How to calculate max velocity Mesa card can handle

- Marcodi

- Offline

- Elite Member

-

- Posts: 198

- Thank you received: 13

My setup

Mesa 6i25 card + 7i85s

1000w servo 5 motors in total on machine

Reducer is 8:1

Steplen is 5000

I know there is a way to calculate max velocity on each motor but I don't know how anymore.

Hope someone remembers the formula

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17605

- Thank you received: 5148

1E9*Lead_Screw_pitch / (reduction*steps_per_turn*(StepLen+Stepspace))

Velocity is distance per second

steplen and stepspace are in nanoseconds

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21183

- Thank you received: 7238

or

1sec / 5 microsec

or

1 sec / 0.005milisec

or

1 sec / 0.000005 sec

=200000

divide that by two as there is usually the same time for the step space, you would get 100000 pulses per second,

Since there is no info on the encoder, can not help any further.

Please Log in or Create an account to join the conversation.

- Marcodi

- Offline

- Elite Member

-

- Posts: 198

- Thank you received: 13

.

My system is rack and pinion only the z axis is lead screw.

Is this total pulses that I need to devide by number of Stepgens or is this capable pulses per stepgen

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17605

- Thank you received: 5148

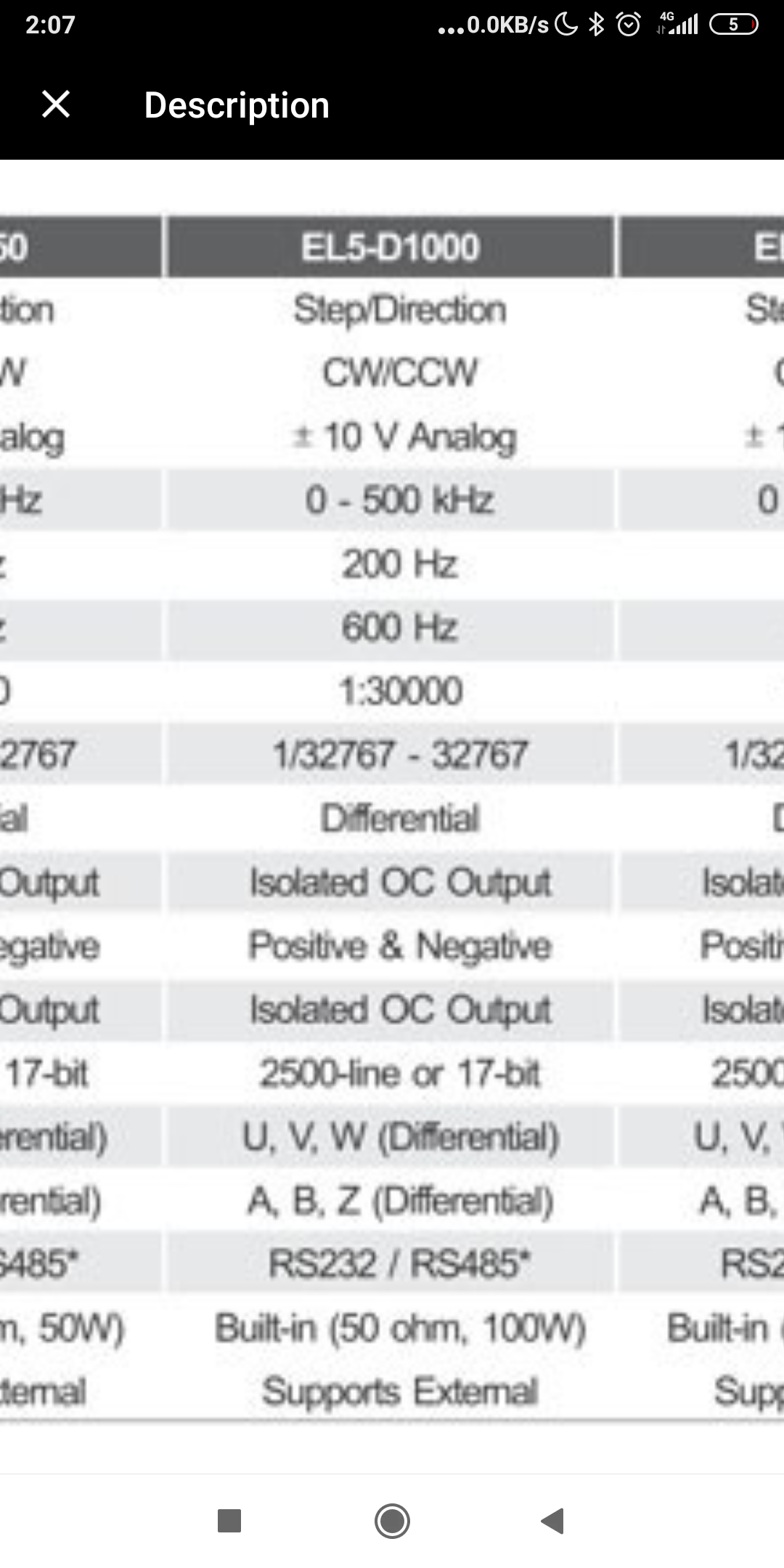

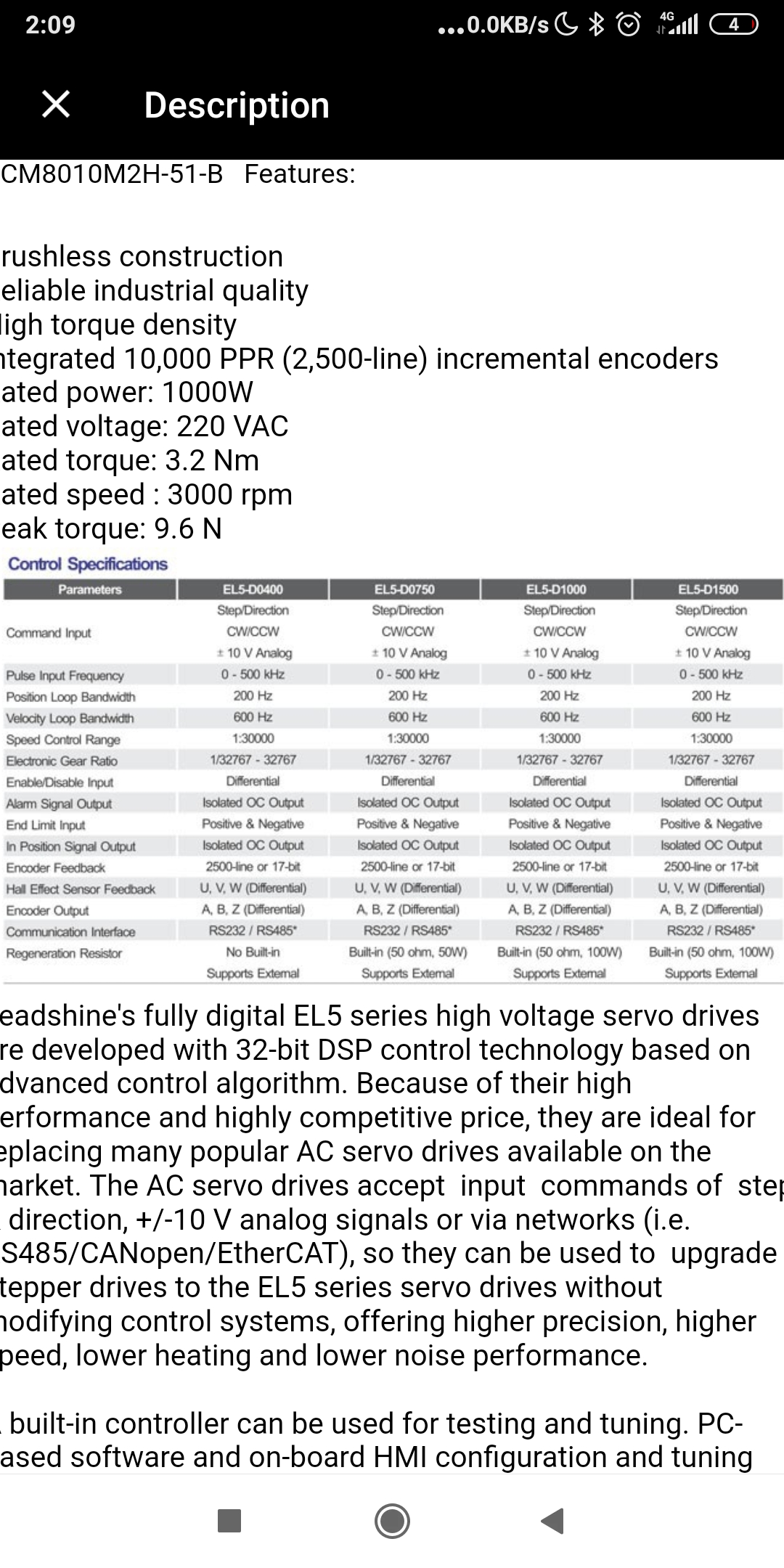

Those drives will take up to 500 KHz pulse rates so you can go much shorter than

5000 ns pulse width

Please Log in or Create an account to join the conversation.

