Motoman K6SB Retrofit

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

I have a 15 year old mitsubishi arm and it offers "soft joints", meaning that you can define the allowed following error along any direction in space which is very useful for placing/removing parts from a fixture. But it does not offer velocity blending across way points for example.

The thing to realize is that robot control is not the same as CNC and robot control is a very closed environment. Using a robot for CNC machining is generally not really all that good of an idea since a robot arm does not offer the required rigidity. All those videos of robot arms cutting circles in the air are maybe fun to look at but the practical application is questionable at best.

GCode is not really used to program robots, they all use some proprietary language so the first stumbling block is usually how to get the GCode generated for a robot arm in the first place.

Don't get me wrong, I do think that LinuxCNC can be very useful to get a decommissioned robot arm do some useful work but if you are expecting it to do machining, complex 3d welding or high speed manipulations you are likely expecting the impossible.

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

- Posts: 27

- Thank you received: 0

Can you share some more info about your arm behavior?

"I have a 15 year old mitsubishi arm and it offers "soft joints", meaning that you can define the allowed following error along any direction in space which is very useful for placing/removing parts from a fixture."

Does this mean that controller in that mode is adjusting velocities, acc,decc in real time to be able to stay within defined borders of following error?

Did you noticed some change in behavior due reducers wear out?

In my arm not all reducers are harmonic some of them are planetary. This could be also issue for control due backlash which could happen.

Do you have option to set manually acc and decc values for joint drives?

Did you noticed any servo noise in any mode/orientation/operation condition of robot arm?

Is there any differences in behavior when arm is not loaded and fully loaded?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

Both my arms have harmonic drives in all the joints (I think) and there does not seem to be any backlash. However some joints seem to require a lot of torque even when moving with no load which makes me think that something is not quite right there. Those joints are also noisier than the others.

Acceleration / deceleration can be set in the program and will need to be adjusted according to the load that is moved around so yes behavior definitely depends on the load.

Just to be clear, I have very little experience using robots in the field. All I know is from playing around with the two used units I bought relatively cheap. I did consider to install one for machine tending in a local shop but I grew wary of dealing with the very closed world of industrial robots.

I had to replace a motor in one of the arms which I was lucky enough to find used on ebay but even just the replacement set of batteries for the absolute encoders cost me more than 100 euros.

I have found the robot forums to be of little help. All very hush-hush and secretive.

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

- Posts: 923

- Thank you received: 275

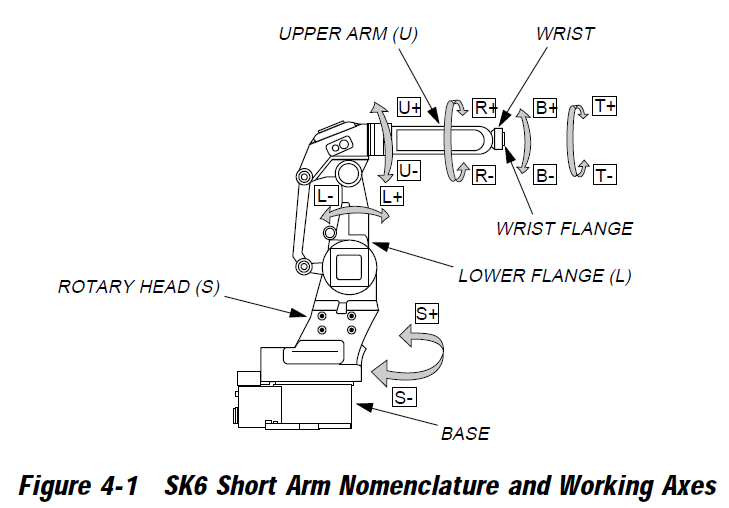

From what Ive seen, usually J1,2 and 3 (or SLU i think is motoman) are not planetary or harmonic, but cyclodial with a (sometimes planetary) gear reduction. Joints 4 and 6 are generally the harmonic ones where speed and load are less , and j5 is a wild card usually , depending on arm configuration. Theres only like 2 manufactures of the gear boxes that are used in most robots, harmonic for the sinewave gears, and the other company does cyclodial, regardless of the robot brand.

However some joints seem to require a lot of torque even when moving with no load which makes me think that something is not quite right there.Those joints are also noisier than the others.

Depends which joints, from what Ive seen, J2 and J3 have the highest load almost all the time. Also depending on the move and speed. I dont know how yours sound, but even new robots make a groaning noise when doing some moves depending on speed and stuff, something I didnt expect.

Did you noticed some change in behavior due reducers wear out?

In my arm not all reducers are harmonic some of them are planetary. This could be also issue for control due backlash which could happen.

Im 90% sure its a planetary gear thats driving the cyclodial gear. I havent really seen any with backlash before. Usually the motors need to be replaced before the gearboxes.

Its pretty cool how they set the acc/decel settings now. You get the center of gravity of the end of arm tool, and the weight, then you run a program that does what I assume is load calculations at slow speed and at fastest speed, and then does all the math in the background.Acceleration / deceleration can be set in the program and will need to be adjusted according to the load that is moved around so yes behavior definitely depends on the load.

