- Configuring LinuxCNC

- Advanced Configuration

- Step/Dir servos + Encoders = follow errors... and so much pain.....

Step/Dir servos + Encoders = follow errors... and so much pain.....

- jhandel

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 7

23 Dec 2020 21:07 #193022

by jhandel

Replied by jhandel on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

So if I am understanding you correctly if I get something back on stepgen feedback that is a committment from the MESA card to have sent the pulses to the servo to do that thing..

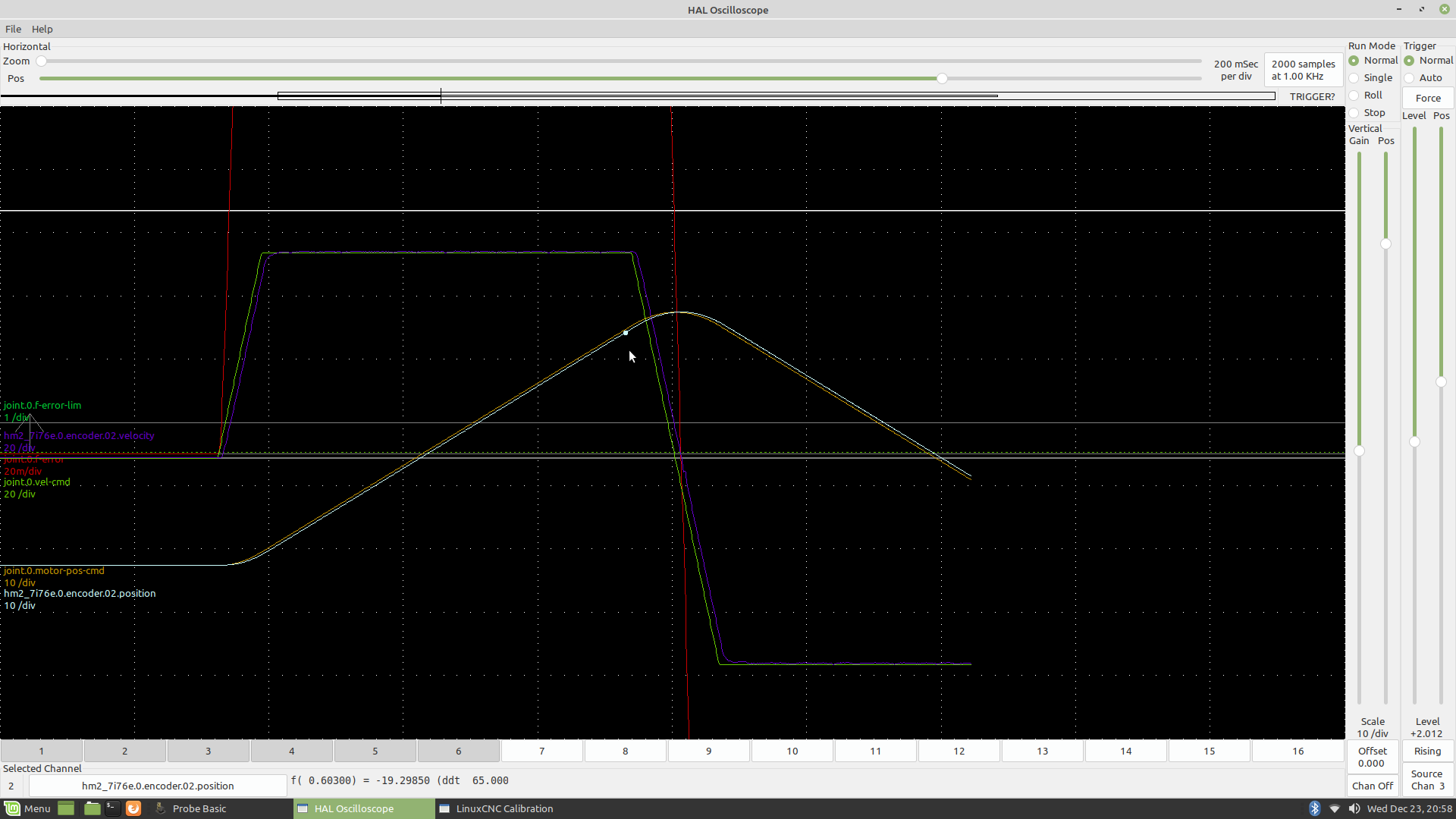

So if we look at the following raw data from the scope of a movement

That its less than 1ms (one sample period) request to MESA card issuing pulses, but that it is an additional 5~6 samples (at 1ms each) for the encoder to respond that it is moving..

