- Configuring LinuxCNC

- Advanced Configuration

- Need help with the orient component for spindle activation (M19)

Need help with the orient component for spindle activation (M19)

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

08 Feb 2022 12:35 - 08 Feb 2022 12:37 #234338

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

Hello ,I modified spindle hal and ini ( I had forgotten DEADBAND & MAX_OUTPUT ) but no change in orient mode (the relay triggers, but no rotation for the engine )

Last edit: 08 Feb 2022 12:37 by jpg.

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

11 Feb 2022 12:08 - 12 Feb 2022 15:17 #234564

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

Hello, after several inconclusive attempts for a week (no spindle rotation in M19 RXX; I think that there is not much missing to get there..), I would like to ask you for help on this port configuration // because I want to make the whole thing work before switching to a MESA card; thank you for your patience.

I found this (that's Andy who developed it).

www.forum.linuxcnc.org/24-hal-components...l-questions?start=90

I attach an extract of the modified HAL, I wonder how to hang up my spindle entries:

net spindle-fwd abs.0.is-positive parport.0.pin-14-out

net spindle-rev abs.0.is-negative parport.0.pin-16-out

addf pid.0.do-pid-calcs servo-thread #Velocity

addf pid.1.do-pid-calcs servo-thread #Position

loadrt orient

addf orient.0 servo-thread

loadrt mux2 count=1 #This has already been loaded in the sim_vmc.hal

addf mux2.0 servo-thread #chooses which pid output goes to the spindle speed control

net spindle-vel pid.0.feedback

net spindle-vel-cmd-rps motion.spindle-speed-out-rps pid.0.command

net spindle-vel-pid pid.0.output mux2.0.in0

net spindle-pos pid.1.feedback orient.0.position

net spindle-pos-cmd orient.0.command pid.1.command

net spindle-angle motion.spindle-orient-angle orient.0.angle

net spindle-pos-pid pid.1.output mux2.0.in1

net spindle-in-pos orient.0.is-oriented => motion.spindle-is-oriented

setp orient.0.tolerance 1

# this switches modes

net orient-mode motion.spindle-orient orient.0.enable pid.1.enable mux2.0.sel

net velocity-mode motion.spindle-on pid.0.enable

#for a real spindle run by a VFD

loadrt or2 count=1 #turn on spindle in both orient & velocity mode

addf or2.0 servo-thread

net orient-mode or2.0.in0

net velocity-mode or2.0.in1

net spindle-either-cmd or2.0.out hm2_5i25.0.7i77.0.1.spinena

net spindle-cmd mux2.0.out hm2_5i25.0.7i77.0.1.analogout5

# Tune the PID from the INI values

setp pid.0.Pgain [SPINDLE]PGAIN_V

setp pid.0.Igain [SPINDLE]IGAIN_V

setp pid.0.Dgain [SPINDLE]DGAIN_V

setp pid.0.FF0 [SPINDLE]FF0_V

setp pid.0.FF1 [SPINDLE]FF1_V

setp pid.1.Pgain [SPINDLE]PGAIN_P

setp pid.1.Igain [SPINDLE]IGAIN_P

setp pid.1.Dgain [SPINDLE]DGAIN_P

setp pid.1.FF0 [SPINDLE]FF0_P

setp pid.1.FF1 [SPINDLE]FF1_P

#Original spindle conf made by Pncconf

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE]OUTPUT_MAX_LIMIT

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 0

setp hm2_5i25.0.encoder.03.scale [SPINDLE]ENCODER_SCALE

net spindle-pos <= hm2_5i25.0.encoder.03.position

net spindle-vel <= hm2_5i25.0.encoder.03.velocity

net spindle-index-enable <=> hm2_5i25.0.encoder.03.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-pos => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

sets spindle-at-speed true

I found this (that's Andy who developed it).

