How Linuxcnc is compensating backlash?

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

14 Oct 2020 04:47 #186063

by scotth

Replied by scotth on topic How Linuxcnc is compensating backlash?

Try to set backlash to "0" and see what it does. Remember you have no lost motion from the moving axis to the scale unless the read head is loose. In the past large analog drive machines would sit and hunt all the time trying to reduce the following error to 0. The race situation of trying to reverse direction with no feedback other than tach will cause an increasing error signal and a race situation. If you can get to it look at the error command in relation to the tach. A encoder on the motor and no scale is much less trouble to control and backlash comp should work better.

I like scales because if aligned right you do not have to do axis comp tables.

I like scales because if aligned right you do not have to do axis comp tables.

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

15 Oct 2020 21:35 #186238

by boksi

Replied by boksi on topic How Linuxcnc is compensating backlash?

Backlash is already set to "0" as glass scale is used in both tests. Yes that is true, there will be no lost motion when scale is used but there will be "lost time" until axis recovers from backlash and catches commanded value. Scale(hh ls-477) is installed correctly according to manufacturers requirements and tolerances so think that there shouldn't be any problems. Yes that is happening also here in dual loop as motor is hunting end position more-less aggressive (depending on the gains) and turning back and forward around backlash value as it holds position between -0.03 mm and +0.03 mm. Currently have only feedback values of speed in both cases from tacho (attached pictures), but soon I will pull out and commanded speed values. This is very good suggestion as I could check if have clean commanded speed signal (this would depend highly on good timing and pulse quality). I am currently evaluating on Mach3 and some usb board but soon will move to Linuxcnc. Your suggestion is true but this could only work if backlash is same along the axis. I didn't do yet measuring it along the axis to know for sure. And one thing which I noticed if go in one direction then stop and again in same direction following error jumps immediately to 0.03 - 0.05mm. Don't know yet for sure why but think it isn't problem weak/strong FFs gains(as tested) then problem is maybe in elasticity of bronze nut which is connected to table and slides along trapezoidal thread.

As I understand axis comp table couldn't compensate temperature influence too?

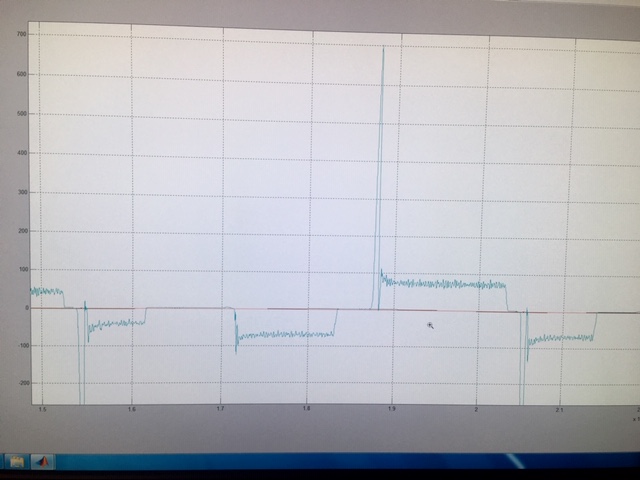

Speed feedback from tacho in closed loop with just glass scale(Y axis in rpm).

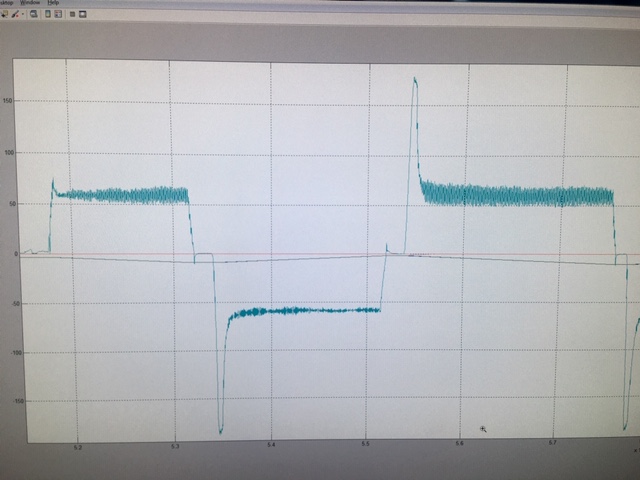

Speed feedback from tacho in dual loop(Y axis in rpm).

As I understand axis comp table couldn't compensate temperature influence too?

Speed feedback from tacho in closed loop with just glass scale(Y axis in rpm).

Speed feedback from tacho in dual loop(Y axis in rpm).

Attachments:

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

16 Oct 2020 05:03 #186246

by scotth

Replied by scotth on topic How Linuxcnc is compensating backlash?

What type slide are we talking about? 170mm travel dose it have gibs or rails?

Loosen the gibs off if you have them and watch your feedback. Lube can also cause problems. Linux or Mach makes little difference in fighting servo loop problems.

Loosen the gibs off if you have them and watch your feedback. Lube can also cause problems. Linux or Mach makes little difference in fighting servo loop problems.

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

16 Oct 2020 06:15 #186252

by boksi

Replied by boksi on topic How Linuxcnc is compensating backlash?

Yes travel path is 170mm. Here is picture of sliding path.

Do I have here just one rail?Motor on picture is for Z axis. I will try this as soon as assemble again axis( currently reworking connection with pulley). Yes there is a metal bar along the axis with screw on top for fine-tuning for axis stiffening. It is already tunned for good results concerning radial backlash seems to much . Also checked with dial indicator when changing direction if axis has some “play”. You are suggesting to tune to find a acceptable balance concerning radial backlash and motor control?

. Also checked with dial indicator when changing direction if axis has some “play”. You are suggesting to tune to find a acceptable balance concerning radial backlash and motor control?