So I really are hunting for 4 to 5 ms between the MESA card and the servo... The issue could be in the issuance of the move command to the physical servo, or it could be in the read/process time for the encoder signal.. either way.. there is a lag somewhere in those settings..

So if we look at the following raw data from the scope of a movement

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -56.00000000000000 hm2_7i76e.0.stepgen.00.position-fb -0.00680662536621 <-- No move

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.99995833333332 hm2_7i76e.0.stepgen.00.position-fb -0.00680662536621 <-- Start command move

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.99962499999998 hm2_7i76e.0.stepgen.00.position-fb -0.00677217102051 <-- StepGen has started the move

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.99858333333333 hm2_7i76e.0.stepgen.00.position-fb -0.00648828125000

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.99658333333332 hm2_7i76e.0.stepgen.00.position-fb -0.00556071472168

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.99358333333333 hm2_7i76e.0.stepgen.00.position-fb -0.00367330932617

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.98958333333331 hm2_7i76e.0.stepgen.00.position-fb -0.00051603698730

hm2_7i76e.0.encoder.02.position -56.00000000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.98458333333332 hm2_7i76e.0.stepgen.00.position-fb +0.00387779235840

hm2_7i76e.0.encoder.02.position -55.99950000000000 hm2_7i76e.0.stepgen.00.position-cmd -55.97858333333335 hm2_7i76e.0.stepgen.00.position-fb +0.00952809143066 <-- Encoder has responded with movementThat its less than 1ms (one sample period) request to MESA card issuing pulses, but that it is an additional 5~6 samples (at 1ms each) for the encoder to respond that it is moving..

So I really are hunting for 4 to 5 ms between the MESA card and the servo... The issue could be in the issuance of the move command to the physical servo, or it could be in the read/process time for the encoder signal.. either way.. there is a lag somewhere in those settings..

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

23 Dec 2020 21:10 #193023

by PCW

Replied by PCW on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

Nope, its all in the servo drive/ mechanics

Please Log in or Create an account to join the conversation.

- jhandel

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 7

23 Dec 2020 21:19 #193028

by jhandel

Replied by jhandel on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

The encoder is connected to the servo drive... so it is one black box from pulse in to encoder movement out.. If I had glass scales on here or something that would almost make this easier as, you are right, the delay would be just in the servo.. But because the Servo Driver is handling the encoder too.. I can't say that the lag is on the way to movement, or if the lag is after movement and on the way back to the MESA card.. its just somewhere between the two points..

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

23 Dec 2020 21:35 #193031

by PCW

Replied by PCW on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

I was thinking that you did have linear scales, as most people that

want encoder feedback on step/dir systems use linear scales.

If the encoder signal is from the drive, the drive may delay that also.

Unfortunately 6 (or more) ms of delay will make it almost untuneable

for closed loop operation

It still looks like the drive itself is not very well tuned. This will affect open loop

operation also. The error during accel and decell indicates that the drives

velocity loop has not been tuned to match the inertia of the load very well.

Are you using encoder feedback just for homing to index?

want encoder feedback on step/dir systems use linear scales.

If the encoder signal is from the drive, the drive may delay that also.

Unfortunately 6 (or more) ms of delay will make it almost untuneable

for closed loop operation

It still looks like the drive itself is not very well tuned. This will affect open loop

operation also. The error during accel and decell indicates that the drives

velocity loop has not been tuned to match the inertia of the load very well.

Are you using encoder feedback just for homing to index?

Please Log in or Create an account to join the conversation.

- jhandel

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 7

24 Dec 2020 03:06 #193059

by jhandel

Replied by jhandel on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

actually the servo does follow the intended movement really well when you set P to 0... Its just 6ms behind.. it does everything its asked to... just 6ms behind..

I am tempted to set P to 0 and then set the f-error and fmin-error so high that they will never trip.

the only thing this time delay may slow up is the touch probe and tool touch... but like both of those are 5 to 10ms slower too (even as physical switches) so I am inclined to just do all my actual probing super slow.. (slow enough that 25 or 30ms is less than .01mm) so yah I can work around that..

Still wierd.. I guess my servo driver just takes 6ms to start doing its work and there isn't anything settings wise I can do to shrink that..

And seriously I dug through every possible setting...

I am tempted to set P to 0 and then set the f-error and fmin-error so high that they will never trip.

the only thing this time delay may slow up is the touch probe and tool touch... but like both of those are 5 to 10ms slower too (even as physical switches) so I am inclined to just do all my actual probing super slow.. (slow enough that 25 or 30ms is less than .01mm) so yah I can work around that..

Still wierd.. I guess my servo driver just takes 6ms to start doing its work and there isn't anything settings wise I can do to shrink that..

