- Configuring LinuxCNC

- Advanced Configuration

- Question on Mesa board best suited for what i need to do.

Question on Mesa board best suited for what i need to do.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Jun 2020 01:07 #171520

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

yeah i think you are right with these drives. i think they work with just the 4 connections for step and direction if you were to use them that way too.

the board does not have a spot for field power like the 7i77 so what is the best way to handle field power?

i'm working on a diagram for the basic wiring of the encoders and analog for the drives now. will post it when i get that far

the board does not have a spot for field power like the 7i77 so what is the best way to handle field power?

i'm working on a diagram for the basic wiring of the encoders and analog for the drives now. will post it when i get that far

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Jun 2020 02:32 #171529

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

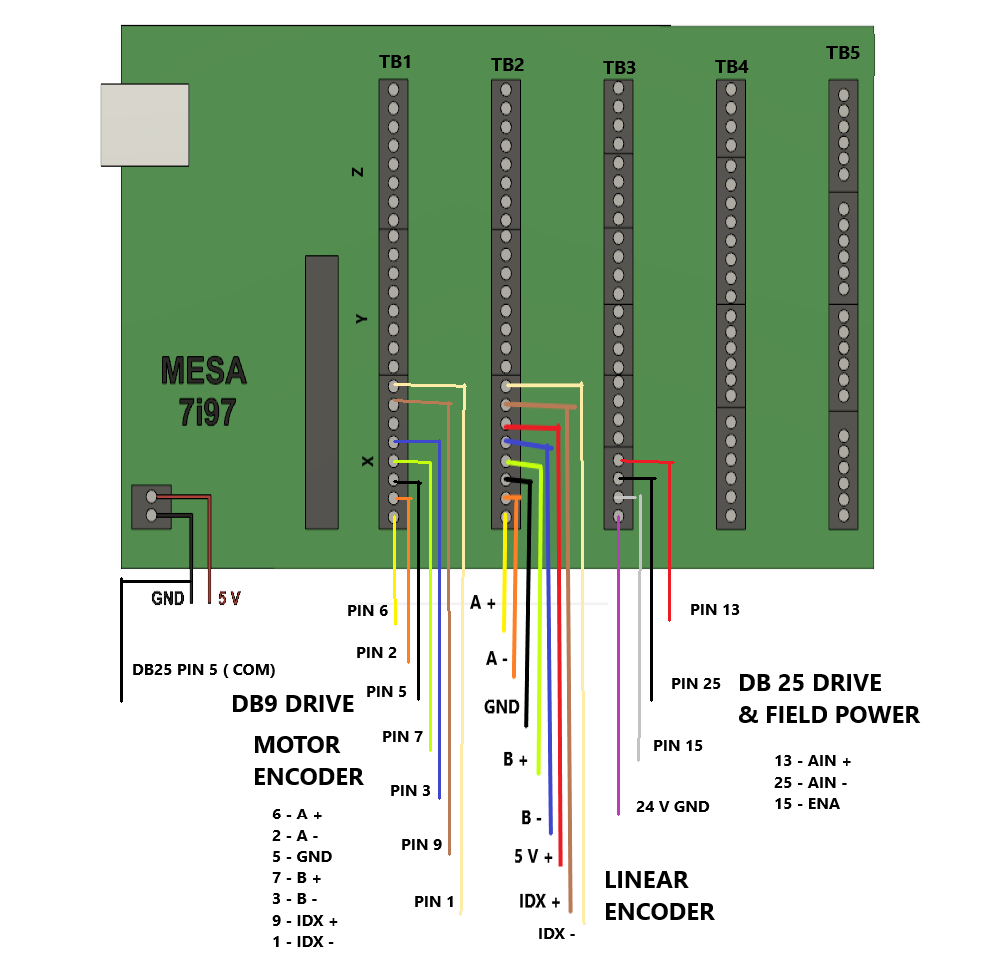

well this is what i think things should look like after reading through everything and making some kind of visual reference. this would be for the DMM drives and a dual loop feedback in velocity mode. as far as i can tell the enable pin is active low in the newer DMM documentation. so that's how i drew it up.

this is just for the encoders and drive for one axis. if it works then just do the same on the other two axis's. the rest is a work in progress i hate this end of the projects just because i feel like a blind rat trying to find a piece of cheese

i hate this end of the projects just because i feel like a blind rat trying to find a piece of cheese  at the very least a e-stop and homing and limit switches are needed so i will just add to my drawing as i go when i figure the rest out.

