Harmonic drive 4th axis build

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

15 Jan 2023 20:43 #262060

by andypugh

Replied by andypugh on topic Harmonic drive 4th axis build

You have

DEFAULT_ANGULAR_VELOCITY = 50.000000

So it seems that probe_basic isn't using that. It might be fixed? You would have to ask there.

The accelerations don't look low (I had already checked) but you could try pushing them a bit higher to see what happens.

DEFAULT_ANGULAR_VELOCITY = 50.000000

So it seems that probe_basic isn't using that. It might be fixed? You would have to ask there.

The accelerations don't look low (I had already checked) but you could try pushing them a bit higher to see what happens.

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

15 Jan 2023 21:10 #262065

by CNC_ANDI

Replied by CNC_ANDI on topic Harmonic drive 4th axis build

yes i will open a topic in the probe basic thread for this.

ok i will test it again with the accelerations tomorrow.

thank you

ok i will test it again with the accelerations tomorrow.

thank you

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

17 Jan 2023 19:44 #262264

by CNC_ANDI

Replied by CNC_ANDI on topic Harmonic drive 4th axis build

So today i have tested the programm with double acclereations.... but nothing changes.

Simultan Programm is slow as before.

Changed the acclereations for xyz from 750 to 1500....

Simultan Programm is slow as before.

Changed the acclereations for xyz from 750 to 1500....

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

17 Jan 2023 20:46 #262269

by andypugh

Replied by andypugh on topic Harmonic drive 4th axis build

Can you explain again which code you are seeing the problem with?

In an earlier post I only saw one B axis move,

N81115 G93 B-982.046 F269.4382

And that isn't a combined move, so perhaps I am on the wrong track.

Anyway, without knowing where the B axis was before the move, it's hard to work out what the speed should be.

Then for example

N81175 G0 Z21.

N81180 G1 Z15. F1100.

So a move of 6mm in 1/1100 of a minute, ie 6600 mm/min

In an earlier post I only saw one B axis move,

N81115 G93 B-982.046 F269.4382

And that isn't a combined move, so perhaps I am on the wrong track.

Anyway, without knowing where the B axis was before the move, it's hard to work out what the speed should be.

Then for example

N81175 G0 Z21.

N81180 G1 Z15. F1100.

So a move of 6mm in 1/1100 of a minute, ie 6600 mm/min

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

18 Jan 2023 09:43 - 18 Jan 2023 09:49 #262327

by CNC_ANDI

Replied by CNC_ANDI on topic Harmonic drive 4th axis build

At this code, the Movements are realy slow

you can see it here -

but at this code:

the movements are fine.

you can see it on the same video at ~16:20min.

you can see it here -

but at this code:

the movements are fine.

you can see it on the same video at ~16:20min.

Attachments:

Last edit: 18 Jan 2023 09:49 by CNC_ANDI.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Jan 2023 10:57 - 18 Jan 2023 10:58 #262330

by andypugh

Replied by andypugh on topic Harmonic drive 4th axis build

I think that it must be due to falling back to the older single-segment lookahead.

It seems to be slower when doing combined Z and B moves and faster when Z is not moving.

Looking a the "slow" G-code it is requesting 207 degrees/sec

delta ZZ vel (mm/sec)delta BB vel (deg/sec)Z11.104B-90.454F27344.8538 Z11.099B-90.859F30739.69230.0052.56164102-0.405207.4929Z11.094B-91.264F30702.33070.0052.55852756-0.405207.2407Z11.089B-91.618F35078.19650.0052.92318304-0.354206.9614Z11.084B-91.973F35055.96770.0052.92133064-0.355207.4145Z11.079B-92.329F35033.21990.0052.91943499-0.356207.8638Z11.074B-92.633F40846.69320.0053.4038911-0.304206.9566Z11.069B-92.938F40823.12950.0053.40192746-0.305207.5176Z11.064B-93.294F34968.8820.0052.9140735-0.356207.482Z11.059B-93.6F40770.33180.0053.39752765-0.306207.9287Z11.054B-93.855F48897.10910.0054.07475909-0.255207.8127Z11.049B-94.161F40724.67460.0053.39372288-0.306207.6958Z11.044B-94.467F40716.77050.0053.39306421-0.306207.6555Z11.039B-94.722F48805.88490.0054.06715708-0.255207.425Z11.034B-94.978F48779.42860.0054.06495238-0.256208.1256Z11.029B-95.234F48753.1790.0054.06276492-0.256208.0136Z11.024B-95.541F40603.31770.0053.38360981-0.307207.7536Z11.019B-95.746F60871.43590.0055.07261966-0.205207.9774

(Edit, this was a neatly formatted table when pasted from Excel..)

The Z step-down is _tiny_ which is probably part of the problem. The system will only reach a speed which will allow it to stop before the end of the next segment (in case that is the last segment. This is what single-segment lookahead means) Can you persuade the CAM to make the Z steps 10x larger? That should help.

To stop in 0.005 mm with an acceleration of 800mm/s the speed can not be higher than 2.6mm/s

To stop in 0.35 degrees with an acceleration of 4000 the angular speed can not be any higher than 50 deg/s

(v^2 = u^2 + 2as equation)

Again, these tiny steps make no sense, the system would smoothly interpolate between steps 10 or 100 times bigger.

It seems to be slower when doing combined Z and B moves and faster when Z is not moving.

