3D Printer Retrofit

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

09 Jun 2020 06:40 #170762

by thefabricator03

Replied by thefabricator03 on topic 3D Printer Retrofit

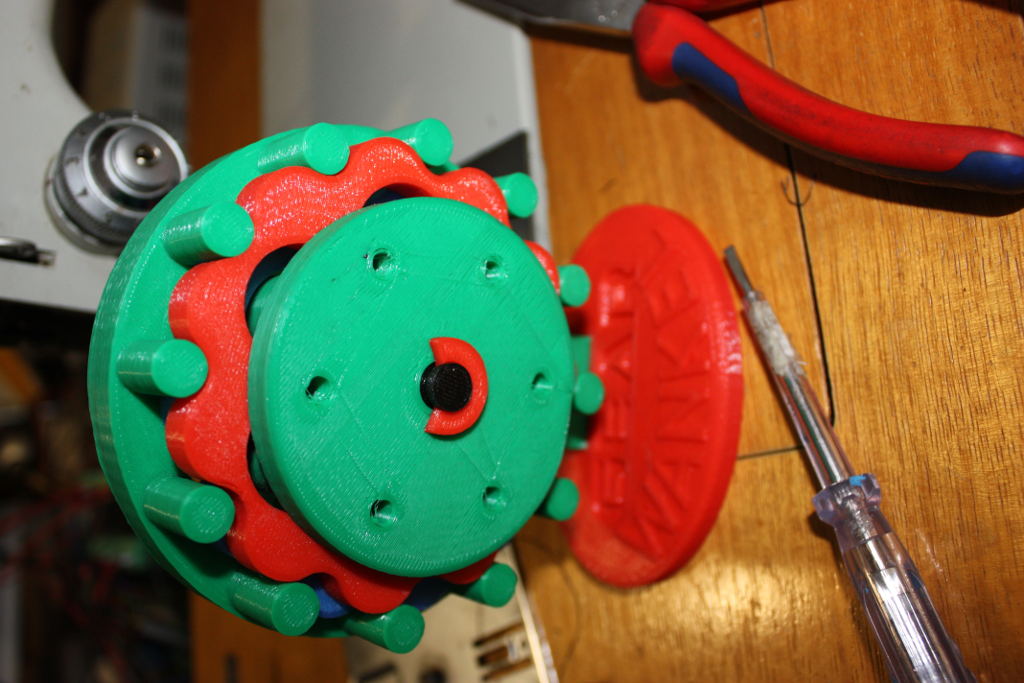

I plan on printing prototypes of gearboxes similar to this,

I would assume the thicker filament would help build those parts up but would it affect accuracy?

I would assume the thicker filament would help build those parts up but would it affect accuracy?

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

09 Jun 2020 06:46 #170764

by bbsr_5a

Replied by bbsr_5a on topic 3D Printer Retrofit

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

09 Jun 2020 06:48 #170765

by thefabricator03

Is that also a cycloidal gear box?

Replied by thefabricator03 on topic 3D Printer Retrofit

i got print this one also

Is that also a cycloidal gear box?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21283

- Thank you received: 7267

09 Jun 2020 11:00 #170811

by tommylight

Replied by tommylight on topic 3D Printer Retrofit

There are 2 guys on youtube that do a lot of testing with layers and nozzles and filament, seen them a while back, one of them test the strength of the end product and the results are surprising for sure. Will try to find it later.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

09 Jun 2020 13:46 #170833

by bbsr_5a

yes it is for E ducation use

Replied by bbsr_5a on topic 3D Printer Retrofit

i got print this one also

Is that also a cycloidal gear box?

yes it is for E ducation use

Attachments:

The following user(s) said Thank You: thefabricator03, Becksvill

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 635

- Thank you received: 232

27 Aug 2020 19:16 #179725

by Bari

Replied by Bari on topic 3D Printer Retrofit

If it's protos I'd use a resin printer and make those parts in minutes vs days.

imgur.com/zvxoHUT

imgur.com/zKNtBAg

Higher res than FDM/FFF and much much faster.

imgur.com/zvxoHUT

imgur.com/zKNtBAg

Higher res than FDM/FFF and much much faster.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

28 Aug 2020 06:24 #179787

by thefabricator03

Replied by thefabricator03 on topic 3D Printer Retrofit

A resin printer would be nice. Maybe one day I will build one. They look pretty interesting. I need to crawl before I can run tho.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

28 Aug 2020 06:54 - 28 Aug 2020 06:56 #179788

by thefabricator03

Replied by thefabricator03 on topic 3D Printer Retrofit

Finally made some progress with my printer.