at the very least a e-stop and homing and limit switches are needed so i will just add to my drawing as i go when i figure the rest out.

if i missed something feel free to to set me straight

this is just for the encoders and drive for one axis. if it works then just do the same on the other two axis's. the rest is a work in progress

if i missed something feel free to to set me straight

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Jun 2020 14:55 #171606

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

i seen in the documentation that that outputs are floating so i'm guessing if those are not used they would need a pull up or pull down resistor to lock the signal to a high or low so nothing is floating? i don't think my control will be very complex beyond the dual loop encoder feedback. i'm thinking i won't be using them for anything right now. the only thing i might use this for would be turning the spindle on and off possibly since it's just wired with a switch at the moment. if i did that then a relay would be needed for that and then i would use something that isolates the board from the spindle motor with the 24 V field power in the logic side. i guess if i wanted to control the mist coolant with a solenoid valve that could be something else to use here?

i have not gotten my self into things this complex in the past so be gentle on me

i have not gotten my self into things this complex in the past so be gentle on me

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

14 Jun 2020 15:12 #171608

by tommylight

Replied by tommylight on topic Question on Mesa board best suited for what i need to do.

Floating outputs do not need pull up or pull down resistors, they can be left floating. Inputs are a different story as any interference may activate them ,hence the need for PU/PD resistors.

7i97 should have a dedicated spindle output, so enable is there, fully isolated, but if you need forward/reverse on the spindle using two relays controlled by 7i97 outputs might be better. You can attach relays directly to 7i97 outputs, granted they do not draw over 30 to 60mA and adding diodes to the coil terminals.

And relays are used for separating high side from low side of things, nothing more required.

7i97 should have a dedicated spindle output, so enable is there, fully isolated, but if you need forward/reverse on the spindle using two relays controlled by 7i97 outputs might be better. You can attach relays directly to 7i97 outputs, granted they do not draw over 30 to 60mA and adding diodes to the coil terminals.

And relays are used for separating high side from low side of things, nothing more required.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Jun 2020 15:48 #171612

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

Ok i remembered reading about floating logic at on point and it must have been for the inputs because what i remembered was what you just explained. i was not sure if it applied to outputs but after thinking about it it seemed like it would not matter if it's not hooked to anything.

i was thinking better relays had the protection against over current so you don't need a fly back diode. it was my understanding that the SSR were Optically coupled circuits? this is just from reading about them so i could have misunderstood something? just about everything that is control related i get from automation direct. since i don't do this often i try to stick to suppliers that have good documentation on products for this sort of thing.

now if it was a cheap mechanical relay then you need the diode in the circuit i can see being needed.

i was thinking better relays had the protection against over current so you don't need a fly back diode. it was my understanding that the SSR were Optically coupled circuits? this is just from reading about them so i could have misunderstood something? just about everything that is control related i get from automation direct. since i don't do this often i try to stick to suppliers that have good documentation on products for this sort of thing.

now if it was a cheap mechanical relay then you need the diode in the circuit i can see being needed.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

14 Jun 2020 15:56 #171613

by tommylight

Replied by tommylight on topic Question on Mesa board best suited for what i need to do.

Yes, SSR are isolated and use a common gnd or +V in case of 7i96 and that is all good in most cases, but there are some spindle controllers that have inputs at 110V, seen that mentioned here several times but do not recall the controller name or type, and that would cause some issues and smoke !

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

14 Jun 2020 16:36 #171620

by machinedude

Replied by machinedude on topic Question on Mesa board best suited for what i need to do.

i think if i want full spindle control and a MPG added later then i need the 7i85 added to the mix this board has the room for the extra analog drive but needs more encoder feedback with how i am doing things. i will have to look into the serial cards too. i seen Mesa has a card for a lot of physical control options i might like to add later. i think that is were the RS-422 header on this board comes into play? and the 7i85 runs off the DB25 connection on the board? i'm still learning how it all fits together in this set up.

to be honest everything i have done up until this point has been through the printer port on the PC with Mach 3 so the whole motion controller is all new to me. i did think a Masso control was more robust and more of what i was looking for but was not impressed with performance of those so here i landed in Linux cnc.

so hopefully this ends up being my go to solution from here on out.

to be honest everything i have done up until this point has been through the printer port on the PC with Mach 3 so the whole motion controller is all new to me. i did think a Masso control was more robust and more of what i was looking for but was not impressed with performance of those so here i landed in Linux cnc.

so hopefully this ends up being my go to solution from here on out.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Question on Mesa board best suited for what i need to do.

Time to create page: 0.185 seconds