- Configuring LinuxCNC

- Advanced Configuration

- Question on Mesa board best suited for what i need to do.

Question on Mesa board best suited for what i need to do.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 May 2020 14:26 - 29 May 2020 14:27 #169320

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

i think this was the link you were talking about and it was me  but i might be getting off track with the advanced form? Galil had some information about changing the loop for improved response time. maybe that's just with their products and not something that linux cnc can do?

but i might be getting off track with the advanced form? Galil had some information about changing the loop for improved response time. maybe that's just with their products and not something that linux cnc can do?

one other thing was tom made reference to 1 of the 6 encoder inputs being a spindle control on the 7i77 but after looking for that in the manual i did not happen to come across it? i did not see anything about spindle control? i could have missed it? plus i thought you needed the 7i92 to connect to the 7i77? i thought the 7i85 was just an expansion card or more encoders? Mesa stuff is hard to keep track off for me since there are so many combinations of boards to use

granitedevices.com/wiki/Dual-loop_feedback_position_control

one other thing was tom made reference to 1 of the 6 encoder inputs being a spindle control on the 7i77 but after looking for that in the manual i did not happen to come across it? i did not see anything about spindle control? i could have missed it? plus i thought you needed the 7i92 to connect to the 7i77? i thought the 7i85 was just an expansion card or more encoders? Mesa stuff is hard to keep track off for me since there are so many combinations of boards to use

granitedevices.com/wiki/Dual-loop_feedback_position_control

Last edit: 29 May 2020 14:27 by machinedude.

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11705

- Thank you received: 3957

29 May 2020 20:01 #169346

by rodw

Replied by rodw on topic Question on Mesa board best suited for what i need to do.

That was the one!

Between it and PCW's post you have everything you need.

If you were working with an older drive (eg. a retrofit) , you need to use the analog 0-10v input which requires a 7i77

But your drives are smarter and can be used with step and direction (if you have a 7i76e or 7i96)

And the mesa stepgens can be told to work in velocity mode. refer the hostmot2 driver docs under stepgen

linuxcnc.org/docs/html/man/man9/hostmot2.9.html#stepgen

So that sorts out the inner loop that is managed by the DYN4

So just add a 7i85s to close the outer loop. Now I've never played with encoders but I think the encoder output feedback is sent back to the feedback signal in the mesa stepgen.

Or for single loop control you would send the feedback signal from the DYN4 drive there.

hope I got that right cos I bought an encoder the other day with the intention of having a play with a 7i76e and its encoder input.

Between it and PCW's post you have everything you need.

If you were working with an older drive (eg. a retrofit) , you need to use the analog 0-10v input which requires a 7i77

But your drives are smarter and can be used with step and direction (if you have a 7i76e or 7i96)

And the mesa stepgens can be told to work in velocity mode. refer the hostmot2 driver docs under stepgen

linuxcnc.org/docs/html/man/man9/hostmot2.9.html#stepgen

So that sorts out the inner loop that is managed by the DYN4

So just add a 7i85s to close the outer loop. Now I've never played with encoders but I think the encoder output feedback is sent back to the feedback signal in the mesa stepgen.

Or for single loop control you would send the feedback signal from the DYN4 drive there.

hope I got that right cos I bought an encoder the other day with the intention of having a play with a 7i76e and its encoder input.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 May 2020 20:25 - 29 May 2020 20:47 #169350

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

it think they work in all modes but from what i have been reading they work best in speed and torque mode of the drive.and when your in those two modes are are always analog and work of the +/- 10 VDC'

it might have to do with the level of PID control in the drive itself and the dumber the drive is the better it works when controlled by an outside force in a dual loop situation. i think it might be something like in the different modes you have different levels of control from the drive. everything i have been coming across seem to imply having you PID LOOP in one place works better because you don't have them conflicting with each other.

on a positive note those scales showed up on my porch today so that was a surprise

it might have to do with the level of PID control in the drive itself and the dumber the drive is the better it works when controlled by an outside force in a dual loop situation. i think it might be something like in the different modes you have different levels of control from the drive. everything i have been coming across seem to imply having you PID LOOP in one place works better because you don't have them conflicting with each other.

on a positive note those scales showed up on my porch today so that was a surprise

Last edit: 29 May 2020 20:47 by machinedude.

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11705

- Thank you received: 3957

29 May 2020 20:41 - 29 May 2020 20:43 #169352

by rodw

Does this matter on a modern drive? There is so much wrong and dated info on the web so choose what you read carefully.

Replied by rodw on topic Question on Mesa board best suited for what i need to do.

it think they work in all modes but from what i have been reading they work best in speed and torque mode of the drive.and when you in those two modes are are always analog and work of the +/- 10 VDC'

Does this matter on a modern drive? There is so much wrong and dated info on the web so choose what you read carefully.

