ProbeBasic and sidemount, retractable 3D Probe

- IB_CnC

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 14

09 Feb 2025 19:56 #321108

by IB_CnC

Replied by IB_CnC on topic ProbeBasic and sidemount, retractable 3D Probe

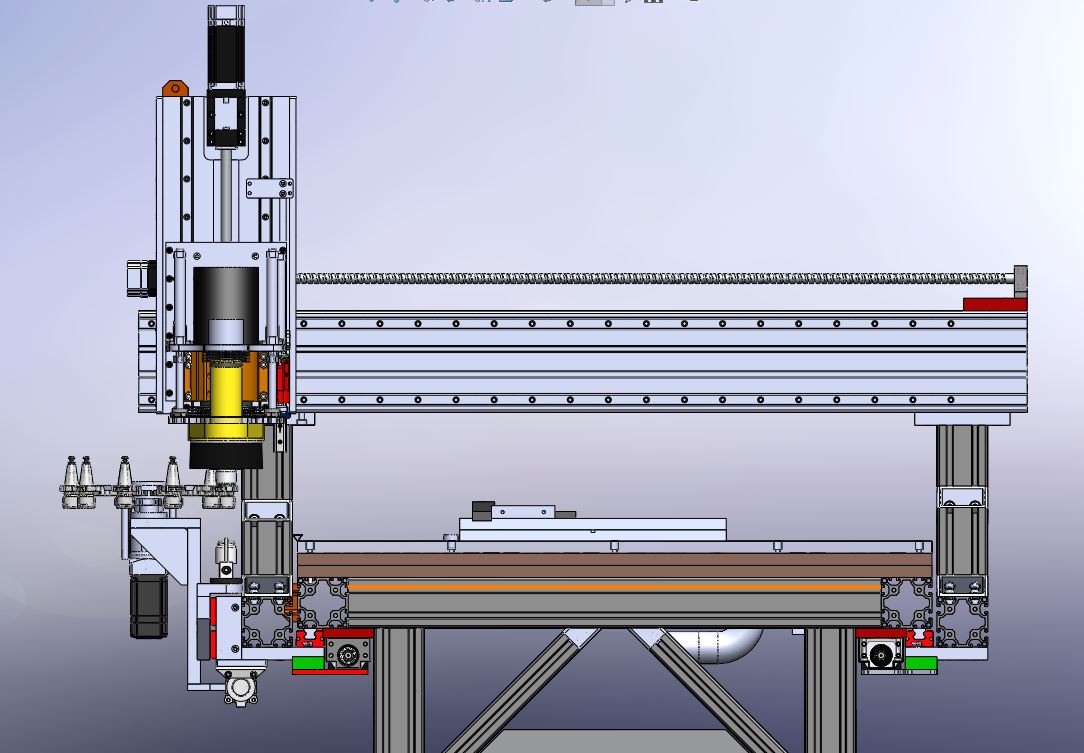

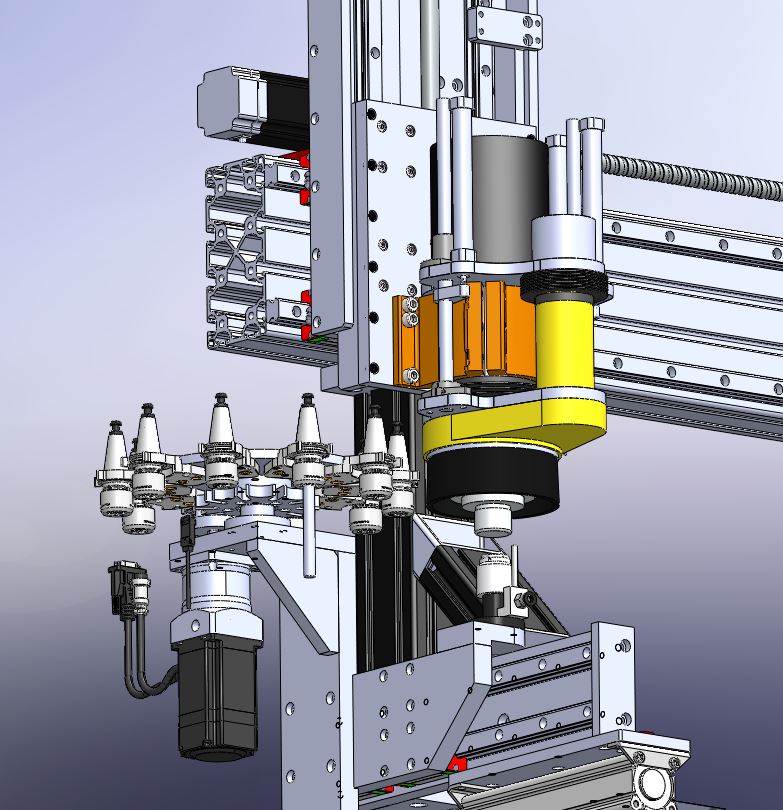

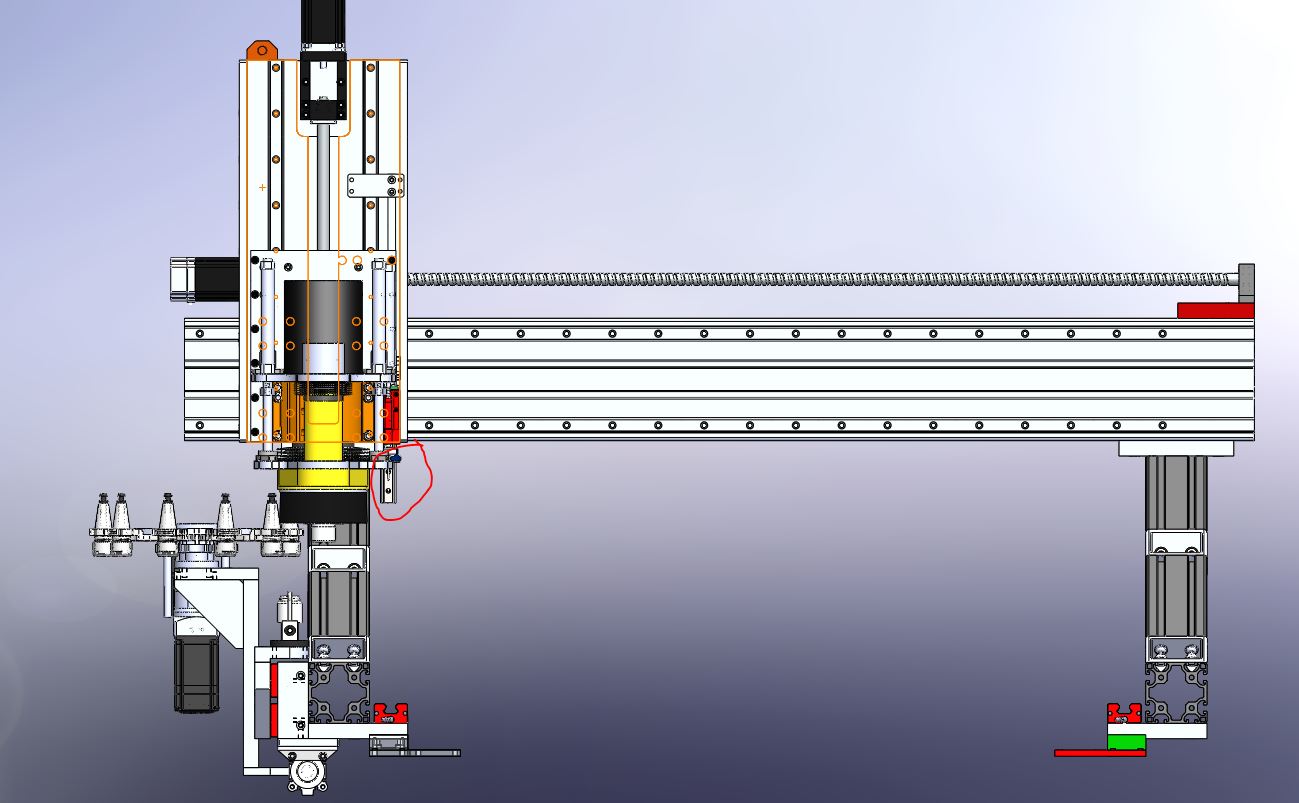

Yes, a rack would be easier for sure and save quite a bit of time, debugging and possibly issues.

But would I extend the work area, I still don't want to lose 10cm to the rack.

Also due to exponentially increase of the risk of ballscrew whip, I don't want to go bigger than 2000mm on the screws, which means 1840mm of work area after extending +200mm.

It's just my application, probably for most other people it would be fine to place the rack.

