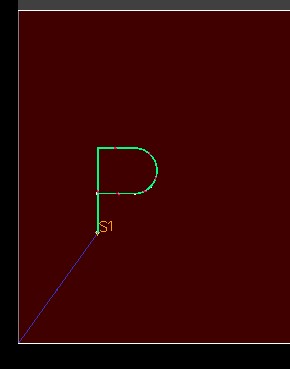

Many thank´s for sharing your work. I was testing your post doing a P (see attach) and i got it mirrored.

I used the rigth hand rule (see attach) to configurate the rotary axis pointing thumb to the chuck.

Since is my 1st time doing this application what i am missing here? Machine setup, Sheetcam setup?

Thank´s in advance.

Many thank´s for sharing your work. I was testing your post doing a P (see attach) and i got it mirrored.

I used the rigth hand rule (see attach) to configurate the rotary axis pointing thumb to the chuck.

Since is my 1st time doing this application what i am missing here? Machine setup, Sheetcam setup?

Thank´s in advance.

Please Log in or Create an account to join the conversation.

Time to create page: 0.140 seconds