I think this happened once manufactures started getting involved (fanuc manuals and motoman master codes for example). I found 2 pretty good solutions around it.I have found the robot forums to be of little help. All very hush-hush and secretive

1. Wayback machine on robot-forum to like 2010, before the good stuff was deleted

2. Networking . years after i joined robotforums, I was talking to a guy from work, and he says "oh yeah, I used to work with that guy on the site, let me text him" 30 min later I had the info

Are you using the MRC controller or linuxcnc? I thought you could do it with the mrc, but now I cant find any reference.Can robot arm g code for joints movement be exported from Linuxcnc?

But if you are using the yasnac controller, check out these guys. I tried to use it before when i really didnt know linux, but I dont think they liked what I was doing.

sudoroom.org/wiki/Giant_robot_arm

I thought it would be scary, and it was. on so many levelsPreparing for a zombie apocalypse ?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4648

- Thank you received: 2068

You are right, good point.but they are unlikely harmonic in all axis or using plantetary gearboxes

On one of mine it's the arm twist (J4) that requires about 40% of the max torque with no load which seems exessive. Mind you there was likely a good reason why those two units got taken out of the production line and sold for about 1% of the original price after 10 years of service.Depends which joints,

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

- Posts: 27

- Thank you received: 0

All I can remember as I pull out motors long time ago. S joint motor and gears look like this.

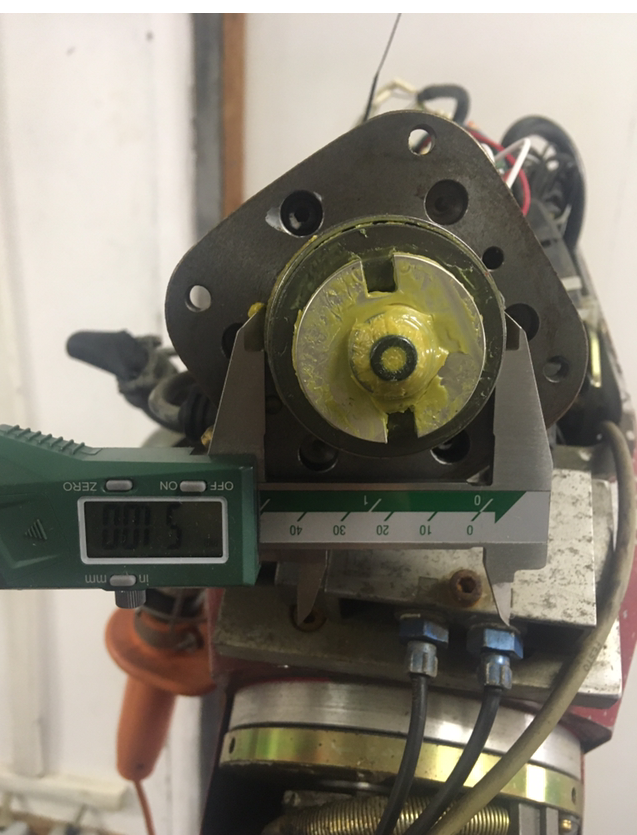

For upper joints R,B and T motors seems to be the same and looked like this.

For U and L joints I have to check.

I little googled about cyclodial drive. I found this on wiki :"Due to the eccentric nature of the drive, if the cycloidal disk is not balanced by a second disk or a counterweight, it will generate vibrations which propagate through the driven shafts and the body. This increases wear on the exterior teeth of the cycloidal disk and the component bearings. With two discs the static imbalance is corrected but a small dynamic imbalance remains. This is generally considered acceptable for most applications. To reduce vibration, high-speed drives use three or more discs to correct the imbalance; the outer discs move in unison, in opposition to the middle one, which is twice as massive."

I mostly test S axis and noticed vibrations. By looking at current/torque plot from drive undamped vibrations are present on constant velocity phase. Tried with a lot of tunning current controllers and position controller but vibrations seems to remain. Current/torque vibrations are reflecting speed and finally following error. I first thought maybe this could be from trapezoidal velocity profile from Linuxcnc(I used for testing 6i25 mesa) as it will give acc/decc step response and inject high impact but this wasn't a problem as I tried also with different hardware which generated cosine S-curve velocity profile and still constant velocity phase of movement has undamped vibrations. S-curve profile improved a lot transition phases acceleration and deacceleration. Is it possible that combination of gear technology(at time of manufacturing) and fact that my arm has about 30 years is responsible for this vibration or this could be something else?

I have this arm without control cabinet, so only mechanics and motors. I used custom driver to run motors. With Linuxcnc, mesa card and G1 command I was just testing move of one at the time joint as currently have only one driver.

For additional info about encoder communication and encoder battery replacement I used this manual also

TSE-S800-17D.pdf , it can be easily found by google.

Yes I saw this link, lot nice documentation.

sudoroom.org/wiki/Giant_robot_arm

Attachments:

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

- Posts: 923

- Thank you received: 275

boksi, yeah the S is cyclodial, L and U are the same thing, except with brakes on the motor,same with fanuc. They sometimes have a secondary gear reduction with spur gears. I dont know the purpose of the 2 spurgears on the cyclodial, but I think its something to keep the 2 disks in sync with the eccentric middle section. R and T are harmonic, B is wild card, sometimes is got belts, sometimes spur gears, sometimes a differential to control J5 and J6 , bevel gears etc. If that motor is your B axis , then it is harmonic, as that is a wave generator at the end of the motor, or at least it looks like.

Please Log in or Create an account to join the conversation.