Automatic touchoff of face mill

- cahlfors

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 3

28 Jun 2018 14:51 #112988

by cahlfors

Automatic touchoff of face mill was created by cahlfors

Dear forum,

I am not an expert user, but with the help of the wiki and forum, I have been able to remap M6 to do automatic touchoff quite nicely. Recently, I got a large face mill and this introduces a problem. The touchoff coordinates are fixed and centers the tool over the touchoff button (which is screwed to the table). However, the face mill is hollow in the center. It would need to be positioned a tool radius to the side, in order to measure at the cutting points . How can this be accomplished?

Thanks for any pointers,

/Chrishttps://forum.linuxcnc.org/10-advanced-configuration/topic/create#write

I am not an expert user, but with the help of the wiki and forum, I have been able to remap M6 to do automatic touchoff quite nicely. Recently, I got a large face mill and this introduces a problem. The touchoff coordinates are fixed and centers the tool over the touchoff button (which is screwed to the table). However, the face mill is hollow in the center. It would need to be positioned a tool radius to the side, in order to measure at the cutting points . How can this be accomplished?

Thanks for any pointers,

/Chrishttps://forum.linuxcnc.org/10-advanced-configuration/topic/create#write

Please Log in or Create an account to join the conversation.

- Sparky961

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 15

28 Jun 2018 16:57 #112999

by Sparky961

Replied by Sparky961 on topic Automatic touchoff of face mill

Why M6? When I see an M6 in a program, the only thing I expect it to do is change the tool. On a mill that usually includes raising the spindle and whatever automatic mechanisms exist to physically swap out the tool. If you're the only one using the machine then it's not so horrible, but what you're doing certainly strikes me as non-standard and could cause a safety issue if someone isn't expecting it to come down on the touch plate. I'd suggest using a different M-code for your custom functionality.

The following user(s) said Thank You: cahlfors

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

28 Jun 2018 19:43 #113014

by andypugh

Replied by andypugh on topic Automatic touchoff of face mill

If you program in the tool diameter in the tool table then you can make your probe routine offset by one tool radius. This is probably also appropriate for smaller cutters, so doesn't need special handling.

G53 G0 X[100 - #5410] Y100

You could, alternatively, turn on cutter diameter compensation before the move to the probing station.

linuxcnc.org/docs/2.7/html/gcode/overview.html#gcode:parameters

G53 G0 X[100 - #5410] Y100

You could, alternatively, turn on cutter diameter compensation before the move to the probing station.

linuxcnc.org/docs/2.7/html/gcode/overview.html#gcode:parameters

The following user(s) said Thank You: cahlfors

Please Log in or Create an account to join the conversation.

- cahlfors

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 3

29 Jun 2018 08:59 #113068

by cahlfors

Replied by cahlfors on topic Automatic touchoff of face mill

Thank you both for valuable input!

Andy's suggestions are exactly what I was looking for and I will go for that for now, but perhaps remapping to accomplish automatic tool length measuring is a bad idea? I am the only one using this machine but, since remapping, the "program pointer" no longer points to the correct location in the g-code, which is awkward.

Also, the place where I found the code is gone:

git.linuxcnc.org/gitweb?p=linuxcnc.git;a...ch;hb=refs/heads/2.6

Maintaining will be difficult and I am still on 2.6...

@Sparky, do you have a better suggestion using other M or G codes?

Thanks,

/Chris

Andy's suggestions are exactly what I was looking for and I will go for that for now, but perhaps remapping to accomplish automatic tool length measuring is a bad idea? I am the only one using this machine but, since remapping, the "program pointer" no longer points to the correct location in the g-code, which is awkward.

Also, the place where I found the code is gone:

git.linuxcnc.org/gitweb?p=linuxcnc.git;a...ch;hb=refs/heads/2.6

Maintaining will be difficult and I am still on 2.6...

@Sparky, do you have a better suggestion using other M or G codes?

Thanks,

/Chris

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

29 Jun 2018 09:33 #113070

by andypugh

If your tool-holding arrangement can not load to a consistent tool length then I think that automatic tool length measurement is a good solution. Doing it as a remap is more convenient than doing it by adding a subroutine to the G-code and is more compatible with CAM systems, so I think it is the correct way to go.

The entire LinuxCNC git archive moved, the sample config you used still exists, but has moved to here:

github.com/LinuxCNC/linuxcnc/tree/master...h-tool-length-switch

Replied by andypugh on topic Automatic touchoff of face mill

Andy's suggestions are exactly what I was looking for and I will go for that for now, but perhaps remapping to accomplish automatic tool length measuring is a bad idea? I am the only one using this machine but, since remapping, the "program pointer" no longer points to the correct location in the g-code, which is awkward.

