Motoman K6SB Retrofit

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 923

- Thank you received: 275

08 Aug 2021 04:36 #217175

by cakeslob

Replied by cakeslob on topic Motoman K6SB Retrofit

Ok, like I said, my controller is one model newer, but they will be pretty close. The encoders plug into the servo amp, but then they connect to the motion control card from the servo amp. Yaskawa is really good when it comes to manual dissemination, the uploaded all their manuals, and digitized some older ones. Yours is CACR-HR

www.yaskawa.com/delegate/getAttachment?c...50e8&TSE-S800-6H.pdf

It describes/defines the different control methods and motor information . The serial comunication looks different to what mechatrolink is, it looks some kind of rs422, its all defined in the manual.

The encoders appear to be similar to mine, which as far as i can tell, output abz differential singals and because their 12 bit absolute encoders, a serial channel.

sudoroom.org/wiki/Giant_robot_arm

github.com/jerkey/yasnac_fakery

This might be relevant to your encoder serial information

Gear ratios, your gears are the same as mine, so ill see what i can do about that,

in the mean time you can cross reference the part numbers in the manual to what ever you can find on google/ebay for information

spaz.org/~jake/robot/02-TOE-C945-111%20-...man%20K6S%20K10S.pdf

I dont know that the controller parameters will yield any useful information or anything relevant to linuxcnc, and many parameters are intentionally left unlabled. it will take some time to dig through parameter manuals

www.yaskawa.com/delegate/getAttachment?c...50e8&TSE-S800-6H.pdf

It describes/defines the different control methods and motor information . The serial comunication looks different to what mechatrolink is, it looks some kind of rs422, its all defined in the manual.

The encoders appear to be similar to mine, which as far as i can tell, output abz differential singals and because their 12 bit absolute encoders, a serial channel.

sudoroom.org/wiki/Giant_robot_arm

github.com/jerkey/yasnac_fakery

This might be relevant to your encoder serial information

Gear ratios, your gears are the same as mine, so ill see what i can do about that,

in the mean time you can cross reference the part numbers in the manual to what ever you can find on google/ebay for information

spaz.org/~jake/robot/02-TOE-C945-111%20-...man%20K6S%20K10S.pdf

I dont know that the controller parameters will yield any useful information or anything relevant to linuxcnc, and many parameters are intentionally left unlabled. it will take some time to dig through parameter manuals

The following user(s) said Thank You: phasefreq

Please Log in or Create an account to join the conversation.

- phasefreq

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 0

20 Jan 2022 22:28 - 20 Jan 2022 22:33 #232558

by phasefreq

Replied by phasefreq on topic Motoman K6SB Retrofit

Holy crap! @cakeslob this is exactly the info I needed, thanks a ton!

So it looks like (a) my encoders do output incremental ABZ once powered on (relative to start position of course), and (b) each encoder transmits it's absolute value serially on the S phase of the encoders (RS-422) at powerup.

It sounds like if I receive the startup absolute offset from each encoder serially before starting linuxcnc, then edit the hal file for my machine and update each axis' bldc.N.encoder-offset to the (signed?) startup absolute offset from machine zero modulus the encoder positions per rev of that servo, I can then start linuxcnc and go about my merry way right? Tie bldc.N.{A,B,C}-{high,low} to some IGBT modules via Mesa PWM outputs, or bldc.N.{A,B,C}-value to H-bridges? Does that sound sane @andypugh and @dm17ry ?

Thanks everyone!

So it looks like (a) my encoders do output incremental ABZ once powered on (relative to start position of course), and (b) each encoder transmits it's absolute value serially on the S phase of the encoders (RS-422) at powerup.

It sounds like if I receive the startup absolute offset from each encoder serially before starting linuxcnc, then edit the hal file for my machine and update each axis' bldc.N.encoder-offset to the (signed?) startup absolute offset from machine zero modulus the encoder positions per rev of that servo, I can then start linuxcnc and go about my merry way right? Tie bldc.N.{A,B,C}-{high,low} to some IGBT modules via Mesa PWM outputs, or bldc.N.{A,B,C}-value to H-bridges? Does that sound sane @andypugh and @dm17ry ?

Thanks everyone!

Last edit: 20 Jan 2022 22:33 by phasefreq. Reason: Grammar/clarity

Please Log in or Create an account to join the conversation.

- phasefreq

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 0

27 Jan 2022 03:50 - 27 Jan 2022 03:54 #233252

by phasefreq

Replied by phasefreq on topic Motoman K6SB Retrofit

Having thought this through more, a simplification and a complication:

- I think, if I am remembering how this worked last time I had puma kinematics working, I can just jog each servo/joint independently until its position in steps is equal to the opposite-sign value the encoder transmitted serially at power on, then machine home/zero that joint and be done with it, right?

- Rather than cobbling together a bunch of dumb drives from half bridges, do you guys think hal latency (with Mesa realtime ethernet, say) is low enough to generate fake hall sensor or resolver signals from the encoder, and give those to a run of the mill ac servo drive?

—- Addendum to above: I have a shelf full of three phase drives that just need feedback, but I don’t appear to have any half bridges or h bridges with anywhere near high enough voltage.

