Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

21 Nov 2017 17:02 #102146

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

That is really frustrating for wait for those balls to arrive, only for them to be junk. Maybe you should post a request for help finding either a reliable ball suppier or a Ball screw refurbisher on Practical Machininist

www.practicalmachinist.com/vb/search.php?searchid=13618306

or if you like I can ask on the German language machining forum...

forum.zerspanungsbude.net/

for a recommendation?

Mark

www.practicalmachinist.com/vb/search.php?searchid=13618306

or if you like I can ask on the German language machining forum...

forum.zerspanungsbude.net/

for a recommendation?

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

21 Nov 2017 18:07 #102148

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Hi, yes plz ask in that site.

John

John

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21239

- Thank you received: 7250

21 Nov 2017 23:36 #102162

by tommylight

Replied by tommylight on topic Retrofitting a 1986 Maho MH400E

Do you have any bicycle repair shop near you? Try there ! I neded some 6.320mm ones some 6 years ago and having no way of getting them, went to such a shop. Got 200 of them for 10 euro, set them up and they are still happily working! I am aware that i lucked out on that, but worth a try, they had only 4 sizes of them.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

22 Nov 2017 14:52 - 22 Nov 2017 15:00 #102189

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

From the Zersannungsbude...

This place has bearing balls:

www.kugel-winnie.de/epages/62136757.sf/d...Path=/Shops/62136757

It was recommended that you contact them which the exact size you need, which may be something they havent listed in the web shop.

There was a short discusion about replacing every second ball, and recommendation that the balls are normally toleranced G5.

The recommendation came for this overhaul facility:

www.eisenmann-hommes.de/reparaturen-%C3%BCberholungen/

Mark

This place has bearing balls:

www.kugel-winnie.de/epages/62136757.sf/d...Path=/Shops/62136757

It was recommended that you contact them which the exact size you need, which may be something they havent listed in the web shop.

There was a short discusion about replacing every second ball, and recommendation that the balls are normally toleranced G5.

The recommendation came for this overhaul facility:

www.eisenmann-hommes.de/reparaturen-%C3%BCberholungen/

Mark

Last edit: 22 Nov 2017 15:00 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 Nov 2017 16:37 - 22 Nov 2017 16:41 #102194

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Thank you Mark, I will contact them to order the right size I need. The replacement of every second ball with one smaller (spacer) helps the balls not to rub with its other. But with halve the balls make contact with ballscrew and nut, the forces on every contact point during accelerations and decelerations is now doubled. I don’t have enough knowledge on the subject to decide such a change in the ballscrew. I am open to suggestions and opinions on the subject.

Tommy thank you for the suggestion. The problem is not to find the balls, the problem is to find ball with the right tolerances (or better) and size with the originals. I have find balls from local stores, but they sound and feel terrible in the ballscrew.

Tommy thank you for the suggestion. The problem is not to find the balls, the problem is to find ball with the right tolerances (or better) and size with the originals. I have find balls from local stores, but they sound and feel terrible in the ballscrew.

Last edit: 22 Nov 2017 16:41 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