www.forum.linuxcnc.org/24-hal-components...l-questions?start=90

I attach an extract of the modified HAL, I wonder how to hang up my spindle entries:

net spindle-fwd abs.0.is-positive parport.0.pin-14-out

net spindle-rev abs.0.is-negative parport.0.pin-16-out

addf pid.0.do-pid-calcs servo-thread #Velocity

addf pid.1.do-pid-calcs servo-thread #Position

loadrt orient

addf orient.0 servo-thread

loadrt mux2 count=1 #This has already been loaded in the sim_vmc.hal

addf mux2.0 servo-thread #chooses which pid output goes to the spindle speed control

net spindle-vel pid.0.feedback

net spindle-vel-cmd-rps motion.spindle-speed-out-rps pid.0.command

net spindle-vel-pid pid.0.output mux2.0.in0

net spindle-pos pid.1.feedback orient.0.position

net spindle-pos-cmd orient.0.command pid.1.command

net spindle-angle motion.spindle-orient-angle orient.0.angle

net spindle-pos-pid pid.1.output mux2.0.in1

net spindle-in-pos orient.0.is-oriented => motion.spindle-is-oriented

setp orient.0.tolerance 1

# this switches modes

net orient-mode motion.spindle-orient orient.0.enable pid.1.enable mux2.0.sel

net velocity-mode motion.spindle-on pid.0.enable

#for a real spindle run by a VFD

loadrt or2 count=1 #turn on spindle in both orient & velocity mode

addf or2.0 servo-thread

net orient-mode or2.0.in0

net velocity-mode or2.0.in1

net spindle-either-cmd or2.0.out hm2_5i25.0.7i77.0.1.spinena

net spindle-cmd mux2.0.out hm2_5i25.0.7i77.0.1.analogout5

# Tune the PID from the INI values

setp pid.0.Pgain [SPINDLE]PGAIN_V

setp pid.0.Igain [SPINDLE]IGAIN_V

setp pid.0.Dgain [SPINDLE]DGAIN_V

setp pid.0.FF0 [SPINDLE]FF0_V

setp pid.0.FF1 [SPINDLE]FF1_V

setp pid.1.Pgain [SPINDLE]PGAIN_P

setp pid.1.Igain [SPINDLE]IGAIN_P

setp pid.1.Dgain [SPINDLE]DGAIN_P

setp pid.1.FF0 [SPINDLE]FF0_P

setp pid.1.FF1 [SPINDLE]FF1_P

#Original spindle conf made by Pncconf

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE]OUTPUT_MAX_LIMIT

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 0

setp hm2_5i25.0.encoder.03.scale [SPINDLE]ENCODER_SCALE

net spindle-pos <= hm2_5i25.0.encoder.03.position

net spindle-vel <= hm2_5i25.0.encoder.03.velocity

net spindle-index-enable <=> hm2_5i25.0.encoder.03.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-pos => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

sets spindle-at-speed true

Last edit: 12 Feb 2022 15:17 by jpg.

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

12 Feb 2022 15:21 #234643

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

08 Mar 2022 20:06 - 08 Mar 2022 20:17 #236706

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

Good evening to all, after some tests, I manage to make orient (I keep the variable speed and the display) with the configuration "gm" (it is functional) on Chinese BOB, but I still can't do the same thing with the configuration "ANDY" this last one seems to me however more evolving because in orient mode, the relay declenches in the 2 directions (CW /CCW) but not the motor (there must not be much missing but there is no example with the parallel port. .), ;-( , I would be really happy if someone can help me

Last edit: 08 Mar 2022 20:17 by jpg.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

09 Mar 2022 23:48 #236794

by andypugh

Replied by andypugh on topic Need help with the orient component for spindle activation (M19)

There is more than one INI in the zip file, which one are you asking about?

How do you drive your spindle motor?

How do you drive your spindle motor?

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

10 Mar 2022 12:33 - 10 Mar 2022 17:05 #236838

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

Hi Andy, I took out the HAL, INI, and SPINDLE files of your vismach version (it's the one I find the most advanced, the splindle turns in both directions in orient mode, like your video) my spindle is in PWM (Altivar 31) and the problem, in this configuration, the relay triggers in both directions, but not the motor (in orient mode)

....

setp parport.0.pin-17-out-invert 1

net spindle-pwm pwmgen.0.pwm parport.0.pin-17-out

net spindle-fwd abs.0.is-positive parport.0.pin-14-out

net spindle-rev abs.0.is-negative parport.0.pin-16-out .... ( I searched in these lines, but nothing concrete )

)

On the "GM" configuration no worries, everything works, but always in only 1 direction (in orient mode, of course)

