Probe_basic Toolchanger

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

30 Mar 2023 19:55 #267937

by CNC_ANDI

Probe_basic Toolchanger was created by CNC_ANDI

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

30 Mar 2023 20:33 #267939

by spumco

Replied by spumco on topic Probe_basic Toolchanger

Yes, I've got an ATC working with PB. I wouldn't trust it for unattended lights-out production work, but it hasn't crashed after a couple hundred changes (obviously completed very recently)

Before I dump my files on you... toolchangers can be very complicated on the software side of things. Any document or manual which explains how to set one up would need to cover all the ways an ATC can be controlled - both on the hardware and software side.

In the mean time, please search the QtPyVCP subforum and you should be able to see rather a lot of posts from me over the past 12-18 months asking questions (and rambling on) about Probe Basic ATC's.

Before I dump my files on you... toolchangers can be very complicated on the software side of things. Any document or manual which explains how to set one up would need to cover all the ways an ATC can be controlled - both on the hardware and software side.

- What type of machine is it on?

- Mill, router, lathe, other?

- What drives the platter rotation?

- Stepper/servo, DC motor, AC motor, geneva wheel mechanism?

- What else moves?

- Platter slides to the spindle? Air or servo/stepper?

- Head moves up/down?

- Platter stationary and gantry & head move to it?

- What releases the tool?

- What level of safety-related sensing do you require?

- How much damage can happen if the ATC sequence goes wrong?

- Imagine the head is up with a tool in the spindle. The ATC moves in to the toolchange position but there's a tool in the supposedly-empty pocket. How much will you care if the head and tool come crashing down at rapid speed in to the ATC? Will you be annoyed a little bit, or will you now have a $10k bill for a new spindle?

- The answer will help determine how much money & time you will want to spend on various sensors & software safety checks to reduce the risk of a crash.

In the mean time, please search the QtPyVCP subforum and you should be able to see rather a lot of posts from me over the past 12-18 months asking questions (and rambling on) about Probe Basic ATC's.

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

31 Mar 2023 10:50 - 31 Mar 2023 12:46 #267962

by CNC_ANDI

Replied by CNC_ANDI on topic Probe_basic Toolchanger

Hello thanks for your post.