Looking a the "slow" G-code it is requesting 207 degrees/sec

delta ZZ vel (mm/sec)delta BB vel (deg/sec)Z11.104B-90.454F27344.8538 Z11.099B-90.859F30739.69230.0052.56164102-0.405207.4929Z11.094B-91.264F30702.33070.0052.55852756-0.405207.2407Z11.089B-91.618F35078.19650.0052.92318304-0.354206.9614Z11.084B-91.973F35055.96770.0052.92133064-0.355207.4145Z11.079B-92.329F35033.21990.0052.91943499-0.356207.8638Z11.074B-92.633F40846.69320.0053.4038911-0.304206.9566Z11.069B-92.938F40823.12950.0053.40192746-0.305207.5176Z11.064B-93.294F34968.8820.0052.9140735-0.356207.482Z11.059B-93.6F40770.33180.0053.39752765-0.306207.9287Z11.054B-93.855F48897.10910.0054.07475909-0.255207.8127Z11.049B-94.161F40724.67460.0053.39372288-0.306207.6958Z11.044B-94.467F40716.77050.0053.39306421-0.306207.6555Z11.039B-94.722F48805.88490.0054.06715708-0.255207.425Z11.034B-94.978F48779.42860.0054.06495238-0.256208.1256Z11.029B-95.234F48753.1790.0054.06276492-0.256208.0136Z11.024B-95.541F40603.31770.0053.38360981-0.307207.7536Z11.019B-95.746F60871.43590.0055.07261966-0.205207.9774

(Edit, this was a neatly formatted table when pasted from Excel..)

The Z step-down is _tiny_ which is probably part of the problem. The system will only reach a speed which will allow it to stop before the end of the next segment (in case that is the last segment. This is what single-segment lookahead means) Can you persuade the CAM to make the Z steps 10x larger? That should help.

To stop in 0.005 mm with an acceleration of 800mm/s the speed can not be higher than 2.6mm/s

To stop in 0.35 degrees with an acceleration of 4000 the angular speed can not be any higher than 50 deg/s

(v^2 = u^2 + 2as equation)

Again, these tiny steps make no sense, the system would smoothly interpolate between steps 10 or 100 times bigger.

Last edit: 18 Jan 2023 10:58 by andypugh.

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

18 Jan 2023 16:05 #262347

by CNC_ANDI

Replied by CNC_ANDI on topic Harmonic drive 4th axis build

i dont know how i can do that. i´m using Fusion360 for this code.Can you persuade the CAM to make the Z steps 10x larger?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Jan 2023 17:03 #262355

by andypugh

Replied by andypugh on topic Harmonic drive 4th axis build

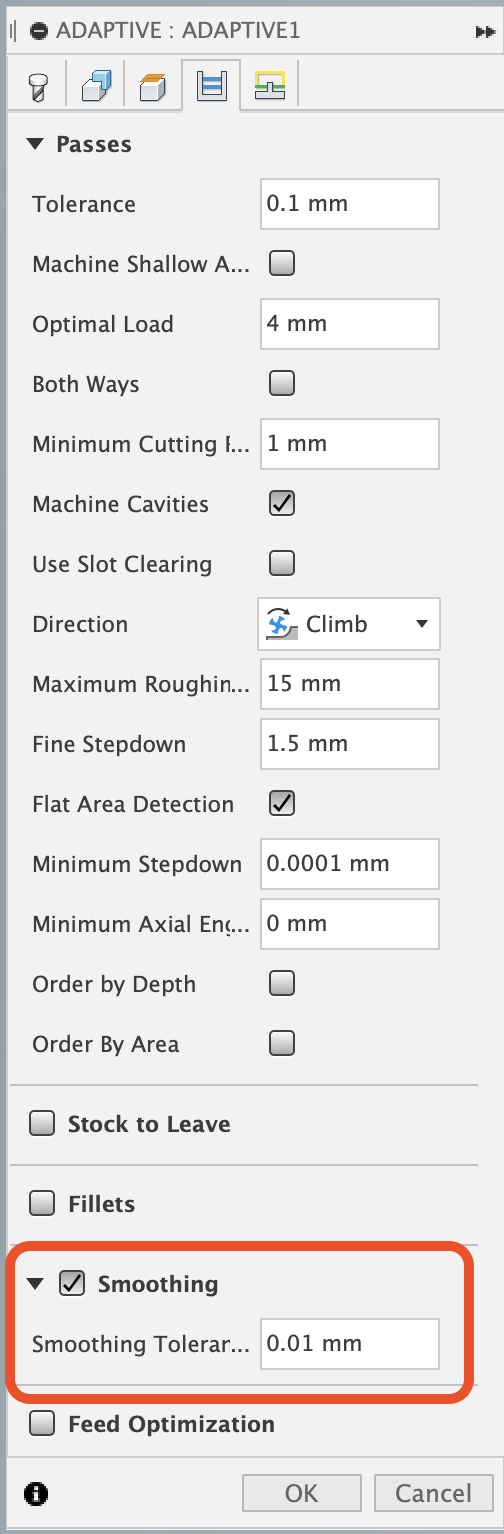

Attachments:

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 31

18 Jan 2023 20:40 - 18 Jan 2023 21:23 #262366

by CNC_ANDI

Replied by CNC_ANDI on topic Harmonic drive 4th axis build

ah ok but smoothing i always have 0.01mm

edit: changed from 0.01 to 0.2mm now works faster. thank you so much!!!

edit: changed from 0.01 to 0.2mm now works faster. thank you so much!!!

Last edit: 18 Jan 2023 21:23 by CNC_ANDI.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Jan 2023 20:56 #262367

by andypugh

Replied by andypugh on topic Harmonic drive 4th axis build

Try 0.1mm and then try cutting air, just to see what happens.

The following user(s) said Thank You: CNC_ANDI

Please Log in or Create an account to join the conversation.

Time to create page: 0.115 seconds