....

setp parport.0.pin-17-out-invert 1

net spindle-pwm pwmgen.0.pwm parport.0.pin-17-out

net spindle-fwd abs.0.is-positive parport.0.pin-14-out

net spindle-rev abs.0.is-negative parport.0.pin-16-out .... ( I searched in these lines, but nothing concrete

On the "GM" configuration no worries, everything works, but always in only 1 direction (in orient mode, of course)

Last edit: 10 Mar 2022 17:05 by jpg.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

11 Mar 2022 00:13 #236909

by andypugh

Replied by andypugh on topic Need help with the orient component for spindle activation (M19)

I think you need to use halmeter to track the signals through the HAL (which is a little bit complicated)

It might just be that your position PID function needs calibrating. (though it looks plausible)

Does the mux "sel" change in orient mode, for example. Do the two PID components turn on at the right times, with plausible outputs.

Is it just that a "motor on" signal is missing from the config?

It might just be that your position PID function needs calibrating. (though it looks plausible)

Does the mux "sel" change in orient mode, for example. Do the two PID components turn on at the right times, with plausible outputs.

Is it just that a "motor on" signal is missing from the config?

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

11 Mar 2022 05:48 #236918

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

I think your last option is the most plausible, but I don't know how to send this information to linuxcnc

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

11 Mar 2022 09:52 #236925

by andypugh

Replied by andypugh on topic Need help with the orient component for spindle activation (M19)

Does the motor turn under normal conditions?

What are the various parallel port pins connected to?

What are the various parallel port pins connected to?

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

11 Mar 2022 16:46 - 11 Mar 2022 17:23 #236944

by jpg

Replied by jpg on topic Need help with the orient component for spindle activation (M19)

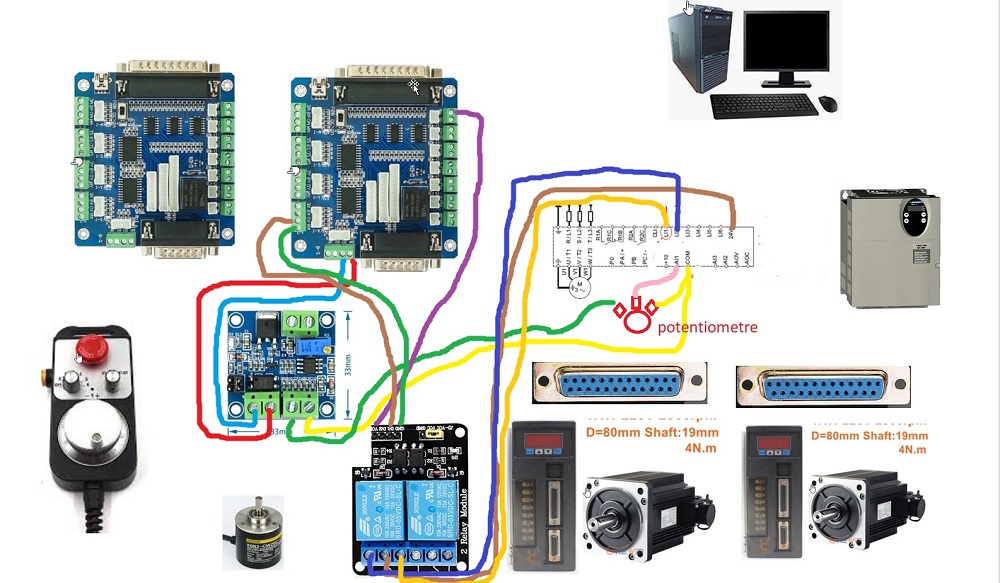

the motor turns normally (PWM), when I type M3/M4 S200 or other and stop (M5), I think only that it does not have the information to turn when I launch a M19 R45 or other; the most vexing for me, it is that the relay starts and stops when I turn the encoder (by hand, I did not connect it to the spindle, for now)

this is what I try to show on the video (at 2mn 11) sorry for the schema, I did it quickly

this is what I try to show on the video (at 2mn 11) sorry for the schema, I did it quickly

Attachments:

Last edit: 11 Mar 2022 17:23 by jpg.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Need help with the orient component for spindle activation (M19)

Time to create page: 0.194 seconds