- Other Stuff

- Show Your Stuff

- Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

05 May 2020 23:07 #166817

by Becksvill

Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ) was created by Becksvill

Hey Everyone

My mill is making parts now and mostly working. I have been thinking of all the helpful build threads on the forum that have helped me when I was searching for info and I have decided to make a bit of a build thread here also.

I am going to be using my machine daily making parts and I have noticed there is a lack of people doing that with linuxcnc and documenting it. So a lot of people online don't really know what linuxcnc can actually do. Anyway hopefully I can change some of that a tiny bit.

I am not sure if there is any interest so comment below you are interested. I will make a better effort if people are interested lol.

photos to follow

My mill is making parts now and mostly working. I have been thinking of all the helpful build threads on the forum that have helped me when I was searching for info and I have decided to make a bit of a build thread here also.

I am going to be using my machine daily making parts and I have noticed there is a lack of people doing that with linuxcnc and documenting it. So a lot of people online don't really know what linuxcnc can actually do. Anyway hopefully I can change some of that a tiny bit.

I am not sure if there is any interest so comment below you are interested. I will make a better effort if people are interested lol.

photos to follow

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

06 May 2020 02:35 #166831

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Ok one thing that I have discovered is that in online forums if there are no photos it didn't happen lol

So here are the first round of photos

for those that want to I will add a google drive link here you can go to that will get updated with photos as I progress.

photos on google drive

So here are the first round of photos

for those that want to I will add a google drive link here you can go to that will get updated with photos as I progress.

photos on google drive

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

06 May 2020 02:44 #166832

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

here are some more photos.

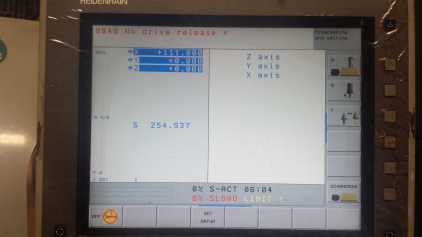

my machine started off as a heidenhain control.

here is what the original machine looked like once I craned it into the shed

it must of had a lightening strike or something and blew a lot of stuff bad.

So I gutted the whole thing and have started from scratch with chinese servos and linuxcnc running mesa cards currently using a 5i25 and 7i76 combo which is great.

looking below in the photos you can see a bunch of stuff and it is all out of order as this has all been done over the last while. the mpg in one of the photos runs on 12 v which is no good for me. I have 5 v from 7i76 and 24v from 7i76 io pins but I don't have 12 v on the machine. but I asked some questions on the user list and found out that I could use a $1 chip that would drop the voltage down for me. so for all intents and purposes the mpg is now a 24 v mpg as I just feed 24v. that works well.

my machine started off as a heidenhain control.

here is what the original machine looked like once I craned it into the shed

it must of had a lightening strike or something and blew a lot of stuff bad.

So I gutted the whole thing and have started from scratch with chinese servos and linuxcnc running mesa cards currently using a 5i25 and 7i76 combo which is great.

looking below in the photos you can see a bunch of stuff and it is all out of order as this has all been done over the last while. the mpg in one of the photos runs on 12 v which is no good for me. I have 5 v from 7i76 and 24v from 7i76 io pins but I don't have 12 v on the machine. but I asked some questions on the user list and found out that I could use a $1 chip that would drop the voltage down for me. so for all intents and purposes the mpg is now a 24 v mpg as I just feed 24v. that works well.

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

06 May 2020 03:03 #166834

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

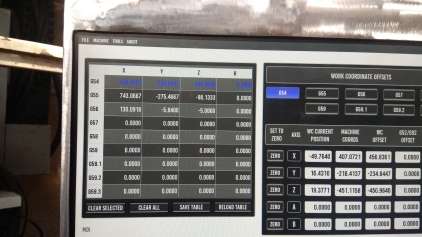

Recently this week I have installed the Probe basic gui.

there is a bit of a learning curve and I was helped heaps by a really nice guy in germany but it is installed and I have run my first part on it.

see my youtube channel for more videos as I add them

I will upload some videos of it cutting soon. I have been running parts all week on the old axis gui before I upgraded. axis was rock solid never missed a beat for months.

the new probe basic gui is also good but significantly more complicated. I definitely recommend starting with axis. get your machine working well and then change once everything works good. probe basic is harder to trouble shoot as there is a extra python layer in the mix.