And seriously I dug through every possible setting...

Attachments:

Please Log in or Create an account to join the conversation.

- dm17ry

-

- Offline

- Elite Member

-

Less

More

- Posts: 194

- Thank you received: 82

24 Dec 2020 06:59 #193073

by dm17ry

Replied by dm17ry on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

i've been playing with several generations of mitsubishi/yaskawa position controlled servos. not actually a pulse train though, but sscnet/mechatrolink - but that shouldn't matter.

so, they all exhibit similar behavior. there's no way to eliminate this time lag completely with tuning without introducing serious overshoots. but to counteract it, those protocols have a provision to latch the motor encoder counter at encoder z-index or some external signal wired directly to the drive. when that happens the drive raises a flag and controller can read back the latched position. kinda like linuxcnc's index-request...

so, they all exhibit similar behavior. there's no way to eliminate this time lag completely with tuning without introducing serious overshoots. but to counteract it, those protocols have a provision to latch the motor encoder counter at encoder z-index or some external signal wired directly to the drive. when that happens the drive raises a flag and controller can read back the latched position. kinda like linuxcnc's index-request...

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

24 Dec 2020 14:26 #193113

by PCW

Replied by PCW on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

Note that you cannot use a P of exactly 0 since you will have long term

position drift due to time base differences between LinuxCNC and the

hardware, jitter in position read and velocity write times, and quantization

of velocity setting.

It honestly looks like the drives should be run in open loop mode.

position drift due to time base differences between LinuxCNC and the

hardware, jitter in position read and velocity write times, and quantization

of velocity setting.

It honestly looks like the drives should be run in open loop mode.

Please Log in or Create an account to join the conversation.

- jhandel

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 7

24 Dec 2020 15:04 #193118

by jhandel

Replied by jhandel on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

If closed loop means its pulling position from the encoder count, why would it drift over time, wouldn't it just take what ever the encoder has as the "gospal"? (not saying it wouldn't, just not following the logic exactly..

Either which way if I go open loop I'll need to see if I can reset the stepgen counters on encoder index either through basic HAL logic, Classic Ladder or as a raw C HAL component.. so I got some fiddling to do to figure that out..

Either which way if I go open loop I'll need to see if I can reset the stepgen counters on encoder index either through basic HAL logic, Classic Ladder or as a raw C HAL component.. so I got some fiddling to do to figure that out..

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

24 Dec 2020 15:14 - 24 Dec 2020 15:17 #193122

by PCW

Replied by PCW on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

If you have P=0 (and I,D =0) the encoders are ignored

FF1 = 1.0 just sets the stepgen velocity to LinuxCNCs

commanded velocity every servo thread.

Sort of like telling someone how to drive to a destination

by just telling him how fast and what direction to drive

every second. Without position feedback there will be

accumulated position error. This is basically "dead reckoning"

I will take a look at index handling for the stepgen

this has been in the firmware for years but there is no

current driver support.

FF1 = 1.0 just sets the stepgen velocity to LinuxCNCs

commanded velocity every servo thread.

Sort of like telling someone how to drive to a destination

by just telling him how fast and what direction to drive

every second. Without position feedback there will be

accumulated position error. This is basically "dead reckoning"

I will take a look at index handling for the stepgen

this has been in the firmware for years but there is no

current driver support.

Last edit: 24 Dec 2020 15:17 by PCW.

Please Log in or Create an account to join the conversation.

- jhandel

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 7

24 Dec 2020 15:26 #193124

by jhandel

Replied by jhandel on topic Step/Dir servos + Encoders = follow errors... and so much pain.....

would a P of virtually zero have the same effect? like P 1 or .01? just enough to have it be part of the equation..

"I will take a look at index handling for the stepgen

this has been in the firmware for years but there is no

current driver support." <-- are you saying the stepgen count and indexing processes are handled by the MESA card itself and not by Linuxcnc? or is firmware short hand for somewhere in the source of Linuxcnc that I should consider poking with a stick? (though I could also poke the MESA firmware with a stick too, mine is already customized)

(Thanks for all the help by the way.. and Happy Holidays/Merry Christmas!)

"I will take a look at index handling for the stepgen

this has been in the firmware for years but there is no

current driver support." <-- are you saying the stepgen count and indexing processes are handled by the MESA card itself and not by Linuxcnc? or is firmware short hand for somewhere in the source of Linuxcnc that I should consider poking with a stick? (though I could also poke the MESA firmware with a stick too, mine is already customized)

(Thanks for all the help by the way.. and Happy Holidays/Merry Christmas!)

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Step/Dir servos + Encoders = follow errors... and so much pain.....

Time to create page: 0.118 seconds