Yes it has lube. You suggest to remove it?

Do I have here just one rail?Motor on picture is for Z axis. I will try this as soon as assemble again axis( currently reworking connection with pulley). Yes there is a metal bar along the axis with screw on top for fine-tuning for axis stiffening. It is already tunned for good results concerning radial backlash seems to much

Yes it has lube. You suggest to remove it?

Attachments:

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

16 Oct 2020 12:57 #186281

by scotth

Replied by scotth on topic How Linuxcnc is compensating backlash?

NO leave the lube you can be fighting a stiction problem.

Wikipedia

"Stiction is the static friction that needs to be overcome to enable relative motion of stationary objects in contact. The term is a portmanteau of the words static and friction, perhaps also influenced by the verb stick.. Any solid objects pressing against each other (but not sliding) will require some threshold of force parallel to the surface of contact in order to overcome static cohesion."

This causes the high following error at the start of the move and or the windup in the screw and motor drive. Anything to reduce the friction will help.

Try an indicator from the front of the knee to the motor base and look for movement.

Or flaking the way surface to reduce contact area and hold oil. Tacky oil can also amplify the problem.

It can also be something easy like slack in a keyway. This is what makes it so much fun or causes you to loose your hair (mine is pretty thin).

Wikipedia

"Stiction is the static friction that needs to be overcome to enable relative motion of stationary objects in contact. The term is a portmanteau of the words static and friction, perhaps also influenced by the verb stick.. Any solid objects pressing against each other (but not sliding) will require some threshold of force parallel to the surface of contact in order to overcome static cohesion."

This causes the high following error at the start of the move and or the windup in the screw and motor drive. Anything to reduce the friction will help.

Try an indicator from the front of the knee to the motor base and look for movement.

Or flaking the way surface to reduce contact area and hold oil. Tacky oil can also amplify the problem.

It can also be something easy like slack in a keyway. This is what makes it so much fun or causes you to loose your hair (mine is pretty thin).

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

16 Oct 2020 13:04 #186283

by scotth

Replied by scotth on topic How Linuxcnc is compensating backlash?

look for the easy stuff first and remove as much lost motion as you can,

The following user(s) said Thank You: boksi

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

18 Oct 2020 22:39 #186526

by boksi

Replied by boksi on topic How Linuxcnc is compensating backlash?

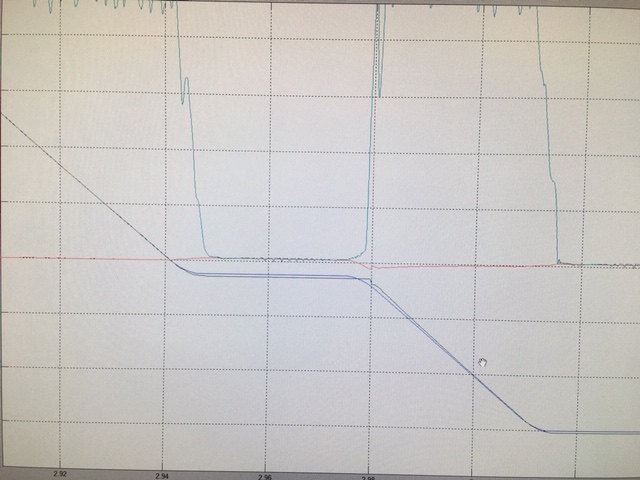

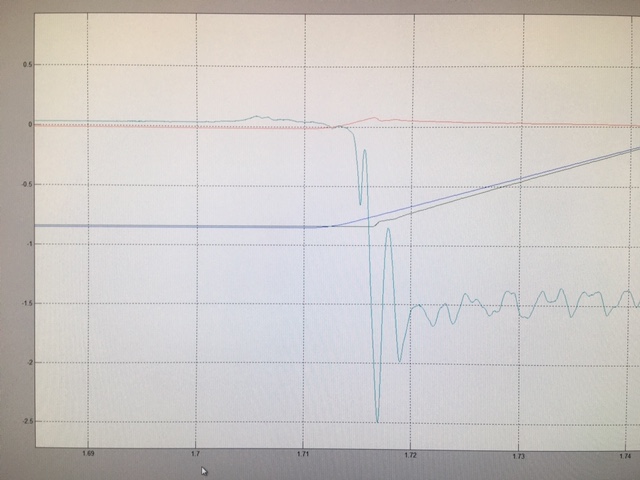

Yes I am aware of this kind of friction but it was strange to me to have such big influence on following error and so high threshold until table starts to move. Concerning other proposals I will check with my father as he is doing mechanical part. Could not measure right now(axis still on service) but I have some earlier graphs showing following error red, commanded value blue, feedback green and tacho speed light blue. Speed is scaled to fit nice to graph. So motor is spinning and following error is rising until some point. Checked connection pulley and motor yes there is some play couple of degrees(i will fix this) but this should not be a problem since motor didn't change direction just made a short break between same direction movements. .

.

I am trying to stay on first optionThis is what makes it so much fun or causes you to loose your hair (mine is pretty thin).

Attachments:

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

21 Oct 2020 16:36 #186819

by scotth

Replied by scotth on topic How Linuxcnc is compensating backlash?

Look at this video.

He has already gone through this. He has the entire series of the conversion to scales.

He has already gone through this. He has the entire series of the conversion to scales.

Please Log in or Create an account to join the conversation.

- boksi

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

26 Oct 2020 18:17 - 26 Oct 2020 18:18 #187329

by boksi

Replied by boksi on topic How Linuxcnc is compensating backlash?

Thanks. Good video I will check the rest.

Last edit: 26 Oct 2020 18:18 by boksi.

Please Log in or Create an account to join the conversation.

Time to create page: 0.391 seconds