26 Nov 2017 20:20 - 04 Sep 2018 20:16 #102369

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

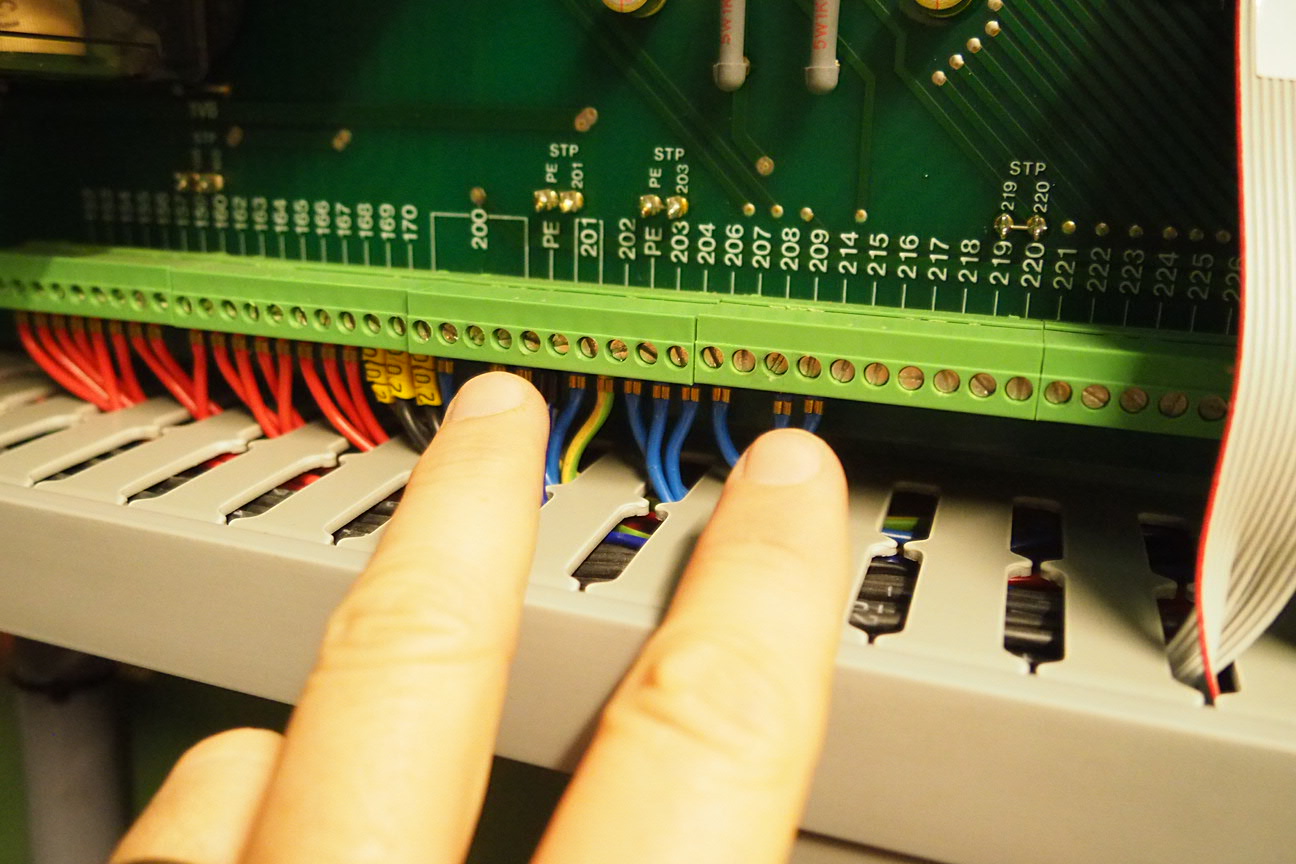

Didn't get anything done on the MAHO last week, but yesterday I reinstalled the ribbon cables.

I took another shot a troubleshooting the "machine on" relay not latching on. I'd already isolated the problem to the MAHO relay panel. I'd been overthinking it, wondering if there was some logic wired into the panel.

I did basic continuity checks according to the wiring diagram. Pulled the 19K1 relay and the manual brake release switch. The problem is in the row of plug in screw connections along the bottom of the MAHO relay board. Resocketing the middle terminal plug closed the circuit.

Turned everything on and sure enough, the control latches on. Woohoo, as I can now move on to getting some motion.

I'd noticed an intermittent contact problem alone that row of plug in screw connections before. The 7i84, and 7i77 pick up 24V and 0v from there, and I have a couple of times where LinuxCNC errored out doing start as they were not getting power. If the the pins in the plugs are worn out, It will be easy enough to buy replacement connectors, and just use the plugs.

Out of batteries on the laptop, but I'll add photos tomorrow in case someone else has the same problem.

Mark

I took another shot a troubleshooting the "machine on" relay not latching on. I'd already isolated the problem to the MAHO relay panel. I'd been overthinking it, wondering if there was some logic wired into the panel.

I did basic continuity checks according to the wiring diagram. Pulled the 19K1 relay and the manual brake release switch. The problem is in the row of plug in screw connections along the bottom of the MAHO relay board. Resocketing the middle terminal plug closed the circuit.

Turned everything on and sure enough, the control latches on. Woohoo, as I can now move on to getting some motion.

I'd noticed an intermittent contact problem alone that row of plug in screw connections before. The 7i84, and 7i77 pick up 24V and 0v from there, and I have a couple of times where LinuxCNC errored out doing start as they were not getting power. If the the pins in the plugs are worn out, It will be easy enough to buy replacement connectors, and just use the plugs.

