THC experimental

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21301

- Thank you received: 7274

22 Jan 2017 21:59 #86432

by tommylight

Replied by tommylight on topic THC experimental

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

23 Jan 2017 09:10 #86462

by rodw

Thanks Rick, I've been working on the gomoccappy plasma screen which has provision for a correction amount. You have a couple of extra pins that will redefine the work I did over the weekend but its all good.

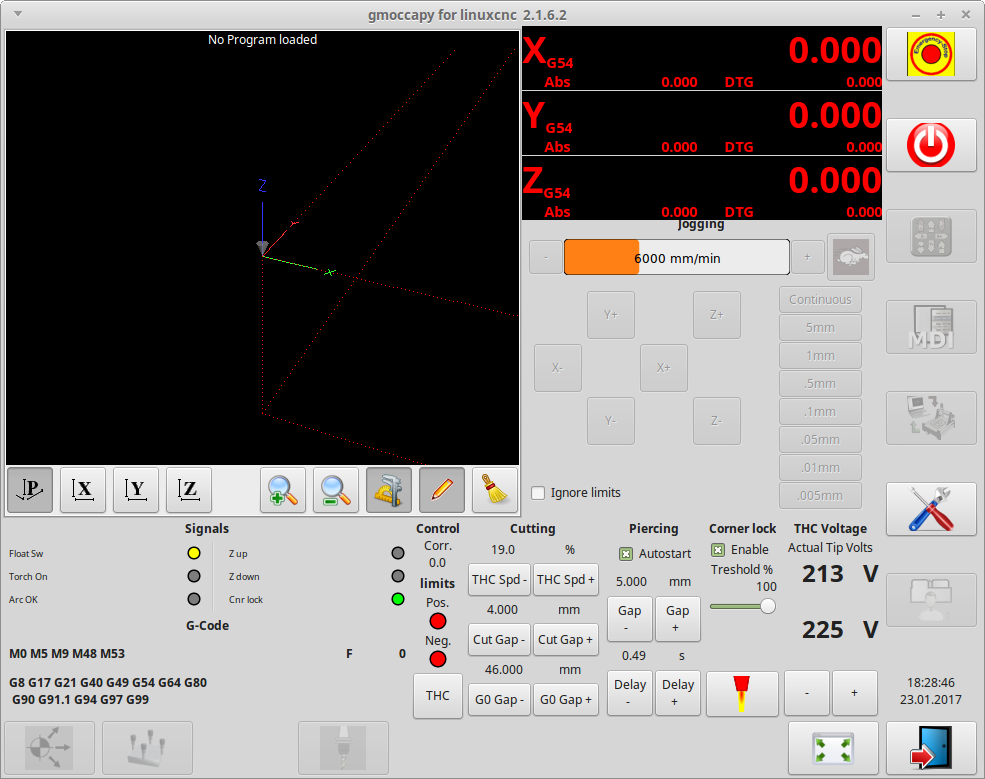

Tommy, I did look at your setup but when I decided to use the Mesa stuff, came up with this in gmoccappy. You've got everything but the volts and I've got everything but the THC correction!

Anyway, I've got all of the THC stuff done but I did not understand what the author had intended what the THC Spd+ and THC Spd- buttons were to do. but now I know what they are designed for. So while those of you that have working machines experiment with cutting, I'll have to stick to the software.so it would be great if you could help with this. So which pin should it control and what is the correction scale? Currently, the readings go from 1-20% which did not make sense to me.

Please let me know and I'll try and finish this off and share my config.

Replied by rodw on topic THC experimental

I'd like to know a bit more about how the Mesa THC component should implement the correction.On the configs i use, i have a setting on the panel for the amount of correction to be applied to Z axis with every up or down pulse, so when cutting flat i set it at a lower value to get smooth cuts, and set it higher when cutting easily bending material or slopes, makes cuts with a bit of bunny hoping but gets the job done nicely.

rodw,

There seems to be a few versions of the THC out there. That one uses a parameter that you can set / change in Hal.

If you are working on your panel you might want to bring the THC correction amount out to the panel also as Tommylight has mentioned.

Rick G

Thanks Rick, I've been working on the gomoccappy plasma screen which has provision for a correction amount. You have a couple of extra pins that will redefine the work I did over the weekend but its all good.

Did anyone have a look at that config to see the panel? It has everything needed except the voltage.

Tommy, I did look at your setup but when I decided to use the Mesa stuff, came up with this in gmoccappy. You've got everything but the volts and I've got everything but the THC correction!

Anyway, I've got all of the THC stuff done but I did not understand what the author had intended what the THC Spd+ and THC Spd- buttons were to do. but now I know what they are designed for. So while those of you that have working machines experiment with cutting, I'll have to stick to the software.so it would be great if you could help with this. So which pin should it control and what is the correction scale? Currently, the readings go from 1-20% which did not make sense to me.

