Retrofitting a 1986 Maho 400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1518

- Thank you received: 560

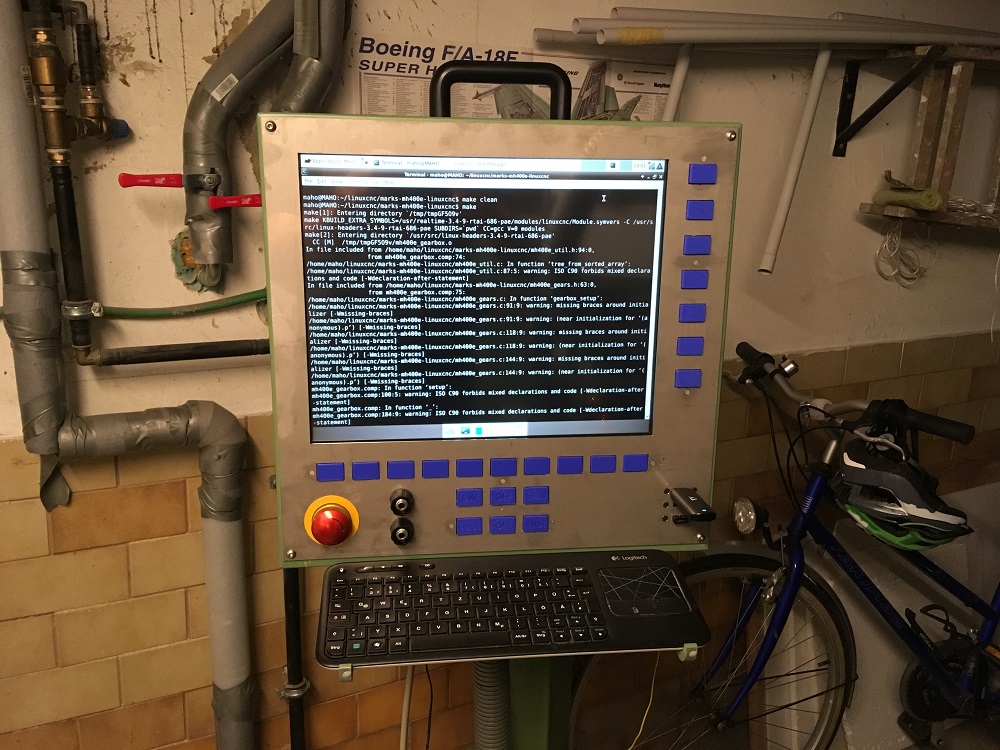

Source code for MAHO gearbox comp

Sergey has been a champion, as he had to edit parts of the code when it turned out LinuxCNC only accepted the C90 flavour of C, whereas he had used the C99 version. A special thank you also to Andy Pugh for supporting Sergey on IRC with some of our questions.

We could have got more done if I was more versed in linux commands, but Sergey has been patiently navigating me through it all.

First we tested the feedback from the the gearbox shifter cam's, to ensure that the comp has mapped the bit mask to the correct speeds.

Then we tested the control of the twitching relays which intermittantly power the main spindle with 90VAC during the change, to prevent binding. The relay control works correctly, but, I missed a point in the specification. It looks like we need to energise the gearbox start relay 11K8 to allow twitching power to the spindle.

The next step will be manually placing the gear shafts to the mid (blue) position, and then giving speed commands which move a stage to one of the end positions, and ensureing that the use of the reversing relay is a correct.

The keyboard is sitting on brackets I had lasered, which are easily removable. In my mind, once the machine is finished, no keyboard should be necessary.

Mark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19731

- Thank you received: 4577

Even on my working machines I occasionally want a keyboard, to open a halmeter or rename a file, that sort of thing. On the mill I have one of these in a holster on the side of the cabinet.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1518

- Thank you received: 560

Under the user module won't work as the support arm comes in the bottom, but I will always be handy close by the mill.

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1518

- Thank you received: 560

I'd messed up the spec, reversing CW and CCW, so Sergey had to change the code a bit, but once it re-complied it is working perfectly. The next step will be getting it integrated into the HAL and seeing if there is any screwy behaviour to deal with from the speed input in gmoccapy, mdi, or gcode.

It was compiled with:

sudo halcomplie --install mh400e_gearbox.compI added...

loadrt mh400e_gearboxaddf mh400e_gearbox servo_threadMark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19731

- Thank you received: 4577

In theory HAL only uses hyphens, but file-names can not contain hyphens, so the loadrt is underscores)

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1518

- Thank you received: 560

loadrt mh400e_gearbox

addf mh400e-gearbox servo-threadMark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1518

- Thank you received: 560

I wanted to test only the gearbox, and since the glass scale encoder on both Y and Z axis are currently U/S, can't home the machine.

In the ini, I edited the current homing lines to immediate homing :

Are those "o" or zero's? I used zero's, but I see today that they look like "o"'s.

First I just commented out the existing settings like this...

HOME_USE_INDEX = NO # reset to yes.LinuxCNC can't deal with comments in this line of the ini. I freezes during the GUI load and has to be manually killed. Moving the comment to the line before corrected that. I see that this behaviour is already described in the INI knowledge file .

When I tested it, the X axis raced off till it hit the hard wired end stop and E-Stopped. Does this immediate homing not work on a closed loop servo axis?

Mark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19731

- Thank you received: 4577

Defintely zeros.Are those "o" or zero's? I used zero's, but I see today that they look like "o"'s.

When I tested it, the X axis raced off till it hit the hard wired end stop and E-Stopped. Does this immediate homing not work on a closed loop servo axis?

It should work. But the servo loop won't work without the position feedback, and you already said that was broken. (though the system still should have f-errored).

Maybe don't enable the servos yet?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1518

- Thank you received: 560

Since I did a LiveCD install, the Gmoccapy Simulator is an easy install. I think I'll install that, and only cut paste the HAL lines necessary to continue testing the gearbox.comp interface, rather working with my machine.hal.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 39

John

Please Log in or Create an account to join the conversation.