- I think, if I am remembering how this worked last time I had puma kinematics working, I can just jog each servo/joint independently until its position in steps is equal to the opposite-sign value the encoder transmitted serially at power on, then machine home/zero that joint and be done with it, right?

- Rather than cobbling together a bunch of dumb drives from half bridges, do you guys think hal latency (with Mesa realtime ethernet, say) is low enough to generate fake hall sensor or resolver signals from the encoder, and give those to a run of the mill ac servo drive?

—- Addendum to above: I have a shelf full of three phase drives that just need feedback, but I don’t appear to have any half bridges or h bridges with anywhere near high enough voltage.

Last edit: 27 Jan 2022 03:54 by phasefreq. Reason: Clarity

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

30 Mar 2023 13:37 #267911

by boksi

Replied by boksi on topic Motoman K6SB Retrofit

Hello, what is current status of retrofit?

If you are still interested I have protocol in pdf for this absolute/inc 12 bit encoders. I believe it is same in your arm. I have YR-K6 motoman.

Also I have some questions. In anybody know please share.

Servo drivers SK6 motoman robot model I believe that are running in torque mode.

Encoder on drives is abs/inc 12bit resolution.

Servo packs recieve current command from upper controler -> servo control board.

Does anybodu knows is this servo control board (as part of MRC) is closing position or both position and velocity loop inside and then sending current reference for torque amplifier(servo pack)?

I little doubt that “good” velocity loop can be closed with 12bit encoder.

Maybe someone has some info or doc about this servo control board

JANCD-MSV01.

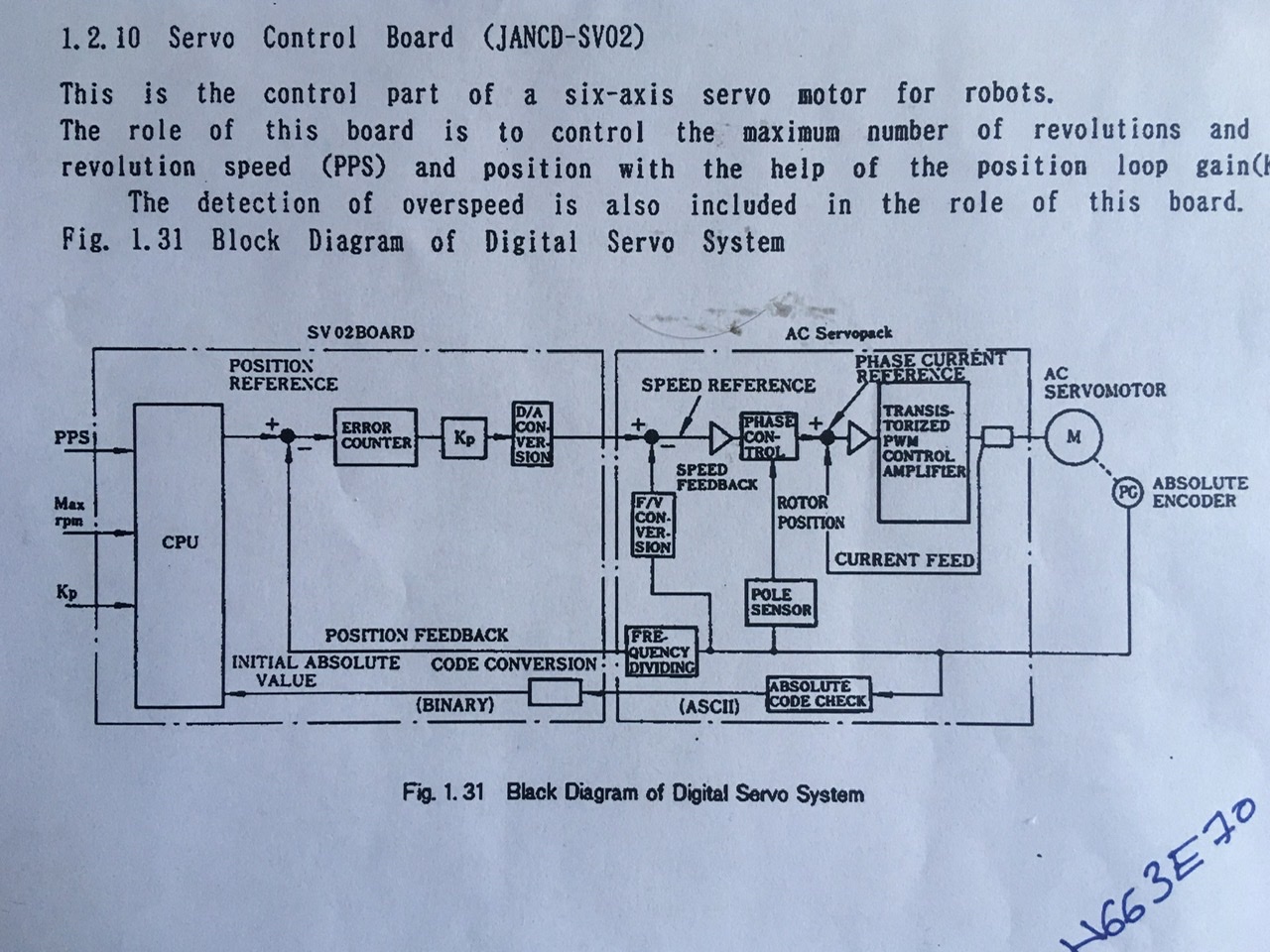

This is what I have found in manuals concerning operation.