I have the Big Tree Tech GTR board set up with Klipper and connected to a Raspberry Pi 3 b+ running Octoprint. Once I got my head around setting up Klipper, setting up the hardware and software was no harder than installing LinuxCNC.

Had a few problems with the mechanical. The linear bearings on the Z axis were somehow bad from factory. The Z axis would not move up or down without binding. Even with the factory electronics I still had that problem.

I replaced the LM12UU bearings with longer LMK12LUU bearings and the z axis moves up and down smoothly.

I also gave up on the idea of using the TMC2209 stepper drivers sensor less homing. I had it set up and tried it but it was pretty hard on the gantry and put a bunch of stress on the belts. On a more solid machine or a machine using lead screws or rack and pinion it would be fine I think.

I had an issue with the cheap limit switched that came with the machine - they did not work properly. So I have replaced them on the X and Y with Omron limit swithes. I use these on my large CNC plasma without and issues. I am still using the factory limit switch on the Z axis but I will replace it soon with a BLTouch unit I have brought.

Now that the machine was set up and functioning I needed to print some parts. I brought a copy of Simplify3D and downloaded a 20mm calibration cube from Thingiverse. Setting up Simplify3D was pretty easy and from the looks of it has plenty of features.

The 20mm cube looks tiny in the center of my 500x500mm build plate.

First print was way under extruded. I calibrated the extruder and tried again. Next couple are still under extruding so I will need to keep playing with the settings.

Once I get the settings correct I will set up my BLTouch sensor, build a cabinet for the electronic hardware and tidy up all the wiring. Its been a pretty fun project so far and I can wait to see what I can print with it.

I have the Big Tree Tech GTR board set up with Klipper and connected to a Raspberry Pi 3 b+ running Octoprint. Once I got my head around setting up Klipper, setting up the hardware and software was no harder than installing LinuxCNC.

Had a few problems with the mechanical. The linear bearings on the Z axis were somehow bad from factory. The Z axis would not move up or down without binding. Even with the factory electronics I still had that problem.

I replaced the LM12UU bearings with longer LMK12LUU bearings and the z axis moves up and down smoothly.

I also gave up on the idea of using the TMC2209 stepper drivers sensor less homing. I had it set up and tried it but it was pretty hard on the gantry and put a bunch of stress on the belts. On a more solid machine or a machine using lead screws or rack and pinion it would be fine I think.

I had an issue with the cheap limit switched that came with the machine - they did not work properly. So I have replaced them on the X and Y with Omron limit swithes. I use these on my large CNC plasma without and issues. I am still using the factory limit switch on the Z axis but I will replace it soon with a BLTouch unit I have brought.

Now that the machine was set up and functioning I needed to print some parts. I brought a copy of Simplify3D and downloaded a 20mm calibration cube from Thingiverse. Setting up Simplify3D was pretty easy and from the looks of it has plenty of features.

The 20mm cube looks tiny in the center of my 500x500mm build plate.

First print was way under extruded. I calibrated the extruder and tried again. Next couple are still under extruding so I will need to keep playing with the settings.

Once I get the settings correct I will set up my BLTouch sensor, build a cabinet for the electronic hardware and tidy up all the wiring. Its been a pretty fun project so far and I can wait to see what I can print with it.

Last edit: 28 Aug 2020 06:56 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21283

- Thank you received: 7267

28 Aug 2020 11:24 #179814

by tommylight

Replied by tommylight on topic 3D Printer Retrofit

To late, but you could have used slicr, it is free and last i tested it it was pretty damn impressive and produced gcode directly usable in LinuxCNC.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

28 Aug 2020 14:53 #179844

by thefabricator03

Replied by thefabricator03 on topic 3D Printer Retrofit

Thanks Tom,

I went with Simplify3D mostly because of the great technical help articles they make, www.simplify3d.com/support/articles/

I have been playing around with my settings and those articles are a real time saver.

I went with Simplify3D mostly because of the great technical help articles they make, www.simplify3d.com/support/articles/

I have been playing around with my settings and those articles are a real time saver.

Please Log in or Create an account to join the conversation.

Time to create page: 0.130 seconds