Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

19 Aug 2020 21:35 - 21 Aug 2020 07:13 #178769

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Placeholder to upload the central lube pump info...

Edit: TOT contacted me over Youtube comments with a couple of questions to regarding the Lube unit and the spindle brake. I'll answer here as I can embed diagrams...

Hi Tony,

I am guessing they put a brake on the main spindle motor, to save time in production. No waiting for the spindle to run down from 4000 rpm.

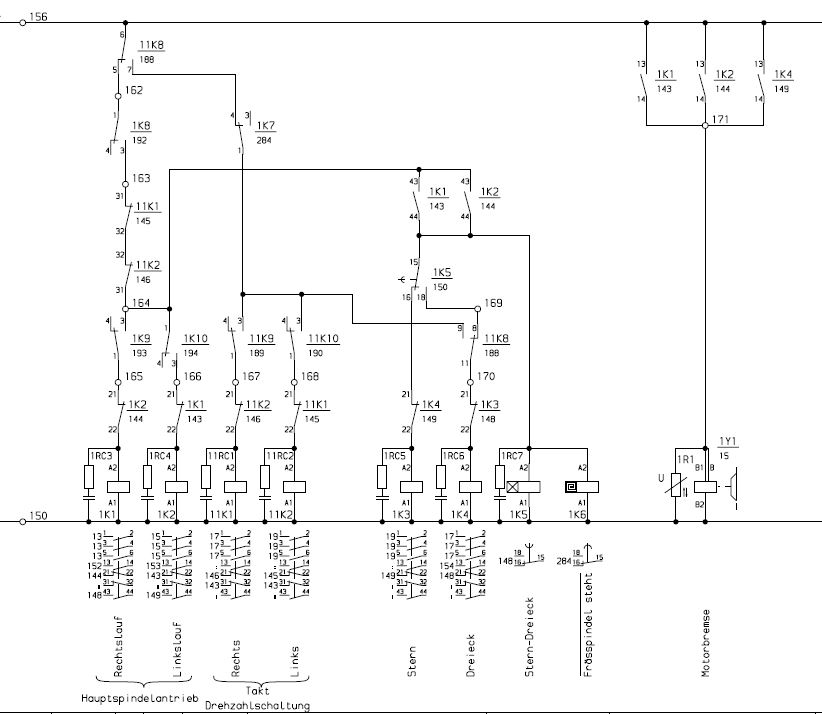

My Maho's main spindle control is surprisingly complex.

CW or CCW is controlled by 1K1 and 1K2

11K1 and 11K2 bring in the 90V 3Ph to twitch the spindle during gear changes

1K3 and 1K4 are on a timer to start in Star before switching to delta for a softer start.

Of more interest to your project...

Maho used secondary contact on any one of 1K1/1K2 or 1K4 to open the brake (Motorbremse) any time rotation was commanded. The brake itself is 110VAC so it will be easy enough for you to control it. Your VFD probably has a output which changes state whenever rotation is commanded, so that could drive your brake release relay. If you ripped everything out of your control cabinet, you should have an assortment of quality relays to choose between

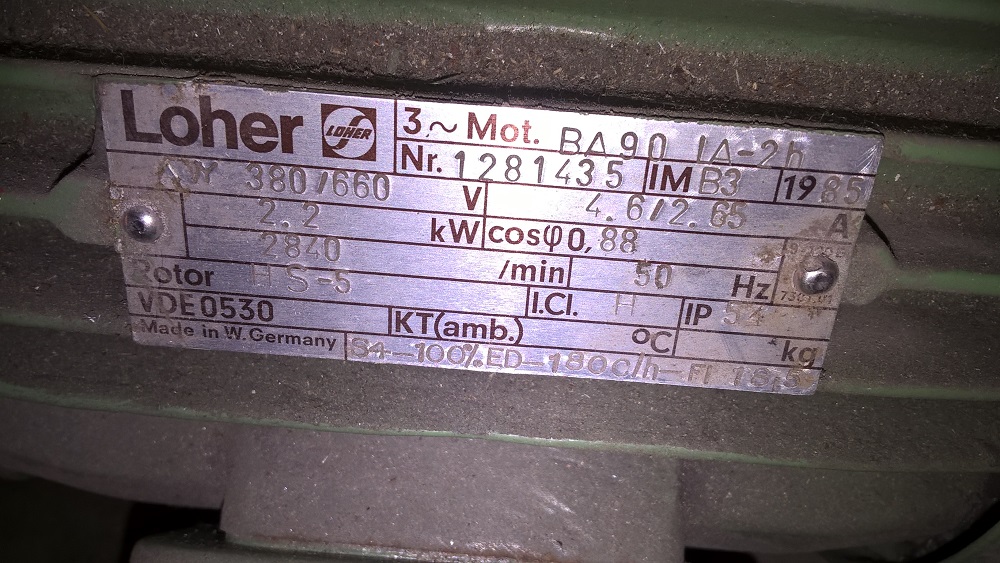

Èdit:This is the dataplate for my spinde motor.

If yours is different, it might be prudant to first try 24VDC onto that spindle brake just in case it is not designed for 110VAC on your model.