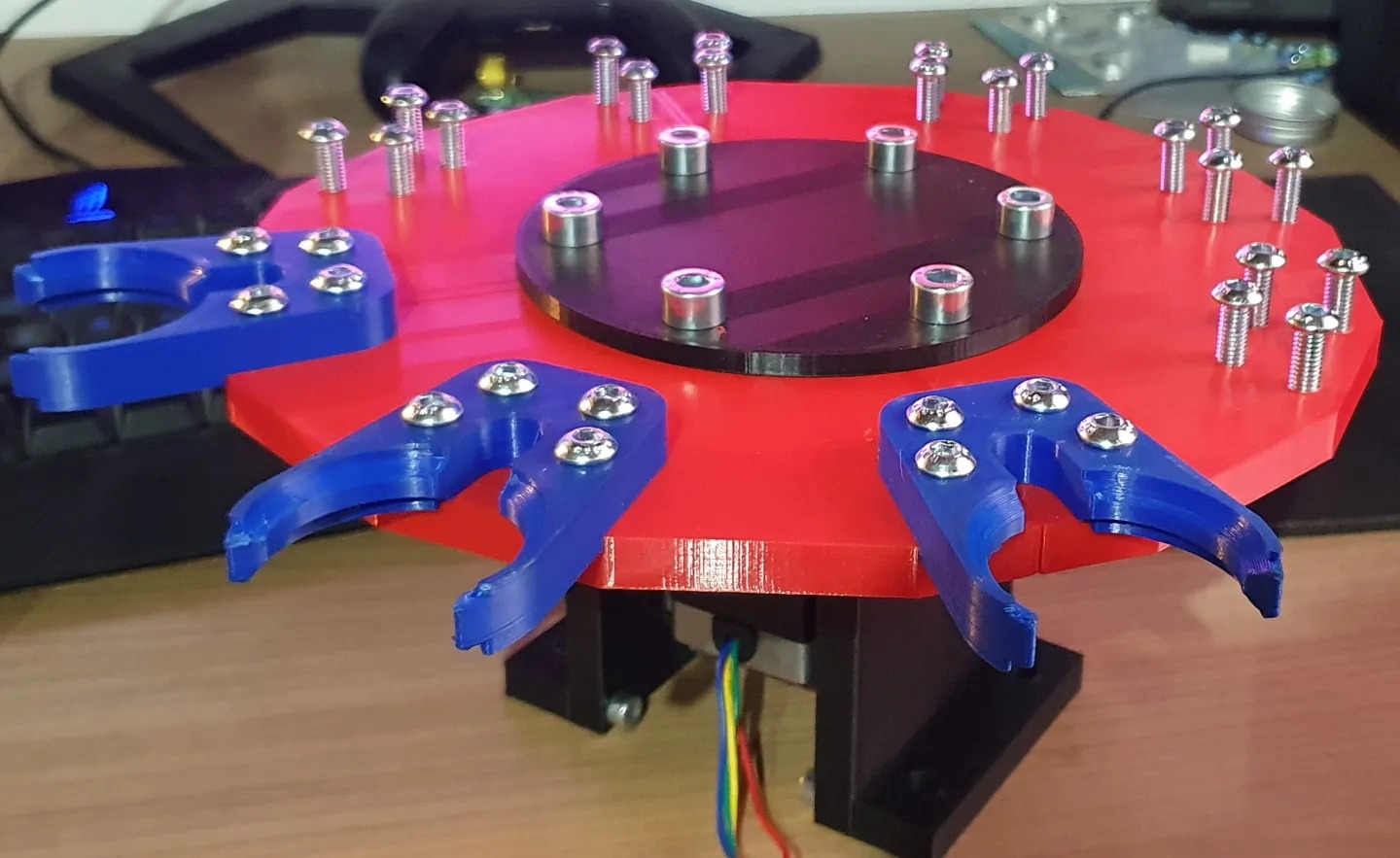

The toolchanger is driven by a Stepper Motor.

The Atc has a fixed position.