Also, the place where I found the code is gone:

git.linuxcnc.org/gitweb?p=linuxcnc.git;a...ch;hb=refs/heads/2.6

Maintaining will be difficult and I am still on 2.6...

If your tool-holding arrangement can not load to a consistent tool length then I think that automatic tool length measurement is a good solution. Doing it as a remap is more convenient than doing it by adding a subroutine to the G-code and is more compatible with CAM systems, so I think it is the correct way to go.

The entire LinuxCNC git archive moved, the sample config you used still exists, but has moved to here:

github.com/LinuxCNC/linuxcnc/tree/master...h-tool-length-switch

The following user(s) said Thank You: cahlfors

Please Log in or Create an account to join the conversation.

- cahlfors

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 3

29 Jun 2018 16:09 #113100

by cahlfors

Replied by cahlfors on topic Automatic touchoff of face mill

Thanks Andy,

I really appreciate this!

/Chris

I really appreciate this!

/Chris

Please Log in or Create an account to join the conversation.

- cahlfors

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 3

18 Feb 2019 18:50 #126721

by cahlfors

Replied by cahlfors on topic Automatic touchoff of face mill

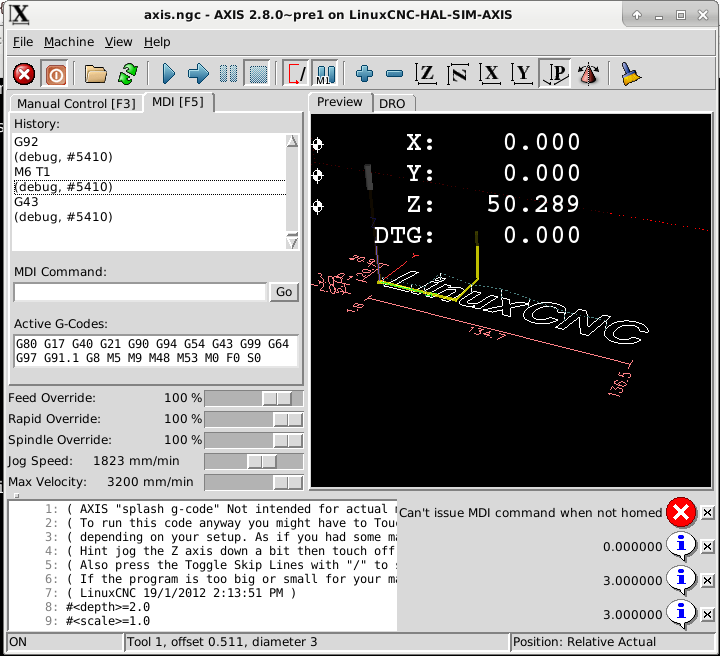

I am having another go with this:

Ideas?

/Chris

It turns out that #5410 is always zero for me. I have added a non-zero diameter in the tool table for a specific tool, reload the tool table and change to that tool. Still zero.G53 G0 X[100 - #5410] Y100

Ideas?

/Chris

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

26 Feb 2019 20:55 #127187

by andypugh

Replied by andypugh on topic Automatic touchoff of face mill

Please Log in or Create an account to join the conversation.

- cahlfors

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 3

12 May 2019 14:25 #133557

by cahlfors

Replied by cahlfors on topic Automatic touchoff of face mill

Had some more time to tinker with this. It turns out that #5410 et al contain information about the *current* tool, not the one we are changing *to* and so cannot be used in the remap code. I suppose that enabling cutter compensation would suffer from the same problem. Is there a way to find out the tool diameter in the remap code?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

18 May 2019 11:45 #134174

by andypugh

G43 takes an optional H parameter, so you can issue a G43 to load the offsets for the next tool and read out the diameter from #5410 without physically changing tool.

You probably then want to zero-out the offsets (G49) before probing and finally load the new offsets at the same time as issuing the M6.

Replied by andypugh on topic Automatic touchoff of face mill

Had some more time to tinker with this. It turns out that #5410 et al contain information about the *current* tool, not the one we are changing *to* and so cannot be used in the remap code.

G43 takes an optional H parameter, so you can issue a G43 to load the offsets for the next tool and read out the diameter from #5410 without physically changing tool.

You probably then want to zero-out the offsets (G49) before probing and finally load the new offsets at the same time as issuing the M6.

Please Log in or Create an account to join the conversation.

Time to create page: 0.114 seconds