Kinematic model for a 5axis mill with universal (nutating) head

- Gurpreet

- Offline

- New Member

-

- Posts: 8

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Away

- Administrator

-

- Posts: 4324

- Thank you received: 1922

Please Log in or Create an account to join the conversation.

- Gurpreet

- Offline

- New Member

-

- Posts: 8

- Thank you received: 1

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Away

- Administrator

-

- Posts: 4324

- Thank you received: 1922

I attach my jupyter notebook (remove the '.txt') which contains all the ipython symbolic math to automatically derive all the formulas in the documentation. Using jupyter and ipython will save you a LOT of paper and headache.

You will need to adjust some of the matrices and order of the matrix multiplications though.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Away

- Platinum Member

-

- Posts: 2407

- Thank you received: 2320

Nice work ! Impressive.

Please Log in or Create an account to join the conversation.

- Paul01

-

- Offline

- Junior Member

-

- Posts: 21

- Thank you received: 2

Thank you for sharing your work with us. It's very impressive. And I have found it invaluable for setting up my own CNC machine.

I've worked through all the files except the remap.py file for the TWP functionality. Everything else seems to be working fine so far and I have a decent understanding of it all, but some help with the remap file would be much appreciated. I'm a little stuck on the opening section where it returns the A/B joint positions for a given tool-orientation vector. I don't fully understand the calculations and how they would need to be modified to suit my particular setup (A/B will become A/C).

As a bit of a background on my machine, I have a fixed table with a rotary B axis, and a moving gantry with an A,C head where the A axis is 55° nutating (similar to the Hiteco head shown here on page 1). I can provide more information if needed.

Basically I'm just looking for a bit of guidance for modifying the remap.py file other than the basics like updating the matrices and changing the values to match my kinematic model. Thanks again.

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Away

- Administrator

-

- Posts: 4324

- Thank you received: 1922

I'll see if I can retrace my steps but it may take me a few days to do so.

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Away

- Administrator

-

- Posts: 4324

- Thank you received: 1922

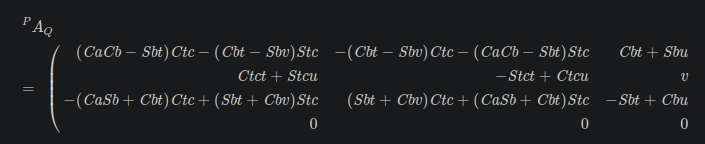

To calculate the joint angles (which is done in the function 'kins_calc_jnt_angles' in 'remap.py' ) we use the rotation matrix part (ie disregard the fourth row with all the zeros ) of the transformation matrix as derived for the inverse tool kinematic:

the columns of this matrix represent the tool orientation vectors [tx, ty, tz] and hence the 3rd column represents the tool-z orientation vector we are trying to orient the spindle head to.

So using the variable names from the remap we get:

Kwx = Cb*t + Sb * u

Kwy = v

Kwz = -Sb*t + Cb*u

with the substitution for 'v' we can then solve for Sa and thus for the angle of joint A

Then we use the two remaining equations to solve for Sb and thus for the angle of Joint B

The output of this calculation needs to conditioned so the correct angle values are output for the machine rotary joints.

As a side note:

in the function ' kins_calc_tool_rot_c_for_horizontal_x' of remap.py there is this comment:

# Mathematically we take the symbolic formula found in row 3, column 1 of the transformation

# matrix from the inverse tool-kinematics, equal that to zero and solve for 'tc'.

# ie: -(tctc-vstc)cb-(cactc-tstc)sb=0

Note that the formula given in the comment may not be readily recognizable in the matrix shown above yet it is indeed identical to the third row of the first column. It seems that in the final version of the documentation 'Ctc' and 'Stc' were factored out instead of 'Cb' and 'Sb'.

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Away

- Administrator

-

- Posts: 4324

- Thank you received: 1922

with the substitution for 'v' we can then solve for Ca and thus for the angle of joint A

Please Log in or Create an account to join the conversation.

- Paul01

-

- Offline

- Junior Member

-

- Posts: 21

- Thank you received: 2

Your help means a lot. I wouldn't know how to do any of this on my own.

I've been trying to understand the if-else statements in 'remap.py' for the tool-orientation vector by substituting known values into the calculations, but my math is a little lacking so I still don't fully understand how the calculations work. And I presume I will need to change them if I have a 55° nutating head. For example, if Kwy = 1, A_j = pi and B_j = 0 will only work on a 45° nutating head.

The part of the calculations I understand the least are the parts of the if-else statements similar to this:

if -(sqrt(2)*Kwz*Sa_j) <= Sa_j*Sa_j:

B_j = (- asin(2*(sqrt(2)*Kwz*Sa_j - (Ca_j + 1)*Kwx)/(Ca_j*Ca_j

+ 2*Sa_j*Sa_j + 2*Ca_j + 1)))

A bit of an explanation about how this works would be great. I'll post the full section of code below.

The '-(tctc-vstc)cb-(cactc-tstc)sb=0' did confuse me for a second, but there was a note in the file stating it referred to row 3, column 1 of the inverse tool kinematic. It was easy enough to understand after this.

Please Log in or Create an account to join the conversation.