Help with external offsets on a Real Plasma machine

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11703

- Thank you received: 3956

04 May 2018 08:23 #110175

by rodw

Replied by rodw on topic Help with external offsets on a Real Plasma machine

Oopos. I forgot to mention. refer to cut line.ngc for example Gcode.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

05 May 2018 08:58 - 05 May 2018 08:59 #110241

by Grotius

Replied by Grotius on topic Help with external offsets on a Real Plasma machine

@Hi Rod,

Thank you for your input.

I was thinking about your steel parts. For 8mm you need 65 amps to cut easy.

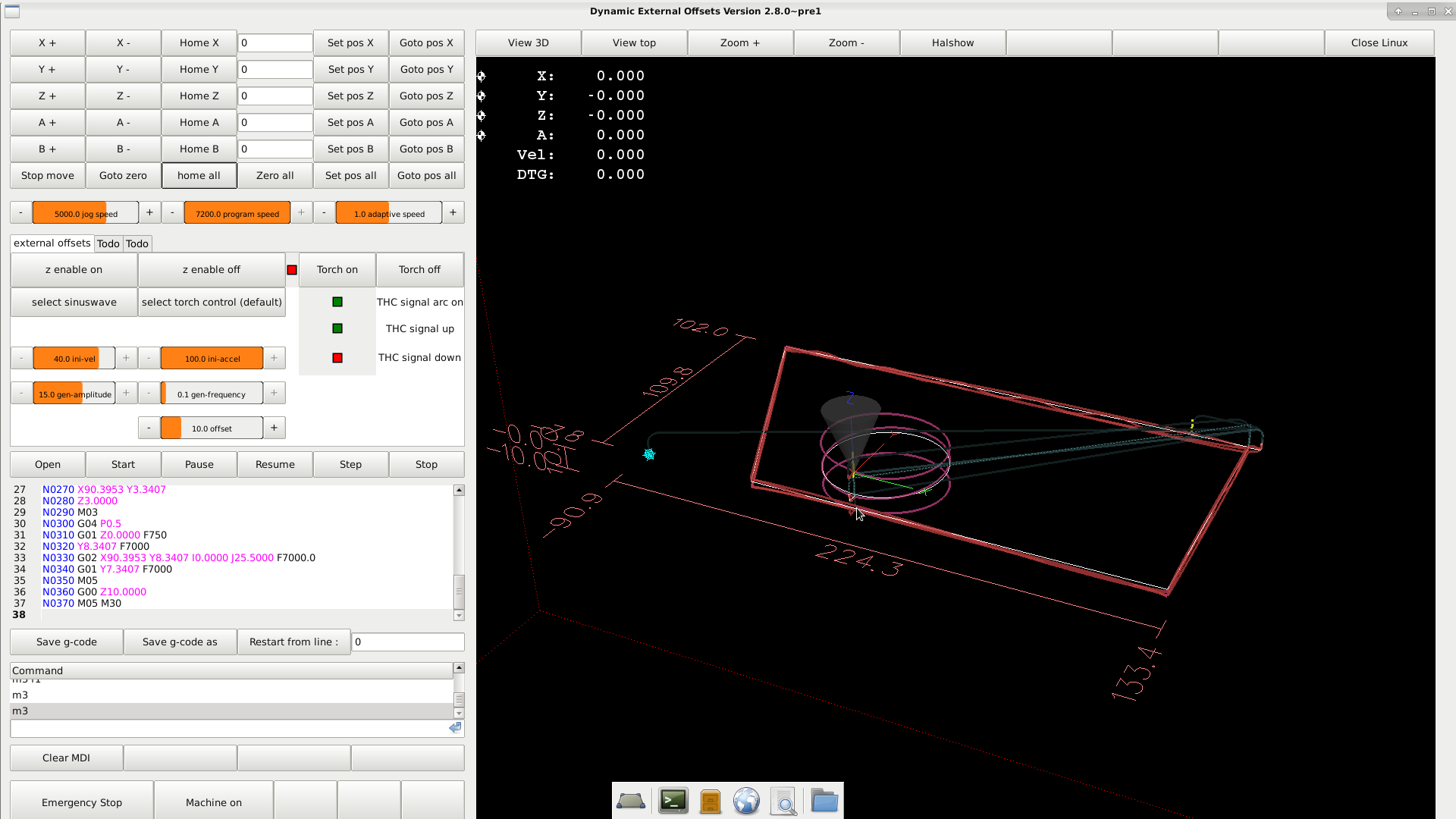

This morning i finally get the external offsets working with proma thc.

I inserted a hal side mux2 to switch between :

- orginal sinusgenerator z axis output, for milling machines, for milling sandwich panels with metal top plates, this is fantastic for tool stand time.

- A glade offset control balk that you can adjust z axis heigt when you want, on top off that item i have build the thcud function. It works amazing !!