Out of batteries on the laptop, but I'll add photos tomorrow in case someone else has the same problem.

Mark

Last edit: 04 Sep 2018 20:16 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

28 Nov 2017 16:38 #102444

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I am a little confused by MESA's instruction for grounding the analog drive control wires shielding...

7I77 14

OPERATION

ANALOG SERVO DRIVE INTERFACE

The 7I77 provides six channels of +-10V analog servo interface on connector TB5.

Minimum load resistance is 2K Ohms. Normally analog servo drives use differential inputs

to avoid ground loops. Suggested wiring is shielded twisted pair with 7I77 AOUTN to drive

AIN+, 7I77 GNDN (adjacent to AOUTN) to drive AIN- as the twisted pair and 7I77 GNDN

connected to the shield at the 7I77 end only. The drives common or GND signal should be

connected to the 7I77 power GND with a separate wire.

That the +10 / -10V wires for the first axis connect to TB5-3 (GND) and TB5-4 (AOUT0) is clear, if somewhat confusingly named. But do I also connect the shield to TB5-3 (GND) or do I connect that to the 7i77 power ground along with that separate wire coming in from the Indramat ground?

I am going to use CAT 5E, as it good quality shielding, and I have some. I plan to run three separate cables, one for each axis, or would it be better to use only one cable with a twisted pair for each axis and common shielding?

Mrk

7I77 14

OPERATION

ANALOG SERVO DRIVE INTERFACE

The 7I77 provides six channels of +-10V analog servo interface on connector TB5.

Minimum load resistance is 2K Ohms. Normally analog servo drives use differential inputs

to avoid ground loops. Suggested wiring is shielded twisted pair with 7I77 AOUTN to drive

AIN+, 7I77 GNDN (adjacent to AOUTN) to drive AIN- as the twisted pair and 7I77 GNDN

connected to the shield at the 7I77 end only. The drives common or GND signal should be

connected to the 7I77 power GND with a separate wire.

That the +10 / -10V wires for the first axis connect to TB5-3 (GND) and TB5-4 (AOUT0) is clear, if somewhat confusingly named. But do I also connect the shield to TB5-3 (GND) or do I connect that to the 7i77 power ground along with that separate wire coming in from the Indramat ground?

I am going to use CAT 5E, as it good quality shielding, and I have some. I plan to run three separate cables, one for each axis, or would it be better to use only one cable with a twisted pair for each axis and common shielding?

Mrk

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

Less

More

- Posts: 17639

- Thank you received: 5160

28 Nov 2017 16:47 #102445

by PCW

Replied by PCW on topic Retrofitting a 1986 Maho MH400E

Do the drives have differential inputs?

if so the wiring is

AOUTN --> AIN+

GNDN --> AIN-

GNDN --> CABLE SHIELD (7I77 end only)

Drive GND --> frame GND

if so the wiring is

AOUTN --> AIN+

GNDN --> AIN-

GNDN --> CABLE SHIELD (7I77 end only)

Drive GND --> frame GND

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

28 Nov 2017 17:33 - 28 Nov 2017 17:36 #102447

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

So that means I connect both the AIN- and the shield together into TB5-3? Seems weird to me.

I found this in google.

forum.linuxcnc.org/media/kunena/attachme...ALOG_REF_CIRCUIT.png

so I guess the do get wired together.

Mark

I found this in google.

forum.linuxcnc.org/media/kunena/attachme...ALOG_REF_CIRCUIT.png

so I guess the do get wired together.

Mark

Last edit: 28 Nov 2017 17:36 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

29 Nov 2017 09:15 - 29 Nov 2017 14:03 #102472

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I made the three +10/-10V cables. Now I have a question about the Indramat gound. The Indramat terminals have three ground connections, one for the shield of each axis cable (MAHO terminated the shielding in three places - The Indramat, the Phillips connector and in the middle of the cable to the Phillips housing).

The three axis grounds have continuity between them. Should I run three wires to the 7i77 field ground or just one?

Mark

The three axis grounds have continuity between them. Should I run three wires to the 7i77 field ground or just one?

Mark

Last edit: 29 Nov 2017 14:03 by RotarySMP.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.250 seconds