Please let me know and I'll try and finish this off and share my config.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

23 Jan 2017 19:56 #86506

by BigJohnT

Replied by BigJohnT on topic THC experimental

LinuxCNC has an up/down THC called thcud linuxcnc.org/docs/devel/html/man/man9/thcud.9.html

I've started using M68 to set the voltage requested. Changed Sheetcam post to use that based on the tip I chose. Keeps me from forgetting to set the voltage!

JT

I've started using M68 to set the voltage requested. Changed Sheetcam post to use that based on the tip I chose. Keeps me from forgetting to set the voltage!

JT

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

26 Jan 2017 10:13 #86693

by rodw

Replied by rodw on topic THC experimental

Hi guys, I have a question. Do you guys run the Z axis in velocity mode when using THC?

I think I have got my head around how to implement a PID control into a THC component and velocity mode seems to be part of the solution but wondered what was going on in the current THC components and I can't find anything that talks about the stepgen mode used.

I think I have got my head around how to implement a PID control into a THC component and velocity mode seems to be part of the solution but wondered what was going on in the current THC components and I can't find anything that talks about the stepgen mode used.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

26 Jan 2017 11:48 #86700

by andypugh

Replied by andypugh on topic THC experimental

The "magic" of PID means that either position or velocity mode can work.

In velocity mode you will end up mainly using PGain, in position mode it will mainly be the I-term that controls the gap.

I noticed a _very_ interesting development in a new feature branch last night. Dewey has been quietly working in the background:

github.com/LinuxCNC/linuxcnc/commit/96a9...da87002d92f63f960e06

In velocity mode you will end up mainly using PGain, in position mode it will mainly be the I-term that controls the gap.

I noticed a _very_ interesting development in a new feature branch last night. Dewey has been quietly working in the background:

github.com/LinuxCNC/linuxcnc/commit/96a9...da87002d92f63f960e06

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

26 Jan 2017 12:07 - 26 Jan 2017 12:10 #86702

by BigJohnT

Thanks to Andy I'm working on a thc component with PID and will test it with the experimental branch Dewey just created. I tested the branch this morning and man it is sweet. The sweet thing about this branch is the thc component will work with any type of drive now.

I use the stepgen in normal mode currently.

JT

Replied by BigJohnT on topic THC experimental

Hi guys, I have a question. Do you guys run the Z axis in velocity mode when using THC?

I think I have got my head around how to implement a PID control into a THC component and velocity mode seems to be part of the solution but wondered what was going on in the current THC components and I can't find anything that talks about the stepgen mode used.

Thanks to Andy I'm working on a thc component with PID and will test it with the experimental branch Dewey just created. I tested the branch this morning and man it is sweet. The sweet thing about this branch is the thc component will work with any type of drive now.

I use the stepgen in normal mode currently.

JT

Last edit: 26 Jan 2017 12:10 by BigJohnT.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

26 Jan 2017 12:46 #86703

by rodw

Replied by rodw on topic THC experimental

Thanks guys. I need to understand a lot more about the LCNC code base to understand what Andy finds very interesting on that link! What are the key features that help THC?

Its great to hear other people are looking at PID control for THC and I'm keen to see what you come up with. John, I must confess that a code snippet Andy posted a couple of months ago got me thinking hard about PID based THC. So here are some discussion points to think about:

1. My thinking was PID based THC was suited to a velocity controlled axis (and even comments the PID code suggests the same). Position is meaningless for THC, we only care about volts.

2. Is the servo thread the right thread for THC when published research worked on a 40ms cycle time?

3. If the THC operated on its own slower thread, another component in the servo thread could calculate average, min, max and moving average data that could be presented to the THC thread. (there would be say 40 readings per data set)

4. Can distance travelled on the xy plane be measured easily? If so, we could extend the averaging technique so we can sample torch voltage for the first say 1/2" of travel to automatically set torch height voltage?

5. Can the mods add a dedicated plasma section? There seems to be a bit of interest right now and the forum nuggets are fragmented and hard to find.

Sorry for the brain dump but RickG did say experimental

Its great to hear other people are looking at PID control for THC and I'm keen to see what you come up with. John, I must confess that a code snippet Andy posted a couple of months ago got me thinking hard about PID based THC. So here are some discussion points to think about:

1. My thinking was PID based THC was suited to a velocity controlled axis (and even comments the PID code suggests the same). Position is meaningless for THC, we only care about volts.

2. Is the servo thread the right thread for THC when published research worked on a 40ms cycle time?

3. If the THC operated on its own slower thread, another component in the servo thread could calculate average, min, max and moving average data that could be presented to the THC thread. (there would be say 40 readings per data set)

4. Can distance travelled on the xy plane be measured easily? If so, we could extend the averaging technique so we can sample torch voltage for the first say 1/2" of travel to automatically set torch height voltage?