You can choose now with a screen button. Now i need to finalize the screen design.

My postgui.hal file stay's very short in code.

Thank you for your input.

I was thinking about your steel parts. For 8mm you need 65 amps to cut easy.

This morning i finally get the external offsets working with proma thc.

I inserted a hal side mux2 to switch between :

- orginal sinusgenerator z axis output, for milling machines, for milling sandwich panels with metal top plates, this is fantastic for tool stand time.

- A glade offset control balk that you can adjust z axis heigt when you want, on top off that item i have build the thcud function. It works amazing !!

You can choose now with a screen button. Now i need to finalize the screen design.

My postgui.hal file stay's very short in code.

Last edit: 05 May 2018 08:59 by Grotius.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11703

- Thank you received: 3956

05 May 2018 09:41 #110244

by rodw

Replied by rodw on topic Help with external offsets on a Real Plasma machine

Glad you made progress and am happy to help.

Yeh thanks, I had that conversation with the local Hypertherm agent as there is not much difference in price between the 65 amp and 45 amp and the 65 amp has a much higher duty cycle.

But ithe 65 amp needs 3 phase power and I don't have that here in my home garage and I'm not quite ready to rent a workshop..

@Hi Rod,

Thank you for your input.

I was thinking about your steel parts. For 8mm you need 65 amps to cut easy.

Yeh thanks, I had that conversation with the local Hypertherm agent as there is not much difference in price between the 65 amp and 45 amp and the 65 amp has a much higher duty cycle.

But ithe 65 amp needs 3 phase power and I don't have that here in my home garage and I'm not quite ready to rent a workshop..

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

05 May 2018 14:28 - 05 May 2018 14:30 #110250

by Grotius

Replied by Grotius on topic Help with external offsets on a Real Plasma machine

Hi Rod,

It is possible with 1 phase hypertherm to cut 8mm. Problem is that 45 amp is a very low power for piercing. But contour cutting you can do at 400-500mm/min on 45 amps. I advise you to make a pre pierce job with old consumables in other autocad layer. After the pre pierce job change nozzle for good one. Finecut is the best.

A perpendicular lead in of 5mm. A lead out of 1mm. Pierceheight 8mm. Pierce speed 500. Order your consumables at borte webshop. Its very cheap over there.

Is it 220 volts in australia? Or different?

Also choose the xp version.

How is mesa connecting? Is mesa connecting behind the hypertherm voltagedivider scale 1 to 50? Or at raw arc voltage?

It is possible with 1 phase hypertherm to cut 8mm. Problem is that 45 amp is a very low power for piercing. But contour cutting you can do at 400-500mm/min on 45 amps. I advise you to make a pre pierce job with old consumables in other autocad layer. After the pre pierce job change nozzle for good one. Finecut is the best.

A perpendicular lead in of 5mm. A lead out of 1mm. Pierceheight 8mm. Pierce speed 500. Order your consumables at borte webshop. Its very cheap over there.

Is it 220 volts in australia? Or different?

Also choose the xp version.

How is mesa connecting? Is mesa connecting behind the hypertherm voltagedivider scale 1 to 50? Or at raw arc voltage?

Last edit: 05 May 2018 14:30 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11703

- Thank you received: 3956

05 May 2018 19:21 #110262

by rodw

Replied by rodw on topic Help with external offsets on a Real Plasma machine

Grotius, thanks for your advice. Much appreciated. When you say pierce speed 500mm, does that mean you drop the torch to the height in the cut charts at that speed?

I am using the THCAD-10 with divided torch voltage. Currently I'm using 16:1 to use more of the THCAD 0-10 volt range but the Hypertherm 50:1 input would be fine as calibration can be changed easily in the LinuxCNC hal file.

We have 230 volts, 50 Hz in Australia.

Hypertherm part numbers I looked at are:

088139 45XP with machine torch, voltage divider and RS485 interface

088141 45XP with machine torch, voltage divider but no interface.

I am using the THCAD-10 with divided torch voltage. Currently I'm using 16:1 to use more of the THCAD 0-10 volt range but the Hypertherm 50:1 input would be fine as calibration can be changed easily in the LinuxCNC hal file.

We have 230 volts, 50 Hz in Australia.

Hypertherm part numbers I looked at are:

088139 45XP with machine torch, voltage divider and RS485 interface

088141 45XP with machine torch, voltage divider but no interface.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

06 May 2018 13:32 - 06 May 2018 13:33 #110276

by Grotius

Replied by Grotius on topic Help with external offsets on a Real Plasma machine

Hi Rod,

For the hypertherm you need powermax 45 xp with non-standard duramax machine torch. This machine torch is with external start spring on electrode, much better for long therm usage. Internal torch start springs, give trouble after 10.000 starts.

I would take a 10.7 m machine torch on your machine. Also this durmax torch is compatible with inverters to 105 amp's

The hypertherm inverter you need is with cpc port. This port has signals : for torch-on/off and voltage divider signal.