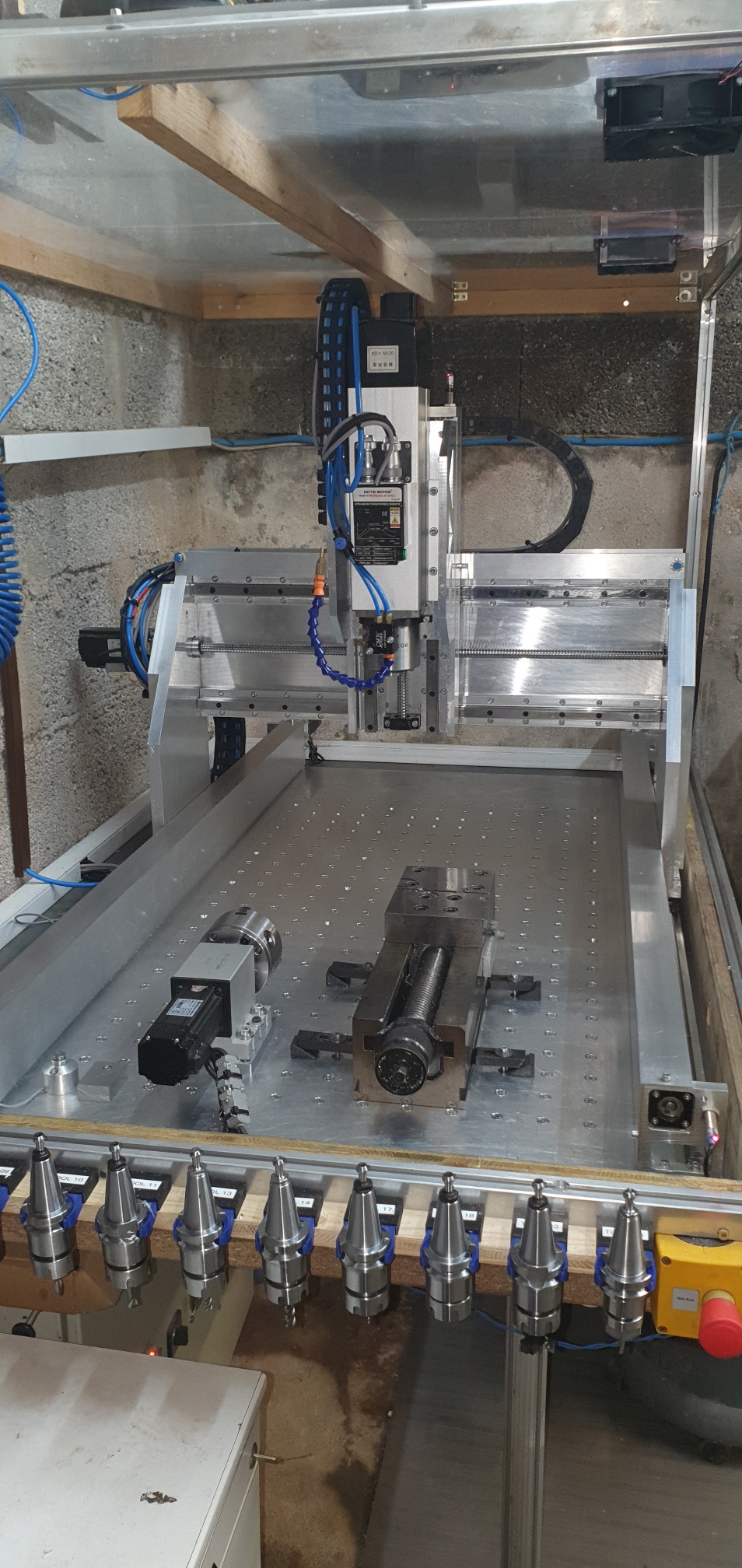

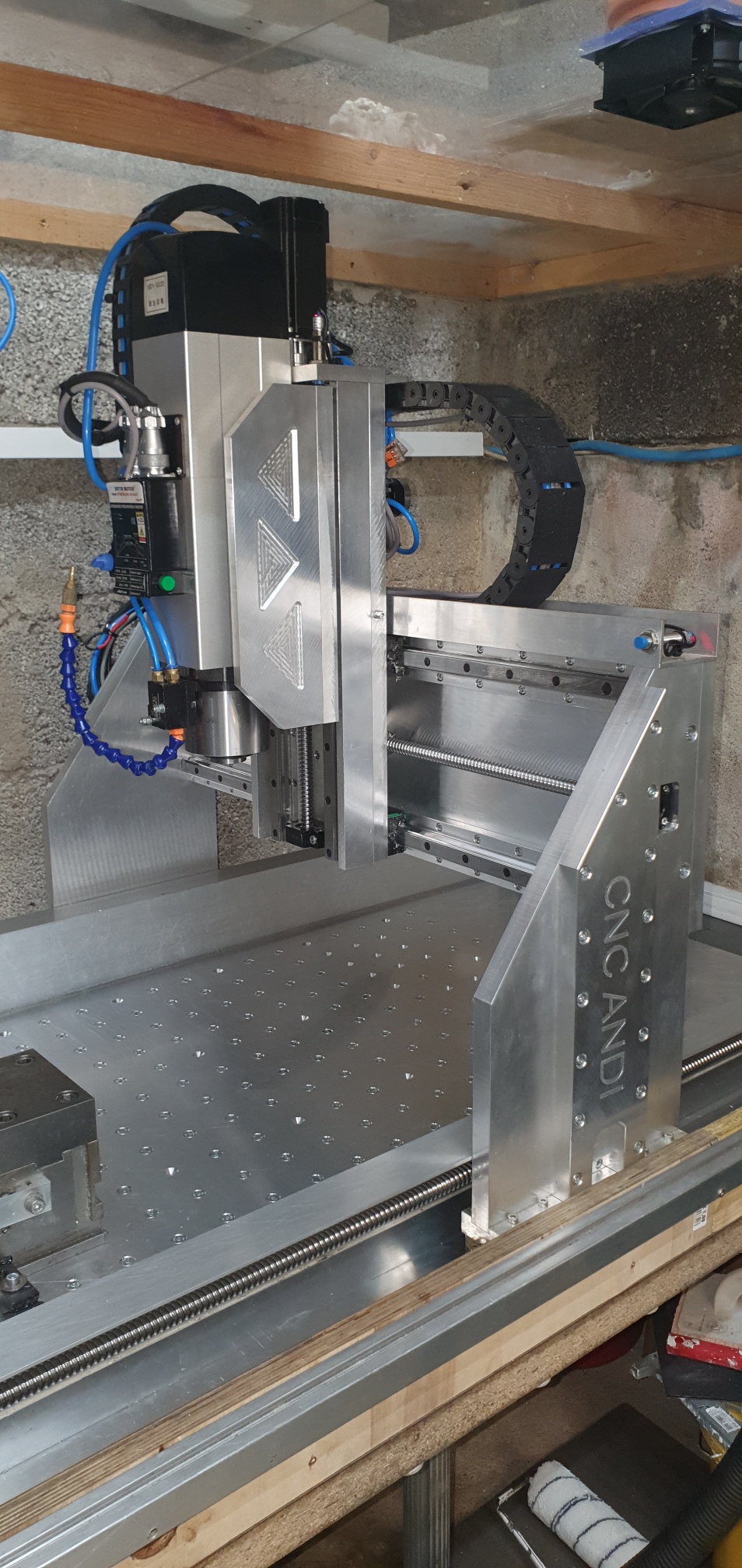

By Bt30 spindle will pick up the tool.

Move to toolchange position in g53 z0 , Z down, Y +, unclamp, z up, clamp, toolchanger rotate, unclamp, z down, clamp, Y -, toolchangeposition g53 z0

I think my spindle have 2 sensors for clamped oder unclamped tool.

see the pictures for my spindle, machine and toolchanger....

the toolchanger will be placed on the back site of the machine...

The toolchanger is driven by a Stepper Motor.

The Atc has a fixed position.

By Bt30 spindle will pick up the tool.

Move to toolchange position in g53 z0 , Z down, Y +, unclamp, z up, clamp, toolchanger rotate, unclamp, z down, clamp, Y -, toolchangeposition g53 z0

I think my spindle have 2 sensors for clamped oder unclamped tool.

see the pictures for my spindle, machine and toolchanger....

the toolchanger will be placed on the back site of the machine...

Attachments:

Last edit: 31 Mar 2023 12:46 by CNC_ANDI.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

31 Mar 2023 19:44 #267981

by spumco

Replied by spumco on topic Probe_basic Toolchanger

You appear to have a rack-type tool changer already. Is it working, and what GUI are you using now?

Is your intention simply to change from the rack-type to a carousel-type?

Is your intention simply to change from the rack-type to a carousel-type?

The following user(s) said Thank You: tommylight, CNC_ANDI

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

31 Mar 2023 19:57 #267982

by tommylight

Replied by tommylight on topic Probe_basic Toolchanger

More important, where are the STL files?

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

01 Apr 2023 07:28 #268010

by CNC_ANDI

Replied by CNC_ANDI on topic Probe_basic Toolchanger

no i don´t have an toolchanger... at this time i change my tools manual...

