8 Spindle Gang Router

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

27 Aug 2024 15:39 #308818

by Todd Zuercher

8 Spindle Gang Router was created by Todd Zuercher

This 8 spindle gang router with 8 independent Z axis (using closed loop stepper motors), tandem servos for the Y axis gantry, and a servo on they X axis.

This machine has evolved a bit over time. It was my very first Linuxcnc(EMC2) retrofit. I have shared some details of it through the years. Here is a link to what it looked like when I was first setting it up on Linuxcnc.

forum.linuxcnc.org/38-general-linuxcnc-q...-help?start=50#11052

The machine originally only had 3 joints, with a single servo moving a large (2ft x 8ft) aluminum plate up and down via a centrally mounted lead screw. All 8 spindles were bolted to that plate with a hand actuated screw to fine tune each spindle's depth. The Y axis was moved by a set of helical rack and pinion gears on each end of the gantry, connected together by a 12ft long torque tube drive shaft, then a 12:1 belt reduction to the servo motor. The X axis was driven by a servo/lead screw combo. After 20years of use all of the linear components needed refreshed, so we decided to redesign most of it.

X axis received the least change, changing from a high lead lead screw connected to the servo via a belt reduction, to a new 25mm x 5mm lead ball screw directly coupled to the servo, and new linear ways.

Y axis, got new larger linear ways, and replaced the rack and pinions with two 25mm x 10mm lead ball screws and 2:1 belt reduction to the old Y and former Z servos.

For the Zs, I removed the large 3/4inch thick by 2ft x 8ft plate, cut off 8 pieces 5inch x 24inch and milled them to mount a pair of linear ways and a ball screw for each spindle and a NEMA 23 closed loop stepper motor for each.

Here is a link to a Google photo album containing some photos of the pieces I milled for each of the 8 Z-axis joints.

photos.app.goo.gl/Tx2oYkS272xBUMvZ7

Then I'm attaching a copy of my config directory so others can see how I implemented the individual Z axis joints. The Z axis is set up as a dummy master joint that automatically homes. Each spindle joint is set up as an "extra" joint. There is a GladeVCP panel that lets the operator enable and disable each of the spindles. When a spindle is enabled, that spindle's Z-joint is connected to the dummy master's position plus a tool offset. When it is disabled the spindle's joint is moved back up to it's home position. This way only the spindles actually being used are ever moved with the Z axis.

There are also buttons on the Glade panel for tool probing routines for each of the spindle Z-axis. These disable all of the other spindle Z-axis and enable the one being probed, then sets the tool offset for that spindle according to the probe results.