Last edit: 29 May 2020 20:43 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11705

- Thank you received: 3957

29 May 2020 20:41 - 29 May 2020 20:42 #169353

by rodw

Replied by rodw on topic Question on Mesa board best suited for what i need to do.

deleted duplicate

Last edit: 29 May 2020 20:42 by rodw.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 May 2020 20:56 #169355

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

that's the hard part when your trying to lean something you know very little about to begin with.

the whole reason for the encoders is to improve response time for smoother tool paths. i'm not really in a rush here but would like to get to the bottom of it in a reasonable amount of time too. so i dig and take it all in with a grain of salt as i go. i don't touch things and start guessing when it comes to the electronics side of things. i know it's not my area of expertise so i take my time. in the last 15 to 20 year of playing around with this stuff i have never fried my electronics so slow and steady as i go

so slow and steady as i go

the whole reason for the encoders is to improve response time for smoother tool paths. i'm not really in a rush here but would like to get to the bottom of it in a reasonable amount of time too. so i dig and take it all in with a grain of salt as i go. i don't touch things and start guessing when it comes to the electronics side of things. i know it's not my area of expertise so i take my time. in the last 15 to 20 year of playing around with this stuff i have never fried my electronics

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 May 2020 21:29 #169358

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

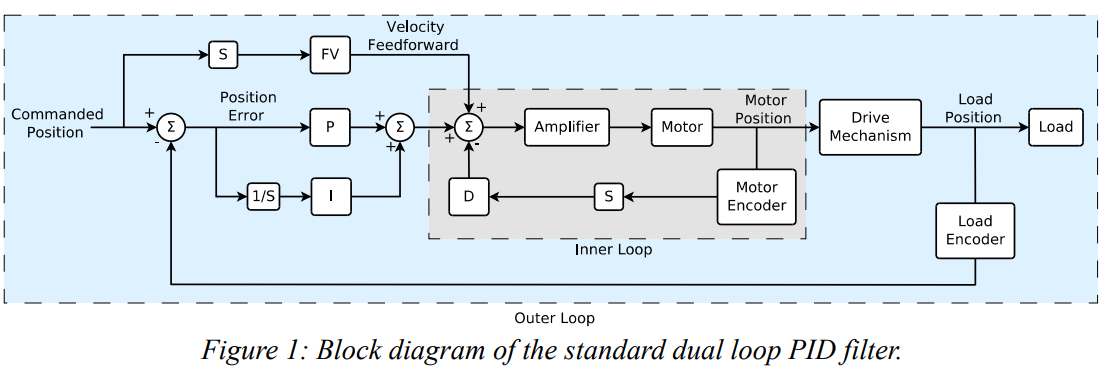

here is some more Galil information in block diagrams for a standard dual loop and an advanced dual loop set up. i'm not sure if linux cnc can do this or not? this could very well be things that only pertain to their motion control products? they have some terms that i have only seen with their stuff. so i will dig into it more and see what i can figure out.

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11705

- Thank you received: 3957

30 May 2020 00:22 #169369

by rodw

Replied by rodw on topic Question on Mesa board best suited for what i need to do.

I don't think that is really any different to the other diagram. Its just drawn with a bit more detail

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

02 Jun 2020 09:44 #169786

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

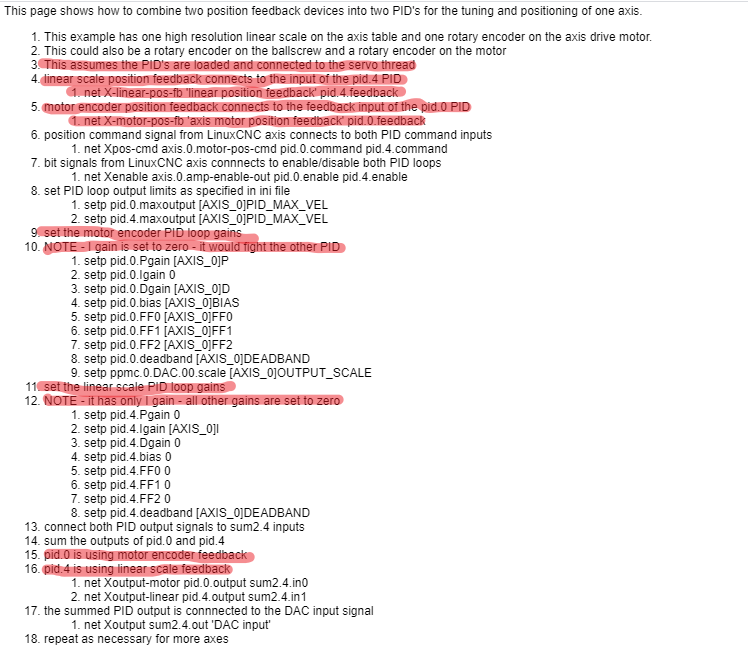

OK i think i figured some stuff out that had me confused. i found something useful on here that filled in a lot of missing details. I also spent a lot of time gaining some understanding to how things tie together between the physical wiring and the software in the big PDF book on Linux cnc. i see how all the HAL files have to be assigned locations to everything on the Physical side of things. so having a better understanding of that lets me see how things fit together. the Servo thread is where the PID Loops fit into this and by only using the P & D gains on the servo motor encoder and leaving the I gain set to 0 and this will handle the inner loop and when you attach the outer loop to that servo thread you only use the I gain and leave the P & D gains set at 0. this explains how you keep things from fighting with each other. and this has to be done for each axis. knowing how to isolate the two good to know. so with out a doubt analog in speed or torque is the way to go since that would give you a stable inner loop the easiest way. so in order to do this on all 3 axis's you would need 6 interfaces for encoders so now i see why tom said you need the extra expansion. so the next question would be how to fit spindle control in this for the use of a 4th servo for that. i did look at the Mesa manuals but nothing stuck out as an obvious solution. but since things are flexible i was thinking this might be something that has to be configured on the card itself?