Mark

Edit: TOT contacted me over Youtube comments with a couple of questions to regarding the Lube unit and the spindle brake. I'll answer here as I can embed diagrams...

Hi Tony,

I am guessing they put a brake on the main spindle motor, to save time in production. No waiting for the spindle to run down from 4000 rpm.

My Maho's main spindle control is surprisingly complex.

Attachment not found

CW or CCW is controlled by 1K1 and 1K2

11K1 and 11K2 bring in the 90V 3Ph to twitch the spindle during gear changes

1K3 and 1K4 are on a timer to start in Star before switching to delta for a softer start.

Of more interest to your project...

Maho used secondary contact on any one of 1K1/1K2 or 1K4 to open the brake (Motorbremse) any time rotation was commanded. The brake itself is 110VAC so it will be easy enough for you to control it. Your VFD probably has a output which changes state whenever rotation is commanded, so that could drive your brake release relay. If you ripped everything out of your control cabinet, you should have an assortment of quality relays to choose between

Èdit:This is the dataplate for my spinde motor.

If yours is different, it might be prudant to first try 24VDC onto that spindle brake just in case it is not designed for 110VAC on your model.

Mark

Last edit: 21 Aug 2020 07:13 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Onkelmat

-

- Offline

- Premium Member

-

Less

More

- Posts: 86

- Thank you received: 4

03 Sep 2020 11:13 #180524

by Onkelmat

Replied by Onkelmat on topic Retrofitting a 1986 Maho MH400E

For the lubrication system of the maho "Vogel" it´s very important to know that the Pump is impulse controlled.

If you set the Relay for the pump in it´s active state, the pump will start running and push ONCE some oil into the system. If you keep the relay high the pump will only heat up.

So you have to pulse the pump every 5 minutes or something like that.

I´ve done that with some easy classic ladder.

If you set the Relay for the pump in it´s active state, the pump will start running and push ONCE some oil into the system. If you keep the relay high the pump will only heat up.

So you have to pulse the pump every 5 minutes or something like that.

I´ve done that with some easy classic ladder.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

03 Sep 2020 11:30 - 03 Sep 2020 11:31 #180526

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks, but there are different pumps with different control logic. Mine runs for 15sec ever 20 minutes, so it receives no control logic, just power.

Mark

Mark

Last edit: 03 Sep 2020 11:31 by RotarySMP.

The following user(s) said Thank You: Onkelmat

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

20 Sep 2020 10:29 #182864

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Here is a summary of my retrofit.

Mark

Mark

The following user(s) said Thank You: arvidb, tommylight, Clive S, drimaropoylos, Himarc3D

Please Log in or Create an account to join the conversation.

- chris mcm

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 1

20 Sep 2020 11:43 #182885

by chris mcm

Replied by chris mcm on topic Retrofitting a 1986 Maho MH400E

Hello Mark

Well explained in your summary, the timing could not suit me better. Very encouraging..

I hope to get the temporary DRO working this week. I just need a working milling machine. Brad is enthusiastic to continue with a full Linux CNC Retrofit. It is likely we will carry on. Thanks again for your help.

Cheers Chris

.

Well explained in your summary, the timing could not suit me better. Very encouraging..

I hope to get the temporary DRO working this week. I just need a working milling machine. Brad is enthusiastic to continue with a full Linux CNC Retrofit. It is likely we will carry on. Thanks again for your help.

Cheers Chris

.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

20 Sep 2020 16:41 - 20 Sep 2020 18:41 #182923

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

G'day Chris,

Hope you can get that encoder scaling sorted.

Mark

Hope you can get that encoder scaling sorted.

Mark

Last edit: 20 Sep 2020 18:41 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

21 Sep 2020 20:08 - 21 Sep 2020 20:29 #183177

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Hello, nice video. The statement in the video that you are going to ruin a good machine with the retrofit to linuxcnc or mach3 comes from people that use these machines every day in their work, from their perspective they have right, even a very successful retrofit like yours probably can not stand in a shop floor. Even with an old mazatrol a skilled machinist can make in minutes the program without cad-cam and run the jobs all day very efficient pressing the minimum number of buttons. With oily fingers and tight deadlines they can not use touch screen to jog the machine.

But those people have also wrong because the machine now belongs to an amateur and this machine must give satisfaction to the owner. The interface of mach3 and linuxcnc is more pleasant and easy to learn than a old controller designed to be extremely productive with trained employs.

But those people have also wrong because the machine now belongs to an amateur and this machine must give satisfaction to the owner. The interface of mach3 and linuxcnc is more pleasant and easy to learn than a old controller designed to be extremely productive with trained employs.

Last edit: 21 Sep 2020 20:29 by drimaropoylos.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

- Visitor

-

22 Sep 2020 02:24 #183232

by BeagleBrainz

Replied by BeagleBrainz on topic Retrofitting a 1986 Maho MH400E

Great video, made it sound so easy,do I detect a hint of Kiwi accent ?

