Mesa 7i76e + 7i85S encoder feedback problem

- fenolski

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

26 Jan 2021 19:02 - 26 Jan 2021 19:08 #196645

by fenolski

Replied by fenolski on topic Mesa 7i76e + 7i85S encoder feedback problem

I did today some tests. I found that MAXVELOCITY parameter has crucial influcence on Joint 0 Following error. Then I hange in .ini file this parameter to 8 (mm/s) system starts to work much better but slowly. When I did tests in pncconf I got 25 mm/s (1500mm/min) so I have no idea why I need to slow the speed to 8mm/s.

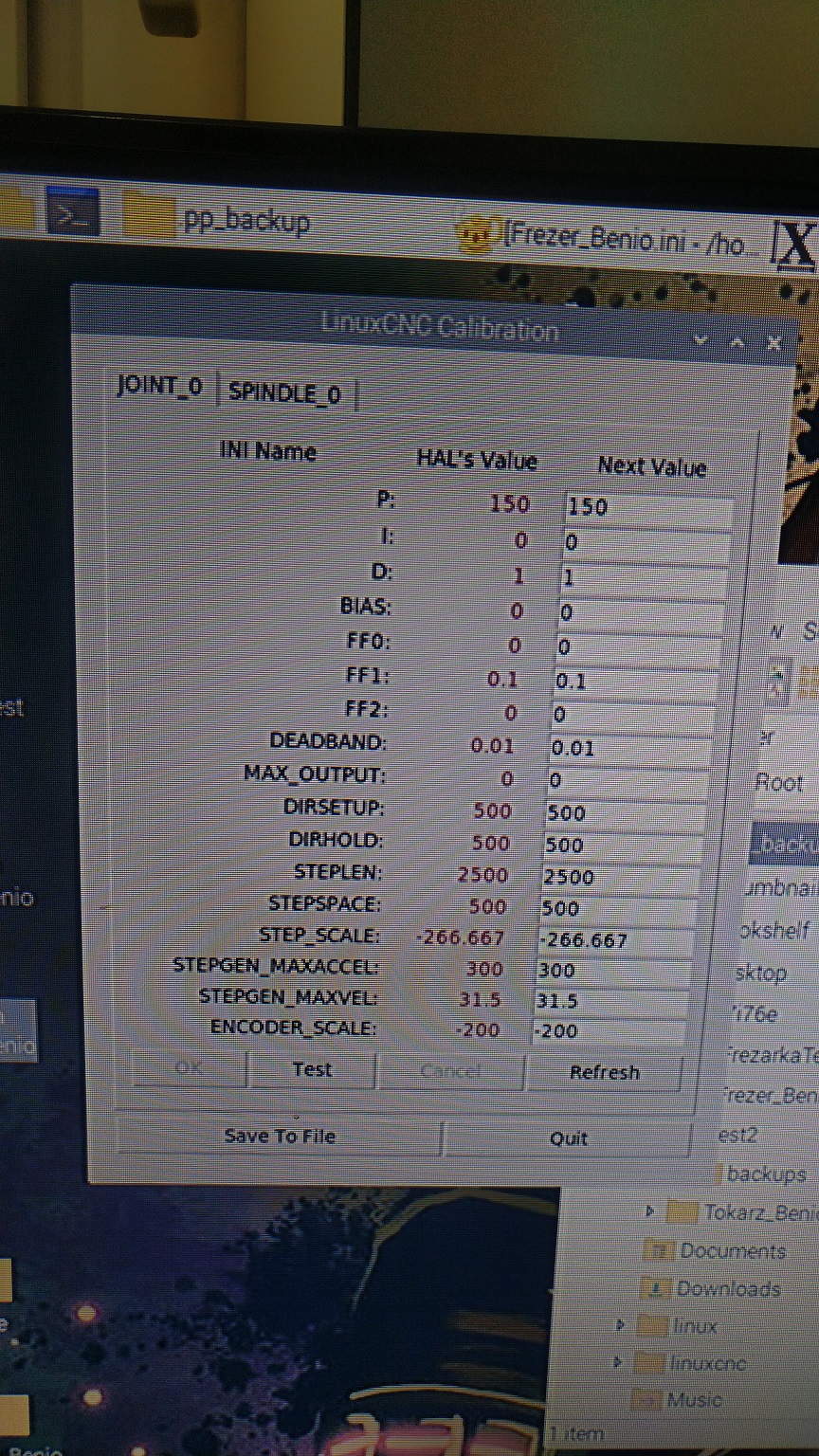

I have used calibration tool. STEPGEN_MAXVELOCITY has no influence on speed. PID parameters only matters when I set MAXVELOCITY to 8mm/s. How do you think where is the reason that I need to set speed so low?