one other thing was if a sinking or sourcing version of board would be better for my situation. the linear encoders are push or pull so they could go either way. i still need to dig through the DMM manual and see what the encoders are on that side. simpler stuff can be wired to suit either or. spent some time understanding the difference on that topic as well

i am pretty sure i looked at LInux cnc when it was EMC a long time ago and was like holy sh!t that's complicated and ended up on the Mach 2 before it was Mach 3 band wagon as a result now that i am a lot old i see now why Mach 3 sucks

now that i am a lot old i see now why Mach 3 sucks  if you want something close to industrial grade for controls.

if you want something close to industrial grade for controls.

i think i will need the 7i92 ,7i77 and 1 7i85 or 7i85s i just need to sort out the versions based on my needs first. if i am not mistaken the 7i92 is the part of the hardware that takes a lot of the load away from the computer?

here is the info that filled in a lot of the question for me.

one other thing was if a sinking or sourcing version of board would be better for my situation. the linear encoders are push or pull so they could go either way. i still need to dig through the DMM manual and see what the encoders are on that side. simpler stuff can be wired to suit either or. spent some time understanding the difference on that topic as well

i am pretty sure i looked at LInux cnc when it was EMC a long time ago and was like holy sh!t that's complicated and ended up on the Mach 2 before it was Mach 3 band wagon as a result

i think i will need the 7i92 ,7i77 and 1 7i85 or 7i85s i just need to sort out the versions based on my needs first. if i am not mistaken the 7i92 is the part of the hardware that takes a lot of the load away from the computer?

here is the info that filled in a lot of the question for me.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11705

- Thank you received: 3957

02 Jun 2020 10:33 - 02 Jun 2020 11:10 #169793

by rodw

Replied by rodw on topic Question on Mesa board best suited for what i need to do.

Here's something I wrote the other day, it might help:

Its taken me a long time to understand all this but essentially Mesa got going when they came up with a PC expansion card that plugs into the PCI (5i25) or PCIe bus (6i25).

These boards include 2 x DB25 connectors that are pin compatible with parallel ports so ordinary parallel port breakout boards plug straight into them.

Then they designed three FGPA daughter boards that can be used on these ports:

7i76 5 axis step and direction board

7i77 6 axis analog servo interface (0-10 volt) with 6 encoder inputs

7i85 4 x encoder inputs which might be handy if using the 7i76 with a step/dir servo if the feedback loop is not closed on the servo drive.

The next step in their evolution was to release the 7i92 which is an ethernet version of the 6i25/5i25 interfaces. That allowed you to run an ethernet cable from the PC to the Mesa environment.

Then they released the 7i76e which rolled the 7i76 and the 7i92 into one board

More recently they released the 7i97 which is an ethernet version of the 7i77 (eg. 7i92+7i77)

Once installed, there is no functional difference between the PCI/PCIe or ethernet connection when it comes to configuring in linuxcnc, just the pin names may change.

In addition, these boards have a RS422 interface on them and Mesa released a range of smart serial cards that use it.

Aside from the 7i73, the other smart serial board of interest to us is the 7i84 which allows expansion of the available I/O ad infinitum.

Its taken me a long time to understand all this but essentially Mesa got going when they came up with a PC expansion card that plugs into the PCI (5i25) or PCIe bus (6i25).

These boards include 2 x DB25 connectors that are pin compatible with parallel ports so ordinary parallel port breakout boards plug straight into them.

Then they designed three FGPA daughter boards that can be used on these ports:

7i76 5 axis step and direction board

7i77 6 axis analog servo interface (0-10 volt) with 6 encoder inputs

7i85 4 x encoder inputs which might be handy if using the 7i76 with a step/dir servo if the feedback loop is not closed on the servo drive.

The next step in their evolution was to release the 7i92 which is an ethernet version of the 6i25/5i25 interfaces. That allowed you to run an ethernet cable from the PC to the Mesa environment.

Then they released the 7i76e which rolled the 7i76 and the 7i92 into one board

More recently they released the 7i97 which is an ethernet version of the 7i77 (eg. 7i92+7i77)

Once installed, there is no functional difference between the PCI/PCIe or ethernet connection when it comes to configuring in linuxcnc, just the pin names may change.

In addition, these boards have a RS422 interface on them and Mesa released a range of smart serial cards that use it.

Aside from the 7i73, the other smart serial board of interest to us is the 7i84 which allows expansion of the available I/O ad infinitum.

Last edit: 02 Jun 2020 11:10 by rodw.

The following user(s) said Thank You: gerritv, machinedude

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Question on Mesa board best suited for what i need to do.

Time to create page: 0.293 seconds