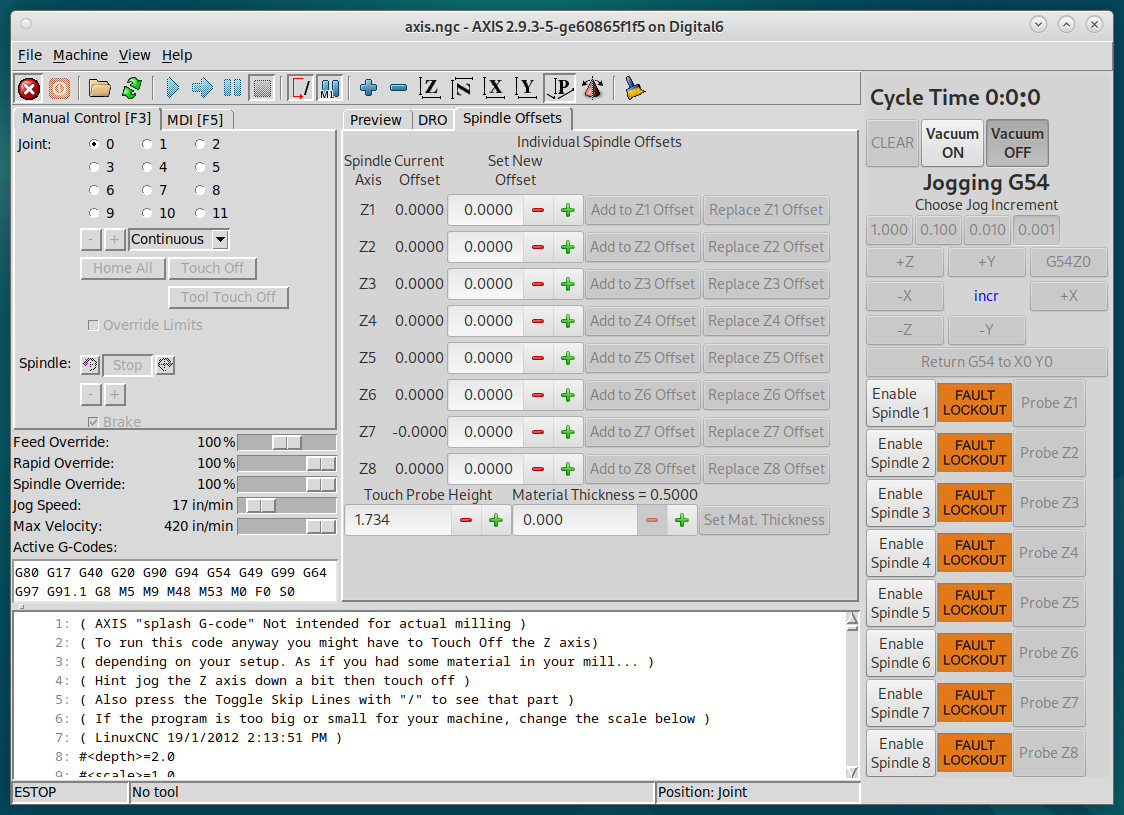

Then I created a GladeVCP tab window for displaying and manipulating the tool offsets for each of the spindles.

This machine has evolved a bit over time. It was my very first Linuxcnc(EMC2) retrofit. I have shared some details of it through the years. Here is a link to what it looked like when I was first setting it up on Linuxcnc.

forum.linuxcnc.org/38-general-linuxcnc-q...-help?start=50#11052

The machine originally only had 3 joints, with a single servo moving a large (2ft x 8ft) aluminum plate up and down via a centrally mounted lead screw. All 8 spindles were bolted to that plate with a hand actuated screw to fine tune each spindle's depth. The Y axis was moved by a set of helical rack and pinion gears on each end of the gantry, connected together by a 12ft long torque tube drive shaft, then a 12:1 belt reduction to the servo motor. The X axis was driven by a servo/lead screw combo. After 20years of use all of the linear components needed refreshed, so we decided to redesign most of it.

X axis received the least change, changing from a high lead lead screw connected to the servo via a belt reduction, to a new 25mm x 5mm lead ball screw directly coupled to the servo, and new linear ways.

Y axis, got new larger linear ways, and replaced the rack and pinions with two 25mm x 10mm lead ball screws and 2:1 belt reduction to the old Y and former Z servos.

For the Zs, I removed the large 3/4inch thick by 2ft x 8ft plate, cut off 8 pieces 5inch x 24inch and milled them to mount a pair of linear ways and a ball screw for each spindle and a NEMA 23 closed loop stepper motor for each.

Here is a link to a Google photo album containing some photos of the pieces I milled for each of the 8 Z-axis joints.

photos.app.goo.gl/Tx2oYkS272xBUMvZ7

Then I'm attaching a copy of my config directory so others can see how I implemented the individual Z axis joints. The Z axis is set up as a dummy master joint that automatically homes. Each spindle joint is set up as an "extra" joint. There is a GladeVCP panel that lets the operator enable and disable each of the spindles. When a spindle is enabled, that spindle's Z-joint is connected to the dummy master's position plus a tool offset. When it is disabled the spindle's joint is moved back up to it's home position. This way only the spindles actually being used are ever moved with the Z axis.

There are also buttons on the Glade panel for tool probing routines for each of the spindle Z-axis. These disable all of the other spindle Z-axis and enable the one being probed, then sets the tool offset for that spindle according to the probe results.

Then I created a GladeVCP tab window for displaying and manipulating the tool offsets for each of the spindles.

Attachments:

The following user(s) said Thank You: tommylight, pommen, spumco, hmnijp

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

26 Sep 2024 14:52 #310834

by Todd Zuercher

Replied by Todd Zuercher on topic 8 Spindle Gang Router

I have sad news. The company I work for is going out of business. I worked on refitting this machine for a little over a year, in my spare time at work. And now it appears that I've completed it just in time to see it sold off (most likely at auction) before ever being put back into production. It's all very depressing.