I have been using industrial controllers for years (fagor and siemens) and probe basic would rank there, right up with the best in my opinion once it is set up properly. just little things make it good like the workoffsets table. axis doesn't have a nice table to reference all your g54 g55 g56 etc workoffsets. having a live real time g code plotter is great lol. If you have ever tried drip feeding into old controllers from another computer you will know what I mean. it is scary not knowing where the machine is going to go next just hoping it is right.

I made the toolholder rack with my younger brother (15years old) as a quick project using fusion 360. I had a bit of scrap and we had a play. the whole job took 37 mins cutting time.

and I have machined 100 of these chainsaw bars this week. the steel is like hardened steel or something. really ate up carbide endmills I eventually changed to a special blue coating endmill for hardened steel. this one did the whole job but even then was pretty bad around the corners by the end of it. The carbide for these comes from sandvic and has some special high temperature coating on it. I sell them as part of my sideline tooling company which is nice for cheap tooling for me lol. You can machine bearings with these bad boys)

Ps I am missing out lots of details here so if anyone is interested in something just let me know and I will add extra photos etc.

and then I will post the current issues lol and hope that people can solve them for me.

there is a bit of a learning curve and I was helped heaps by a really nice guy in germany but it is installed and I have run my first part on it.

see my youtube channel for more videos as I add them

I will upload some videos of it cutting soon. I have been running parts all week on the old axis gui before I upgraded. axis was rock solid never missed a beat for months.

the new probe basic gui is also good but significantly more complicated. I definitely recommend starting with axis. get your machine working well and then change once everything works good. probe basic is harder to trouble shoot as there is a extra python layer in the mix.

I have been using industrial controllers for years (fagor and siemens) and probe basic would rank there, right up with the best in my opinion once it is set up properly. just little things make it good like the workoffsets table. axis doesn't have a nice table to reference all your g54 g55 g56 etc workoffsets. having a live real time g code plotter is great lol. If you have ever tried drip feeding into old controllers from another computer you will know what I mean. it is scary not knowing where the machine is going to go next just hoping it is right.

I made the toolholder rack with my younger brother (15years old) as a quick project using fusion 360. I had a bit of scrap and we had a play. the whole job took 37 mins cutting time.

and I have machined 100 of these chainsaw bars this week. the steel is like hardened steel or something. really ate up carbide endmills I eventually changed to a special blue coating endmill for hardened steel. this one did the whole job but even then was pretty bad around the corners by the end of it. The carbide for these comes from sandvic and has some special high temperature coating on it. I sell them as part of my sideline tooling company which is nice for cheap tooling for me lol. You can machine bearings with these bad boys)

Ps I am missing out lots of details here so if anyone is interested in something just let me know and I will add extra photos etc.

and then I will post the current issues lol and hope that people can solve them for me.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21378

- Thank you received: 7290

06 May 2020 08:51 #166852

by tommylight

Replied by tommylight on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Very nice, indeed ! Thank you.

Pictures and videos are always nice to look at, and one of the longest threads on this forum is "Maho retrofit......" .

Pictures and videos are always nice to look at, and one of the longest threads on this forum is "Maho retrofit......" .

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

06 May 2020 10:50 #166856

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

thanks tom

I need to get some actual proper videos and photos up. this is just what I found on my ph. I am only just learning linuxcnc compared to you.

But hopefully I can help some people and this will be a good place for others to answer any questions I have.

I need to get some actual proper videos and photos up. this is just what I found on my ph. I am only just learning linuxcnc compared to you.

But hopefully I can help some people and this will be a good place for others to answer any questions I have.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

07 May 2020 00:39 #166914

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

hey tom

since you answered my other question so fast and since you have been doing this before I have another quick question here.