“

SERVO CONTROL BOARD

This board controls the robot's 6-axis servo motors. Speed (pps) and position are controlled using the maximum rotation speed and position loop gain (kp). Overspeed is detected by this board. Additional system control boards can be added to the CPU rack to control additional axes.

“

Thanks

Borko

If you are still interested I have protocol in pdf for this absolute/inc 12 bit encoders. I believe it is same in your arm. I have YR-K6 motoman.

Also I have some questions. In anybody know please share.

Servo drivers SK6 motoman robot model I believe that are running in torque mode.

Encoder on drives is abs/inc 12bit resolution.

Servo packs recieve current command from upper controler -> servo control board.

Does anybodu knows is this servo control board (as part of MRC) is closing position or both position and velocity loop inside and then sending current reference for torque amplifier(servo pack)?

I little doubt that “good” velocity loop can be closed with 12bit encoder.

Maybe someone has some info or doc about this servo control board

JANCD-MSV01.

This is what I have found in manuals concerning operation.

“

SERVO CONTROL BOARD

This board controls the robot's 6-axis servo motors. Speed (pps) and position are controlled using the maximum rotation speed and position loop gain (kp). Overspeed is detected by this board. Additional system control boards can be added to the CPU rack to control additional axes.

“

Thanks

Borko

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 923

- Thank you received: 275

09 Apr 2023 02:39 #268640

by cakeslob

Replied by cakeslob on topic Motoman K6SB Retrofit

Well, I dont know if you will find out much info on that. I havent found a dedicated manual for that before. Boards like the MSV-01 have very little documentation, I assume because they are a more proprietary part of the robot that requires little interaction from the end user. The most reference I see about it is, "REPLACE MSV-01 OR CALL MOTOMAN". robot-forum is probably a better place to ask that.

If you want to do some digging and find out, you can make conclusions based on the information surrounding the MSV-01. Motoman has all their old ass manuals online, digitized for free, which is very cool of them to do so. If you look into the external axis board, it might have some more info, because I would wager it is a 2 axis version of the MSv-01.

There is def an current ref for the amp, because there is an alarm for it. Based on the manual for the servo drives, I also believe they are running torque mode. The board itself is 6 yaskawa DSP;s, with a daughter board add on. Ive also attached the wire diag for MSV-01

I will take any info you have on the encoder if you dont mind. It was expensive to replace, and complicated.

If you want to do some digging and find out, you can make conclusions based on the information surrounding the MSV-01. Motoman has all their old ass manuals online, digitized for free, which is very cool of them to do so. If you look into the external axis board, it might have some more info, because I would wager it is a 2 axis version of the MSv-01.

There is def an current ref for the amp, because there is an alarm for it. Based on the manual for the servo drives, I also believe they are running torque mode. The board itself is 6 yaskawa DSP;s, with a daughter board add on. Ive also attached the wire diag for MSV-01

I will take any info you have on the encoder if you dont mind. It was expensive to replace, and complicated.

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

09 Apr 2023 07:24 #268650

by boksi

Replied by boksi on topic Motoman K6SB Retrofit

Thanks.

I asked on robot forum but get very little info. I suppose for different versions could be some differences. In mean time found this diagram for K6SB.

It seems that that velocity loop is closed in drive. But in drive manual it looks like it is accepting current command. I will check more detailed.

Concerning encoder info check pdf.

