Servo drives costing 22 euros for 2 motors

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

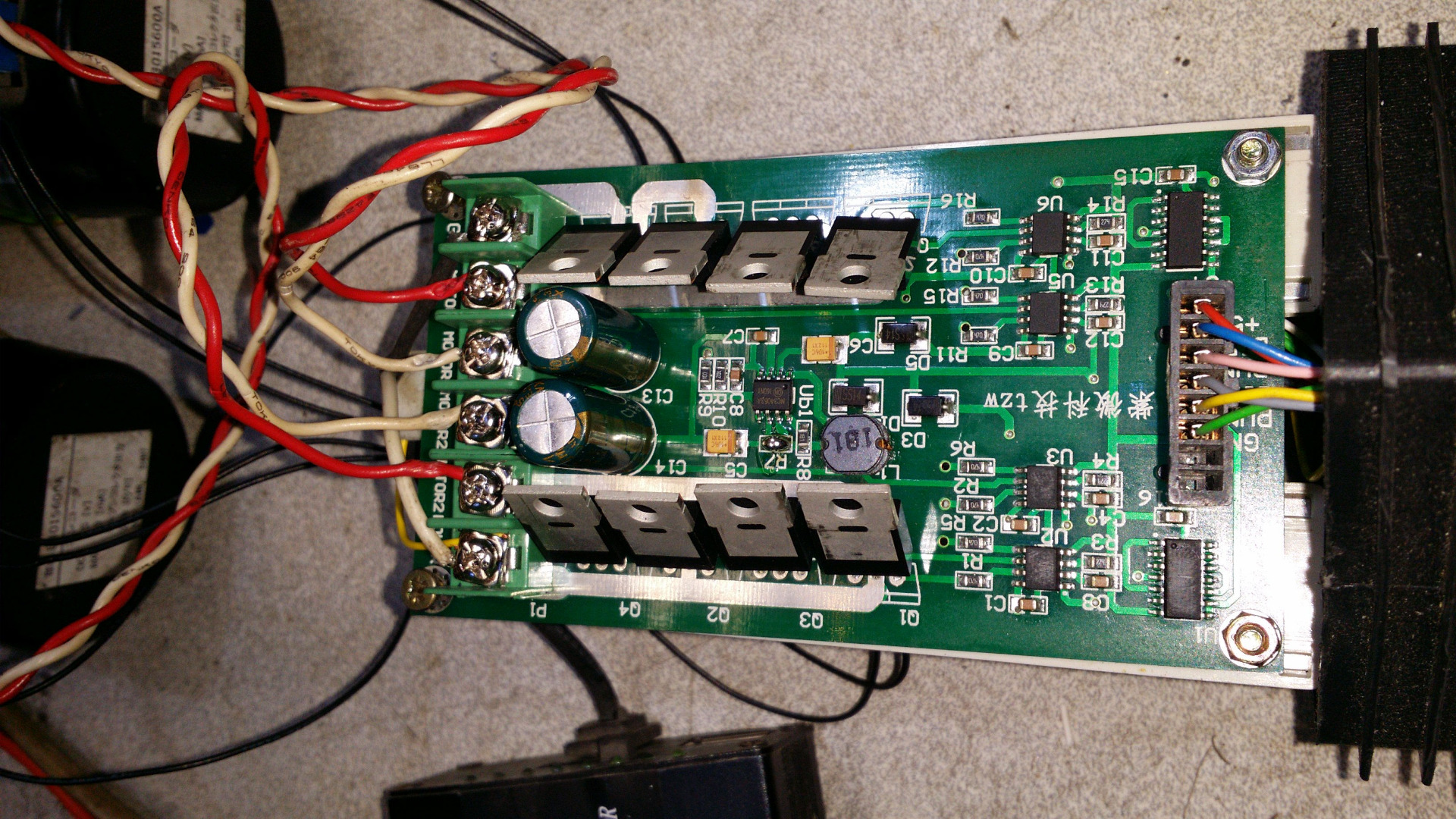

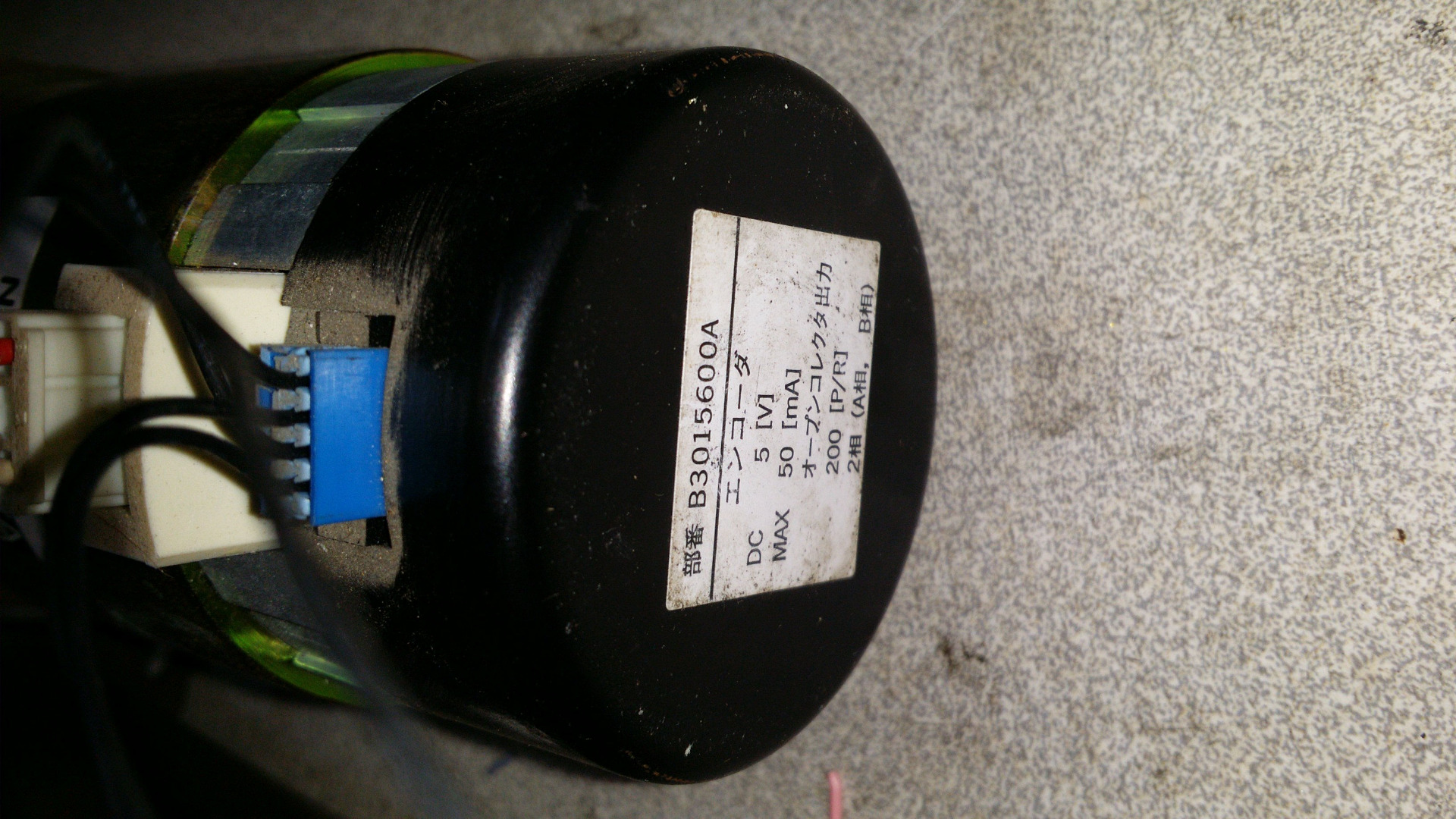

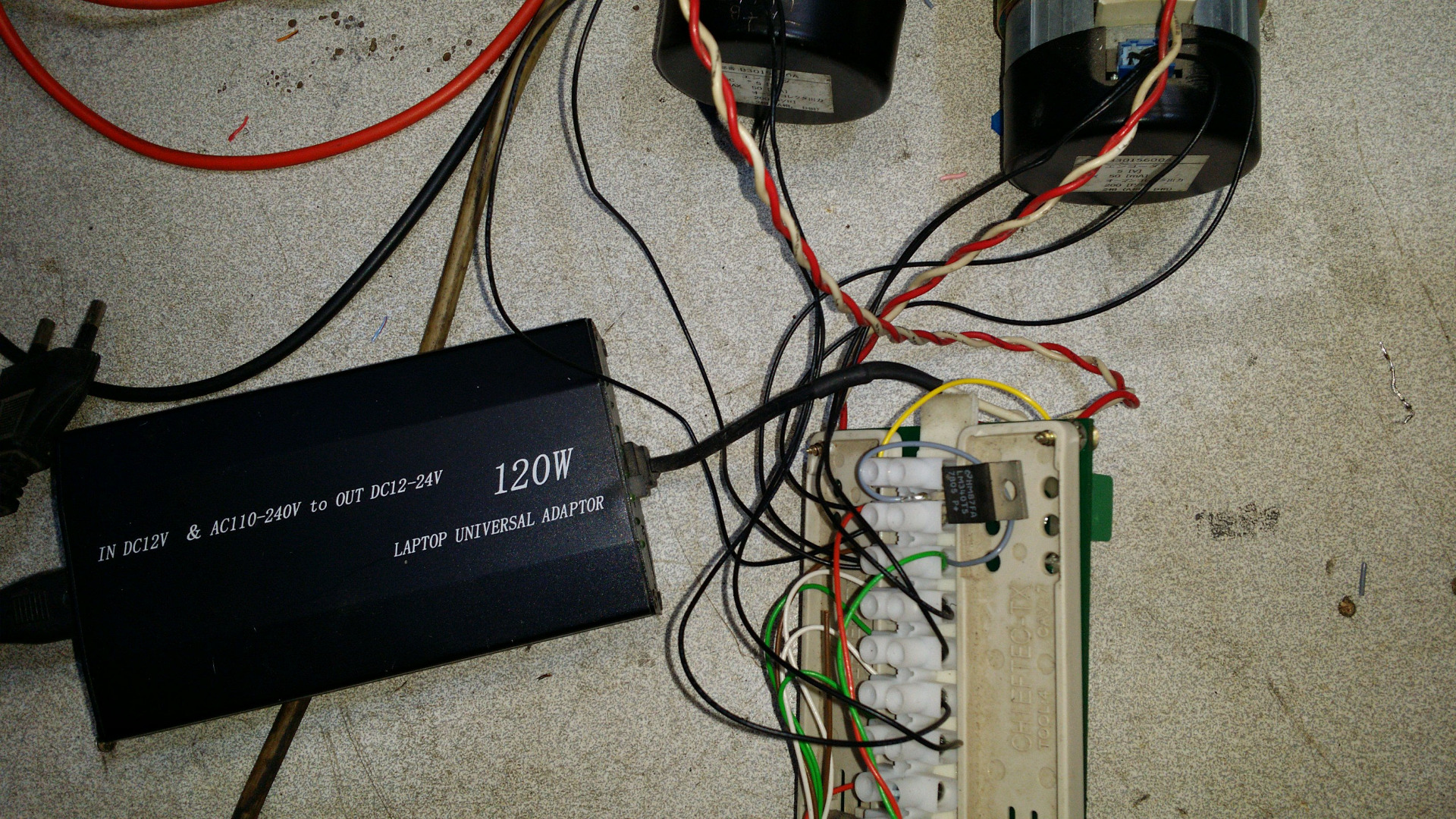

Used the "etch servo" config as a base for it and modified it with PWM and encoder monitoring.