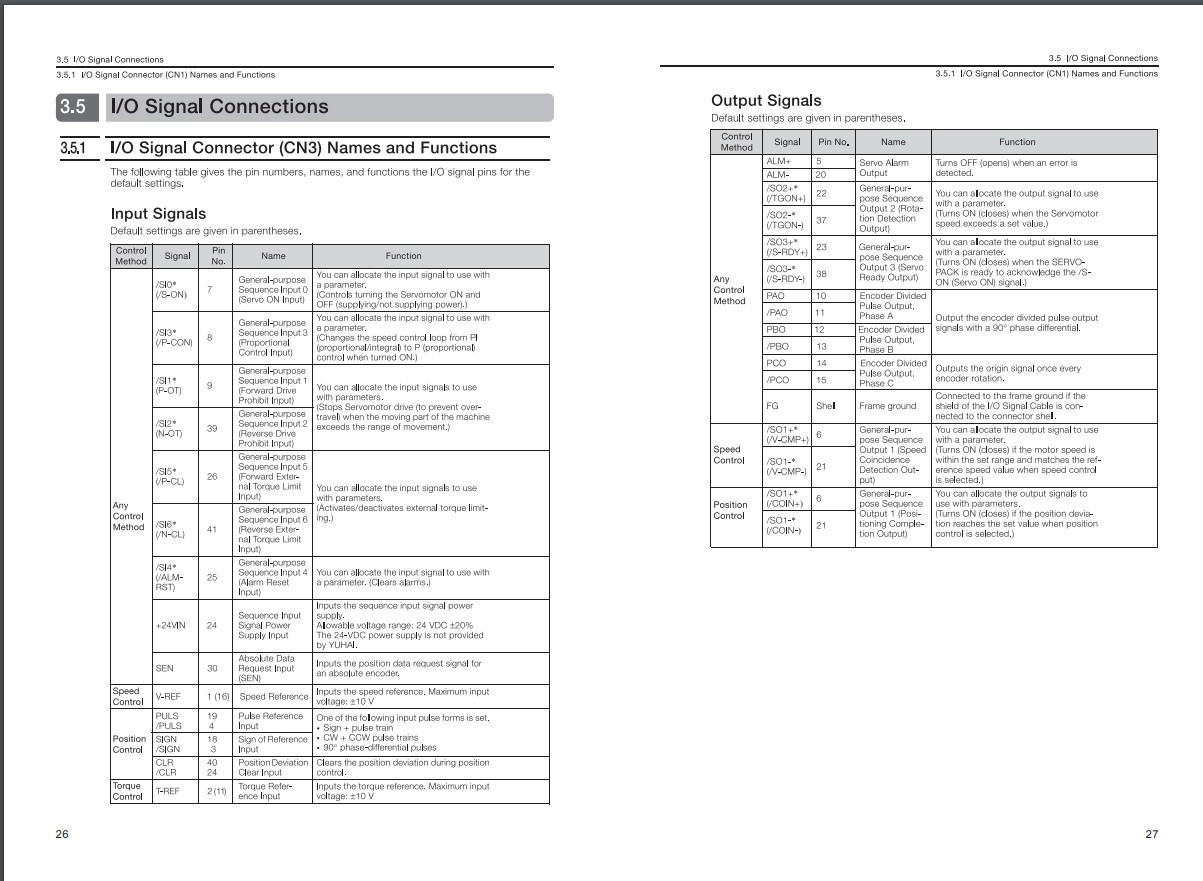

I am using step dir chinese servo drives and the drives are "smart" eg they close the loop with the servo motor/ servo drive loop.

these drives like most of yaskawa copies can output the encoder pulses to a external controller in my case mesa 7i76 spindle encoder input.

I have checked and the drive outputs standard 5 v differential signals suitable for the mesa to read.

my only question is how do i connect up at the mesa end. I have 3 pairs of differential signals from the servo drive. A B Z. Since this comes from the servo drive not a standard encoder I assume the signals get powered from the servo drive and I leave the 5v and ground unconnected on the mesa encoder inputs?

just a little bit stuck here. been trawling the forum for hrs trying to find a definitive answer

regards

Andrew

since you answered my other question so fast and since you have been doing this before I have another quick question here.

I am using step dir chinese servo drives and the drives are "smart" eg they close the loop with the servo motor/ servo drive loop.

these drives like most of yaskawa copies can output the encoder pulses to a external controller in my case mesa 7i76 spindle encoder input.