Rs-485 is optional, we have the python code and the hypertherm doc's, so you can take this also to make it working.

I will look for the complete order numbers.

For the hypertherm you need powermax 45 xp with non-standard duramax machine torch. This machine torch is with external start spring on electrode, much better for long therm usage. Internal torch start springs, give trouble after 10.000 starts.

I would take a 10.7 m machine torch on your machine. Also this durmax torch is compatible with inverters to 105 amp's

The hypertherm inverter you need is with cpc port. This port has signals : for torch-on/off and voltage divider signal.

Rs-485 is optional, we have the python code and the hypertherm doc's, so you can take this also to make it working.

I will look for the complete order numbers.

Last edit: 06 May 2018 13:33 by Grotius.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

06 May 2018 19:52 - 06 May 2018 19:55 #110289

by Grotius

Replied by Grotius on topic Help with external offsets on a Real Plasma machine

Hi Rod,

I was testing with the arc-ok signal. The thcud component has in the document's a motion.digital.in to wait for arc on.

We do this with macro call M66.

For example : M66 P0 L3 Q5 (wait up to 5 seconds for digital input 0 to turn on)

Problem is during cutting, when arc transfer is lost, this can happen when electrode is at the end of life time, machine is not stopping because there is no connection to :

- motion.feed-hold

I was testing with the arc-ok signal. The thcud component has in the document's a motion.digital.in to wait for arc on.

We do this with macro call M66.

For example : M66 P0 L3 Q5 (wait up to 5 seconds for digital input 0 to turn on)

Problem is during cutting, when arc transfer is lost, this can happen when electrode is at the end of life time, machine is not stopping because there is no connection to :

- motion.feed-hold

Last edit: 06 May 2018 19:55 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11703

- Thank you received: 3956

06 May 2018 21:49 #110297

by rodw

Replied by rodw on topic Help with external offsets on a Real Plasma machine

Interesting. I've not seen anybody mention that.

motion.feed−hold docs say nothing about stopping the spindle. I found it was important to use motion.spindle−on to trigger the torch becasue signals such as motion.digital-out-00 triggered by M64/M65 are not turned off on an estop so if the torch falls off in a crash and it will still be firing.

On my Plasma machine, if the arcOK is not established, it turns the torch off and trys to reestablish the arc multiple times. I'm not sure if Hypertherm has the same behaviour.

So i think the torch needs to be somehow turned off when motion.feed−hold is asserted

I'll give some thought to how this can be done in hal.

motion.feed−hold docs say nothing about stopping the spindle. I found it was important to use motion.spindle−on to trigger the torch becasue signals such as motion.digital-out-00 triggered by M64/M65 are not turned off on an estop so if the torch falls off in a crash and it will still be firing.

On my Plasma machine, if the arcOK is not established, it turns the torch off and trys to reestablish the arc multiple times. I'm not sure if Hypertherm has the same behaviour.

So i think the torch needs to be somehow turned off when motion.feed−hold is asserted

I'll give some thought to how this can be done in hal.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

07 May 2018 03:04 #110308

by islander261

Replied by islander261 on topic Help with external offsets on a Real Plasma machine

Guys

I just use a number of AND components to make sure everything quits on error. I am sure I have not worked through all the possible e-stop para-mutations yet. If the torch crash goes true it stops machine motion via feed hold and turns off the the arc enable bit. Don't ask how I know it works!

Grotius

If you are using the EO branch to track the Z movement during THC why not just ditch the Proma all together? The THCad works really well and except for Rod seems to be really bullet proof. Because I wanted the maximum resolution ( I didn't know how the encoder velocity worked at the time) mine is over ranged on the input every pierce and seems to just keep ticking along.

John

I just use a number of AND components to make sure everything quits on error. I am sure I have not worked through all the possible e-stop para-mutations yet. If the torch crash goes true it stops machine motion via feed hold and turns off the the arc enable bit. Don't ask how I know it works!

Grotius

If you are using the EO branch to track the Z movement during THC why not just ditch the Proma all together? The THCad works really well and except for Rod seems to be really bullet proof. Because I wanted the maximum resolution ( I didn't know how the encoder velocity worked at the time) mine is over ranged on the input every pierce and seems to just keep ticking along.

John

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11703

- Thank you received: 3956

07 May 2018 03:41 #110309

by rodw

Replied by rodw on topic Help with external offsets on a Real Plasma machine

I've had no problems with the THCAD itself. I've been thwarted by crappy plasma hardware, user error (where I blew something up) and also an enormous lack of electronics knowledge and having to focus on other priorities for a long time. I think the THC component with a Mesa THCAD should give similar results to a Proma external THC. I'm looking forward to getting back into it when some replacement parts arrive.

Please Log in or Create an account to join the conversation.

Time to create page: 0.109 seconds