5. Can the mods add a dedicated plasma section? There seems to be a bit of interest right now and the forum nuggets are fragmented and hard to find.

Sorry for the brain dump but RickG did say experimental

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

26 Jan 2017 13:07 #86705

by andypugh

It adds a HAL pin to offset an axis. G10 Z10 will move the axis to 10. Set the HAL pin to 1 and the axis goes to 11.

So, you would feed the THC offset straight into that pin, and the axis would move as required while observing speed, acceleration and axis soft-limits

No need to mess about lying about feedback positions or such, either. The offset-position becomes the position that LnuxCNC expects to see.

Replied by andypugh on topic THC experimental

Thanks guys. I need to understand a lot more about the LCNC code base to understand what Andy finds very interesting on that link! What are the key features that help THC?

It adds a HAL pin to offset an axis. G10 Z10 will move the axis to 10. Set the HAL pin to 1 and the axis goes to 11.

So, you would feed the THC offset straight into that pin, and the axis would move as required while observing speed, acceleration and axis soft-limits

No need to mess about lying about feedback positions or such, either. The offset-position becomes the position that LnuxCNC expects to see.

The following user(s) said Thank You: Rick G, rodw

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

27 Jan 2017 15:01 #86784

by Rick G

Replied by Rick G on topic THC experimental

Andy,

Thanks for the link and info.

If that works as hoped it would certainly simplify things.

We did try a PID in the past with THC but was disappointed with the results. However I have limited experience with PID, and it may in fact work better with the new branch.

Not sure how coordinated motion would be effected with a THC comp or if that could effect blending.

Pretty sure you meant "G01 Z10 will move the axis to 10." not G10

Rick G

Thanks for the link and info.

If that works as hoped it would certainly simplify things.

We did try a PID in the past with THC but was disappointed with the results. However I have limited experience with PID, and it may in fact work better with the new branch.

) After homing, support external axis offsets for

a) teleop (world) jogging

b) coordinated motion (gcode)

Not sure how coordinated motion would be effected with a THC comp or if that could effect blending.

Pretty sure you meant "G01 Z10 will move the axis to 10." not G10

Rick G

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

01 Feb 2017 19:09 #87133

by islander261

Replied by islander261 on topic THC experimental

Hello

I am following this with great interest. I am afraid that some of the discussion here is quickly going far above my knowledge of lcnc.

FWIW my commercial THC uses the P and I terms of a PID control. The output of the control when servoing to the arc voltage is a position correction (encoder counts) sent to the servo motor controller (Anamatics Smart Motor).

I looked at Dewey's branch and it didn't make much sense to me because of my lack of knowledge of lcnc. Is the short summary of his work that he has modified the motion component to add an offset summer with scaling to each joint? The external connection is handled through a new HAL pin, axis.N.external_offset? I haven't gotten my head around the value being a fraction and the changes to the limits but I just started looking at this. Can the same general thing be done by connecting a sum2 component between the axis.N.pos-cmd motion output and the PID or stepgen input? Where one input to the sum2 component is the axis.N.pos-cmd and the other is the correction from a THC component?

rodw

The halcompile works exactly as in the docs. I have modified JT's THC so that it has pins that work directly with the Gmoccapy Plasma screen that I have modified. I have also added the arc voltage sample mode of operation to it. I appears to work with my simulation setup now. It is not a finished work as quite a bit still requires the correct connection of external hal parts between the GUI and the hal component. The short story is with the programming skill you have this is easy.

All is this a better place to discuss new THC related things or should I continue in the general and gmoccapy sections?

John

I am following this with great interest. I am afraid that some of the discussion here is quickly going far above my knowledge of lcnc.

FWIW my commercial THC uses the P and I terms of a PID control. The output of the control when servoing to the arc voltage is a position correction (encoder counts) sent to the servo motor controller (Anamatics Smart Motor).

I looked at Dewey's branch and it didn't make much sense to me because of my lack of knowledge of lcnc. Is the short summary of his work that he has modified the motion component to add an offset summer with scaling to each joint? The external connection is handled through a new HAL pin, axis.N.external_offset? I haven't gotten my head around the value being a fraction and the changes to the limits but I just started looking at this. Can the same general thing be done by connecting a sum2 component between the axis.N.pos-cmd motion output and the PID or stepgen input? Where one input to the sum2 component is the axis.N.pos-cmd and the other is the correction from a THC component?

rodw

The halcompile works exactly as in the docs. I have modified JT's THC so that it has pins that work directly with the Gmoccapy Plasma screen that I have modified. I have also added the arc voltage sample mode of operation to it. I appears to work with my simulation setup now. It is not a finished work as quite a bit still requires the correct connection of external hal parts between the GUI and the hal component. The short story is with the programming skill you have this is easy.

All is this a better place to discuss new THC related things or should I continue in the general and gmoccapy sections?

John

Please Log in or Create an account to join the conversation.

Time to create page: 0.124 seconds