I have checked and the drive outputs standard 5 v differential signals suitable for the mesa to read.

my only question is how do i connect up at the mesa end. I have 3 pairs of differential signals from the servo drive. A B Z. Since this comes from the servo drive not a standard encoder I assume the signals get powered from the servo drive and I leave the 5v and ground unconnected on the mesa encoder inputs?

just a little bit stuck here. been trawling the forum for hrs trying to find a definitive answer

regards

Andrew

The following user(s) said Thank You: johnmc1

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

07 May 2020 02:34 #166928

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

this is a general call for help now.

I am need some positive confirmation here about what I need to connect.

just to refresh everyone. I have 5i25 and 7i76 mesa cards. 7i76 is powered from a 24v dc powersupply for the field IO.

currently the jumpers are setup to supply the 7i76 5v logic power from the 5i25.

I am trying to connect this encoder signal from my servo drive into the spindle encoder input in the 7i76

as you can see the servo powers the encoder so I think I don't need the 5v from the mesa card.

Now what gets me confused is the grounding of everything.

question 1: Do I even need to use a ground with differential signals

question 2 if I need to connect the ground what in my servo drive do I connect it to?

I want to avoid any grounding loops and am a little confused

I will make up a big diagram soon showing how everything is connected.

regards

Andrew

I am need some positive confirmation here about what I need to connect.

just to refresh everyone. I have 5i25 and 7i76 mesa cards. 7i76 is powered from a 24v dc powersupply for the field IO.

currently the jumpers are setup to supply the 7i76 5v logic power from the 5i25.

I am trying to connect this encoder signal from my servo drive into the spindle encoder input in the 7i76

as you can see the servo powers the encoder so I think I don't need the 5v from the mesa card.

Now what gets me confused is the grounding of everything.

question 1: Do I even need to use a ground with differential signals

question 2 if I need to connect the ground what in my servo drive do I connect it to?

I want to avoid any grounding loops and am a little confused

I will make up a big diagram soon showing how everything is connected.

regards

Andrew

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21378

- Thank you received: 7290

07 May 2020 09:00 #166935

by tommylight

Replied by tommylight on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

1 No, just use the shield from the drive but do not connect the other side of it, meaning the shield is connected only to the drive, the Mesa side should not be connected to anything.

2 encoder shield.

And you will need another Mesa board, something like 7i85X , but not sure exactly, so someone else might chime in.

2 encoder shield.

And you will need another Mesa board, something like 7i85X , but not sure exactly, so someone else might chime in.

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

07 May 2020 09:19 #166941

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

hey tom

so just to clarify

I already have the cable shield grounded to the servo drive connector case to reduce interference.

does that mean that I can just connect the 3 differential pairs up (so 6 wires in total and I am good to go) So the encoder differiential pairs don't need a ground also?

and also what about the 7i76 logic 5v power from the 5i25? will that be ok for now as is. I know eventually I will need to get a separate 5v powersupply so I don't put too much load on the pci slot with 5 encoders running..

All I want to do for now is connect each axis up in turn, to the spindle encoder in the 7i76 and then use the encoder feedback in halscope to know what I need to set the Pid loop in the servo drive to. then I will remove the feedback and tune the next axis and so on...

I should have a 7i89 mesa card (this has 5 encoder inputs on it) coming asap once I can get it shipped from america. and I will get a 7i84 also for some more IO pins as I need about another 20 IO pins for buttons and such.

regards

Andrew

so just to clarify

I already have the cable shield grounded to the servo drive connector case to reduce interference.

does that mean that I can just connect the 3 differential pairs up (so 6 wires in total and I am good to go) So the encoder differiential pairs don't need a ground also?

and also what about the 7i76 logic 5v power from the 5i25? will that be ok for now as is. I know eventually I will need to get a separate 5v powersupply so I don't put too much load on the pci slot with 5 encoders running..

All I want to do for now is connect each axis up in turn, to the spindle encoder in the 7i76 and then use the encoder feedback in halscope to know what I need to set the Pid loop in the servo drive to. then I will remove the feedback and tune the next axis and so on...

I should have a 7i89 mesa card (this has 5 encoder inputs on it) coming asap once I can get it shipped from america. and I will get a 7i84 also for some more IO pins as I need about another 20 IO pins for buttons and such.

regards

Andrew

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Time to create page: 0.390 seconds