i´m interested who i can configure the standart probe_basic toolchanger...

is the probe_basic toolchanger running by an axis? or can i run the toolchanger by an arduino?

my 5th axis connector of the mesacard is full ^^ XYYZB...

which stl files? from the toolchanger or the machine ^^

i´m interested who i can configure the standart probe_basic toolchanger...

is the probe_basic toolchanger running by an axis? or can i run the toolchanger by an arduino?

my 5th axis connector of the mesacard is full ^^ XYYZB...

More important, where are the STL files?

which stl files? from the toolchanger or the machine ^^

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

01 Apr 2023 10:32 #268014

by tommylight

Replied by tommylight on topic Probe_basic Toolchanger

Tool changer, it is 3D printed in your pictures.

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

01 Apr 2023 11:10 #268015

by CNC_ANDI

Replied by CNC_ANDI on topic Probe_basic Toolchanger

yes, it´s my prototype and all parts are 3D printed...if this toolchanger works fine i will mill all parts in alloy...

but now it´s time to configure this thing...

but i don´t now how. so i need much help to realize this.

i will make a deal with you... help me to get this to work fine and i will give you the complete projekt as an .step

but now it´s time to configure this thing...

but i don´t now how. so i need much help to realize this.

i will make a deal with you... help me to get this to work fine and i will give you the complete projekt as an .step

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

01 Apr 2023 18:57 #268026

by spumco

Replied by spumco on topic Probe_basic Toolchanger

Ok, thanks for the background. As I mentioned there a quite a few ways to control a toolchanger, but let's settle on the hardware config before working on the control scheme.