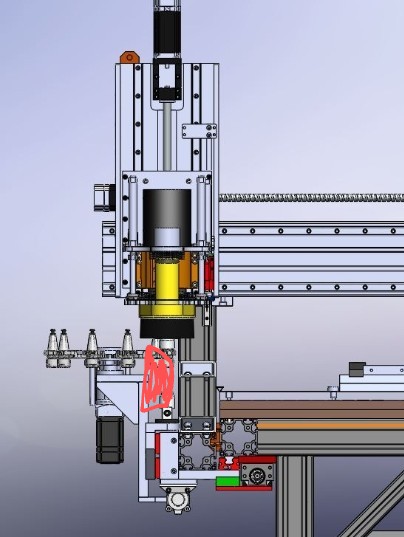

Construction wise, I only shifted the X beam about 5cm from the current symmetric configuration.

It wasn't easy to design but there is room to do the toolchange outside of the working area and still reach the full width with the mill and probe.

One issue I have to solve is the retractable probe is entering the work area, so I will change that later on to a different construction not protruding, with two carriers,

Would only be an issue if I put something on the table which occupies the whole space, like a huge block of foam.

But would I extend the work area, I still don't want to lose 10cm to the rack.

Also due to exponentially increase of the risk of ballscrew whip, I don't want to go bigger than 2000mm on the screws, which means 1840mm of work area after extending +200mm.

It's just my application, probably for most other people it would be fine to place the rack.

Construction wise, I only shifted the X beam about 5cm from the current symmetric configuration.

It wasn't easy to design but there is room to do the toolchange outside of the working area and still reach the full width with the mill and probe.

One issue I have to solve is the retractable probe is entering the work area, so I will change that later on to a different construction not protruding, with two carriers,

Would only be an issue if I put something on the table which occupies the whole space, like a huge block of foam.

Attachments:

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Away

- Moderator

-

Less

More

- Posts: 1549

- Thank you received: 727

10 Feb 2025 02:18 #321134

by Lcvette

Replied by Lcvette on topic ProbeBasic and sidemount, retractable 3D Probe

Attachments:

Please Log in or Create an account to join the conversation.

- IB_CnC

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 14

10 Feb 2025 16:43 - 10 Feb 2025 16:52 #321171

by IB_CnC

Replied by IB_CnC on topic ProbeBasic and sidemount, retractable 3D Probe

Ahh yes, apologies I did misinterpret.

Yes that would be possibly I think, I did not see this possibility when I was drawing out concepts.

It would require a fairly large (stationary) support structure outside of gantry support, and access to table would be limited a bit, but other than that it should work.

I did already buy all parts for the carousel and got all the aluminum plates ready to route the holes, but its a good alternative option without loosing work area!

Yes that would be possibly I think, I did not see this possibility when I was drawing out concepts.

It would require a fairly large (stationary) support structure outside of gantry support, and access to table would be limited a bit, but other than that it should work.

I did already buy all parts for the carousel and got all the aluminum plates ready to route the holes, but its a good alternative option without loosing work area!

Last edit: 10 Feb 2025 16:52 by IB_CnC.

Please Log in or Create an account to join the conversation.

- IB_CnC

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 14

10 Feb 2025 20:38 #321185

by IB_CnC

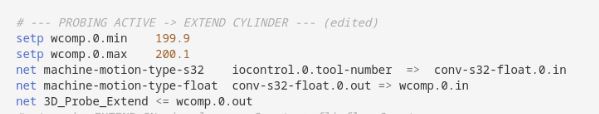

I made it like this now, reading the tool number, converting to float, compare with wcomp.

3D_Probe_Extend is bound to an output pin on my mesa daughter card.

Replied by IB_CnC on topic ProbeBasic and sidemount, retractable 3D Probe

nice.. have you considered simply adding the probing tool number parameter to the toolchange call with an if statement? this way anytime you load or unload the probe tool it would activate a subroutine to either deploy the probe or retract it?

I made it like this now, reading the tool number, converting to float, compare with wcomp.

3D_Probe_Extend is bound to an output pin on my mesa daughter card.

Attachments:

Please Log in or Create an account to join the conversation.

- IB_CnC

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 14

11 Feb 2025 06:33 #321210

by IB_CnC

Replied by IB_CnC on topic ProbeBasic and sidemount, retractable 3D Probe

I obviously forgot to rename the signals.

motion-type isn't used anymore, so naming should be:

tool-number-s32 and tool-number-float.

motion-type isn't used anymore, so naming should be:

tool-number-s32 and tool-number-float.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Away

- Moderator

-

Less

More

- Posts: 1549

- Thank you received: 727

11 Feb 2025 19:25 #321268

by Lcvette

Replied by Lcvette on topic ProbeBasic and sidemount, retractable 3D Probe

sweet! let me know how it works for you!

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.180 seconds