Here is my Configuration tool screenshot:

I have used calibration tool. STEPGEN_MAXVELOCITY has no influence on speed. PID parameters only matters when I set MAXVELOCITY to 8mm/s. How do you think where is the reason that I need to set speed so low?

Here is my Configuration tool screenshot:

Attachments:

Last edit: 26 Jan 2021 19:08 by fenolski.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1129

- Thank you received: 398

26 Jan 2021 19:21 - 26 Jan 2021 19:30 #196648

by Hakan

Replied by Hakan on topic Mesa 7i76e + 7i85S encoder feedback problem

Hi, I have linear encoders on my stepper motor milling machine.

I see some things in the PID screen.

FF1 should be 1. When you set this to 1 and P I D to 0 0 0 you basically have a stepper motor system without feedback. It should work fine with only FF1=1. Use velocity mode. FF1 should always be 1, don't ever change it.

Then to gradually start reducing the following error, start with P=10 or maybe even P=1 and gradually increase P until ferror overshoot and there is vibration in the following error. Use halscope as you have done. Let I and D be 0 until you have P dialled in. D can get a value of you like, but if you set I there will be a constant search back and forth around the zero position that never stops. So let I=0.

I have P=40 and D=0.025

You can increase STEPGEN_MAXACCEL and STEPGEN_MAXVEL to ridiculously high numbers, I have 2000000 and 800 respectively. It allows stepgen (I think) to react as fast as possible to output extra steps needed to compensate for error. MAX_VELOCITY and MAX_ACCELERATION are 70 and 250 thats what my machine likes.

I see some things in the PID screen.

FF1 should be 1. When you set this to 1 and P I D to 0 0 0 you basically have a stepper motor system without feedback. It should work fine with only FF1=1. Use velocity mode. FF1 should always be 1, don't ever change it.

Then to gradually start reducing the following error, start with P=10 or maybe even P=1 and gradually increase P until ferror overshoot and there is vibration in the following error. Use halscope as you have done. Let I and D be 0 until you have P dialled in. D can get a value of you like, but if you set I there will be a constant search back and forth around the zero position that never stops. So let I=0.

I have P=40 and D=0.025

You can increase STEPGEN_MAXACCEL and STEPGEN_MAXVEL to ridiculously high numbers, I have 2000000 and 800 respectively. It allows stepgen (I think) to react as fast as possible to output extra steps needed to compensate for error. MAX_VELOCITY and MAX_ACCELERATION are 70 and 250 thats what my machine likes.

Last edit: 26 Jan 2021 19:30 by Hakan. Reason: i wish i could write

Please Log in or Create an account to join the conversation.

- fenolski

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

27 Jan 2021 20:09 #196804

by fenolski

Replied by fenolski on topic Mesa 7i76e + 7i85S encoder feedback problem

Hello again!

I did some mods in PID controler and finally it works much better. Unfortunately follow error shows from time to time. I realized that backlash of my Chinese mill is huge - 0.4mm! I think this could be additional reason that follow error appears. I will do next tests after making new drive nut on lathe.

My question now is about Stepgen_maxvel and Stepgen_maxaccel. Whtat is correlation between them and maxvel and maxaccel parameters? What these parameters change in PID?

Thank you for your support!

I did some mods in PID controler and finally it works much better. Unfortunately follow error shows from time to time. I realized that backlash of my Chinese mill is huge - 0.4mm! I think this could be additional reason that follow error appears. I will do next tests after making new drive nut on lathe.

My question now is about Stepgen_maxvel and Stepgen_maxaccel. Whtat is correlation between them and maxvel and maxaccel parameters? What these parameters change in PID?

Thank you for your support!

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17525

- Thank you received: 5123

27 Jan 2021 20:55 #196810

by PCW

Replied by PCW on topic Mesa 7i76e + 7i85S encoder feedback problem

The stepgen maxvel and maxaccel number should be about 25% greater

than the joint values (to allow some headroom for the PID to operate when at

max joint velocity and acceleration)

than the joint values (to allow some headroom for the PID to operate when at

max joint velocity and acceleration)

Please Log in or Create an account to join the conversation.

Time to create page: 0.511 seconds