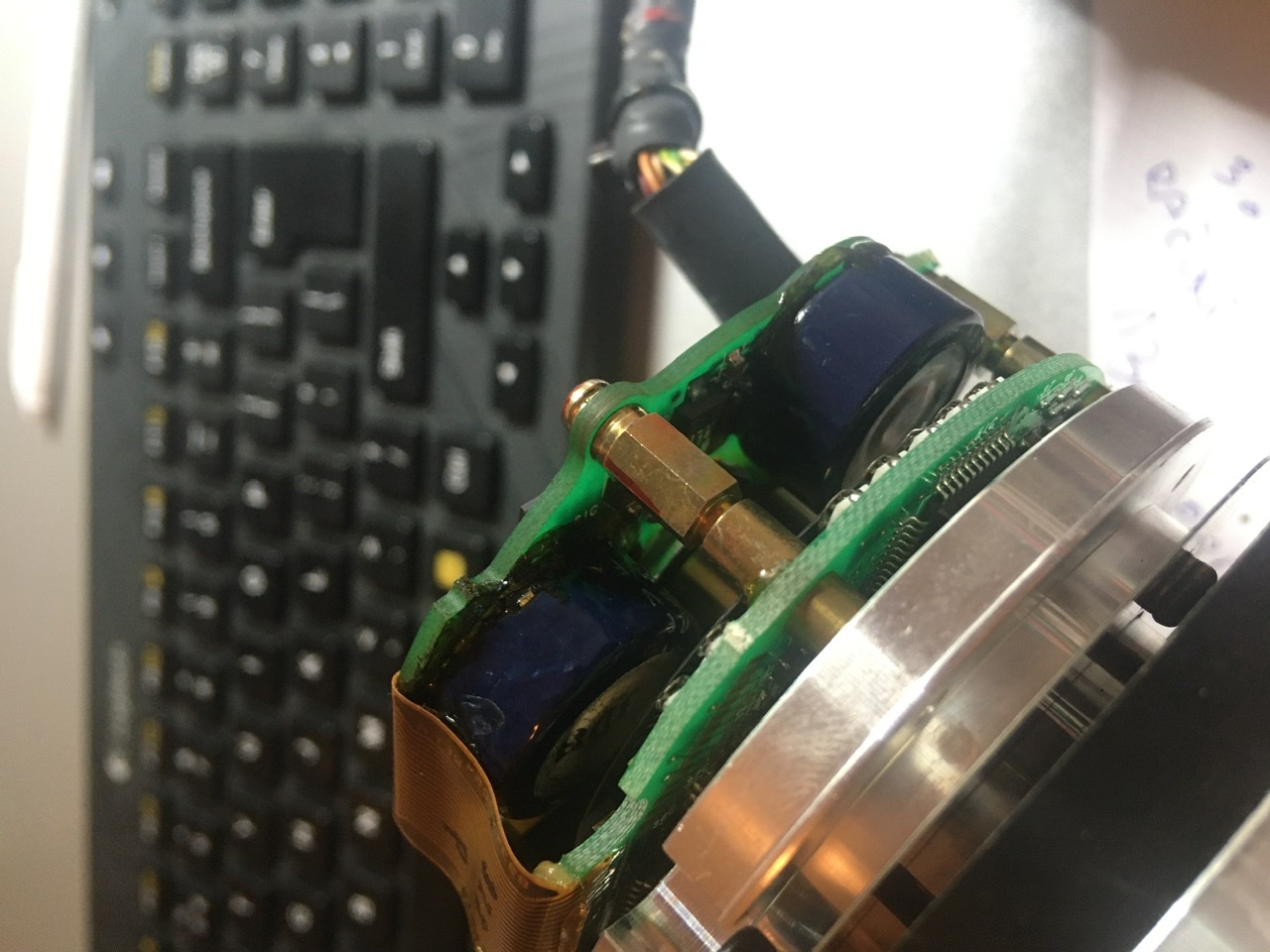

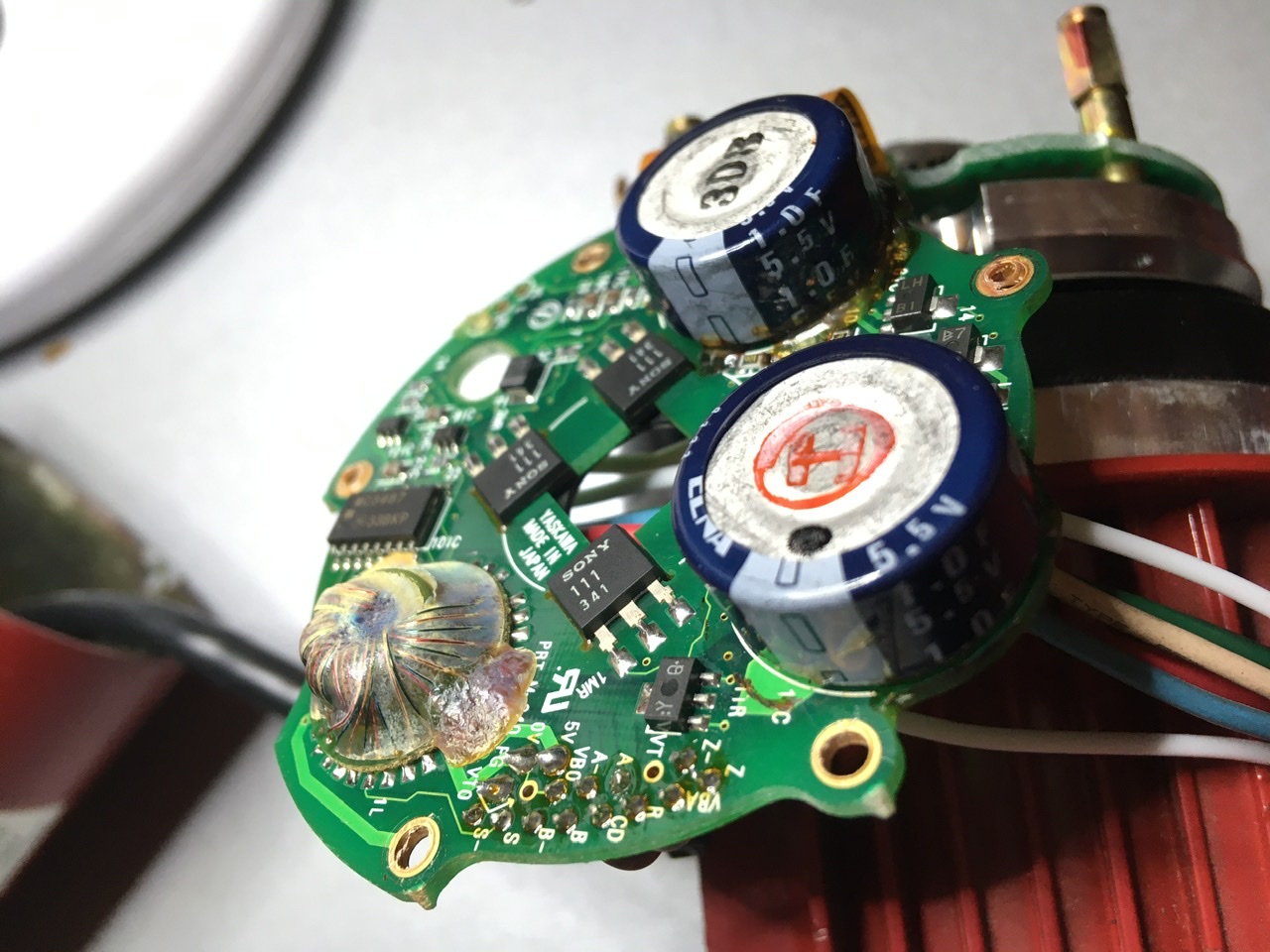

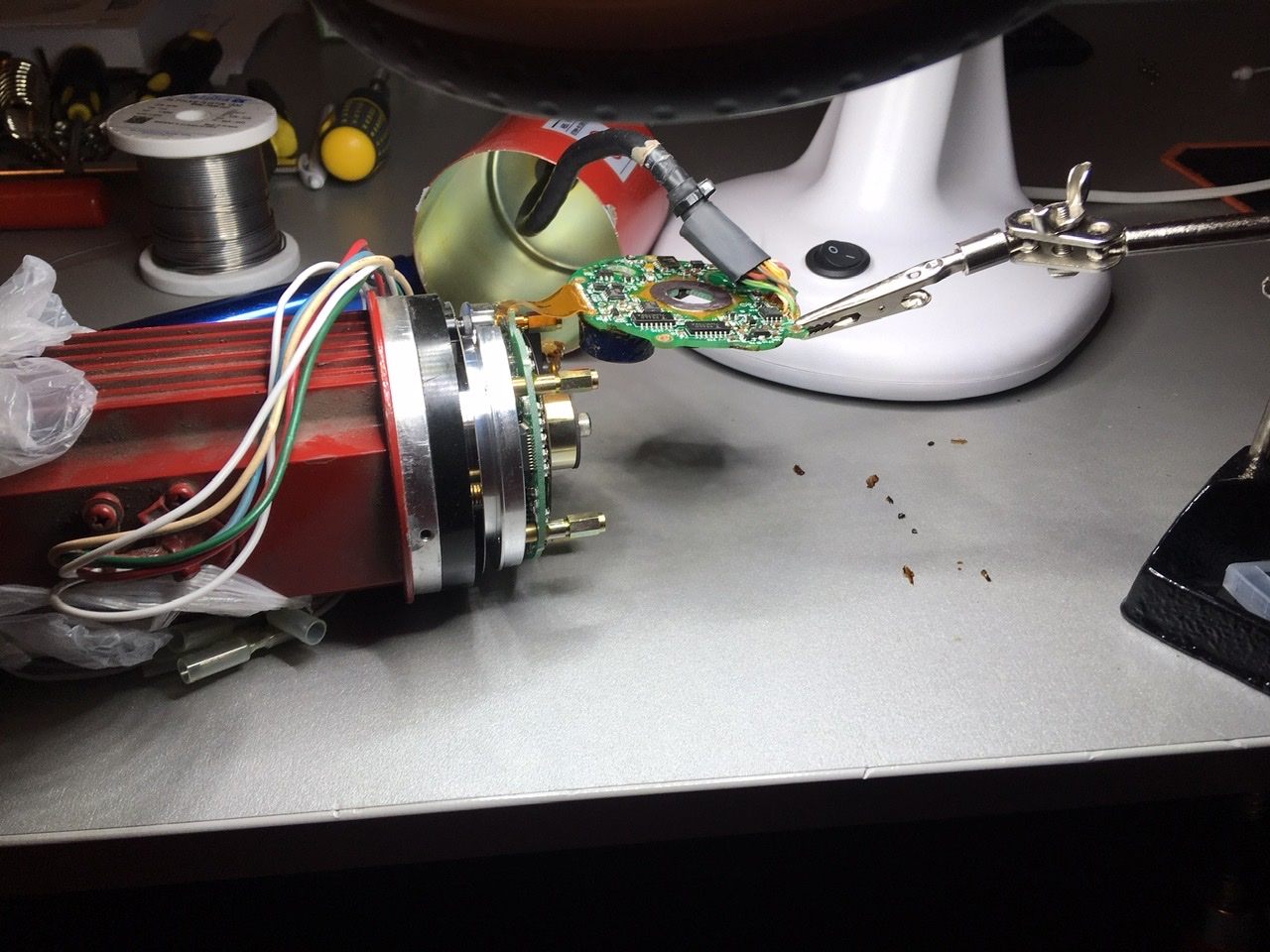

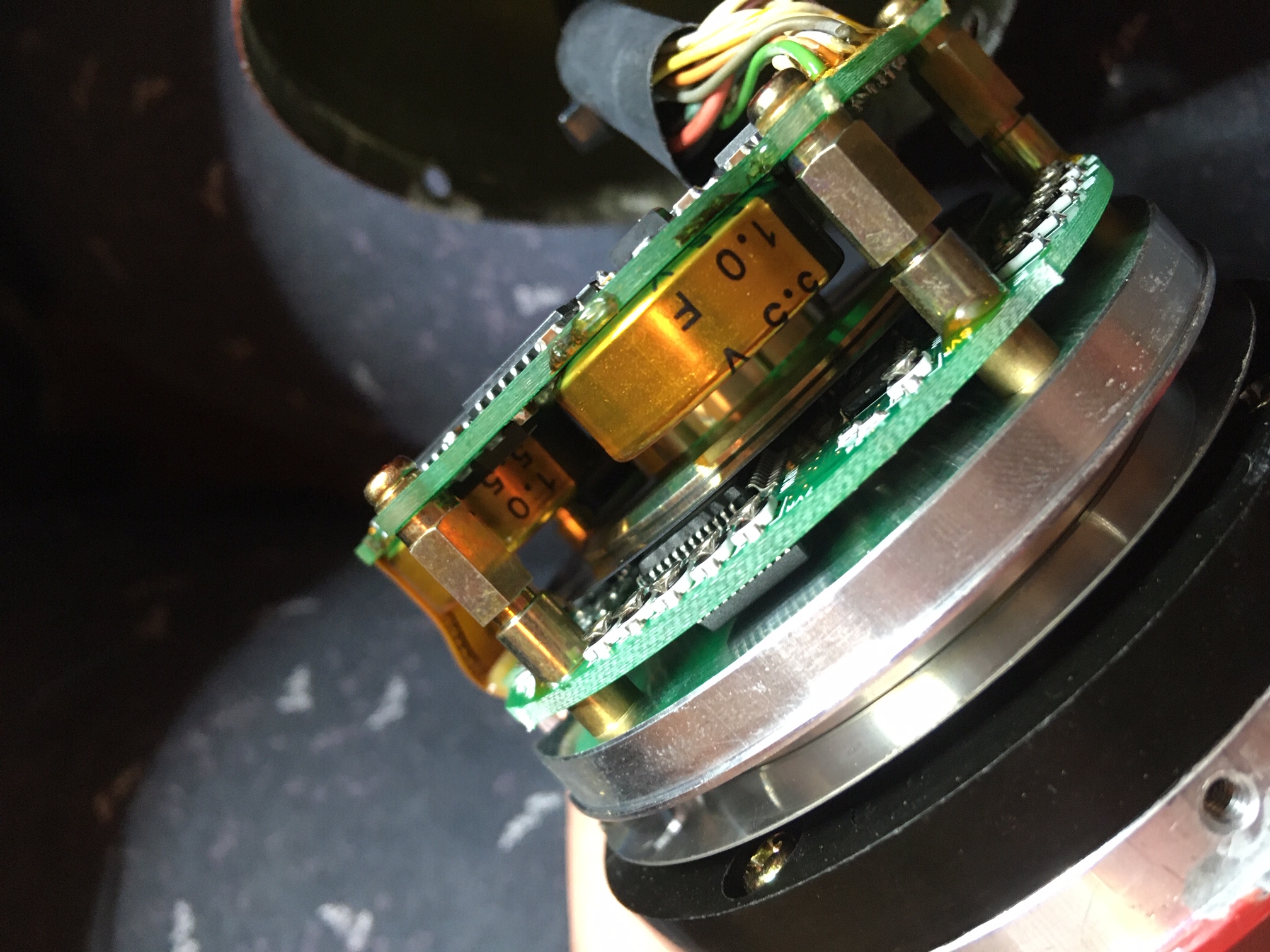

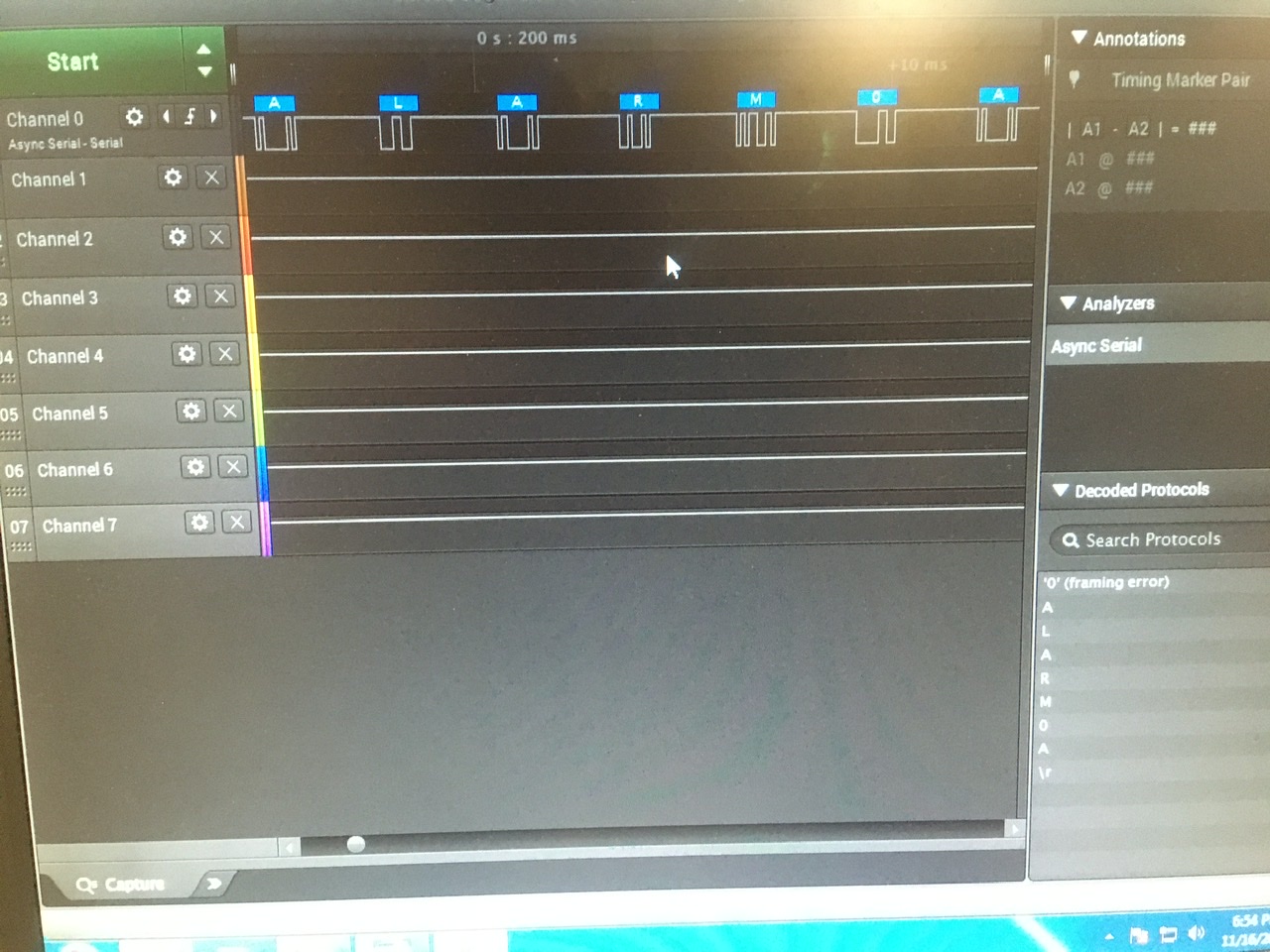

If caps in encoder are bad you should replace them to be able to get rid of alarm and get position informations.

Here ara some pics how this looks like and some exaple of communication.

Alarms concernig bad caps and missing battery if I remember good

I asked on robot forum but get very little info. I suppose for different versions could be some differences. In mean time found this diagram for K6SB.

It seems that that velocity loop is closed in drive. But in drive manual it looks like it is accepting current command. I will check more detailed.

Concerning encoder info check pdf.

If caps in encoder are bad you should replace them to be able to get rid of alarm and get position informations.

Here ara some pics how this looks like and some exaple of communication.

Alarms concernig bad caps and missing battery if I remember good

Attachments:

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

09 Apr 2023 08:12 - 09 Apr 2023 08:36 #268654

by boksi

Replied by boksi on topic Motoman K6SB Retrofit

Attachments:

Last edit: 09 Apr 2023 08:36 by boksi.

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 923

- Thank you received: 275

09 Apr 2023 15:56 #268684

by cakeslob

Replied by cakeslob on topic Motoman K6SB Retrofit

Thanks thats some good stufflol, yeah I did the same thing with the caps. I even tried redoing the cable. It was fine with me jiggling it for a while, but one time the robot arm lost position in that joint and the arm just dropped like a bag of shit, so I sent the motor for rebuild after that.