The fundamental objective is to rotate the ATC platter to a specific location. That must be done using a mechanical stop/index (of some sort) or by using a positioning system. All the other functions of the ATC system are secondary - or at least there is some flexibility in how/what is implemented.

You mentioned that you are out of stepper motor outputs on your Mesa config. As the motor system will likely drive (or be driven by) the above hardware choices...you have a few options:

That's a lot to chew on. Once you've decided on a motor/drive & hardware scheme - or you have more questions about what to do - we can move on to the control side of things.

The fundamental objective is to rotate the ATC platter to a specific location. That must be done using a mechanical stop/index (of some sort) or by using a positioning system. All the other functions of the ATC system are secondary - or at least there is some flexibility in how/what is implemented.

- Geneva wheel mechanism

- Acts as a mechanical indexer

- Can use a 'dumb' DC/AC motor

- Can also use a stepper or servo in velocity or position mode

- Likely requires more fabrication and mechanical fiddling than a planetary/belt drive

- Requires much less programming modifications to Probe Basic

- The "OEM" version of Probe Basic (PB from now on) is designed to control an ATC disc/platter/carousel using a fixed-speed reversable motor (DC or 3phase AC) and a geneva wheel mechanism.

- Planetary reducer (or belt drive, or similar)

- Does not mechanically align the pocket with the spindle

- Thus, requires a motor to be controlled in position mode, OR

- Requires some other mechanism to ensure the pocket is aligned (like a pneumatic shot pin or detent at each pocket)

- Must use stepper or servo motor (if no additional locking alignment mechanism present)

- Likely requires less fabrication and mechanical fiddling

- Requires more programming modifications to PB

- My modified version of PB uses a stepper motor and a 5:1 planetary reducer to index the carousel.

- Does not mechanically align the pocket with the spindle

- Other drive mechanism

- If you want, you could have a 'one-way' carousel/platter like some lathe turrets. These have a ratchet & pawl mechanism and you drive the turret in one direction past a stop and then the motor reverses against the stop for pocket alignment.

- This could use a dumb motor or a step/servo

- I'm sure there are other hardware configurations you can use, but the further you get from the "OEM" version of PB or my stepper w/planetary config, the less help I can be.

- If you want, you could have a 'one-way' carousel/platter like some lathe turrets. These have a ratchet & pawl mechanism and you drive the turret in one direction past a stop and then the motor reverses against the stop for pocket alignment.

You mentioned that you are out of stepper motor outputs on your Mesa config. As the motor system will likely drive (or be driven by) the above hardware choices...you have a few options:

- Geneva wheel or ratchet/pawl only:

- Buy a DC or reversable AC motor and buy or fabricate a geneva wheel mechanism

- Planetary OR geneva wheel:

- Buy another Mesa card to support an additional step/direction output

- Ethercat step/servo drive and control it directly (not wired to Mesa)

- Step/servo drive that has internal indexing functions and uses a digital input (or an array of inputs) to move a specific distance

- Depending on your computer, you might have a parallel port and can use that to control an additional step/servo drive

- Use an arduino (or similar) as an 'indexer'

- LCNC outputs a digital on/off signal to the arduino

- Arduino sends a pre-programmed number of pulses to the step/servo drive

That's a lot to chew on. Once you've decided on a motor/drive & hardware scheme - or you have more questions about what to do - we can move on to the control side of things.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

01 Apr 2023 22:08 #268037

by tommylight

Replied by tommylight on topic Probe_basic Toolchanger

What Mesa board?

And thank you for the offer/deal, i would like to have the time to build a tool changer to experiment with and to test the carousel component with real hardware, and i have plenty of hardware so i can do stepper/position driven, DC motor driven, or whatever might be a good idea to try, also have a big box of sensors in all types and shapes.

Also, i would like to build a decent mill from all the cr@p... stuff i have in the shop, the HiWin and THK rails are getting rusty without ever being used!

And thank you for the offer/deal, i would like to have the time to build a tool changer to experiment with and to test the carousel component with real hardware, and i have plenty of hardware so i can do stepper/position driven, DC motor driven, or whatever might be a good idea to try, also have a big box of sensors in all types and shapes.

Also, i would like to build a decent mill from all the cr@p... stuff i have in the shop, the HiWin and THK rails are getting rusty without ever being used!

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.169 seconds