- Marcodi

- Offline

- Elite Member

-

- Posts: 198

- Thank you received: 13

Stepscale means 500 pulses for 1mm of lineair motion correct?

Hope this helps to calculate max velocity and that I understand it again.

Could my steplen be set lower than this?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17605

- Thank you received: 5148

(200 KHz max) the maximum speed would be 400 mm/s (if not limited by maximum motor RPM lead-screw whip or other limits)

Typically you would set the axis limits to a bit less (25% is standard) than the stepgen limits

Please Log in or Create an account to join the conversation.

- Marcodi

- Offline

- Elite Member

-

- Posts: 198

- Thank you received: 13

One more question though based on those specs can the steplen be lowered below 2500.

And how can you see this in the specs what steplen should be?

Regards,

Stephane

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17605

- Thank you received: 5148

should in general not use minimum values but add some margin.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

PCW post=169593 userid=481 The maximum velocity of a step/dir system would be1E9*Lead_Screw_pitch / (reduction*steps_per_turn*(StepLen Stepspace))Velocity is distance per secondsteplen and stepspace are in nanoseconds

Sorry for resurrecting an old thread but: Re the above regarding the steps per turn just for clarification is the steps_per_turn the screw or the motor shaft?

Does this look correct in the attachment.

Please Log in or Create an account to join the conversation.