Hmm the MSV-02 is the daughter board on the msv-01

my arm is the SK6

Hmm the MSV-02 is the daughter board on the msv-01

my arm is the SK6

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21231

- Thank you received: 7249

09 Apr 2023 18:20 #268697

by tommylight

Replied by tommylight on topic Motoman K6SB Retrofit

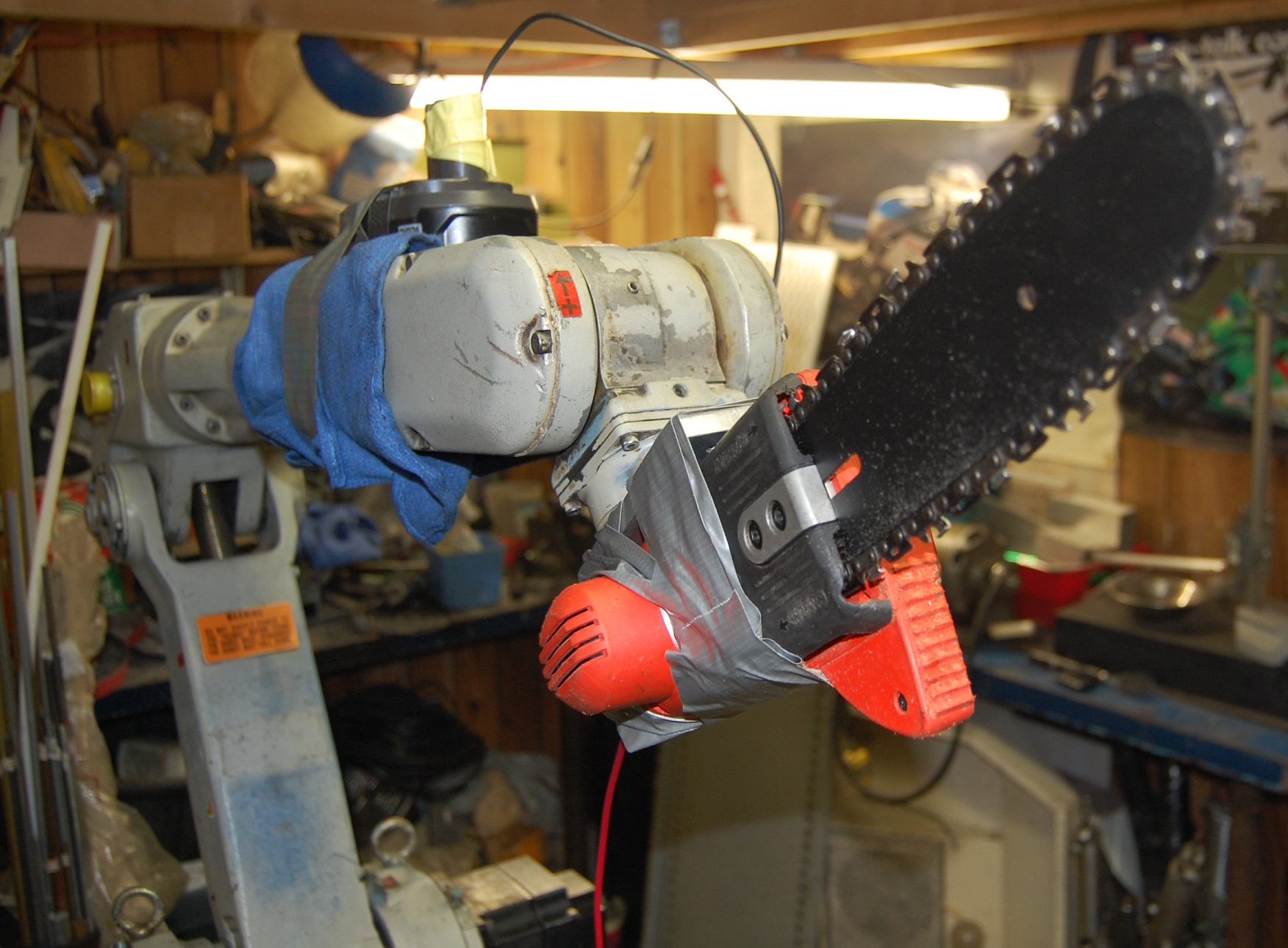

Preparing for a zombie apocalypse ?

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

11 Apr 2023 19:23 #268837

by boksi

Replied by boksi on topic Motoman K6SB Retrofit

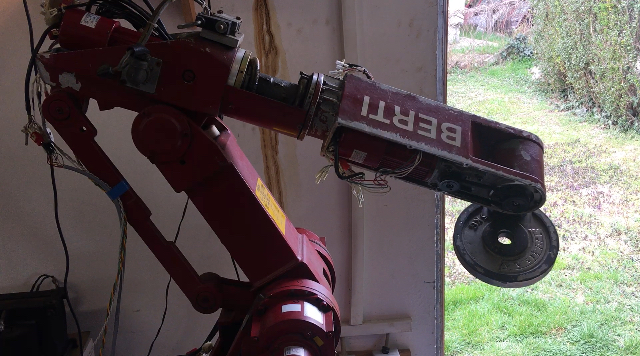

Mine is also preparing for sometning seems for bodybuilding competition

I have some questions for robot control with Linuxcnc.

How far or close quality of robot arm control could be done with Linuxcnc in comparison with original control?

Could it be used for production?

I don’t know for sure but believe that original control work with S velocity curves giving lot smoother movements than trapezoidal profiles.

Also not sure, someone correct me if wrong, but original control should have some sort of real time moment of inertia calculation based on joints position so it could be able to adjust feedforward parameters for velocity and acc + gravity influence.

Also maybe some vibration compensation.

Possibly a lot more involved...

Is it possible on commercial robots to access data like following error or steady state error?

I saw in most cases manufacturers guarantee precision on final position but I don’t know what happens during the way.

I watched Linuxcnc controlling manutec arm with stmbl drives, it looks very nice with slow speeds but with high speed movement it shakes a little bit at top.

Can robot arm g code for joints movement be exported from Linuxcnc?

If can than it can possibly be used with some custom hardware which provides smoother velocity profiles.

I have some questions for robot control with Linuxcnc.

How far or close quality of robot arm control could be done with Linuxcnc in comparison with original control?

Could it be used for production?

I don’t know for sure but believe that original control work with S velocity curves giving lot smoother movements than trapezoidal profiles.

Also not sure, someone correct me if wrong, but original control should have some sort of real time moment of inertia calculation based on joints position so it could be able to adjust feedforward parameters for velocity and acc + gravity influence.

Also maybe some vibration compensation.

Possibly a lot more involved...

Is it possible on commercial robots to access data like following error or steady state error?

I saw in most cases manufacturers guarantee precision on final position but I don’t know what happens during the way.

I watched Linuxcnc controlling manutec arm with stmbl drives, it looks very nice with slow speeds but with high speed movement it shakes a little bit at top.

Can robot arm g code for joints movement be exported from Linuxcnc?

If can than it can possibly be used with some custom hardware which provides smoother velocity profiles.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.315 seconds