Took a lot of trial and error, but they do work quite nicely and i think they can do a decent job on a small hobby machine, and as a useful tool to understand servo drives and PID loops etc.

Video

Please Log in or Create an account to join the conversation.

- jtc

-

- Offline

- Premium Member

-

- Posts: 147

- Thank you received: 12

recently I bought a IGBT module with hope of some of this days start to build a servo drive, something like that to start

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Platinum Member

-

- Posts: 1931

- Thank you received: 394

If you build them yourself yo will have to spend about 70 Euro for parts

stmbl servo

Norbert

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

so this is basically a H bridge that the pwm is controlled by the PID of linuxcnc? It should be interesting attach a load to the motors ans see how it preforms.

recently I bought a IGBT module with hope of some of this days start to build a servo drive, something like that to start

Yes and i did connect them on a mill i am building, it takes quite some time to set them up properly, but it does pay off as they do work nicely and stop at 0.02mm max difference. I can live with that!

Then again they do not have current limiting, so i have to use power supply and motors that do not draw over 7-8 amp at stall.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

I use stmbl servo drives for some of my stuff. This are servo amplifieres for AC servos of aprox 1kW and does support mot feedback systems.

If you build them yourself yo will have to spend about 70 Euro for parts

stmbl servo

Norbert

Damn, those are nice.

I do have professional servo drives from NORWIN collecting dust, this is something i like to do, not something i need. I have around 20 of those small motors so it is useful for smaller machines that i build. I can also use one of those as a stepper drive, and configure Linuxcnc to drive it at half step, but then again i have plenty pf Gecko drives and other very powerful stepper drives i modified to push 15A per phase easily with current limiting and everything.

This was more to show other forum members that they can use Linuxcnc with some work a very little money to drive stepper motors ( there is an thread on this forum i did for cheapest stepper drives ever using 4 Darlington transistors and 4 resistors to drive one motor) or servo motors, at least they can have the control and drive system on the cheap, some scavenging for motors required ! At 2$ for a stepper and at 11$ for a servo, there is nothing cheaper.

Question: Those drives you mentioned, they use a IC for the power stage, right?

I intentionally chose exactly these drives as the mosfets can be replaced if the magic smoke escapes, in most cases the gate drive IC survive.

Please Log in or Create an account to join the conversation.

- jtc

-

- Offline

- Premium Member

-

- Posts: 147

- Thank you received: 12

Yes and i did connect them on a mill i am building, it takes quite some time to set them up properly, but it does pay off as they do work nicely and stop at 0.02mm max difference. I can live with that!

Then again they do not have current limiting, so i have to use power supply and motors that do not draw over 7-8 amp at stall.

and why not let the linuxcnc sense the current apart from the drive? then it can limit the pwm width (maybe limiting PID output).

João

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

To many projects, not enough time.

Please Log in or Create an account to join the conversation.

- jtc

-

- Offline

- Premium Member

-

- Posts: 147

- Thank you received: 12

That would require ADC (analog to digital) conversion, so "cheap" goes out the window. But every computer has at least 2 analog to digital converters built in and another but, someone has to sit down and write a bit of code to get that analog signal from the audio input and send it to linuxcnc so it can deal with that.

To many projects, not enough time.

I was tinkling on a voltage to frequency converter, there are 2€ or less that can do that, and read the freq (amps) in a encoder input.

but yes, maybe it don't wroth the case.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

As of now i will not be able to order anything online for another month or so as the person who orders stuff for me is on vacation. If by any chance you can not wait that long, just mail one of those to me, and i will gladly test it one evening.

Tomorrow i have to install an 80 Amp plasma cuter to an existing CNC machine and from Sunday i have to start a retrofit of an Elumatec SBZ 130/01. That is going to be .......interesting !!!

Please Log in or Create an account to join the conversation.

- jtc

-

- Offline

- Premium Member

-

- Posts: 147

- Thank you received: 12

take a look at the lm331

www.peduto.it/data_sheet/LM231.pdf

and should be many others capable to do that...

João

Please Log in or Create an account to join the conversation.