The company buying us out has no interest in our production facility or machinery, and is merely buying our name and intellectual property. A different company who is buying the property (and all left over machinery) will not want to use it, so will most likely dump it at a dispersal auction after they take possession of the property. Considering the uniqueness of the machine I would not be surprised to see it cut up for scrap. I'm almost sadder about that, than having to find a new job.

The company buying us out has no interest in our production facility or machinery, and is merely buying our name and intellectual property. A different company who is buying the property (and all left over machinery) will not want to use it, so will most likely dump it at a dispersal auction after they take possession of the property. Considering the uniqueness of the machine I would not be surprised to see it cut up for scrap. I'm almost sadder about that, than having to find a new job.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1975

- Thank you received: 808

26 Sep 2024 17:35 #310844

by spumco

Buy it at auction and strip out the good parts? You know nobody else will bid on it.

Or make an offer to the existing owner to purchase the components out of the machine before the deal is finalized.

Sorry to hear about the job and situation.

Replied by spumco on topic 8 Spindle Gang Router

most likely dump it at a dispersal auction after they take possession of the property

Buy it at auction and strip out the good parts? You know nobody else will bid on it.

Or make an offer to the existing owner to purchase the components out of the machine before the deal is finalized.

Sorry to hear about the job and situation.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

26 Sep 2024 19:50 #310851

by Todd Zuercher

Replied by Todd Zuercher on topic 8 Spindle Gang Router

There are no "special" parts there that I want or are worth much on their own. It is all of the time I put into building it that I hate to see go for naught. (There is a lot of "me" in that machine.)

The following user(s) said Thank You: tommylight, Clive S, pommen

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1975

- Thank you received: 808

26 Sep 2024 20:25 #310853

by spumco

Gut-punch understood.

Replied by spumco on topic 8 Spindle Gang Router

There are no "special" parts there that I want or are worth much on their own. It is all of the time I put into building it that I hate to see go for naught. (There is a lot of "me" in that machine.)

Gut-punch understood.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7287

27 Sep 2024 01:22 #310866

by tommylight

Replied by tommylight on topic 8 Spindle Gang Router

At the risk of getting banned:

FUCK!

-

Sorry Todd.

FUCK!

-

Sorry Todd.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

27 Sep 2024 02:30 #310867

by PCW

Replied by PCW on topic 8 Spindle Gang Router

So sorry about that Todd.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

28 Sep 2024 01:49 #310933

by rodw

Replied by rodw on topic 8 Spindle Gang Router

Sorry to hear that Todd. I'm sure many of us who you have helped over the years will feel the same,

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

25 Nov 2024 23:39 #315263

by Todd Zuercher

Replied by Todd Zuercher on topic 8 Spindle Gang Router

I've found out that the 8 spindle machine is to be auctioned off on Dec. 18th 2024. As well as all other machinery. There are 3 other routers I've converted to running Linuxcnc, as well as as a number of other larger routers (mostly Fanuc controls.)

airworksauction.proxibid.com/CNC/lotInformation/88606700

airworksauction.proxibid.com/CNC/lotInformation/88606700

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 973

- Thank you received: 429

26 Nov 2024 10:20 - 26 Nov 2024 13:32 #315283

by my1987toyota

Replied by my1987toyota on topic 8 Spindle Gang Router

Sorry to hear that . This has been an ongoing trend for years now unfortunately. And these companies wonder why

nobody has loyalty any more. If it weren't for how terrible looking for a new job has become I would say time to

find a new one. Once another owner comes in they use the original personnel to train the new hires and push

the old ones out the door in a year or two. I have seen it happen time and again. And yes it's a worry where I work

as well. It's one of the reasons I am so cynical about things.

nobody has loyalty any more. If it weren't for how terrible looking for a new job has become I would say time to

find a new one. Once another owner comes in they use the original personnel to train the new hires and push

the old ones out the door in a year or two. I have seen it happen time and again. And yes it's a worry where I work

as well. It's one of the reasons I am so cynical about things.

Last edit: 26 Nov 2024 13:32 by my1987toyota.

Please Log in or Create an account to join the conversation.

Time to create page: 0.163 seconds