Just measured up my garage.....no room for Maho

Just measured up my garage.....no room for Maho

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

22 Sep 2020 08:22 #183262

by rodw

I'm not so sure this applies today so much. With the right touch screen, oily fingers and gloves are not an impediment. But they cost way more than a home user is prepared to spend.

The other thing is we probably don't need skilled machinists so much as skilled programmers. The unfortunate fact is that technology continues to deskill our workforce in every industry. Remember when map reading was a required skill to get around? Today we leave it to our phone to guide us to the destination.

Replied by rodw on topic Retrofitting a 1986 Maho MH400E

Even with an old mazatrol a skilled machinist can make in minutes the program without cad-cam and run the jobs all day very efficient pressing the minimum number of buttons. With oily fingers and tight deadlines they can not use touch screen to jog the machine.

I'm not so sure this applies today so much. With the right touch screen, oily fingers and gloves are not an impediment. But they cost way more than a home user is prepared to spend.

The other thing is we probably don't need skilled machinists so much as skilled programmers. The unfortunate fact is that technology continues to deskill our workforce in every industry. Remember when map reading was a required skill to get around? Today we leave it to our phone to guide us to the destination.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

22 Sep 2020 14:11 #183304

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I think Norbert has done a really outstanding job with Gmoccapy.

<Rant> I see a number of efforts to do "new" "better" screens, but they all look focused on eye candy and copying the latest color trends, rather than workflow. Rather than loading up a 21" touch screen with zillion tiny functional buttons, Gmoccapy is a really well sorted workflow, gouping functions as you logically use them, while remaining uncluttered </rant>

I took advantage of the HAL pins Gmoccapy generates to duplicate the on screen soft keys with physical soft keys, and made the pendant, for exactly the reasons drimaropoylos stated, because touch screen jobing for touch off gets old really fast. That I haven't finished installing the pendant is on me not on LinuxCNC though. Once the pendant is installed, I won't be touching the screen much at all.

I get what you say about the experienced machinist being able to make a program on the machine without CAD/CAM. The Phillips 432 had a good reputation for that. I see in myself when I just want to square up stock, or drill some holes etc, there in no reason to fire up CAD/CAM but line by line in the MDI I make too many mistakes. So mostly I write a short G code program using loops. I kind of hope that NativeCAM duplicates the simple part programming functionality of many legacy system, as you point out, and more, but also haven't got off my backside to implement it yet. It would be interesting to hear from a machinist with Mazatrol, or Phillip 432 etc experience who has also implemented and learnt NativeCam.

In hindsight, my attempt to make the interface keyboardless was a mistake. Typing code on at the touch screen keyboard is not pleasant. I use a cheap USB keyboard plugged in more often than not. It would have been better to have butchered the original user module with an industrial keyboard, and better, 15" monitor (this 17" one is shite). Not sure I'd add a whole lot of additional single function buttons, as they are really well thought out on Gmoccapys soft keys, and I have physical buttons for them.

Otherwise, the only thing I can see in the argument that a retrofit can't hack it on the shop floor is quality of wiring, shielding etc. (I am not going to pretend mine is good enough). I see no reason to doubt the reliablity of the MESA hardware. Maybe a better protected MoBo with a better quality, shock mounted hard drive would also be a good idea.

<Rant> I see a number of efforts to do "new" "better" screens, but they all look focused on eye candy and copying the latest color trends, rather than workflow. Rather than loading up a 21" touch screen with zillion tiny functional buttons, Gmoccapy is a really well sorted workflow, gouping functions as you logically use them, while remaining uncluttered </rant>

I took advantage of the HAL pins Gmoccapy generates to duplicate the on screen soft keys with physical soft keys, and made the pendant, for exactly the reasons drimaropoylos stated, because touch screen jobing for touch off gets old really fast. That I haven't finished installing the pendant is on me not on LinuxCNC though. Once the pendant is installed, I won't be touching the screen much at all.

I get what you say about the experienced machinist being able to make a program on the machine without CAD/CAM. The Phillips 432 had a good reputation for that. I see in myself when I just want to square up stock, or drill some holes etc, there in no reason to fire up CAD/CAM but line by line in the MDI I make too many mistakes. So mostly I write a short G code program using loops. I kind of hope that NativeCAM duplicates the simple part programming functionality of many legacy system, as you point out, and more, but also haven't got off my backside to implement it yet. It would be interesting to hear from a machinist with Mazatrol, or Phillip 432 etc experience who has also implemented and learnt NativeCam.

In hindsight, my attempt to make the interface keyboardless was a mistake. Typing code on at the touch screen keyboard is not pleasant. I use a cheap USB keyboard plugged in more often than not. It would have been better to have butchered the original user module with an industrial keyboard, and better, 15" monitor (this 17" one is shite). Not sure I'd add a whole lot of additional single function buttons, as they are really well thought out on Gmoccapys soft keys, and I have physical buttons for them.

Otherwise, the only thing I can see in the argument that a retrofit can't hack it on the shop floor is quality of wiring, shielding etc. (I am not going to pretend mine is good enough). I see no reason to doubt the reliablity of the MESA hardware. Maybe a better protected MoBo with a better quality, shock mounted hard drive would also be a good idea.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.238 seconds